27 Shielded Cable Manufacturers in 2024

This section provides an overview for shielded cables as well as their applications and principles. Also, please take a look at the list of 27 shielded cable manufacturers and their company rankings. Here are the top-ranked shielded cable companies as of April, 2024: 1.Victor Wire & Cable, 2.Micro-Tek Corp., 3.EIS Wire & Cable.

Table of Contents

What Is a Shielded Cable?

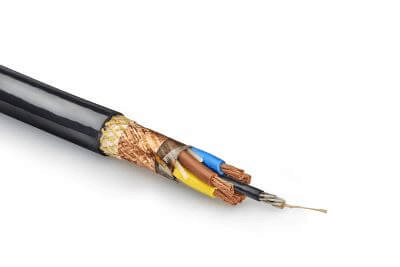

A shielded cable is a cable in which the metal conductor portion that transmits signals and power is covered with a grounded metal layer.

A shielded cable is a cable in which the metal conductor portion that transmits signals and power is covered with a grounded metal layer.

The grounding metal layer is made of a thin film or other material that is braided into a structure. Covering the conductor section with a metallic layer blocks electromagnetic waves from the outside and, at the same time, prevents leakage of electromagnetic waves to the outside.

This structure contributes to high-speed communication in the communication and instrumentation fields and is important for ensuring safety in the high-power field. Multi-core cables also play a role in canceling out inter-wire noise.

Uses of Shielded Cables

Shielded cables are widely used in LAN cables for OA equipment and loudspeakers for audio equipment.

The purpose of these applications is to protect equipment from electromagnetic waves emitted from outside. In contrast, shielded cables are also used in high-voltage power distribution applications. The purpose of these applications is to prevent the generation of electromagnetic waves.

Principle of Shielded Cables

The main components of a shielded cable are the conductor, the shielding layer (shield), the insulation layer, and the sheath.

In ordinary metal cables, the outer conductor is covered by an insulating layer. Shielded cable, on the other hand, is covered with a shielding layer, such as a thin metal film, on top of the insulation layer covering the conductor.

The outside of the shielding layer is covered with an insulating film called a sheath to protect the wire from the outside environment. By grounding the shielding layer, signal cables can be protected from noise. Shielded cable can also be used for power cables to cancel out the electromagnetic waves generated.

Canceling electromagnetic waves from power cables is often used from a safety perspective because it leads to the prevention of electric shock accidents due to induction.

Types of Shielded Cable

Shielded cables include "electrostatic shielded cables," which prevent external noise, and "electromagnetic shielded cables," which prevent magnetic flux caused by electric current from affecting external equipment. Since the method of grounding the shielding layer differs depending on the type, it is important to ground the cable using a method appropriate for the type.

1. Electrostatic Shielded Cable

Electrostatic shielded cable is a cable with a core wire covered with metallic tape, such as copper or aluminum, or mesh braided wire.

This absorbs external noise and conducts it to ground, preventing noise from entering the core wire. It is mainly used for signal and communication cables. The basic grounding method for electrostatically seeded cables is single end grounding. This is to prevent the return current from flowing into the shield.

If both ends are connected to ground, there is a greater possibility of current flowing through the shield, and there is a risk of noise being generated from the shield due to current flow. Also, if the shield is not connected to ground, not only will the shield not be effective, but the electrical charge accumulated in the shield will be released in some way, causing noise in the signal, so care must be taken. When shielded cable is used, it must be grounded.

2. Electromagnetic Shielded Cable

Electromagnetic shielded cable is a cable with a core wire covered with iron and copper to prevent magnetic flux caused by electric current from escaping.

The disadvantage of this cable is that it is vulnerable to bending and folding due to the iron covering. It is mainly used for power cables, motors, and other cables in which large currents flow. When grounding an electromagnetically shielded cable, choose between grounding at both ends or at one end, depending on the distance. For long-distance power transmission, grounding should be done at both ends, and for short distances, grounding should be done at one end. In both cases, the grounding wiring should have as low electrical resistance as possible to increase the shielding effect.

Generally, copper plates or copper piles are embedded several meters underground to reduce grounding resistance. This underground buried conductor is the grounding pole. Wires rising to the ground surface from the grounding pole are connected to a copper bar called a ground bar or bus bar.

List of 27 Shielded Cable Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- China

- Germany

- Japan

-

-

-

Switchcraft, Inc.

AUDIO CABLES

Manufacturer Overview

Switchcraft, Inc., established in 1946 with headquarters in the USA, is a manufacturer of jacks, plugs, and switches, mainly for the communications industry. After acquiring Conxall in 1999, the company's product line has grown to include connectors, jacks, plugs, molded cable assemblies, and switches used in the medical, process control, transportation, homeland security, and broadcast markets. Switchcraft, Inc. also offers a custom product service that includes consultation, design, and manufacturing in high volumes to meet client-specific requirements.

-

-

-

-

-

MURRELEKTRONIK INC.

Bulk cable

Manufacturer Overview

Murrelektronik, established in 1975 and headquartered in Oppenweiler, Germany, is a manufacturer of electrical and electronic installation concepts for machine and system installations. The company's product range includes power supplies, M12 cable, fieldbus I/O, and more. It also offers a wide variety of jacket colors and cable types, including M8 and M12 sensor cables and Mini (7/8”) power cables. Its products simplify industrial image processing with its installation concept. The company is among the TOP 100 for Cube67 Diagnostic Gateway for Cube67 Diagnostic Gateway Students. It serves a wide range of industries, including automotive, food and beverage, and robotics.

-

-

-

-

-

TEAM SOLUTIONS, INC.

Standard round 2m cables, shielded, for higher current

Manufacturer Overview

Team Solutions, Inc., established in 1989 and headquartered in Laguna Niguel, California, USA, is a manufacturer of control systems, automation systems and various measurement instruments. The company specializes in automated, PC-based test and measurement instruments, data acquisition (DAQ) systems, and process control equipment, and it is ISO 9001 certified for consistent and accurate instrumentation, data acquisition, and process control applications. Advanced control capabilities, accuracy, and easy connection with computer systems are among the features of the products. These devices are used in a variety of industries, including electronics, research and development, production, and automation.

-

-

-

-

-

Consolidated Electronic Wire & Cable

Shielded Cables

Manufacturer Overview

Consolidated Electronic Wire & Cable, established in 1919, is headquartered in Franklin Park, Illinois, and is a manufacturer and supplier of wire and cable solutions. They offer a full line of standard and custom electronic wire, cable, power supply cords, molded cable assemblies, and wiring harnesses. Consolidated Electronic Wire & Cable has a wide range of certifications including ISO 9001:2015, RoHS, CE Mark, and NEC certification, serving industries such as telecommunications, aerospace, automotive, and lighting industry.

-

-

-

-

-

Victor Wire & Cable

Shielded Cables

Manufacturer Overview

Victor Wire & Cable (VWC) is an American manufacturer of custom cable and wire products that was established in Los Angeles, California in 1984. The company manufactures wire and cable products to various standards and certifications, such as Underwriters Laboratories (UL) approved or MIL SPEC compliant types. It primarily produces composite cables, hook-up wires, and coaxial cables with various material combinations (e.g. jackets, fillers, conductors) to optimize for high temperature, low noise, or hybrid applications. VWC mainly serves clients in the telecommunications, medical, aerospace, and industrial processing sectors.

-

-

-

-

-

Excel Connection

Shielded Cables

Manufacturer Overview

Excel Connection was founded in 1986 and is headquartered in Milwaukee, Wisconsin. The company is a manufacturer of standard and custom lead wires, wire harnesses, cable assemblies, and electro-mechanical panels for mining, agriculture, automotive, and mechanical drives industries. The company’s lineup of cables includes ribbon cables, braided cables, fiber optic cables, terminal block assemblies, and heavy gauge cables meeting pull test up to 1,000 pounds. The company offers services including vendor-managed inventory, kitting services, engineering support, and prototyping services.

-

-

-

-

-

Dielectric Sciences, Inc.

Shielded Cables

Manufacturer Overview

Dielectric Sciences, Inc., established in Chelmsford, Massachusetts in 1970 is a manufacturer of high voltage cable assemblies, connectors, and insulation systems. The company's product portfolio includes Custom-designed cable assemblies capable of handling high voltage requirements for power transmission and distribution, Precision-engineered connectors for secure and efficient electrical connections in high voltage systems, and insulation materials and systems. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation.

-

-

-

-

-

EIS Wire & Cable

Shielded Cables

Manufacturer Overview

EIS Wire & Cable, established in South Hadley, Massachusetts, in 1910 is a manufacturer of Custom Cables & Bulk Wire Products. The company's product range includes Single Conductor Hook-up Wires, power cables, data cables, Complex Multi Conductors and Composite Cables. Their products are used in industries such as Electronics and Telecommunications, Automotive, Transportation and aerospace and Defense. The company also provides services including full Hi-pot and Continuity testing on every cable, Custom built for exact specifications, Custom or Bulk packaging, technical support and customer service.

-

-

-

-

-

Brim Electronics, Inc.

Shielded Cables

Manufacturer Overview

Brim Electronics was established in 1975 and is based in Lodi, New Jersey, serving as a manufacturer and marketer of electronic equipment. The company manufactures and markets electronic and electrical wires, fastening devices, electronic fasteners, and ceramic insulators. Additionally, they perform secondary manufacturing activities such as harness/cable assemblies, cable dying, striping, cutting, and hot tin dipping. Their wire and cable products include UL/CUL and CSA certified flexible, ultra-flexible, commercial, and MIL spec wires and cables.

-

-

-

-

-

Multi/Cable Corp.

Shielded Cables

Manufacturer Overview

Multi/Cable Corp., established in Bristol, CT in 1975, is a manufacturer of custom made multi-conductor and multi-pair electrical wire and cable. The company's product range includes Instrumentation Cable & Control Cable, PLTC Instrumentation Cable, Tray Cable, Utility Control Cable and High Temperature Wire & Cable. Their products are used in industries such as Electronics and Telecommunications, Automotive, Transportation and aerospace and Defense. The company provides Quality Assurance, Technical Support, national distribution, customized services and customer support.

-

-

-

-

-

Swift Bridge Technologies

Shielded Cables

Manufacturer Overview

Swift Bridge Technologies, established in 2012 and situated in Tigard, Oregon, is a manufacturer and supplier of custom cable solutions. The company specializes in cable solutions for high density board-to-board interconnects, logic analysis, real time oscilloscopes, digital storage oscilloscopes and 65 GHzsignal transmission. Its product range encompasses high-speed data cables, power cables, fiber optic cables, coaxial cables, and custom cable assemblies. Indicating adherence to quality standards, the company possesses ISO 9001 certifications in both Malaysia and Portland, alongside an IATF certificate.

-

-

-

-

-

Daburn Electronics & Cable

Shielded Cables

Manufacturer Overview

Daburn Electronics & Cable was founded in 1964 and is based in Dover, New Jersey. The company is a supplier of over 500 products including wire, cable, sleeving, vacuum systems, and related products produced in ISO 9001:2008 and AS9100-certified facilities. The company operates through two divisions: Wire & Cable Division and Electronic Hardware Division. The Wire & Cable Division offs military and commercial specification products including wire, cable, tubing, and over 20,000 standard items, mostly available for special construction to order. The Electronic Hardware Division produces in-house porcelain insulators, plugs, fastening devices, cords, and other devices and components.

-

-

-

-

-

Casco Manufacturing

Shielded Cables

Manufacturer Overview

Casco Manufacturing is an American ISO 9001 certified contract manufacturer specializing in cable assemblies that was established in 1996. Based in Bolingbrook, Illinois, the company produces various custom cable assemblies including coaxial and fiber optic models, which are commonly used in the electronics, telecommunications, transportation, and construction markets. They also offer power cables, grounding equipment, and box builds for cable organization. Casco offers additional engineering, labeling, and kitting/packaging services to aid in medium- to large-scale customer projects.

-

-

-

-

-

American Wire Group

Shielded Cables

Manufacturer Overview

America Wire Group (AWG) is a manufacturer and supplier of wires, cables, and related accessories in the utility and renewable energy market. AWG provides high-quality products for various applications, including wind, solar, and electric vehicle infrastructure. Headquartered in Miami, Florida, AWG has been expanding rapidly and has three other regional distribution centres in California, Pennsylvania, and Texas. In addition to distribution and storage services, offer customer support services like cable management. With a focus on innovation and quality, AWG remains a trusted partner for businesses looking for reliable wire solutions.

-

-

-

-

-

L. A. Woolley Electric, Inc.

Shielded Cables

Company Overview

L.A. Woolley Electric, Inc. (L.A. Woolley) was founded in Buffalo, New York in 1916 as a supply distributor to serve the industrial and commercial marketplace. The company offers products from such manufacturers as Acme, Mersen, Pass & Seymor, and Wago. The company specializes in control and panel board products, transformers, terminal blocks, wiring accessories, as well as hazardous location products. The company's in-house sales team also support customers in selecting, ordering, and receiving the correct order.

-

-

-

-

-

ETH-messtechnik

Measuring Cable

Manufacturer Overview

ETH Messtechnik, established in 1987 in Gschwend, Germany, is a manufacturer of static or rotating transducers and individual sensors for measurement solutions. The company specializes in providing adaptive measurement technology solutions for various industries. The company's product range includes data loggers, temperature sensors, and pressure transducers. These solutions find diverse applications in industries such as automotive, aerospace, and research, offering accurate and seamless data acquisition. The main advantages of these products include improved process optimization, enhanced product quality, and streamlined data analysis.

-

-

-

-

-

HIRAKAWA HEWTECH CORP.

BroadCast CABLES & Optical FiberCable

Manufacturer Overview

HIRAKAWA HEWTECH CORP., founded in 1948 and headquartered in Tokyo, Japan, is a manufacturer and supplier specializing in cables, electronic equipment, and medical equipment. The company's product portfolio includes high-speed cables, factory automation cables, optical converters, network equipment, and medical tubing. These products are utilized by various industries, including electronics, digital technology, information communication, broadcasting, and the medical sector. The company is ISO 14001 and ISO 9001 certified, with overseas subsidiaries in America, Mexico, Thailand, the Philippines, and Taiwan.

-

-

-

-

-

TATSUTA Electric Wire and Cable Co.,Ltd.

EMI shielding film

Manufacturer Overview

Tatsuta Electric Wire and Cable Co. Ltd., established in 1945 and headquartered in Higashiosaka, Japan, is a manufacturer of electric wires, electronic materials, medical products, and sensors. The company began manufacturing and selling telecommunication wires and cables in 1955. In 1981, it started manufacturing water leakage detection systems, and in 1984, it began selling bonding wire. Its telecommunications division received ISO 9001 certification in 1996, and the electric wire and cable division in 1998. The company began the production of EMI shielding film in 2003, and its product portfolio includes broadcasting cables, bonding wires, liquid leakage sensors, and functional paste.

-

-

-

-

-

Black Box

CAT6A cable

Manufacturer Overview

Black Box, established in 1976 and headquartered in Texas, USA, is a manufacturer and distributor of IT solutions, technology products, and consulting services. The company specializes in conference rooms, control rooms, and cybersecurity. Its technology products include KVM switching, networking solutions, and mobile device storage. Its voice and data services encompass wired/wireless infrastructures, data center design/build, and unified communications. The company’s infrastructure solutions feature cabinets, power management, and cable management solutions tailored for various industries like manufacturing, healthcare, and government.

-

-

-

-

-

LEMO S.A.

CABLE ASSEMBLIES

Manufacturer Overview

LEMO, founded in Écublens, Vaud in 1946 is a manufacturer of medical connectors, Plastic Connectors and Miniature Connectors. The company's product portfolio includes Low voltage connectors, High Pressure Connectors, High Voltage Connectors, Media converters and Harsh Environment Connectors. The company serves markets such as , medicine, robotics, communication, transport, power and energy. The company also provides services including national distribution, product selection, installation, preventative maintenance, troubleshooting, repair and customer service.

-

-

-

-

-

Micro-Tek Corp.

Shielded Cables

Manufacturer Overview

Micro-Tek Corp. (MTC) is a custom manufacturer of wires, cables, and assemblies originally founded in 1965 as the Miniature Insulated Wire Company before its incorporation in 1966. Based in Cinnaminson, New Jersey, the company produces wire and cable products in a wide range of materials that can be drawn, flattened, insulated, and cut to customer specifications. It also stocks wire varieties used for shielding or braiding. In addition to customization options, MTC provides additional stripping, inspection, and testing services to its clients in the military and medical sectors, as well as audio and computer manufacturers.

-

-

-

-

-

Canare Electric Co., Ltd.

Microphone cable

Company Overview

Canare Electric Co., Ltd., established in Nagoya, Japan, in 1974, is a manufacturer engaged in cable, assembly, connectors, passive and active equipment, and incidental instruments for the broadcast and communication industry. Their product range includes HFO Camera cables, fiber optic systems, cable assemblies, and transmission devices. The company entered the U.S. market in 1983 with an office in Los Angeles, California and has distributors in Canada, the United Kingdom, Germany and France.

-

-

-

-

-

CHANGZHOU EAGLE ELECTRONICS COMPANY

AV Cable/AC Cable/COAXIAL Cable

Company Overview

Changzhou Eagle Electronics Company, established in 2006 and headquartered in Jiangsu, China, is a manufacturer and supplier of electronic products. The company offers a range of products, including amplifiers, car players, LED screens, LED lamps, solar panels, and more. It also offers microphones, speakers, remote controls, cables, and LED TV light bars. Its LED lamps are resistant to shock, vibration, and temperature changes. The company has received CE and SGS certifications. It serves several industries such as automotive, electronics, and more.

-

-

-

-

-

Lapp Tannehill

Wire & Cable

Company Overview

Lapp Tannehill, established in 1955, and headquartered in Savage, Minnesota, is a supplier and distributor providing wire, cable, and connectivity solutions. Their product range includes cables, wires, connectors, and accessories for industries such as automotive, aerospace, oil and gas, and renewable energy. Lapp Tannehill's products are designed to deliver electrical connections, data transmission, and signal integrity, they ensure efficient power distribution, communication, and control in various industrial applications. Lapp Tannehill maintains standards and works with reputable manufacturers to provide solutions to their customers.

-

-

-

-

-

Sumitomo Electric Industries, Ltd

Spiral Shielded Wire

Company Overview

Sumitomo Electric Industries Ltd. is an ISO 45001-certified manufacturer of optical fiber and electrical wire cables that was established in Osaka, Japan, in 1897. The company produces optical fiber products for data communication or telecom applications, wire cable products for power transmission and automotive electronics, and flexible printed circuits for electronic device assembly. It also offers compound semiconductors for use in optical and wireless communication. The company’s products are commonly used by clients in the aerospace, telecommunications, and consumer electronics industries.

-

-

-

-

-

Metrofunk Kabel-Union GmbH

Abgeschirmtes Kabel

Company Overview

Founded in 1946 and headquartered in Germany, Metrofunk Kabel Union is a premier company famous for its premium cables and accessories. With a vast array of products, they offer power cables, data cables, and audio-video cables that cater to diverse sectors and applications. Offering more than just products, Metrofunk provides specialized cable assembly and custom solutions to meet unique requirements. The company's ISO 9001 certification demonstrates its determination to deliver quality standards. Based in Germany, they are a reputable source of cutting-edge cable solutions, thriving and setting trade benchmarks.

-

-

-

-

-

kabeltronik Arthur Volland GmbH

Shielded cable

Company Overview

Kabeltronik, a German-based company founded in 1983, is a principal provider of premium cables, wires, cable assemblies, conduits, tubing, and sleeving. They specialize in an extensive range of offerings, encompassing cables, wires, cable assemblies, and conduits, ensuring efficient signal conveyance and safeguarding. Their array of services spans technical consultation, cable design, and bespoke cable assembly to cater to unique needs. With a constant pursuit of excellence and dependability, Kabeltronik delivers impeccable post-sale assistance and swift delivery. Their profound expertise within the sector positions them as solid collaborators for all cable and wire solutions.

-

-

Shielded Cable Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Victor Wire & Cable |

12.5%

|

| 2 | Micro-Tek Corp. |

10.4%

|

| 3 | Metrofunk Kabel-Union GmbH |

10.4%

|

| 4 | EIS Wire & Cable |

8.3%

|

| 5 | Casco Manufacturing |

8.3%

|

| 6 | Black Box |

4.2%

|

| 7 | Consolidated Electronic Wire & Cable |

4.2%

|

| 8 | Dielectric Sciences, Inc. |

4.2%

|

| 9 | Brim Electronics, Inc. |

4.2%

|

| 10 | Multi/Cable Corp. |

4.2%

|

Derivation Method

The ranking is calculated based on the click share within the shielded cable page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- HIRAKAWA HEWTECH CORP.: 2,367

- TATSUTA Electric Wire and Cable Co.,Ltd.: 1,011

- Canare Electric Co., Ltd.: 284

Newly Established Company

- Excel Connection: 1986 (38 years ago)

- Dielectric Sciences, Inc.: 1970 (54 years ago)

- Canare Electric Co., Ltd.: 1970 (54 years ago)

Company with a History

- L. A. Woolley Electric, Inc.: 1916 (108 years ago)

- TATSUTA Electric Wire and Cable Co.,Ltd.: 1945 (79 years ago)

- Switchcraft, Inc.: 1946 (78 years ago)

Shielded Cable Manufacturers in United States

*Including some distributors, etc.

- Switchcraft, Inc.

- MURRELEKTRONIK INC.

- TEAM SOLUTIONS, INC.

- Consolidated Electronic Wire & Cable

- Victor Wire & Cable

- Excel Connection

- Dielectric Sciences, Inc.

- EIS Wire & Cable

- Brim Electronics, Inc.

- Multi/Cable Corp.

- Swift Bridge Technologies

- Daburn Electronics & Cable

- Casco Manufacturing

- American Wire Group

- L. A. Woolley Electric, Inc.

Global Distribution of Shielded Cable Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

15 | 68.2% |

Germany

Germany

|

3 | 13.6% |

Japan

Japan

|

3 | 13.6% |

China

China

|

1 | 4.5% |

List of Shielded Cable Products

1 product is listed.

SISI Co., Ltd.

Rapid charging & 5g 5G generational latest standard graphene shield cable

A new material cable with high flexibility, heat dissipation, and shielding using the next -generation high -functioning insulating sheet "Grafen" ...