All Categories

History

This section provides an overview for bevel gears as well as their applications and principles. Also, please take a look at the list of 33 bevel gear manufacturers and their company rankings. Here are the top-ranked bevel gear companies as of March, 2026: 1.NEWSTART MOTION INDUSTRIES LTD., 2.Dayton Gear & Tool, 3.The Adams Company.

Table of Contents

Categories Related to Bevel Gears

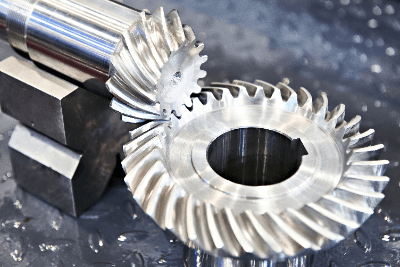

Bevel Gears are gears with teeth carved on a conical surface, and each axis is angled rather than parallel. They are used to transmit power by changing the direction of the axis of rotation.

Bevel Gears are gears with teeth carved on a conical surface, and each axis is angled rather than parallel. They are used to transmit power by changing the direction of the axis of rotation.

Bevel Gears are named as such because they look like umbrellas. They are classified into straight bevel gears, spiral bevel gears, helical bevel gears, zerol bevel gears and hypoid gears according to the tooth shape.

Materials used for bevel gears include carbon steel for machine structural purposes, alloy steel for machine structural purposes, rolled steel for general structural purposes, cast iron, stainless steel, nonferrous metals, MC nylon and duracon.

Bevel gears are used to transmit power by changing the direction of a rotating shaft. In bevel gears using straight, spiral, and helical gears, the axes of rotation of the two gears intersect. The angle of intersection is generally 90°, but may be acute or obtuse. Gears whose axes do not intersect are called hypoid gears.

Familiar examples are hand-turned coffee mills, hand-turned mixers, and hand drills. They are also used in differential gears in the automotive field, as well as in machine tools and printing machinery. They are especially useful in differential equipment.

Hypoid gears differ from spiral bevel gears in that multiple teeth engage simultaneously and there is tooth slippage. This allows them to withstand large torques and to produce little noise. Hypoid gears are often used to drive automobiles and trains.

Bevel gears are gears with pitch conical surfaces that contact each other without sliding. Gears are determined by module, number of teeth, reduction ratio, material, surface treatment, shaft hole shape, shaft hole diameter, and precision.

Straight bevel gears have a straight tooth trace and are relatively easy to manufacture. Reduction ratios of up to about 1:5 are possible. If no specific gear is specified, they are generally used as bevel gears for transmitting power.

Spiral bevel gears are characterized by the curved tooth trace. They have the advantages of high strength, quiet rotation, and high efficiency due to the large area per tooth. Zerol bevel gears are spiral bevel gears with a cross-torsion of approximately zero on the shaft, and have the characteristics of both immediate and spiral bevel gears.

Gears can accurately transmit power and motion, but in principle, they generate noise. To reduce noise, it is necessary to take measures such as proper backlash, increasing the gear meshing ratio, downsizing the tooth profile, using plastic gears, and proper lubrication.

To improve tooth contact, an appropriate bulge may be added in the direction of the tooth flanks. This is called crowning.

When selecting bevel gears, special consideration should be given to tooth strength and allowable tooth surface load. The bending strength of a tooth is the allowable circumferential force of the tooth calculated from the strength of the tooth base during mesh transmission. It increases with increasing tooth module size.

The allowable tooth surface load is the circumferential force specified to prevent progressive pitting. The smaller of the two circumferential forces is multiplied by the pitch circle radius of the gear to obtain the allowable torque of the gear. This value should be selected so that it is greater than the design torque actually used. The characteristics of each gear are described in the manufacturer's technical data.

Some manufacturers also provide a list of gears that meet their requirements by entering the conditions of use on their website. This is useful when narrowing down specifications from broad conditions.

When designing bevel gears, it is important to tentatively determine the reduction ratio and shaft angle and check the gear specifications because, unlike spur gears, there are limitations on the combination of the number of teeth on the meshing gears and the dimensions such as the bevel angle are different.

After tentatively determining the shape and mounting posture, strength calculations are performed. If the conditions are not satisfied, the module is enlarged and the dimensional calculations are redone again. Gear strength and other meshing calculations can be approximated with spur gears.

When the load is large, when repeated loads are applied, or when the gear is operated continuously for a long period of time, a large safety factor can be used to provide a margin against impact loads and fatigue.

For material selection, carbon steel is generally used and its surface hardness is increased by quenching, but for some applications, alloy steel or other materials are used and their hardness is increased by quenching. Generally, only the tooth flanks are quenched by high-frequency induction hardening, while other parts are tempered.

In addition to calculating dimensions and strength, lubrication must also be considered in gear design. Lubrication and lubrication systems are determined and designed for easy maintenance.

*Including some distributors, etc.

Sort by Features

Sort by Area

Arrow Gear Co., founded in 1947 and headquartered in Downers Grove, Illinois, is a manufacturer of high-precision gears catering to aerospace and commercial industries. Its specialization lies in spiral bevel gears, and it also offers a comprehensive range of gearing solutions, including bevel gears, spur gears, helical gears, curvic couplings, and complete gearboxes. These products find applications across various machinery and equipment, facilitating power and motion transfer. The company holds several certifications in quality standards such as ISO 9001:2015, AS9100 REV D, and Nadcap for Heat Treating and Non-Destructive Testing.

Gear Motions is a custom gear manufacturer for global OEMs. Founded in 1960 and headquartered in Syracuse, New York, with additional locations in Buffalo and Oliver Springs, Gear Motions has grown significantly since its founding. Initially a ten-man company serving primarily in the New England Area, they have since expanded through acquisitions of companies such as Nixon Gear, Gear Supply and Broaching, and Pro-Gear Co Inc. The company provides custom gear solutions for various custom and precision applications, offering products such as ground helical gears, spur gears, pump gears, timing pulleys, shafts and splines.

The Adams Company was established in 1883 and is located in Dubuque, Iowa, United States is a manufacturer of custom gears, shafts, and power transmission parts for various industrial and commercial applications. The company produces straight bevel, helical, spur & worm gears along with power transmission parts including sprockets, couplings, clutches & shafts that have applications in agriculture&construction machinery manufacturing industry, oil recovery equipment, winches, and industrial pumps. They also offer services including CNC blanking, hobbing, shaping, vertical machining, and gear shaving that are needed in the thread grinding, broaching, milling, tapping, and deburring systems.

Dayton Gear, founded in 1946 and headquartered in Dayton, Ohio, is a manufacturer specializing in gears, pinions, and related products. Their diverse product range includes spur gears, helical gears, bevel gears, worm gears, racks, as well as pinions, gear housings, gear couplings, and gear reducers. Dayton Gear produces custom-designs gears to meet specific customer requirements, and cater to various industries, including automotive, aerospace, industrial, and agricultural. Their state-of-the-art manufacturing facility equipped with modern CNC machines allows them to offer additional services like gear repair, rebuilding, and inspection.

Butler Gear Enterprises (BGE) is a Wisconsin-based gear manufacturer and service company established in 1960. They manufacture custom gear and transmission products from various materials, including metals and non-metals, to plastic and carbon steel. Butler’s extensive gear catalogue includes spur, helical, to worm gear sets featuring British Standard metric, straight and stub gear tooth forms. Their market includes small-scale shops to large oil, auto, military, drilling, aerospace, government and food service companies. As a service provider, Butler Gear offers gear drawings, coatings & plating and engineering services.

Cleveland Gear Company, Inc. was founded in 1912 and is headquartered in Cleveland, Ohio. The company is a manufacturer of gears, speed reducers, and other parts for industries such as manufacturing, mining, and packaging. The company has four product and service categories: Enclosed Drives, Open Gearing, Custom Drives, and Field Service & Rebuilds. Enclosed Drives include modular gear products, larger enclosed drive products, and helical enclosed drive products. Open Gearing includes Master Worm Systems and services such as case hardening. Custom drives are produced according to industry need such as rubber production and mineral processing.

Formerly known as the Globe Gear Company and founded in 1919, Rush Gear Inc. is a manufacturer of custom gears for industrial and commercial applications. Rush Gear's facility is equipped with gear manufacturing technology, including CNC gear cutting machines, gear hobbing machines, and gear shaping machines. The company produces gears in a range of sizes, from small precision gears to large industrial gears that serve thousands of applications across industries such as agriculture, machine shops, manufacturing, robotics, and many more.

PSM Industries is a family business founded in 1956 and is based in Los Angeles, California. PSM provides solutions in parts fabrication through powder metal technology. Through this, PSM serves industries including medical, sporting goods, food service, and aerospace. PSM Industries consists of 4 categories of divisions throughout the United States. High-Performance PM includes Pacific Sintered Metals, PM Engineered Solutions, and BestMetal. High Wear Carbides Includes PM Krupp High-Speed Steels and Yilik Precision Carbides. The other two categories are metal injection molding featuring PolyAlloys and engineered plastics featuring W.M. Guliksen.

American Precision Gear Co., Inc. is a manufacturer of gears since 1956 and is based in California. The company not only manufactures precision gears but crafts many custom gears as well which include spur, ring, miniature, and helical. Splines and worms for industrial machining applications are also designed including custom machined gear racks for various linear motion applications. The company serves numerous industries that require the use of precision and custom gears for various applications, some of them being Biomedical, Aerospace, Oil & Gas, Medical devices, Technology, and lots more.

Circle Gear & Machine Co., Inc., established in 1951 and based in Illinois, USA, is a manufacturer of gears and gearboxes. The company manufactures a range of gears including bevel, helical and worm gear for automotive, construction, chemical and other industries. It provides reverse engineering for gear and gear boxes, from worn samples, prints or sketches, along with rebuild, repair and emergency services. The company has a quality management system in compliance with ISO 9001:2015, and has a complete inspection lab with CMM(Coordinate Measuring Machine).

SDP/SI was founded in 1950 and is situated in New Hyde Park, New York. SDPP/SI is a manufacturer of precision gears and high-quality mechanical components used in the aerospace, industrial manufacturing, medical technology, and robotics fields. The company manufactures parts in a variety of materials including alloy steel, stainless steel, bronze, brass, nylon, and titanium. The company also provides coating services such as heat treating, zinc plating, and painting. Additional custom options are available including manufacturing to customer drawings and specifications.

Commercial Gear & Sprocket Company Inc. is located 20 miles southeast of Boston in East Walpole, Massachusetts, and is a manufacturer of machine tool builders, construction equipment, mining, power hand tools, medical equipment, defense suppliers, mass transit, rail cars & track equipment, and many more. The portfolio of the company consists of machining gears, splines, sprockets, and other related products for over 70 years. The products also include Bevel and Mitre Gears, Helical Gears, Rack and Pinion, Ratchets and Jaw Clutches, Splines, and more.

Newstart Motion Industries Ltd. is a manufacturer of gearboxes and gearbox components established in 2006 and based in Sheridan, Wyoming, USA. The company’s products include planetary gearboxes for precision applications such as in the medical or aerospace industries, and planetary servo gearheads for automation engineering or mechanical engineering. It also offers strain wave reducers for CNC automation, and spiral bevel gearboxes for angular power transmission. The company mainly serves clients in industrial manufacturing, processing, and packaging operations.

INOCON GmbH, established in 1997 and based in Rheinbach, Germany, is a manufacturer of assembly components such as tube clamps and linear units. The company produces products such as compact clamps, clamp mountings, single-tube linear units, positioning accessories, and custom-made products. Different industries, including food technology, medical laboratories, universities, private research institutes, and in-house quality control laboratories, use all its products. The company has added precision double-tube linear units to its portfolio and has automated inventory management using multiple vertical lifts.

Cross+Morse, founded in 1984 and headquartered in Birmingham, England, is a manufacturer of power transmission products and solutions. The company's product portfolio includes various belt drives and roller chain drives, shaft couplings, clutches, gears and torque limiters. It offers custom made bespoke components as well as rework services like reboring, keywaying and setscrewing of standard sprockets, pulleys and gears to turn it around to a required specification. The company is ISO 9001:2015 accredited and has a range measuring equipment like Coordinate Measuring Machine (CMM), digital tri-bore gauges and micrometres which are calibrated to comply with ISO standards.

Bea Ingranaggi SPA, established in 1960 and headquartered in Cavaria Con Premezzo, Italy, is a manufacturer of standard and special products. The company offers a wide range of products, including chain transmission, worm gears, belt drive, and chain drive. It also offers couplings, clamp elements, pulleys, gears, and electric motors. Its worm gear can transmit power at a right angle, making it useful in tight spaces. The company serves a range of industries, including automotive, mechanical engineering, and agriculture.

ESA Eppinger GmbH (Eppinger Group), founded in 1925 and headquartered in Denkendorf, Germany, is a developer and manufacturer of tool holders for CNC turning, milling centers, and precision gears. The company's portfolio includes fixed and driven tool holders and complete tooling systems, spiral, hypoid, and Zerol bevel gears, rotary tables for machine tools, and special gears. These products are used in machine and plant engineering, robotics, and CNC technology. The company offers individual machine customization and end-to-end solutions from a single source.

Hangzhou Chinabase Machinery Co., Ltd., founded in 1992 and based in Hangzhou, China, is a manufacturer specializing in an array of products, including power transmission components. Its key products encompass chains and sprockets for industrial power transmission, gearboxes to enhance torque and reduce speed, couplings for shaft connections, and gears used across industrial applications. Its products find applications in automation, conveyor technology, packaging, food, pharmaceuticals, and more. The company maintains quality and sustainability, holding certifications like ISO 9002, ISO 9001, API, ISO/TS 16949:2002, and ISO 10012 measurement management system.

ATEK Drive Solutions GmbH, founded in 2024 and based in Rellingen, Germany, is an ISO 90001-certified manufacturer of drive train solutions and is a part of the Obermark Group. Its product portfolio includes engines, brakes, and gearboxes, and it has a stock of almost 500,000 individual parts. Its products can be used in several industries, including agriculture, energy, and shipbuilding. The company’s WFG spring-actuated shaft brakes have a breaking force of 2,600 N - 33,000 N and are mounted directly on the shaft. Its HDVLM hygienic bevel gearbox has all its external components designed in stainless steel to prevent corrosion.

Hangzhou Ocean Industry Co., Ltd. is a manufacturer and a supplier of transmission spare parts, headquartered in Century City District, Hangzhou, China. The company offers a full range of products, including chains, sprockets, couplings, timing pulleys, and V-belt pulleys. Additionally, it provides shafts, gears, gear racks, and various other transmission spare parts. All of its production procedures adhere to ISO9002 standards. Moreover, it possess the capability to design and manufacture non-standard products to fulfill specific customer requirements.

TANDLER is a designer and manufacturer of high-precision gears and special gearboxes founded in 1949 and based in Bremen, Germany. Its product list consists of bevel gears, spur and helical gears, racing gears, and splined shafts. It also offers high-accuracy torque transmission with minimal backlash gearboxes such as bevel gearbox, speed modulation gearbox, and servo gearbox. With a 100% in-house production process, the company designs and produces custom-made gearboxes with different housing and connection dimensions. It is ISO 9001:2015 certified and caters to various markets, including industrial machinery, automation, and robotics.

Aichi Forge USA, Inc. founded in Georgetown, Kentucky, in 1919 is a manufacturer of die forging products. The company's product portfolio includes Custom Die Forgings, Automotive Components, aerospace components, including landing gear parts, engine mounts, and structural components, and generator components. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. The company provides services such as Product Selection Guidance, Engineering Support, and Custom Manufacturing.

Mädler GmbH, established in 1882 and headquartered in Baden-Württemberg, Germany, is a manufacturer of industrial machinery that specializes in drive-train components. The company offers a wide range of products, including clutches and safety couplings, ball bearings, bevel gears, and hinges. It also offers a wide range of services related to power transmission elements and standard parts. Its coupling has reduced wear of the elastomer components, which increases the lifespan of the coupling. The company's quality management is certified according to DIN 9001:2015. Its products are used in various industries such as automation, robotics, automotive, medical, and FnB.

Perry Technology Corporation was founded in 1938 and is based in New Hartford, Connecticut, USA, as a manufacturer of aviation and aerospace components. The product list of the company includes bevel gears, helicals, racks, sectors, and splines. The products are integral to critical aircraft systems like flap actuators, fuel controls, landing gear, pilot controls, and air turbines and are also employed in various applications within the US military defense systems. The company serves various industries, such as commercial aviation, military, defense, engineering, and inspection services.

Precipart was founded in 1950 and is based in Farmingdale, New York, as a manufacturer of precision mechanical components and motion control systems for various industries. The company produces precision gears, custom gearboxes, micro springs & metal stampings, and electromechanical assemblies that have applications in the aerospace, automotive, electronics, defense, and photonics industries. They also offer hearing aid components, medical devices, and technical ceramic injection molding, along with services including micro 3D printing & micro laser sintering that are required in the medical sector, hydraulic components manufacturing, and sensor & instrumentation markets.

Atlas Pressed Metals, established in 1976 and headquartered in DuBois, Pennsylvania, is a manufacturer of precision powdered metal parts. They specialize in producing complex and simple structural components using materials like iron, sinter-hardened steel, stainless steel, copper, brass, and bronze. Serving diverse industries such as automotive, industrial, medical, energy, and more, their product range includes bushings, bearings, gears, structural components, wear plates, and other custom parts. These components find applications in load-bearing, wear resistance, and corrosion resistance scenarios. relaible

American Gear, Inc., since 1990, has been a manufacturer of fine and medium pitch gears and accessories such as worms, timing pulleys, involute splines, segments, and ratchets. The gear types are spur, helical, straight bevel, and miniature gears serving the aviation, commercial, film, office, and hobbyist industries. The company Prophetstown, IL, offers machining services such as CNC milling & turning, screw machining, heat hobbing & shaping, heat resting, and finishing services. The company produces products with ISO 9000 standards and is an American Gear Manufacturers Association member.

Roller Industrial S.A., established in 1948 and located in Bilbao, Spain, is a manufacturer and distributor of various types of industrial products and custom-made solutions. The company produces carriages with ball recirculation systems, bearings, bearing units and balls, roller chains, and sprockets. It also offers ball screws, split-bearing assemblies, and linear movement and industrial automation systems. It has over 4,000 references to cater to its customers’ every need. It engages in international trade in more or less 40 countries.

CDM Electronics Inc. is a manufacturer of cable assembly products and a distributor of interconnect products that was established in 1993 in Turnersville, New Jersey, USA. The company’s products include various cable assembly products including for A/V setups, ruggedized Ethernet connections, and telecom networks. It also stocks internet products such as relays and sockets from brands such as Corsair Electrical Connectors, Amphenol Nexus Technologies, and Sumitomo Electric Interconnect Products. The company chiefly serves clients in the communications, networking, and commercial sectors.

Itafran, located in Rhone, France, is a supplier of a broad collection of mechanical transmission components. The company procures motor brackets, cylindrical bushings, deep groove ball bearings, cylindrical bearing rollers, and track rollers. It also sources classic toothed belts, imperial profiles, heavy-duty conveyor chains, and clamping rings. A motor bracket is specifically used to support the motor and dampen the shocks due to the vibrations induced by the operation of the engine. It manages a close relationship with 1,600 customers, mainly located in France and neighboring countries.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | NEWSTART MOTION INDUSTRIES LTD. |

13.3%

|

| 2 | Dayton Gear & Tool |

6.1%

|

| 3 | The Adams Company |

5.5%

|

| 4 | Arrow Gear Co. |

4.4%

|

| 5 | Cleveland Gear Company |

4.4%

|

| 6 | PSM Industries, Inc. |

4.0%

|

| 7 | Gear Motions, Inc. |

3.6%

|

| 8 | Stock Drive Products/Sterling Instrument - SDP/SI |

3.6%

|

| 9 | INOCON GmbH |

3.4%

|

| 10 | Commercial Gear & Sprocket Company, Inc. |

3.4%

|

Derivation Method

The ranking is calculated based on the click share within the bevel gear page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

12 | 46.2% |

Germany

Germany

|

4 | 15.4% |

China

China

|

3 | 11.5% |

Italy

Italy

|

3 | 11.5% |

United Kingdom

United Kingdom

|

1 | 3.8% |

Japan

Japan

|

1 | 3.8% |

Spain

Spain

|

1 | 3.8% |

France

France

|

1 | 3.8% |

71 products found

71 products

Apex Dynamics Japan Co., Ltd.

180+ people viewing

Last viewed: 10 hours ago

8 models listed

Kouki Kasei Co., Ltd.

470+ people viewing

Last viewed: 1 hour ago

■Features ・Precision injection compression molding makes it possible to increase the thickness of the web and maintain gear accuracy at the same t...

Kaneko Gear Industry Co., Ltd.

460+ people viewing

Last viewed: 21 hours ago

■Achieved short delivery times and low costs by using the gear cutting method that uses existing blades and jigs. We use the Gleason single-side me...

Kaneko Gear Industry Co., Ltd.

540+ people viewing

■Achieved short delivery times and low costs by using the gear cutting method that uses existing blades and jigs. We use the Gleason single-side me...

Saito Koki Co., Ltd.

630+ people viewing

Last viewed: 1 hour ago

A pair of gears used to transmit power between two axes that neither intersect nor are parallel. Basically, they intersect at an axis angle of 90°....

Saito Koki Co., Ltd.

560+ people viewing

Last viewed: 1 hour ago

A pair of conical gears used to transmit power from two intersecting axes. The shapes of tooth streaks include straight, curved, and hashedral. Our...

Kaneko Gear Industry Co., Ltd.

530+ people viewing

Last viewed: 12 minutes ago

■Achieved short delivery times and low costs by using the gear cutting method that uses existing blades and jigs. We use the Gleason single-side me...

Goto Gear Co., Ltd.

470+ people viewing

Last viewed: 17 hours ago

Spiral gears are useful gears that transmit power between two intersecting axes. Standard spiral gears are manufactured based on orthogonal interse...

Kikui Gear Co., Ltd.

270+ people viewing

Last viewed: 10 hours ago

NIPPON GEAR CO., LTD.

420+ people viewing

■Summary A highly efficient manual jack with self-locking function. ■Features ・Basic capacity: 10kN to 300kN ・Constructed with an efficient beve...

NIPPON GEAR CO., LTD.

480+ people viewing

Last viewed: 3 hours ago

■Summary This is a new generation jack that enables high efficiency, high speed, and high frequency operation by combining a bevel gear and a high ...