54 Plastic Pallet Manufacturers in 2024

This section provides an overview for plastic pallets as well as their applications and principles. Also, please take a look at the list of 54 plastic pallet manufacturers and their company rankings. Here are the top-ranked plastic pallet companies as of April, 2024: 1.Monoflo International, 2.The Nelson Company, 3.Alpha Packaging, Inc..

Table of Contents

1987~1991: Engaged in research on wire covering materials at Polymer Materials Laboratory.

1991~1997: Worked as a patent Engineer at Koike International Patent Office.

1997~2005 Worked as an intellectual property member at GE Yokogawa Medical System, currently working as a writer.

Linkedinhttps://www.linkedin.com/in/%E8%A3%95%E5%AD%90-%E9%88%B4%E6%9C%A8-92b21a234/

researchmap

https://researchmap.jp/0315rs2017

What Is a Plastic Pallet?

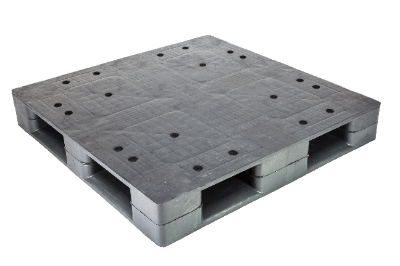

In warehouses, you've likely seen forklifts carrying loads on platforms known as pallets. These pallets come in two primary varieties: wooden pallets and plastic pallets. Plastic pallets are utilized for transportation, logistics, and storage, serving the dual purpose of supporting cargo and safeguarding it during storage. They are characterized by their distinctive sawtooth design.

Plastic Pallet Sizes

The most common size for plastic pallets is Type 11, featuring 1100 mm x 1100 mm squares. Other variations include Type 14, with 1400 mm x 1100 mm rectangles, smaller pallets under 1000 mm, and larger pallets exceeding 2000 mm in size.

Advantages and Disadvantages of Plastic Pallets

1. Durability:

Compared to wooden pallets, plastic pallets excel in durability. Unlike wooden counterparts that are susceptible to moisture absorption and subsequent corrosion, plastic pallets remain impervious to moisture. This resilience extends to protection against pests and bacteria, which can affect wooden pallets. However, it's important to note that plastic pallets cannot be repaired by replacing damaged sections since the pallet's surface is molded as a single piece.

2. Impact on Cargo:

Plastic pallets offer an advantage by preventing surface cracks and wood "scuffing" on the underlying surface, a common occurrence with wooden pallets. As a result, the bottom of loaded plastic pallets is less prone to scratching. Additionally, unlike wooden pallets that can absorb odors, plastic pallets are odor-resistant and won't transfer unwanted smells to the cargo they carry. This makes them suitable for transporting goods where odor contamination is a concern.

Other Advantages of Plastic Pallets

Due to their lightweight nature, plastic pallets reduce labor and physical strain during transportation, thus improving workplace conditions. Unlike wooden pallets, which cannot be recycled and must be disposed of as waste, plastic pallets can be crushed and processed into pellets for recycling, aligning with ecological and SDGs (Sustainable Development Goals) considerations.

Conclusion

While plastic pallets may have a higher initial cost compared to wooden pallets, their superior durability, ability to maintain product quality, lightweight design for enhanced work environments, and recyclability make them a compelling choice. Consider incorporating plastic pallets into your company's operations to reap these benefits.

List of 54 Plastic Pallet Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- Canada

- China

- Germany

- India

- Israel

- Italy

- Netherlands

- Switzerland

- United Kingdom

-

-

-

Buckhorn Inc.

PALLETS

Manufacturer Overview

Buckhorn Inc., founded in the United States is a manufacturer of material handling systems. The company's product portfolio includes palletizing and depalletizing systems designed to optimize the stacking and unstacking of goods on pallets, ensuring safe and efficient handling, overhead cranes and gantry cranes, for heavy-duty lifting applications and bulk boxes. It serves industries such as industrial manufacturing, food & beverage, distribution, grocery & bakery, and seed & bulk flowable.

-

-

-

-

-

The Nelson Company

CPP100/ACM

Manufacturer Overview

The Nelson Company, founded in 1918 and headquartered in Baltimore, Maryland ,is a manufacturer of transport packaging solutions. The company has established itself as a producer of pallets, containers, crates and specialty handling products for transporting, storing and protecting products. It also engages in custom designs, wood manufacturing, systems analysis and programs for distribution. The company is an authorized participant in the USDA BioPreferred Program in partnership with its license to use Pallet Design Software.

-

-

-

-

-

Orbis Investment Management Limited

NESTABLE PLASTIC PALLETS

Manufacturer Overview

ORBIS Corporation was founded in 1849 and is headquartered in Oconomowoc, Wisconsin, USA, as a manufacturer of packaging and containers. The product list of the company includes nesting containers, stack and nest, beverage crates, nestable plastic pallets, and stackable plastic pallets, among others. The company also provides services such as engineering services, reusable packaging management, commercial services, and recycling with ORBIS. The products offer efficient and space-saving storage solutions that enhance material handling and logistics efficiency, while the services help industries optimize the packaging and sustainability practices. The company serves various industries, including agriculture, automotive, bakery, beverage, dairy, and e-commerce.

-

-

-

-

-

US Plastic Pallets & Handling

Economical Export Pallets

Manufacturer Overview

US Plastic Pallets & Handling, founded in 1996 and headquartered in South Street, Hopkinton, MA, is a manufacturer and supplier of plastic pallets and material handling solutions. The company specializes in producing a diverse range of plastic pallets that cater to various industries, ensuring safe and efficient storage and transportation of goods. Its product line includes rackable, stackable, nestable, and export pallets designed to meet specific storage and shipping requirements. The company maintains ISO certifications, reflecting its products' industry standards.

-

-

-

-

-

Monoflo International

Nestable & Rackable Pallets

Manufacturer Overview

Monoflo International, a company founded in 1973 and headquartered in Winchester, Virginia, United States, is a manufacturer of injection-molded plastic products. Specializing in reusable plastic containers and pallets, the company serves various industries including logistics, agriculture, and retail. The company’s product line includes durable storage containers, automation trays, collapsible containers, and stackable pallets designed to streamline material handling and storage processes. Its uses optional reusable packaging system to reduce packaging waste and enhance efficient supply chain processes. The company's holds ISO certifications, ensuring quality and eco-friendly products and services to meet customers' needs.

-

-

-

-

-

Port Erie Plastics

Plastic Pallets

Manufacturer Overview

Port Erie Plastics, founded in Harborcreek, Pennsylvania in 1966 is a manufacturer of custom injection molding solutions. The company's product portfolio includes Automation and injection Molding Industry, Mold Design and tooling Transfer, and Structural Foam Molding and extrusion Services. The company serves markets including Medical and Healthcare, Aerospace and Defense, Consumer Goods, Industrial Manufacturing and Construction and Building. The company also provides services such as Product Selection Guidance, warehousing and distribution, repair services and customer and technical support.

-

-

-

-

-

Kiva Container

Plastic Pallets

Manufacturer Overview

Kiva Container, formerly CP Products, started in 186, is a manufacturer of plastic reusable and returnable packaging related to corrugated plastic. The product line includes custom products such as ESD packaging, plastic pallets, integrated packaging, corrugated plastic fabrications, and standard items, including handling totes, wet floor signs, recycle bins, and hinged lid boxes used in supply chain management, medical, industrial, design 2 part, and aerospace industries. The Anaheim, CA company offers custom vacuum forming and light gauge thermoforming services.

-

-

-

-

-

TMF Corporation

Plastic Pallets

Manufacturer Overview

TMF Corporation, founded in Havertown, Pennsylvania, in 1988 is a manufacturer of plastic containers. The company's product portfolio includes Long Term Use / Warehouse Pallets, Fire Retardant Pallets, Shipping Pallets, Drum Pallets and Automotive Industry Pallets. The company serves markets including Medical and Healthcare, Aerospace and Defense, Consumer Goods, Industrial Manufacturing and Construction and Building. The company provides services such as Product Selection Guidance, Engineering and technical Support, and Custom Manufacturing.

-

-

-

-

-

Robinson Industries, Inc.

Plastic Pallets

Manufacturer Overview

Robinson Industries, Inc. is an ISO 9001 certified manufacturer of reusable plastic pallets, packaging and dunnage established in 1947 and based in Coleman, Michigan. The company produces thermoformed as well as structural foam trays, lids, industrial packaging solutions, and plastic pallets for shipping and storing purposes. They also provide design, engineering, and tooling services for custom thermoform, sheet extrusion, and injection molding projects. Robinson Industries products supply client companies and businesses in various industries including retail, defense, agriculture, and automotives.

-

-

-

-

-

Gibraltar Plastic Products Corp.

Plastic Pallets

Manufacturer Overview

Gibraltar Plastic Products Corp., established in 1952, is a manufacturer of fabricated plastic displays, signage, and packaging products. The company is based in San Fernando, California, from where it conducts all it's production processes, including design, prototype development, production, and assembly. They produce enclosures, store fixtures, floor, and counter displays. These are used in the electronics, gaming, automotive, health, and beauty industries. The company has served Disney Stores, Yamaha, Neutrogena, Panavision, and Baskin- Robbins.

-

-

-

-

-

Bermar Associates, Inc.

Plastic Pallets

Manufacturer Overview

Bermar Associates, Inc., based in Troy, Michigan, is a manufacturer, specializing in economical tooling and plastic parts since 1969. Their custom plastic injection molding capabilities, encompasses of high press tonnage molding for larger parts, over molding for enhanced product structure, and solid molding for solid parts. The company caters to various industries, including components, consumer products, and hardware. Additionally, they provide Master Wipe Way Wipers, which protect machines from corrosive fluids and sprays, ensuring optimal performance and longevity. Bermar Associates is ISO 9001 compliant, maintaining adherence to industry standards.

-

-

-

-

-

APR Allen Plastics Repair, Inc.

Plastic Pallets

Company Overview

APR Allen Plastics Repair, Inc., founded in 1985 and based in Fort Wayne, IN, is a manufacturer and distributor of container and accessory equipment in the plastic fabrication industry. It provides design and customization services for fabricated plastic tanks, rotationally molded tanks, secondary containment systems, liners, and accessory equipment. The company also provides replacement tanks, as well as offers onsite installation, inspection and maintenance services for tanks in the refrigeration and metal finishing industries.

-

-

-

-

-

Perfect Pallets, Inc.

Plastic Pallets

Company Overview

Perfect Pallets, Inc., founded in 1992 and headquartered in Indianapolis, Indiana, is a manufacturer and distributor of industrial pallets. The company offers a wide range of plastic pallets, including standard pallets, custom pallets, reusable pallets, heavy-duty pallets, and food-grade pallets. These pallets are designed to support and transport goods and materials within warehouses, distribution centers, and during shipping and logistics operations. Perfect Pallets, Inc. also provides comprehensive rental programs based on a per transaction fee and transportation services.

-

-

-

-

-

American Surplus, Inc.

Plastic Pallets

Company Overview

American Surplus Inc (ASI) was founded in Rumford, Rhode Island in the early 1990s. ASI is a distributor of both new and used material handling equipment and warehouse equipment and also purchases used equipment. ASI specializes in distributing both new and used pallet racks, conveyor systems, mezzanines, industrial, and other warehouse equipment. Other offers include cantilever racks, dock equipment, floor scrubbers, flow racks, forklifts, inplant offices, industrial cabinets, industrial containers, lift equipment, lockers, packing equipment, pallet racking, scales, and pick modules.

-

-

-

-

-

-

-

New Day Packaging Products

Plastic Pallets

Company Overview

New Day Packaging Products was founded in 1989 as a division of T & H Sales Inc. New Day Packaging designs and manufactures packaging and inventory management services. New Day Packaging products include cushioning material, tapes, fasteners, films, paper wraps & tissue, boxes, janitorial supplies, and safety products. Custom packaging solutions include general capabilities of design and distribution, full packaging materials and container styles, creation services, custom specifications, secondary services such as labeling and validating, and production volume.

-

-

-

-

-

Advance Cutting Systems

Plastic Pallets

Distributor Overview

Advance Cutting Systems (ACS), formed in 1989 and situated in Alabama, USA, is a supplier of fabrication, precision, and HVAC cutting machines. The company provides Conventional Plasma, Precision Plasma, Abrasive Waterjet, Non-Abrasive Waterjet, Oxy-Fuel and Fiber Laser cutting machines. The company works closely with its major vendors, including Koike Aronson, Micro Application Packages, AutoFold Systems Ltd., and Hypertherm Automation. It provides a 7000 sq. ft. Demo Center area for customers to find which cutting machines suit their requirements.

-

-

-

-

-

MH Containers & Equipment Co.

Plastic Pallets

Distributor Overview

MH Containers & Equipment Co., Inc., established in 1964, is a supplier of collapsible steel, plastic, and wire containers, boxes, pallets, rackings, and totes. The company provides new and used storage containers, cantilever racks, straight-walled plastic containers, and intermediate bulk containers for the shipping and storing of liquid food goods, hazardous commodities, and bulk chemicals. The Willoughby, Ohio-based business buys used wire baskets, plastic totes, corrugated steel containers, steel boxes, and plastic racks.

-

-

-

-

-

Thornel Associates, Inc.

Plastic Pallets

Distributor Overview

Thornel Associates, Inc.,headquartered in Lisle, Illinois, has been a material handling equipment supplier since 1955. The company provides a diverse range of material handling solutions, including conveyors like belt and roller conveyors, racks such as pallet and cantilever racks, and mezzanines for additional storage space. Its offerings extend to lift trucks encompassing electric and gas forklifts, catering to heavy-duty material movement. The company also delivers other essential equipment like dock levelers, palletizers, and shrink wrap machines, utilized for efficient and organized material handling operations in various industries.

-

-

-

-

-

Martini Alfredo S.p.A.

Pallet

Manufacturer Overview

Martini Alfredo S.p.A., founded in 1945 and based in Turate, Italy is a manufacturer of plastic containers and pallets. The company is among the first sectors to receive ISO 9001 certification. The company holds SQS, IQNET, and second-life plastic certifications. The company’s marina systems have fingers and a unique self-bearing gangway. It provides accessories like ladders and safety ladders, signal lights, joint knees, quay cleats, and cranes for people with disabilities. The firm provides useful sun or rain protection in the form of a customizable white PVC sheet canopy.

-

-

-

-

-

Superlift Material Handling Inc.

Plastic Pallets

Manufacturer Overview

Superlift Material Handling Inc. (SMH) is a manufacturer of standard and custom material handling equipment based in Ontario, Canada. The company was established in 1982 and offers sale, rental, and rental purchase options to clients in hospitality, automotive, construction, and pharmaceuticals. The company produces various ergonomic handling solutions including lift tables, carts, and stackers for vertical transportation, pallet trucks, and skid lifters for horizontal transportation, upenders for rotating transporters up to 90 degrees, and work positioners for adjusting surface ergonomics. SMH also provides custom design and engineering services for customers with unique specifications.

-

-

-

-

-

DENIOS, Inc.

Plastic Pallets

Manufacturer Overview

DENIOS US was founded in 1990 and is headquartered in Louisville, Kentucky. Denios is a manufactuer of storage and barriers solutions to safely store chemicals and heat sensitive materials. DENIOS’s product ranges include non-occupancy storage buildings, storage rooms and test rooms for lithium batteries, occupancy storage buildings, chemical storage lockers, and pop-up flood and spill barriers. Additionally, DENIOS offers hazardous material storage, secondary spill containment, spill and flood control, handling equipment and accessories, and facility maintenance and work safety product lines.

-

-

-

-

-

Southland Equipment Service

Pallets

Manufacturer Overview

Southland Equipment Service is a manufacturer of material handling equipment for the warehousing industry that was established in Columbia, South Carolina, USA, in 1971. The company’s product lineup includes rough terrain and electric scissor lifts, propane and diesel forklifts, and ride-on as well as walk-behind scrubbers or sweepers. It also offers shelving and racking products, as well as dock equipment such as levelers and seals. The company mainly serves clients in the logistics, construction, and retail industries.

-

-

-

-

-

Chase Doors

Spill Containment Platform

Manufacturer Overview

Chase Doors, established in 1986 and headquartered in Cincinnati, Ohio, United States, is a designer and manufacturer of fiberglass reinforced plastic (FRP) doors and frame systems for corrosive environments. The company's products include FDA- and USDA-approved traffic impact doors, Chase TMI roll-up doors, and corrosion-resistant doors. It also produces air barriers and loading dock and warehouse safety solutions. These products are used in warehouses, restaurants, and cooling facilities. It serves sectors that include offshore drilling, power plants, and water treatment plants.

-

-

-

-

-

Basic Crating & Packaging

Plastic Pallets

Manufacturer Overview

Basic Crating & Packaging, established in 2011 and headquartered in Elk Grove Village, Illinois, is a custom manufacturer of packaging solutions. The company offers packaging solutions for various types of goods, including corrugated boxes, wood crates, plastic crates, packing materials, and dangerous goods packaging. They also provide services such as rigging and dismantling, transportation, container loading, export coordination, and trade show services. These offerings help protect goods, ensure regulatory compliance, improve operational efficiency, and enhance safety.

-

-

-

-

-

Premier Handling Solutions

Plastic Pallets

Manufacturer Overview

Premier Handling Solutions, established in 1977, and headquartered in Elgin, Illinois, is a manufacturer of machines and tools for material handling, providing warehouse equipment solutions for productivity, safety, and speed throughout the entire supply chain process. They specialize in Pallet Inverters and Load Transfer Systems. Some of their products include Pallet Inverters, Pallet Stackers & Dispensers, Load Transfer Systems, Stretch Wrappers, Wire Containers, 5S Floor Tapes, and Lift Tables. They also offer free consultations to help companies streamline supply chain processes through efficient operations.

-

-

-

-

-

Alpha Packaging, Inc.

Plastic Pallets

Manufacturer Overview

Alpha Packaging, Inc. was founded in 187 and is headquartered in Greenwood, Arkansas. Alpha Packaging is a producer of custom packaging materials. Alpha Packaging offers custom services including custom packaging, custom foam and package filling, as well as custom printing. Product offerings include box foam inserts, corrugated boxes of various flute profiles, die cut boxes, corrugated plastic shipping boxes, mailer boxes, and heavy duty shipping boxes. Box foam inserts include anti-static foam, and foam pouches, rolls, and edge protectors. Plastic shipping boxes include numerous options such as reusable, tamper-resistant, and shock-resistant. Mailer boxes include boxes, tubes, envelopes, and packing list envelopes.

-

-

-

-

-

Plasgad

Plastic Pallets

Company Overview

Plasgad is a developer and manufacturer of reusable packaging, storage and transport solutions established in Upper Galilee, Israel in 1982, The company produces various plastic boxes, crates, and pallets in different dimensions and specifications (e.g. lightweight, heavy duty) as well as storage and tilt bins, dollies, and airtight containers. These supply the storage and transportation needs of clients in the airline, maritime, tourism, e-commerce and textiles sectors. Plasgad does business internationally through a network of partner distributors and subsidiaries in Germany, Spain, Poland, and the United States.

-

-

-

-

-

Sanko Corporation

Plastic Pallet

Company Overview

Sanko Corporation, founded in 1951 and headquartered in Selangor, Malaysia, is a manufacturer and supplier specializing in the production of plastic-molded products. The company’s range of plastic-molded products includes plastic pallets, plastic containers, and internal logistic carry systems. These plastic products find applications in various sectors, including manufacturing, warehousing, retail, automotive, and logistics and distribution. The company also provides customer services, including customization, tailor-made solutions, and product catalogs. The company is ISO 9001 certified and has 27 manufacturing plants, 9 branches, and 63 sales offices throughout Japan.

-

-

-

-

-

Nationwide Industrial Supply

Plastic Pallets

Company Overview

Nationwide Industrial Supply was founded in Youngstown Ohio in 2006. Nationwide Industrial Supply is a distributor of industrial equipment, serving both public and private institutions and companies in the United States and overseas. Some of Nationwide’s offerings maintenance, operating products, safety supplies repair products, storage equipment, tubing, pipe, and hose material, electrical and plumbing supplies repair and operating products, storage equipment, safety supplies, material handling equipment, shelving, and work platforms.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Plastic Pallet & Container

Plastic Pallets

-

-

-

-

-

Greystone Logistics, Inc.

PLASTIC SHIPPING PALLETS

-

-

-

-

-

Gamma-Wopla and Smart-Flow form

Plastic pallets 600x400

-

-

-

-

-

ELKOPLAST CZ, s.r.o.

Plastic Pallets

-

-

-

-

-

WERIT Kunststoffwerke W. Schneider GmbH & Co. KG

PLASTIC PALLETS

-

-

-

-

-

PSAplast

PLASTIC BOXES AND PALLET

-

-

-

-

-

SUMOOAK

Pallets

-

-

-

-

-

Cabka Cabka digital

Plastic Pallets

-

-

-

-

-

BearBoard

Light Duty Pallet - 40x48

Company Overview

BearBoard, a company founded in 2000 and located northwest of Chicago, Illinois, is a manufacturing company specializing in synthetic lumber fabrication and product development. It is a subsidiary of Engineered Plastic Systems LLC. The company provides private consumers with ecological, long-lasting alternatives to traditional wood building materials. It offers sustainable practices and durable products catering to the construction sector. The company has garnered ISO certifications for its production processes, ensuring environmentally conscious manufacturing.

-

-

-

-

-

Uline

EXPORT PALLETS

-

-

-

-

-

Miles Manufactured Products, Inc.

Plastic Pallets

-

-

-

-

-

H & P Packaging, Inc.

Plastic Pallets

-

-

-

-

-

Rapid Racking Ltd

Hinged Lid Heavy Duty Plastic Pallets

Distributor Overview

Rapid Racking Ltd, founded in 1986 and headquartered in Kemble, Cirencester, United Kingdom is a supplier of shelving and racking solutions. The company specializes in manufacturing and distributing an array of shelving, racking, and storage equipment. Additionally, the company also conducts a thorough load test on single bays of shelving that establishes safe working loads by overloading shelf levels. Its products cater to diverse industries, optimizing storage spaces in warehouses, offices, and retail environments. The company holds ISO 9001 and ISO 14001 certifications, ensuring durability of products.

-

-

-

-

-

Tosca

Pallets

Distributor Overview

Tosca is based in Atlanta, Georgia, and is a supplier of reusable packaging solutions that was established in 1959 before its acquisition by Apax Partners LLP in 2017. The company offers reusable plastic containers (RPCs) for perishable food supply chain products such as poultry, meat, eggs, and dairy. It also offers reusable plastic dollies, pallets, trays, and dividers for handling its various RPCs. Aside from its products, the company provides sanitization, asset management, and consulting services for clients using its products.

-

-

-

-

-

Arcawa

Plastic pallets

Distributor Overview

Arcawa is based in Berlin, Germany, and is a distributor of Arca industrial valves that was established in 2007 as a subsidiary of Arca Regler AG. The company stocks various valve models, including steam conditioning, control, desuperheater, butterfly, and pressure reducing valves. It also offers related accessories such as actuators and positioners, as well as engineering, consulting, valve service, and valve repair services for customers requiring additional support. The company mainly markets to clients in the petrochemical, power generation, pulp and paper, and food and beverage processing industries.

-

-

-

-

-

Polymer Solutions International, Inc.

Plastic Pallets

Distributor Overview

Polymer Solutions International, Inc., founded in 1997, is a global supplier of reusable material handling products based in Pennsylvania. Polymer Solutions International specializes in engineering and manufacturing bottled water racks and plastic pallets used across various industries including pharmaceutical, food & beverage, as well as the retail market. The company also offers custom manufacturing solutions for all material handling needs such as custom plastic molding for transporting larger-than-standard water bottles or custom shipping pallets.

-

-

Plastic Pallet Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Monoflo International |

6.1%

|

| 2 | Alpha Packaging, Inc. |

5.4%

|

| 3 | The Nelson Company |

5.2%

|

| 4 | US Plastic Pallets & Handling |

4.9%

|

| 5 | Port Erie Plastics |

3.8%

|

| 6 | Orbis Investment Management Limited |

3.7%

|

| 7 | TMF Corporation |

3.5%

|

| 8 | Kiva Container |

3.4%

|

| 9 | DENIOS, Inc. |

3.3%

|

| 10 | Robinson Industries, Inc. |

3.2%

|

Derivation Method

The ranking is calculated based on the click share within the plastic pallet page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

- BearBoard: 2000 (24 years ago)

- Aceally International Co.,Ltd.: 1999 (25 years ago)

- Polymer Solutions International, Inc.: 1997 (27 years ago)

Company with a History

- The Nelson Company: 1918 (106 years ago)

- PSAplast: 1955 (69 years ago)

- Engels Logistiek BV: 1955 (69 years ago)

Plastic Pallet Manufacturers in United States

*Including some distributors, etc.

- Buckhorn Inc.

- The Nelson Company

- Orbis Investment Management Limited

- US Plastic Pallets & Handling

- Monoflo International

- Port Erie Plastics

- Kiva Container

- TMF Corporation

- Robinson Industries, Inc.

- Gibraltar Plastic Products Corp.

- Bermar Associates, Inc.

- APR Allen Plastics Repair, Inc.

- Perfect Pallets, Inc.

- American Surplus, Inc.

- Rehrig Pacific Co.

- New Day Packaging Products

- Advance Cutting Systems

- MH Containers & Equipment Co.

- Thornel Associates, Inc.

Global Distribution of Plastic Pallet Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

19 | 59.4% |

Italy

Italy

|

3 | 9.4% |

Germany

Germany

|

2 | 6.3% |

Israel

Israel

|

2 | 6.3% |

Canada

Canada

|

1 | 3.1% |

Switzerland

Switzerland

|

1 | 3.1% |

Netherlands

Netherlands

|

1 | 3.1% |

China

China

|

1 | 3.1% |

India

India

|

1 | 3.1% |

United Kingdom

United Kingdom

|

1 | 3.1% |

List of Plastic Pallet Products

125 products are listed.

Sanko Corporation

Back -shaped palette (plastic parallet) S type (single type)

10+ people viewing

The S type (single -sided) palette has a getter -like shape, so you can do handlift work smoothly. The back side, which has a getter shape, can be ...

Sanko Corporation

100 % of waste plastic pallets (plastic para) press palette

<Environmental -friendly> recycle palette that uses 100 % abandoned plastic. The abandoned plastic, which was difficult with injection molding, is ...

Sanko Corporation

Standard specification palette (plastic para) 1,000 x 1,200 size

10+ people viewing

The 1,000 x 1,200 size palette is a standard palette set by JIS standards that are second only to 1,100 x 1,100 size pallets. It is mainly used in ...

Sanko Corporation

100 % recycled pallet (plastic parent) recycle palette

10+ people viewing

Sankori cycle palette is a pallet that collects plastic containers and pallets and uses 100 % recap resources. It is a 21st century green product t...

Sanko Corporation

Deck face thickness than conventional equivalent 1/2 Tafrite G (ultra -high rigidity product) TL palette

10+ people viewing

■ Features ・ Compared to the existing pallet, it has a lightweight and high rigidity. ・ Tafrite G series. ・ Keep rigidity even if the deck is 1/2 t...

Sanko Corporation

Lightweight palette (plastic parent) LX pallet with a SCP method of 20 % compared to the conventional

10+ people viewing

Realizes weight reduction by Sanko's unique special low foaming formation "SCP method". Lightweight = resource saving contributes to reducing carbo...

Horitomi Commerce and Industry

Holicon palette

10+ people viewing

① Full nesting HDPE (recycled resin) product (2) Compatible with the standards of the food industry ③ Zero wooden and pests because of the use of w...

Sanko Corporation

Lightweight design and transportation efficiency pallet (plastic para) plastic pallet for export packing

40+ people viewing

Last viewed: 19 hours ago

Sanko's Pallet "Export Packing Plastic Pallet" is a plastic logistics material that can be used as an export palette and one -way parent. This is a...

Sanko Corporation

At a glance, the stacking state is determined (plastic parallet) SN pallet

10+ people viewing

A pallet that can return the empty palette and have excellent storage efficiency. Various ideas for improving transportation efficiency are include...

Sanko Corporation

1,100 x 1,100 size

10+ people viewing

The 1,100 x 1,100 size palette is specified by the JIS standard as an integrated pallet "pool palette" that consistently transported from the produ...

Sanko Corporation

Lightweight & high rigidity palette (plastic parallet) GT pallet

10+ people viewing

A palette that acquire the strength of the next generation with the new technical structure. Realized high rigidity while being lightweight. ■ Poi...

Sanko Corporation

Palette (plastic parallet) D type (one -sided used type)

30+ people viewing

The d type palette has a different shape on the upper and lower surfaces. The back of the palette is the shape of the "rice" shape, taking into acc...

Sanko Corporation

Pallet (plastic parallet) R type (plastic parallet) R type (double -sided used type)

10+ people viewing

Last viewed: 10 hours ago

The R type palette is a palette designed with almost the same shape on the upper and lower surface. Whichever surface is used is almost the same st...

Sanko Corporation

Special enhanced PP recruitment palette (plastic parallet) HG type

10+ people viewing

The HG type palette is a palette that has a remarkable rigidity by adopting a special enhanced PP. Excellent rigidity is ideal for more severe usag...

Sanko Corporation

30 % to 50 % reduction of fire prevention safety measures (plastic parent) FR palette

10+ people viewing

A palette using flame retardant resin. Use ULSB94 combustion test category [V-1] using flame retardant PPE (V1) for the material. When used in a ra...

Sanko Corporation

Install protrusion (rib) on the outer periphery of the deck (plastic para) Palette with a projection

A palette with a protrusion (rib) installed on the outer periphery of the deck. Prevents packing of loading such as containers.

SeaS Japan Co., Ltd.

A plastic palette that is hygienic and easy to remove dirt

■ Characteristics ・ Because it is hygienic and easy to remove dirt, we are active in many logistics sites such as food and medical products. ・ We...