All Categories

History

This section provides an overview for robotic arms as well as their applications and principles. Also, please take a look at the list of 36 robotic arm manufacturers and their company rankings. Here are the top-ranked robotic arm companies as of February, 2026: 1.Trossen Robotics, 2.Machine Saver Inc., 3.Yaskawa America, Inc. - Drives & Motion Division.

Table of Contents

Categories Related to Robotic Arms

A robotic arm is an industrial robot that resembles the movement of a human hand.

The robot is mainly composed of a manipulator section consisting of six rotational axes and links, a hand section for grasping cargo, and a controller section for controlling the robot and checking its current status.

When introducing a robot, a safety fence must be provided for the safety of workers. However, for robots called cooperative robots, safety fences are not always necessary as long as risk assessments are conducted and the robot is operated at an appropriate risk level.

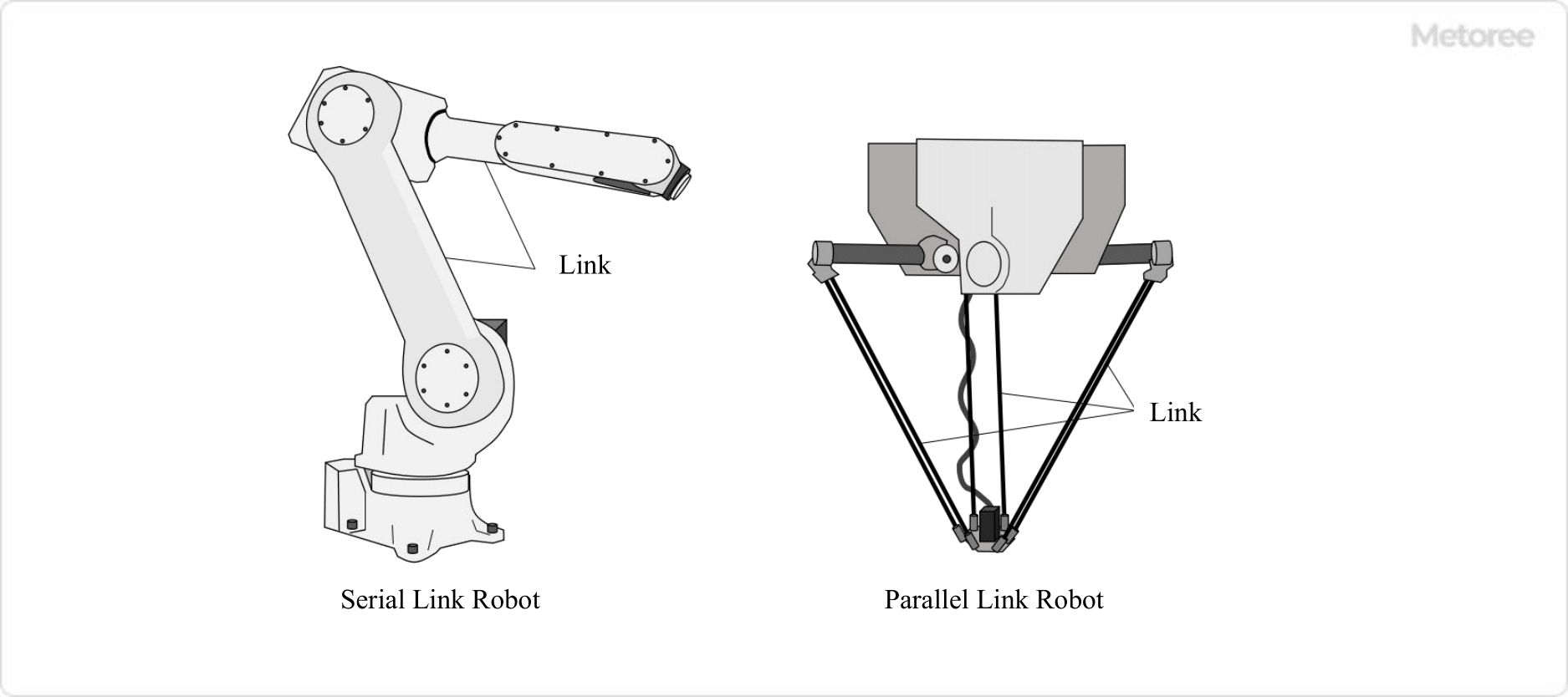

Robotic arms are classified into serial links and parallel links according to the connection method of the links. Serial link robots have links that are connected in a straight line, while parallel link robots have links that are connected in parallel.

Figure 1. Serial Link Robot and Parallel Link Robot

A serial link robot is a robot in which one link is followed by the next link in a series. It is characterized by a wide range of motion and the ability to approach and work from diagonal directions, like a human hand. Taking advantage of their high degree of freedom of movement, serial link robots are used in the following applications.

This is the process of joining automobile bodies and other components by melting the metal of the parts. Welding can be performed by a robot to ensure accurate welding with little variation, which is expected to improve quality.

This work involves assembling parts that have been incorporated into other parts, tightening screws, etc. Vertically articulated robots perform this work by hand. Vertically articulated robots can also handle tasks that are performed by human hands, allowing them to reproduce the skills of skilled craftsmen accurately.

This work involves applying color to automobile bodies and other objects using a spray gun attached to the end of a vertically articulated robot.

Parallel link robots are robots with parallel links coming out from the base, and the hand tips are attached to the ends of the links. Parallel link robots are characterized by their fast movement and are used for the following applications:

Packing food products (e.g., individually wrapped snacks) into plastic trays that flow on a conveyor belt.

Using a camera suspended from the ceiling, the quality of parts is determined as OK/NG, and the parts are either passed on to the next process or not.

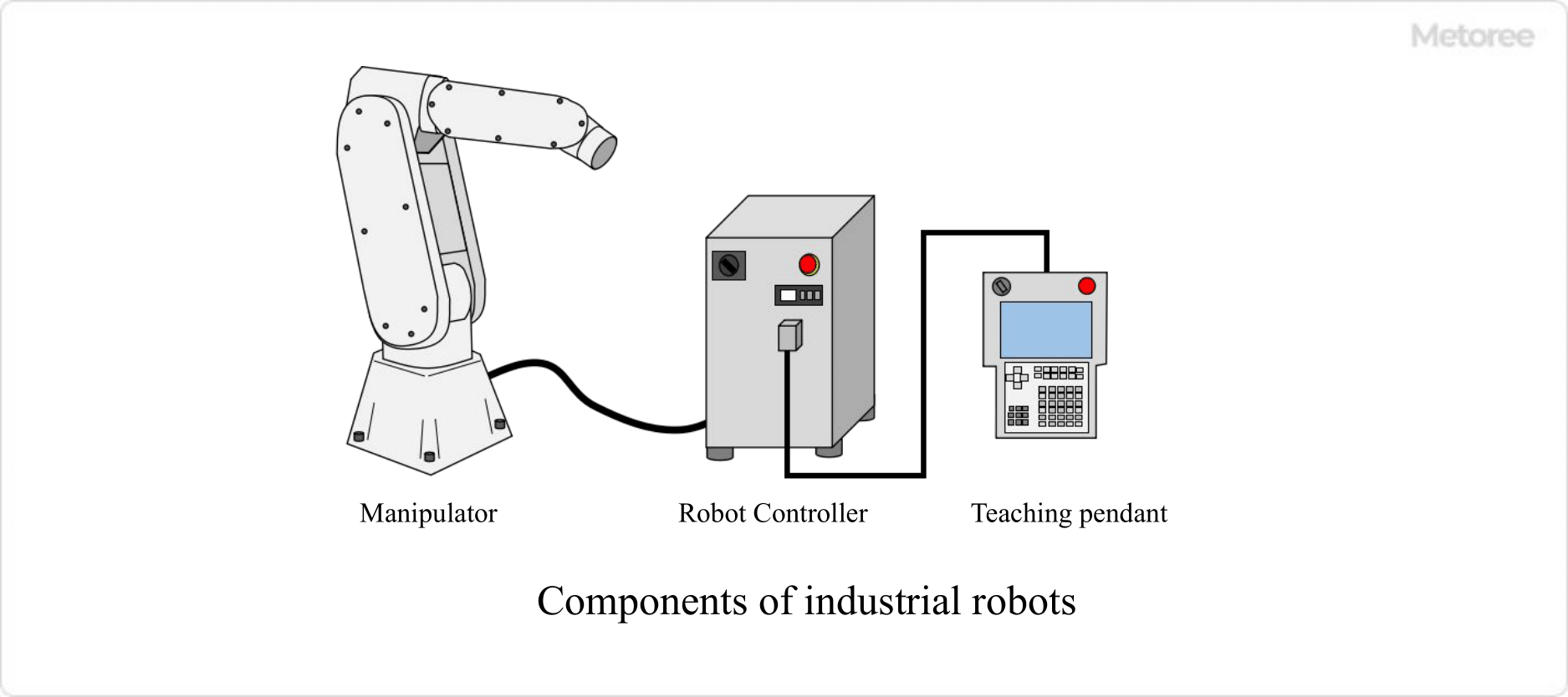

An industrial robot is composed of three elements: a manipulator that operates, a robot controller that moves and controls the manipulator, and a teaching pendant that teaches the manipulator the operation.

Figure 2. Components of an industrial robot

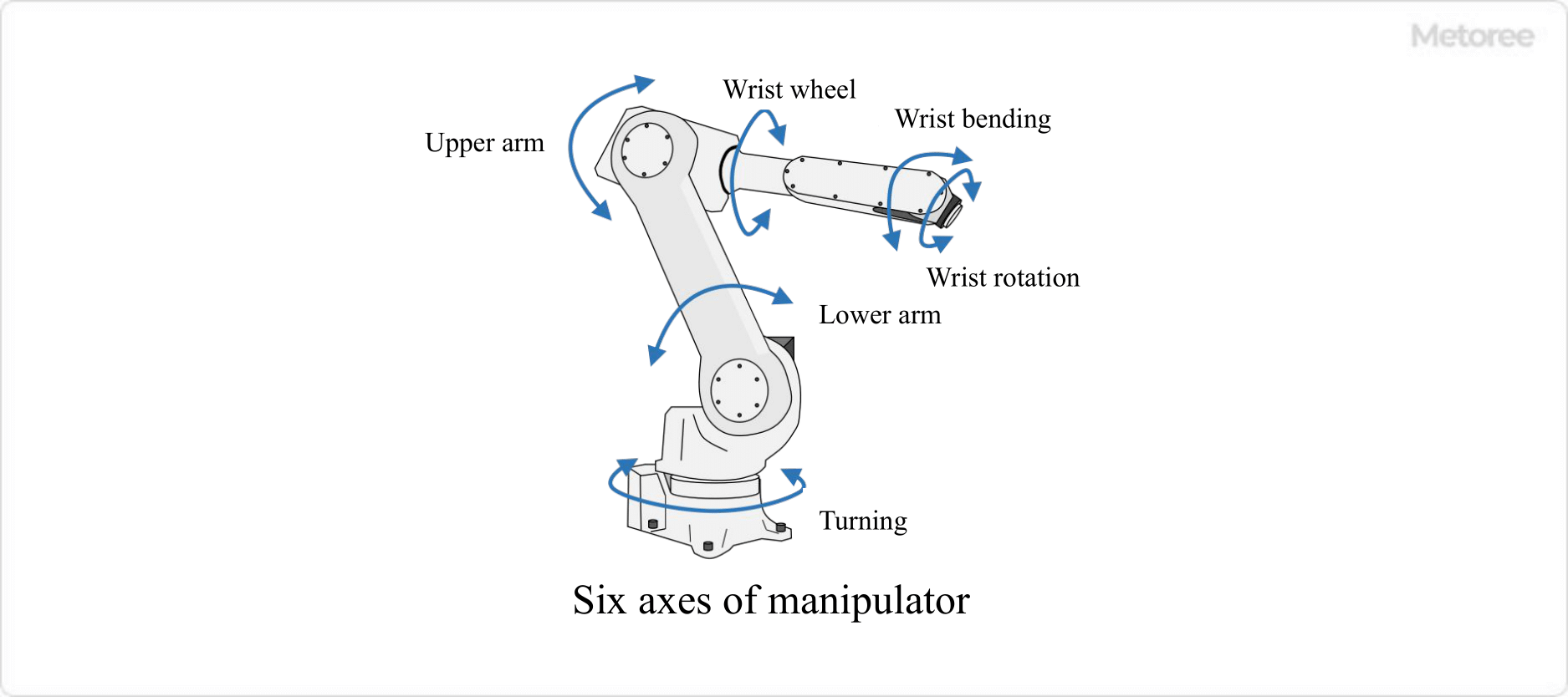

Serial link manipulators consist of a link and a rotary axis. There are six rotary axes, each of which is driven by an AC servo motor. Each of these six axes performs the following movements:

Figure 3. The six axes of the manipulator

When the robot performs a movement, the robot controller is given the position coordinates (X, Y, Z) and the rotation coordinates (Rx, Ry, Rz) of the manipulator's hand tip. The motors of each axis move to match the position and rotation angle of the manipulator's hand, allowing the robot to perform the desired motion.

Teaching Position to the Robot With a Teaching Pendant

A teaching pendant is an input device that stores (teaches) positions to the robot. The robot can be moved directly using a keyboard or touch panel, and its posture can be taught and reproduced by the robot.

Conventional teaching pendants for industrial robots require some familiarity with their operation. In recent years, a technique called direct teaching has emerged that allows even novice operators to teach robots easily.

Programming Coordinates With a Personal Computer

This is a method in which the coordinates of the robot are specified by programming on a personal computer.

Until now, coding-type programming, such as C language, has been mainstream, but coding requires proficiency in programming itself, and debugging the program takes a lot of time.

In recent years, an increasing number of robot manufacturers have offered simulator-type programming tools. This programming tool projects a robot model on a PC and allows the user to manipulate the robot on the PC to teach the coordinates. The feature of this tool is that the movements of the robot can be visually understood, and the robot's movements can be taught without requiring coding expertise.

Recognizing Coordinates by Image Recognition

A camera takes pictures from the top, determines where the robot should move next, and automatically calculates the coordinates. This method is used for bulk picking. Picking in bulk is the process of grabbing parts randomly stacked in boxes and placing them on a conveyor belt for the next process or packing them in boxes.

Image recognition is effective for tasks where the coordinates of the robot's movement change each time, but it is important to note that the cost of building the system is high.

Industrial robotic arms are becoming increasingly popular in various industries, such as factories, manufacturing sites, and distribution centers. The advantage of introducing a robotic arm is that it can work in place of humans without taking a day off, even at night or on holidays. For these users, the robotic arm is expected to contribute to labor-saving to solve manpower shortages, and to improve productivity.

It is said that many of the mistakes that occur at production sites are human errors, and human work can lead to variations in quality and reduced efficiency. The introduction of an industrial robotic arm can reduce human error and maintain a consistent quality of work and products. In addition, since production history data is kept, analysis for quality improvement and prompt feedback in response to complaints can be realized.

Furthermore, robots can be used to handle hazardous materials, work in high places, transport heavy objects, and perform other heavy work that requires precision, which could lead to injury risks and potential accidents, thereby ensuring the safety of workers and improving the working environment.

*Including some distributors, etc.

Sort by Features

Sort by Area

Machine Saver Inc. is a manufacturer and supplier of vibration monitoring and protection systems. Established in 2013, the company is headquartered in Houston, Texas, USA. The company develops, manufactures, and markets a wide range of vibration monitoring products including Vibration Sensors, Proximity Probes, Proximitors or Probe Drivers, Reliability and Machine Health Software as well as offering Reliability Services. Its solutions are designed to help industries prevent equipment failures and downtime. Machine Saver Inc’s main services encompass designing and implementing customized vibration monitoring solutions, catering to a wide range of industries including oil and gas, power generation, and manufacturing.

Fronius USA LLC is an electronic appliances manufacturer based in Portage, Indiana, since its establishment in 1945. The company belongs to the appliances, electrical, and electronic manufacturing industry. It offers a range of solutions, from manual gas-shielded arc welding to MIG/MAG, TIG, and MMA welding processes. The company provides photovoltaic solutions, energy consumption monitoring systems, and battery charging technology in the solar energy sector. The company began as a one-person operation and now supplies its products, including grid-connected inverters, laser and arc welding, automation, and residential and commercial solar worldwide.

Trossen Robotics, founded in 2005, and located in Downers Grove, Illinois, is a manufacturer of robotics. The company specializes in robotic manipulators / arms, used by major universities and research institutions in the USA along with fortune 100 tech companies in all variety of industries. Offerings are an array of products including robot kits for hobbyists and students, encompassing frames, motors, sensors, and controllers. Additionally, the company also produces RFID products like tags, readers, and antennas, facilitating RFID-based systems for inventory management, access control, and tracking purposes.

Yaskawa America, Inc. - Drives & Motion Division, founded in 1967 and located in Waukegan, Illinois, is a manufacturer of AC inverter drives, servo and motion control, and robotic automation systems. They offer a range of products that include industrial AC drives, HVAC drives, machine controllers, gear motors, and articulated robots. Yaskawa's products are used for precise control, automation, and motion capabilities, enhancing efficiency and productivity in diverse manufacturing, industrial, and automation processes. These applications include factory automation, CNC machining, material handling, packaging machinery, and HVAC systems. The company is also ISO 9001:2015 certified.

Jennerjahn Machine, Inc. is an American ISO 9001 certified manufacturer of industrial packaging equipment that was established in 1979. Based in Matthews, Indiana, the company produces various standard and coreless surface slitter rewinders, non-woven fabric slitting machines, center slitter rewinders, and automated packaging machinery. These are primarily used by client manufacturers of paper, foil, film, and nonwoven products across six continents. Jennerjahn Machine also provides custom engineering solutions, as well as after-sales services including training, installation, and product servicing.

Based in Bayville, NY, SAE Manufacturing Specialties Corp. is an ISO-certified supplier and manufacturer of industrial equipment, chemicals, components, ordinance, electronics, and systems for industries ranging from aerospace to high tech to law enforcement. Examples of product offerings include raw materials, chemicals, and lubricants for industrial purposes to finished products such as security helmets for law enforcement, and military ordnances. SAE also provides research and development as well as technical support for other companies in similar industries.

Dixon Automatic Tool, Inc. was originally founded in 1946 in Rockford Illinois. Dixon Automatic Tool is an automated assembly products and services supplier. Dixon Automatic Tool offerings include automatic screwdrivers, automatic nut-runners, automatic part placers, automatic setting systems, robotic end effectors, assembly work cells, hand-held drivers, feeder bowls and feed systems, and features Stöger products for customers’s automation needs. Dixon Automatic Tool also offers two escapement types that can be tooled to escape and transfer piece parts, as well as electric hand-held screwdrivers.

Force Design, Inc., founded in 1998, and headquartered in Troy, Ohio, is a manufacturer of custom robotic automation equipment. The companys's offerings include robotic machine tending, robotic welding, robotic assembly, robotic painting, and robotic packaging, which are used in industries such as automotive, food and beverages, heavy equipment, industrial, and medical. Motion control and mechanical engineering, machine language programming and automation consultation services are also offered. Its products are used to automate and enhance various manufacturing processes, increasing efficiency and precision across industries.

Igus, founded in 1964 and headquartered in Cologne, Germany, is a manufacturer of energy chain systems and polymer plain bearings. The company manufactures low-wear and high-performance polymers using injection mold processing. It also produces motion plastic products made of lubrication-free plastic, including energy chains, cables, and lead screw technology. The company offers services like installation, custom solution, and online resources. It serves the automotive, packaging, agriculture, and other industries, and maintains several certifications, including ISO 9001, IATF16949, and RoHS.

Thomas Welding Systems SA, founded in 1988, is a manufacturer based in Jumet, Hainaut, Belgium, offering welding studs and stud welders. These studs and welders are designed for capacitor discharge, drawn arc, and short-cycle welding applications. The company's product lineup also includes a range of stud welding guns. Stationary stud welding machines, ranging from manually operated benchtop units to automatic computer numerical control (CNC) systems, are also part of the company's portfolio. These products cater to customers in Europe, Australia, and Colombia.

Laser Mechanisms, Inc., established in 1980 and based in Michigan, USA, is a manufacturer of laser beam delivery components and articulated arm systems for high power CO2, YAG, Fiber Lasers and other wavelengths. The company's main products are the Fiber series of laser beams. The company's products are used in multiple types of industrial application including cutting, welding, drilling, scribing, surface treatment, and other processes. The company also offers flexible solutions for connecting common industrial CO2 lasers to different motion systems.

CKD Corporation, established in 1943 under the name of Japan Aircraft Electric Co., Ltd., is a Japanese manufacturer of automation machinery and manufacturing components, headquartered in Komaki, Aichi. Their diverse portfolio includes pneumatic and fluid control components, fine system components, drive components, and labor-saving components. The company has also developed various types of automation machinery, such as transparent object inspection systems, pharmaceutical products packaging machines, and more. These products find applications in various industries, for example their automated food packaging systems are designed for maintaining food quality and hygienic conditions. Their fluid control components are used in the solar cell manufacturing process.

MCI Robotics Pvt. Ltd., established in 2008 and headquartered in Chennai, India, is a pioneering manufacturer and supplier of advanced robotic solutions. Their main products encompass a diverse range of industrial robots and automation systems, catering to sectors such as manufacturing, logistics, and healthcare. For its technological modernization, MCI Robotics plays a pivotal role in enhancing operational efficiency and precision in various industries. As a manufacturer, they subsidize significantly to the field of robotics, providing modern automation solutions that empower businesses with increased productivity and flexibility in their processes.

FANUC Corporation, established in 1972 and headquartered in Yamanashi Prefecture, Japan, is a manufacturer of factory automation, robomachine, IoT, and robotics. The company offers an extensive and diversified product portfolio including, servomotor, robodrill small cutting machine, roboshot electric injection molding machine, robocut wire electrical discharge machine, and lasers. These cutting-edge products cater to a wide range of industries, spanning from automotive, health care, and aerospace to electronics. The aim of the company is to provide efficient and low-cost products to customers.

Mecademic Robotics, founded in Montreal, Quebec, in 2013 is a manufacturer of industrial robot arms that enable the accurate and repetitive micro-manipulation of small parts and tools. The company's product portfolio includes micro-automation robots designed for component manufacturing, optics & photonics, electronics, medical devices, biopharmaceuticals, and research centers. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. They also provide services including product selection, installation, preventative maintenance, troubleshooting, and repair.

Universal Robots was founded in 2005 in Odsense, Germany as a manufacturer of collaborative robots known as Cobots. The company provides automation solutions by designing flexible industrial collaborative robotic arms that are implemented for faster production, and increased accuracy. They are light in weight so they can be easily relocated and can be reprogrammed for different applications. Besides Electronics and Technology, numerous industries benefit from Cobots including Education and Science, Food and Beverage, Medical and Cosmetics, and even Metal and Machining.

Stäubli began in Horgen, Switzerland in 1892. Stäubli designs, produces, distributes, and provides support for products for numerous industries including aerospace, alternative fuels, medical devices, packaging, photovoltaics, and semiconductors. Stäubli has 4 primary product lines including electrical connectors, fluid connectors, robotics, and textile. Electrical connector products include cable couplers, modular connectors, and test and measurement connectors. Fluid connectors include mold clamping systems, quick and dry disconnect couplings, and safety breakaway couplings. Robotics include industrial robots, collaborative robots, and mobile robots. Textile includes weaving preparation and frame weaving.

Rozum Robotics, founded in 2015, is a manufacturer of advanced robotic systems and components based in Minsk, Belarus. The company's offerings include various robotic products, including robotic arms, robot controllers, linear actuators, and custom solutions. One of the standout features of the company's robotic arms is its precision. These arms are engineered to perform tasks accurately, ideal in applications requiring precise movements, such as assembly, quality control, and material handling. The company has also ventured into the field of collaborative robots. These robots are designed to work safely alongside humans and are particularly valuable in medical environments and research labs.

KUKA AG was founded in 1898 in Augsburg, Germany. The company is a subsidiary of GD Midea Holding Co., Ltd. and is an automation developer, designing and manufacturing robot-based automation solutions for medical, automotive, warehousing, and distribution industries. The company’s product segments include robot systems, production machines, and systems, mobility as a driver of Industry 4.0, and process technologies that provide special welding processes to factories. The company’s services include repair and servicing for robots and machines and engineering services for designing and programming robotic systems.

igus GmbH, established in 1964 and based in Cologne, Germany, is a manufacturer and distributor of technical products made using polymers for movement. Its products include injection molding frames, motor control systems, and plain bearings, and it has over 240,000 products in over 1,000,000 variations. It serves 188,000 companies from over 80 countries worldwide in 50 different industries, including packaging, automotive, and renewable energy. The company is ISO 9001, ISO 14001, and ISO 50001 certified, and in 2023, it recorded €1.115 billion in sales. Since 2021, the company has purchased 380 new injection-molding machines and has replaced 275 old ones.

ABB E-mobility provides electric vehicle charging solutions for customers around the globe. ABB E-mobility offers DC fast chargers as well as AC chargers with focus on reliability and uptime. Since 2010, ABB E-mobility has sold over 50,000 DC fast chargers and over 1 million total AC chargers. ABB E-mobility offers home single and multi-charge units, retail, workplace, and hospitality charge units, electric vehicle fleet sales, as well as public transportation. Additionally, numerous digital solutions and software services are available.

Rapid Robotics has been a manufacturer of case palletizing solutions in California since 2019. The company designs a complete palletizing solution that can handle multiple SKUs & pallet patterns on a single line, moreover, it can be pre-trained on multiple SKUs and pallet patterns, making it adaptable to various operations. These robotic arms have applications in case packing, Multi-step Machine Tending, Loading & Unloading Fragile Materials, Adhesive Dispensing, and Metal Punching to name a few. They largely serve many manufacturing industries and logistics operators.

CIM SYSTEMS, INC. is a manufacturer of robotic automation systems founded in 1989 and based in Noblesville, Indiana. The company provides material handling solutions for use in complex production processes such as packaging, palletizing, or machine tending for clients in automotive, aerospace, and consumer goods. The company’s product lineup includes components like positioners, conveyors, end-of-arm tooling, and deburring spindles, as well as accessories like grippers and sensors. CIM SYSTEMS, INC also develops and supplies clients with CAD and CAM software for industrial applications, including RhinoNC, MillBox, Pyramis, and SUM3D.

ST Robotics is a manufacturer of bench-top industrial robot arms and Cartesian robots that is headquartered in Cambridge, England, and New Jersey, United States, and was established in 1981. The company’s product catalog for robot arms ranges from the ultra-safe R12 which is a collaborative robot to the R17HS. The robots from the company range from delta, Cartesian linear, and cylindrical robots. The company also offers accessories such as grippers, linear tracks, wireless teach consoles and tool changers. Industries served by the company include automation, life science, vending and entertainment, and educational markets.

Stucchi 1950 Srl, established in 1950 and located in Baranzate, Milano, Italy, is a manufacturer specializing in industrial vacuum cleaners and related equipment. The company offers exhaust gas extractors with and without fans, industrial vacuum cleaners for standard industrial applications, and dust extractors for centralized systems. It also offers welding fume extractors for metalworking lines, and energy distribution terminals for the distribution of compressed air or suction. The company is ISO 9001-certified, and mainly serves clients in the automotive, nautical, and joinery industries.

Hirata Corporation is a manufacturer and distributor of industrial robotic and logistics equipment based in Kumamoto, Japan. Established in 1951, the company first dabbled in manufacturing and marketing industrial vehicles. In 1958, they turned to manufacturing agricultural-related products. By 1959, they started their first conveyor belt line, and in May 1964, their television assembly line was launched. In 1977, they developed their first robot-controlled machine, and from there, they shifted towards robotic logistical equipment. The company is present in eight countries, namely Japan, Taiwan, the United States, Mexico, China, Singapore, Malaysia, and Thailand.

Ellison Technologies was founded in 1983 as a supplier of machining solutions and is headquartered in California. The company provides CNC machining solutions, including lathes, machining centers, lasers, and metrology tools that help manufacturers to meet all their production needs. There are also EDMs, Saws, Grinding machines, and Automation systems for part set-up, production set-up, production movement, cobots, and robotics. They also provide services that include maintenance and repair of machines along with supplying parts and accessories. They serve industries that are complete Machining centers, or Turning centers.

WENZEL Group, founded in 1968 and headquartered in Wiesthal, Bayern, Germany, is a manufacturer of industrial metrology and styling solutions. The company offers a range of products, including coordinate measuring machines (CMMs), gear measuring machines, optical high-speed scanning systems, 3D X-ray measuring technology via computer tomography, and multi-sensor systems. These tools cater to diverse industries such as automotive, aircraft, mechanical engineering, and medical technology for precise measurement and analysis. It holds ISO 9001 and VDA 6.4 certifications for its quality management system, alongside accreditation confirming competence in dimensional measurands as per DIN EN ISO/IEC 17025:2018 standards.

Yaskawa Motoman, founded in 1989, is a manufacturing company which offers industrial automation and robotics solutions in the Americas. With more than 540,000 industrial robots, 18 million servos and 30 million inverter drives installed globally, the company provides automation products and solutions for virtually every industry and robotic application including arc welding, assembly, packaging, dispensing and more. Their product line includes more than 150 distinct industrial arm, a full-line of pre-engineered "World" solutions that are complete application-specific robotic systems that include robot, process and safety equipment. They are backed by a powerful parent, Yaskawa Electric Corporation of Japan.

Googol Technology Co. Ltd., founded in 1999 and headquartered in Shenzhen, Guangdong, China, is now the head organization of numerous subsidiaries that specialize in the manufacture of IoT and networked automation components and the supply of product development technologies. The group's main product categories include motion control components, servo drives, and intelligent PLC control boxes. It also offers an extensive range of product application and type-specific development platforms, featuring tools for device management and the development of hardware devices and application software. These products allow customers to design and build their own technology as well as integrate the company's products.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Trossen Robotics |

9.0%

|

| 2 | UNIVERSAL ROBOTS A/S |

6.6%

|

| 3 | Machine Saver Inc. |

5.5%

|

| 4 | Yaskawa America, Inc. - Drives & Motion Division |

4.7%

|

| 5 | KUKA AG |

4.7%

|

| 6 | Force Design, Inc. |

4.6%

|

| 7 | SAE Manufacturing Specialties Corp |

4.5%

|

| 8 | Jomar Corp. |

4.0%

|

| 9 | Jennerjahn Machine, Inc. |

4.0%

|

| 10 | Dixon Automatic Tool, Inc. |

3.7%

|

Derivation Method

The ranking is calculated based on the click share within the robotic arm page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

9 | 36.0% |

Japan

Japan

|

5 | 20.0% |

Germany

Germany

|

3 | 12.0% |

Switzerland

Switzerland

|

2 | 8.0% |

Belgium

Belgium

|

1 | 4.0% |

India

India

|

1 | 4.0% |

Canada

Canada

|

1 | 4.0% |

Denmark

Denmark

|

1 | 4.0% |

Italy

Italy

|

1 | 4.0% |

Hong Kong

Hong Kong

|

1 | 4.0% |

193 products found - Page 2

193 products - Page 2

Maruka Corporation

170+ people viewing

■Features A linkless type heavy-lift robot based on a new idea. With its generous wrist torque and operating range, it opens up a new era in transp...

SmartOne Co., Ltd.

170+ people viewing

The FR10 cobot not only upgrades flexibility, safety, ease of use, and flexibility, but also has superior industrial-grade precision, stability. Co...

Maruka Corporation

190+ people viewing

■Features The LP series is a robot dedicated to palletizing that has the ability to perform large operations at high speed. Products in boxes such ...

SmartOne Co., Ltd.

200+ people viewing

FR5 is the first in the cobot field to receive CR certification. Adopting self-developed real-time control system, it integrates fully upgraded fea...

Maruka Corporation

340+ people viewing

Last viewed: 15 hours ago

■Features This is a next-generation spot welding robot with a hollow arm structure. The cables used for the welding gun are built-in, increasing th...

SmartOne Co., Ltd.

200+ people viewing

System setup available. FANUC's collaborative robot CRX10iA is a robot that combines high flexibility and ease of use. Its main features are as fol...

Maruka Corporation

300+ people viewing

Last viewed: 15 hours ago

■Features The definitive spot welding robot. In pursuit of acceleration and vibration damping, we have achieved a 30% reduction in cycle time (comp...

SmartOne Co., Ltd.

160+ people viewing

It is characterized by being lightweight, compact, highly flexible and easy to install. It uses an integrated intelligent drive module to achieve a...

SmartOne Co., Ltd.

180+ people viewing

■DOBOT NOVA series DOBOT NOVA collaborative robot. DOBOT Nova is an ultra-light and compact 6-axis robot arm designed by DOBOT for the service indu...

SmartOne Co., Ltd.

160+ people viewing

JAKA collaborative robots (JAKA Cobots) have been successfully applied in automated production in multiple industrial sectors, bringing innovation ...

SmartOne Co., Ltd.

260+ people viewing

Last viewed: 2 hours ago

■DOBOT NOVA series DOBOT NOVA collaborative robot. DOBOT Nova is an ultra-light and compact 6-axis robot arm designed by DOBOT for the service indu...

SmartOne Co., Ltd.

250+ people viewing

■Learn through play Learn the basics of AI in a fun and creative way. The kit also provides step-by-step tutorials online so beginners can start bu...

SmartOne Co., Ltd.

200+ people viewing

■DOBOT CR cobot series DOBOT CR collaborative robot. With a wide range of payloads from 3kg to 16kg, DOBOT cobots can be applied in multiple indust...