All Categories

History

This section provides an overview for plasma cutting equipment as well as their applications and principles. Also, please take a look at the list of 15 plasma cutting equipment manufacturers and their company rankings. Here are the top-ranked plasma cutting equipment companies as of February, 2026: 1.MicroStep Europa, 2.Miller Electric Mfg. LLC, 3.Stürmer Maschinen GmbH.

Table of Contents

Categories Related to Plasma Cutting Equipment

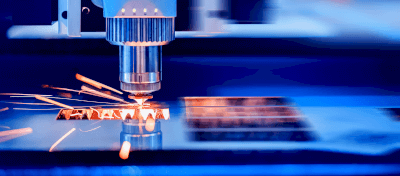

Plasma cutting equipment utilizes plasma from an arc discharge for cutting, offering shorter cutting times and higher efficiency compared to traditional laser and gas cutting methods. Capable of cutting materials up to 100 mm thick at low costs, plasma cutting is versatile, allowing for the cutting of metals like stainless steel and complex curves.

Primarily used for metal cutting in shipyards and steel bridge construction, plasma cutting excels with materials that resist oxidation, such as stainless steel and aluminum alloys. It supports a wide range of material thicknesses, making it ideal for cutting thick materials that lasers struggle with.

Plasma cutting generates an arc discharge between the workpiece and an electrode, melting the material with arc heat. A surrounding airflow then expels the molten material, facilitating the cut.

Types vary based on the plasma gas used, including argon and hydrogen for stainless steel and nonferrous metals, oxygen for carbon steel, compressed air for cost efficiency, and nitrogen, though its use has declined due to environmental concerns.

While laser cutting is faster for materials 1-6 mm thick, plasma cutting is advantageous for thicker materials, handling up to 150 mm. It can process nearly all conductive materials, including those not suitable for gas cutting. However, its requirement for a high-voltage power supply limits its outdoor use.

Plasma, the fourth state of matter, forms at high temperatures when gases ionize into electrons and positive ions. It is essential for plasma cutting, leveraging its conductive properties to efficiently process metals.

*Including some distributors, etc.

Sort by Features

Sort by Area

Koike Aronson, Inc., established in 1918 and headquartered in Arcade, New York, USA, is a manufacturer of cutting, welding, and positioning equipment. The company produces a diverse range of products, including CNC cutting machines, welding positioners, and portable cutting equipment that offer precise and efficient cutting, improved welding accuracy, and streamlined material handling. The products are used in industries such as metal fabrication, construction, automotive, and aerospace for advanced manufacturing processes, efficient material handling, and enhanced productivity. It has an ISO 9001:2000 certification and the 3D-Link Plasma Bevel Unit received awards from the Japan Welding Engineering Society.

Miller Electric Mfg. LLC (MEM) is an American manufacturer of arc welding and cutting equipment originally founded in 1929 before its acquisition by Illinois Tool Works (ITW) in 1993. Headquartered in Appleton, Wisconsin, the company produces various welders such as tungsten inert gas (TIG) and engine-driven models, wire feeders, and plasma cutters. It also offers related consumables and accessories, such as connector kits, spot welding tongs, safety equipment, and flux-cored wires. MEM products are commonly used in metal fabrication, manufacturing, and construction, as well as in the aviation industry.

Carlson Engineering & Manufacturing Inc., established in 1985 and headquartered in San Dimas, California, is a manufacturer specializing in automatic screwdriving and screw feeding systems. Its product range includes handheld drive heads for precision screw installation, drive heads designed for collaborative robots (CoBots), fixtured drive heads that work with robotic positioning systems, screw feeders for presenting screws to drive heads, and step feeders, another type of screw feeder integral to its systems. Its distributors are located in strategic distribution positions across North and Central America, Europe, and Asia, with numerous end-users across the globe.

DAIHEN Corporation, established in 1919 and headquartered in Osaka, Japan, is a manufacturer of Power Products, Industrial Robots, and RF/MW Generators & Automatic Matching Units for plasma applications. The company provides an extensive array of products, including Oil-immersed Transformer, Cast Resin Transformer suitable for high buildings, public facilities, and hospitals, Power Distribution Equipment such as closed type power distribution boards and remote monitoring systems, as well as Sensors for Robot Welding and Positioners & Sliders. The company also offers various welding & cutting machines, including TIG Welding Machines, Plasma Cutting Machines, as well as Peripheral Devices for Welding.

Plazmamax, in Tiberias, Israel, founded in 2000, is a manufacturer and designer of equipment for thermal cutting. The company produces hand-held and mechanized cutting machines and robots for pipes, rails, sheet metals, scrap, and rolled sheets. It also produces coating, spraying, deburring, shipbuilding, and thermal cutting machines used in aerospace, automotive, oil, general fabrication, and power generation industries. The company produces solutions such as underwater welding, scrap cutting, heat treatment, and cutting thickness over 500mm.

Stürmer Maschinen GmbH, founded in 1982 and based in Hallstadt, Germany, is a manufacturer and wholesale retailer of professional machinery to German machinery retailers. It provides compressors and compressed air technology for the aircraft industry and DIYers. The company offers woodworking machines and workshop equipment for the application industry. Stürmer Maschinen also provides metalworking, cleaning and welding technology. The product development process involves 3D CAD software. Its customers include individuals and traders from 20 European and more than 40 non-European countries.

MicroStep Europa in Bad Worishofen, Bayern, Germany, founded in 1999, is a manufacturer and supplier of CNC and automation systems for the metal and automotive industries. The company offers cutting technologies such as plasma, waterjet, laser, and oxyfuel in 2D and 3D for processing options such as dome processing, material handling, bending, drilling, and sheet processing in the power, rubber, automotive, and mechanical engineering industries. The company produces software solutions and control systems compatible with the machines produced.

KERF DEVELOPMENTS LIMITED has been a manufacturer of CNC profile-cutting machines in Queensway Rochdale, UK, since 2002. The company manufactures oxyfuel, plasma, ultrasharp, and waterjet cutting machines used to cut aluminum, stainless steel, wear-resistant plates, acrylic foam, and mild steel with thicknesses ranging from 1mm to 150mm in the vehicle and food manufacturing, electronics processing, metal fabrication, and industrial artwork industries. The company is privately held and provides installation and post-sale support and services.

ESAB, founded in 1904 and headquartered in Maryland, United States, is a manufacturer of welding as well as cutting equipment and consumables. It manufactures accessories and consumables, arc welding equipment, cutting automation, filler metals, and gas equipment. Moreover, it offers manual plasma cutting, PPE/Safety, robotics, torches, and welding automation. For arc welding, Fabricator EM 400i, for instance, is ideal for heavy industries due to the use of solid and flux-cored wires together with fabricator feed. ESAB has earned ISO 9001, ISO 14001, and the Occupational Health and Safety Advisory Services 18001 certifications.

Voortman Steel Machinery, founded in Rijssen, Overijssel, in 1968 is a manufacturer of CNC steel processing machines and a creator of solid steel solutions. The company's product portfolio includes Steel Shot Blasting, Steel Layout Marking, Steel Painting, Steel Shearing, and Oxy-fuel cutting machines. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. They have international offices in Europe and the USA and also provides packaging, warehousing, and distribution services.

Dener Makina, founded in 1974 in Kayseri, Turkey, is a metal-forming machine manufacturer. The company manufactures fiber laser cutting, ball screw press brake, shear cutting, hydraulic press brake, and servo-electric press brake machines. It also manufactures CNC plasma standard equipment such as cutting heads, oxygen torches, control units, cable trays, and power sources for the processing and manufacturing industries. The company manufactures spare parts and provides technical assistance, and it has a 9001-certified quality system in place to make CE-certified devices.

Lincoln Electric, established in 1895, is a supplier of cutting-edge products, welding processes, and automated solutions based in Cleveland, Ohio, United States. Lincoln Electric provides equipment, systems, and solutions for every segment of industry around the world. The company offers various products needed for welding and cutting, filler metals, weld fume control, and automation. Lincoln Electric's range of automation solutions includes Laser System Integration and Processing, Metalforming and Press Automation, and various automation needs of the Automotive industry.

Daito Seiki Co. Ltd., established in 1959 and headquartered in Amagasaki, Hyogo, Japan, is a manufacturer of metalworking machinery and equipment. The company initiates each business cycle by listening to customer feedback, understanding its operational details, including production output and bottlenecks, and closely analyzing these factors to provide machinery, automation, and output solutions. The company offers a range of products, including band sawing machines, drilling machines, scaling machines, drilling & sawing line systems, and band saw blades. Its engineers can provide detailed line system drafts and simulations to meet specific needs.

KNUTH Machine Tools USA is the American subsidiary of Knuth, originally founded in 1928. The American subsidiary is headquartered in Lincolnshire, Illinois. The company is a manufacturer of industrial machinery and accessories. The company has an extensive product listing including lathes, milling machines, grinding machines, drilling machines, as well as several others. The company’s accessories include consumables for EDM and cutting machines, machining tools, and machine accessories. The company also offers start-up services, maintenance services, repair, and spare parts services.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | MicroStep Europa |

12.4%

|

| 2 | Miller Electric Mfg. LLC |

10.5%

|

| 3 | Stürmer Maschinen GmbH |

8.1%

|

| 4 | Koike Aronson, Inc. |

7.9%

|

| 5 | DAIHEN Corporation |

7.7%

|

| 6 | Plazmamax |

7.4%

|

| 7 | KNUTH Machine Tools USA, Inc |

7.4%

|

| 8 | Carlson Engineering & Manufacturing, Inc. |

6.3%

|

| 9 | Dener Makina |

5.9%

|

| 10 | KERF DEVELOPMENTS LIMITED |

5.9%

|

Derivation Method

The ranking is calculated based on the click share within the plasma cutting equipment page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

3 | 37.5% |

Japan

Japan

|

1 | 12.5% |

Israel

Israel

|

1 | 12.5% |

Germany

Germany

|

1 | 12.5% |

| Slovakia | 1 | 12.5% |

United Kingdom

United Kingdom

|

1 | 12.5% |

65 products found

65 products

Kokusai Dengyo Co., Ltd.

500+ people viewing

Last viewed: 1 day ago

KOKUSAI Standard Compatible with small spaces, 6 widths, 3.5m stroke ■KPC-04 series overview The plasma automatic cutting system for air condition...

Is tail

440+ people viewing

Last viewed: 1 day ago

"HPR" cuts the precision product with the highest quality and stability of the Hyperformance plasma, significantly reducing secondary work costs. T...

4 models listed

Japanese Corporation

370+ people viewing

Last viewed: 1 hour ago

■Summary ・Can be used not only at 200V but also at 100V ・100V can be used with household power supply ・Automatic airflow and corner protectors p...

Ikura Seiki Co., Ltd.

590+ people viewing

Full digital control makes detailed settings easy ■Features ・Inverter control ・Compressor external connection ・Maximum t=36mm high power model ...

Is tail

1460+ people viewing

Last viewed: 10 hours ago

"HPR" cuts the precision product with the highest quality and stability of the Hyperformance plasma, significantly reducing secondary work costs. T...

Is tail

790+ people viewing

Last viewed: 1 day ago

HYPERTHERM Air Prasma Cutter PowerMAX Series It is a plasma cutting machine that can be used outdoors. There are options for machine systems that c...

Is tail

410+ people viewing

Last viewed: 1 day ago

"XPR" is a plasma cutting machine that enables maximum productivity at the minimum cost. In addition, the operability is high, and it is possible t...

2 models listed

Ikura Seiki Co., Ltd.

510+ people viewing

Last viewed: 1 day ago

Input current value 20A with maximum t=9mm cutting ■Features ・Inverter control ・Built-in compressor ・Power supply 200V ■Caution Please use it ...

Is tail

1040+ people viewing

Last viewed: 1 day ago

HYPERTHERM Air Prasma Cutter PowerMAX Series It is a plasma cutting machine that can be used outdoors. There are options for machine systems that c...

Is tail

860+ people viewing

Last viewed: 17 hours ago

"MAXPRO200" is an oxygen plasma cutting system created by the experience and technology that Hypertherm has cultivated so far. Oxygen, air, or air ...

Ikura Seiki Co., Ltd.

500+ people viewing

Sharp, power-saving design ■Features ・Inverter control ・Built-in compressor ・Power supply 100V ■Caution Please use it in the correct power env...

Might Industry Co., Ltd.

680+ people viewing

Last viewed: 1 day ago

■Features ・Ideal for all medium-thick plate metals such as iron, stainless steel, aluminum, and copper ・High power machine that can cut up to 36m...

Is tail

1010+ people viewing

Last viewed: 1 day ago

HYPERTHERM Air Prasma Cutter PowerMAX Series It is a plasma cutting machine that can be used outdoors. There are options for machine systems that c...

Is tail

880+ people viewing

Last viewed: 1 day ago

HYPERTHERM Air Prasma Cutter PowerMAX Series It is a plasma cutting machine that can be used outdoors. There are options for machine systems that c...

Ikura Seiki Co., Ltd.

590+ people viewing

Full digital control makes detailed settings easy ■Features ・Inverter control ・Compressor external connection ・Super lightweight 14kg compact t...

Is tail

780+ people viewing

HYPERTHERM Air Prasma Cutter PowerMAX Series It is a plasma cutting machine that can be used outdoors. There are options for machine systems that c...

Is tail

1000+ people viewing

Last viewed: 3 hours ago

The CG1-30K is a half-cutting half-cutting machine for plasma and is a product with excellent cost performance. Plasma cutting direction high -spee...

Is tail

400+ people viewing

Last viewed: 1 day ago

HYPERTHERM Air Prasma Cutter PowerMAX Series It is a plasma cutting machine that can be used outdoors. There are options for machine systems that c...

2 models listed

Is tail

290+ people viewing

Last viewed: 1 day ago

We propose a robot cutting system that maximizes productivity by combining each company robot and Hypertherm plasma cutting machine. The plasma can...

4 models listed

Panasonic Industry Co., Ltd.

350+ people viewing

Last viewed: 1 day ago

■APX300-PD is a multi-chamber system that realizes automation and high productivity in semiconductor factories. Panasonic's unique chamber has been...

Is tail

830+ people viewing

Last viewed: 3 hours ago

High -precision and high -performance portable CNC cutting machine even if small Steel -made rails and strong housing are improved and new! It can...

Is tail

380+ people viewing

Last viewed: 1 day ago

Proarc's Athlete series is a table type high -precision plasma cutting machine. The drive device uses a precision gear reducer that offers a loan r...

3 models listed

Is tail

1780+ people viewing

Last viewed: 1 day ago

PROARC's Master series is a reliable and reliable gate -type cutting machine. It is a stable and excellent cost performance that matches all the cu...

Is tail

1020+ people viewing

Last viewed: 2 hours ago

PROARC's dust collector is an original design dust collector that uses a fire -resistant nanopharber filter. [Master: Master] -Tot type [Athlete: ...

Panasonic Industry Co., Ltd.

280+ people viewing

Last viewed: 1 day ago

■APX300-DM uses a chemical reaction process using plasma, and offers clean processing without the mechanical dust, debris, vibration, and water pre...