11 Timing Pulley Manufacturers in 2024

This section provides an overview for timing pulleys as well as their applications and principles. Also, please take a look at the list of 11 timing pulley manufacturers and their company rankings. Here are the top-ranked timing pulley companies as of July, 2024: 1.Torque Transmission, 2.Grob, Inc., 3.York Industries, Inc..

Table of Contents

Engaged in research on nitride semiconductor growth using the MBE method at Waseda University Graduate School. After graduating from graduate school in 2016, he joined a non-ferrous metal manufacturer.

Engaged in equipment maintenance and engineering work at metal smelting plants. Moved to a chemical manufacturer in 2022. Engaging in similar tasks.

What Is a Timing Pulley?

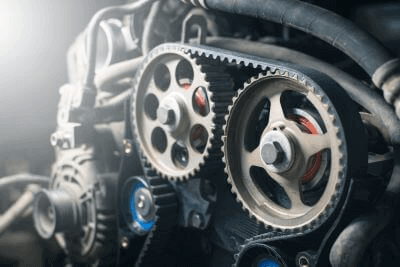

A timing pulley is a mechanical element used to precisely synchronize multiple parts of an internal combustion engine or automobile engine.

It is a type of pulley used to transmit power with a belt. Basically, timing belts and timing pulleys are used as a set.

Specifically, they are used to precisely synchronize the camshaft and crankshaft in the engine and to control the timing of valve opening and closing. Timing pulleys are gear-shaped components that drive the timing belt connecting the camshaft and crankshaft, which rotates at a precise angle.

It must be manufactured from high-quality materials and accurately designed because it has a significant impact on engine performance and fuel economy. In addition, timing pulleys are generally replaced at the same time when timing belts are replaced.

Uses of Timing Pulleys

A familiar application for timing pulleys is in automobile engines. The engine has intake valves to intake the air mixture into the cylinders and exhaust valves to exhaust the exhaust gases after combustion. These valves are opened and closed by camshafts, and timing pulleys are used to drive the camshafts.

The intake and exhaust valves must open and close in accordance with the timing of the pistons, which repeat their up-and-down motion at high speed. If the timing is off, the engine will malfunction or fail.

In order for the engine to produce power, it is very important to match the piston movement, valve opening and closing, and ignition timing. Timing belts and timing pulleys play this role.

They are sometimes used in machines other than automobiles when the timing of the internal components must be matched. Timing pulleys are also used in production lines for industrial products such as printing and textile machinery.

Principle of Timing Pulleys

Timing pulleys are intermeshing transmissions. Like a gear, it has a set number of teeth, and the timing can be adjusted by setting the number of teeth. If the number of teeth on the drive timing pulley is 20 and the number of teeth on the transmission side is 40, two revolutions on the drive side will result in one revolution on the transmission side.

If the number of teeth is incorrectly set, the timing will be off each time the pulley rotates, causing damage to the machine or equipment. Otherwise, the tooth profile and pitch of the pulley are used in conjunction with the timing belt.

Timing pulleys come in a very wide variety of types and are available in many different types for mounting on a shaft. Keyway, shaft hole, crimp type with threaded holes, and keyless type (with integrated fasteners) are available, allowing for installation in any location.

Types of Timing Pulleys

There are various types of timing pulleys, which are classified by tooth shape and size standard.

1. Inch Type

In the inch series, trapezoidal type MXL, XL, L, and H are available. They are used for general transmission and light-load conveyance.

2. Millimeter Series

The millimeter series includes trapezoidal T, AT, S and R types for high-torque transmission, and H type for high-precision positioning. The S and R types are often used for positioning because of their low backlash, while the H type is used in situations that require particularly high accuracy. The trapezoidal type is often used for conveyance, and AT has 1.3 times the allowable tension of T, enabling high-load conveyance.

How to Select a Timing Pulley

Because of the great variety of types and standards, care must be taken when selecting a timing pulley. Timing pulleys should be selected by calculating the load, safety factor, and other factors based on the conditions under which they will be used.

1. Confirmation of Usage Conditions

First, clarify the conditions of use. Determine the transmission power from the rated power of the prime mover, and determine the correction factor based on the conditions of use. The method for determining the correction factor is described in the manufacturer's literature.

For example, the correction factor is determined based on the presence of repetitive loads, vibration, and daily operating hours. The transmission power multiplied by the correction factor is called the design power, which is the transmission power used in the selection process.

2. Determination of Tooth Profile and Belt Width

Next, a simplified selection table is used to select a belt type (tooth profile) based on the pulley rotation speed and design power. A simplified selection table is provided in the selection documents of each manufacturer.

Once the tooth profile is determined, use the standard transmission capacity table to determine the standard transmission capacity based on the pulley rotation speed. Calculate the required belt width from the design power, standard transmission capacity, standard belt width, and engagement coefficient.

3. Mounting Method and Belt Length

Select the mounting conditions, such as whether a flange should be attached and how many shafts should be spaced. The belt tensioning mechanism is also designed, and the mounting dimensions and belt length are determined.

4. Material

Pulley materials include aluminum and iron, which must be selected according to the application. Iron or stainless steel is used when strength is required. Aluminum is often used for precision positioning that requires a low moment of inertia.

List of 11 Timing Pulley Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- India

-

-

-

Torque Transmission

TIMING PULLEYS

Manufacturer Overview

Torque Transmission, founded in 1947 and headquartered in Fairport Harbor, Ohio, is a manufacturer and designer of custom power transmission components. The company specializes in producing precision-machined components, such as pulleys, clutches, and flexible couplings, for various industries, including automation, packaging, and material handling. Its main products encompass timing pulleys, roller chain sprockets, speed reducers, and flexible shaft couplings. These components find applications in power transmission systems and motion control equipment. The company is ISO 9001 certified, ensuring a quality management system.

-

-

-

-

-

Grob, Inc.

Timing Pulleys

Manufacturer Overview

Grob, Inc., established in 1929, and headquartered in Grafton, Wisconsin, is a manufacturer of custom metalworking equipment and components. Their custom products, includes band saws, cold rolled steel products, blade welders, heat exchangers, and custom machine tools, that cater to industries like industrial manufacturing, machinery manufacturing, and manufacturing. Grob, Inc. is known for their quality machines that enhance productivity and accuracy in cutting and machining processes. They are ISO 9001:2015 certified, ensuring to provide stringent quality standards and excellent industrial solutions.

-

-

-

-

-

York Industries, Inc.

Timing Pulley

Company Overview

York Industries, Inc., founded in 1946, based in Garden City Park, New York, USA, is a manufacturer and supplier of custom and standard timing pulleys, gears, gear racks, and custom assemblies. The company offers various products such as TriMix tungsten, pre-ground tungsten electrodes, tungsten electrode grinders, plasma welding torches and accessories, and replacement grinder wheels. It is a manufacturer of custom timing pulleys, gears, and gear racks. Its products are used in various applications, including the automotive, medical, and industrial machinery industries.

-

-

-

-

-

Pearl Engineers

Timing Pulley

Manufacturer Overview

Pearl Engineers is a gear manufacturer, established in 1989 and based in Vadodara, Gujarat, India. The company’s product range includes different types of gears, such as compound, spiral bevel, and spur gears, along with various types of gearboxes. The company also produces helical geared motors, racks and pinions, and timing pulleys. It further offers ratchet wheels and worm and worm wheels. Some of the company’s notable customers include Elecon Engineering Company Limited, Escorts Kubota Limited, and TTK Group.

-

-

-

-

-

Advance Precision Technology.

Timing Pulley

Manufacturer Overview

Advance Precision Technology is a manufacturer of ball screws, linear shafts, and the like, started in 2013 and based in Pune, India. The company fabricates ball screws, flexible couplings, industrial couplings, and linear bearings. It also produces torque limiters, precision lock nuts, and XYZ axis slides to be sold to its customers. To manufacture rolled ball screws, the variant of its ball screws, it uses metal alloys like stainless steel, mild steel, aluminum, galvanized iron, and their mixture.

-

-

-

-

-

B.V. Transmission Industries

TIMING PULLEYS

Manufacturer Overview

B.V. Transmission Industries, founded in Mumbai, India, in 1963 is a manufacturer of industrial Components that includes Stainless Steel Slate Chains, Universal Joints Couplings, and Pulleys. The company's product portfolio includes Chain Sprockets, Chains, Mechanical Gears, belts, gears and racks & pinions. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. They have operations in UK, Dubai, Oman, Gulf, Argentina, Sri Lanka, and European countries.

-

-

-

-

-

Mitsuboshi Belting Ltd.

Industrial Power Transmission Belts

Manufacturer Overview

Mitsuboshi Belting Ltd. was founded in 1919 and headquartered in Japan is a manufacturer of rubber and plastics for automotive and industrial power transmission belts. The company offers an extensive and diversified product portfolio including conveyor belts, waterproof materials for civil engineering, architectural waterproofing materials, engineering plastic materials and processing, and SF foam injection molding. These products span a wide spectrum of industries and sectors including housing complexes, transportation, automobiles, and construction as heat resistors.

-

-

-

-

-

Dayal Marketing Services

Timing Pulley

Company Overview

Dayal Marketing Services, established in 1996, is an Indian manufacturer and supplier based in Titwala, Maharashtra, producing commercial and industrial belts. The company’s product portfolio includes conveyor belts made from various materials, including carbon steel, polyvinyl chloride (PVC), and polyurethane (PU). The company also provides other types of belts, such as circular knitting belts as well as leather nylon and rubber nylon sandwich belts. It further offers various spindle tapes, such as synthetic and textile tapes, along with timing pulleys.

-

-

-

-

-

Nishi Enterprise.

Timing Pulley

Company Overview

Nishi Enterprise, established in 1978 and based in Ahmedabad, Gujarat, India, is a manufacturer and supplier of high-end mechanical power transmission products. The company's product range includes conveyors, head pulleys, tail pulleys, idler rollers, ball mill parts, and simplex duplex sprockets. These products facilitate the efficiency of power transmission systems. They serve industries such as power plants, steel plants, sinter plants, fertilizers, and cement plants. It also provides services like versatile manufacturing techniques, delivering customized solutions, using quality raw materials, and ensuring prompt deliveries.

-

-

-

-

-

Bestomech

TIMING PULLEY

Company Overview

Bestomech Industries, an Indian company established in 1991 and based in Mylampatti, Coimbatore, India, is a manufacturer and supplier specializing in pulleys, sprockets, and traction sheaves. The company’s product range comprises various pulleys, couplings, and transmissions. The company also provides parts for compressors and elevator tractions, along with precision-machined components. It further offers custom precision-machined products made from aluminum, iron, and steel as well as design solutions to enhance product performance and quality.

-

-

-

-

Timing Pulley Manufacturer Ranking

*Including some distributors, etc.Ranking as of July 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Torque Transmission |

18.4%

|

| 2 | Grob, Inc. |

14.3%

|

| 3 | York Industries, Inc. |

12.2%

|

| 4 | Pearl Engineers |

10.2%

|

| 5 | Advance Precision Technology. |

10.2%

|

| 6 | B.V. Transmission Industries |

10.2%

|

| 7 | Bestomech |

8.2%

|

| 8 | Associated Bearing Corporation. |

6.1%

|

| 9 | Mitsuboshi Belting Ltd. |

6.1%

|

| 10 | Dayal Marketing Services |

2.0%

|

Derivation Method

The ranking is calculated based on the click share within the timing pulley page as of July 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- Mitsuboshi Belting Ltd.: 4,201

Newly Established Company

- Advance Precision Technology.: 2013 (11 years ago)

- Dayal Marketing Services: 1996 (28 years ago)

- Associated Bearing Corporation.: 1991 (33 years ago)

Company with a History

- Torque Transmission: 1947 (77 years ago)

- B.V. Transmission Industries: 1963 (61 years ago)

- Nishi Enterprise.: 1978 (46 years ago)

Timing Pulley Manufacturers in United States

*Including some distributors, etc.

Global Distribution of Timing Pulley Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

India

India

|

6 | 66.7% |

United States of America

United States of America

|

3 | 33.3% |