All Categories

History

This section provides an overview for molding machinery as well as their applications and principles. Also, please take a look at the list of 25 molding machinery manufacturers and their company rankings. Here are the top-ranked molding machinery companies as of January, 2026: 1.Wabash Plastics, Incorporated, 2.Wilmington Machinery, Incorporated, 3.BOLE Machinery Inc..

Table of Contents

Categories Related to Molding Machinery

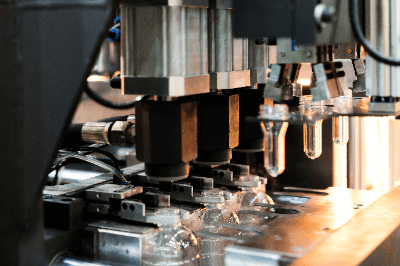

Molding machinery is machinery used in the molding of plastics and resins.

Molding machinery is machinery used in the molding of plastics and resins.

Specific uses include the manufacture of appliances and components. Extrusion machinery is used to produce tubes and rod products, molding machinery is used for styrene foam, and blow molding machinery is used for hollow products.

Molding machinery includes specialized machines for fluoroplastics, which are difficult to process, and vacuum molding machines, which mold under vacuum conditions, enabling high-precision molding. Molding machinery is suitable for mass production, but is now also used for small lot production.

For this reason, flexible molding machinery that can be switched in a short period of time has also been developed.

Molding machinery can mold a wide variety of materials, including plastics, metals, rubber, and ceramics. In the automotive and electrical/electronics industries, they can produce parts with complex shapes.

In the medical field, they are used in producing medical devices and prosthetics. They are also used in the construction industry to produce plastic exterior materials and roofing materials, in the food industry to produce chocolate and silicone molds, and in the textile industry to produce accessories and fabrics for spinning and weaving machines.

Injection molding machinery consists of heating plastic raw materials and other materials, injecting them through an injection port, and placing them in a mold. In extrusion molding machinery, plastic materials are placed in a hopper, pushed out through an extrusion opening, and shaped by a mold.

Molding machinery is a machine that extrudes thermoplastic materials by means of special mechanical pressure and heating. Plastic particles are fed from the machine's feeder and melted by a heated screw.

The plastic material extruded at high pressure is then formed to fit the shape of the die, creating a shape. Finally, the formed product is cooled and separated by a cooling system.

In blow molding machinery, plastic material is heated and placed into a hollow shaped die, which is inflated by air pressure to form the product. In molding machinery, thermoplastic resin is injected into the mold, cooled, and formed. In vacuum molding machinery, heated plastic film is applied to the mold under vacuum conditions.

Molding machinery performs molding operations in a high-temperature, high-pressure environment, so safety measures are important. In addition, factors that affect the quality of molded products include the type and quality of raw materials, mold design, and the adjustment of molding conditions. Molding machinery is suited for mass production, but today, flexible molding machines that can be switched in a short time are being developed to accommodate small-lot production.

Molding machinery includes injection molding machinery, extrusion molding machinery, and blow molding machinery.

Injection molding machinery is a machine that molds plastic material by injecting it into a mold. Injection molding machinery is characterized by its ability to mass produce at high speed. They are also highly automated, with operators simply operating the machine, which automatically performs everything from molding to ejection.

Injection molding machinery heats plastic material to melt it, and then injects the plastic through the injection port to form the mold. The plastic injected into the mold cools and hardens to form the desired shape.

Injection molding machinery is used for many products such as car panels, bumpers, computers, scissors handles, syringes, and smartphone covers. Mold design and manufacturing technology are important, as molds need to be designed according to the material and shape.

Extrusion machinery is a machine that melts plastic, rubber, metal, or other materials and pressurizes and extrudes them to make tubes, sheets, profiles, pipes, and other shapes.

Plastic or resin is placed in the hopper, and the material is fed into the screw while adjusting the amount. The material is heated inside the screw to melt it and extrude it. At the end of extrusion, a mouthpiece called a die is attached to determine the shape.

Blow molding machinery is a machine that uses air pressure to expand the material, which is then cooled and hardened as it is pushed into the die.

The temperature is raised to soften the material, which is then extruded through an extrusion screw to form a parison. The parison is cooled and molded by pressing it against the mold while blowing compressed air into it.

*Including some distributors, etc.

Sort by Features

Sort by Area

Wabash Plastics, Incorporated, founded in 1973 and headquartered in Evansville, Indiana, is a manufacturer of custom injection-molded components and assemblies. The company offers a broad range of products that include injection molding machinery, stack molding, pad printing, part marking, and custom assembly cells. These products are used across industries such as automotive, consumer goods, electronics, and medical devices. The company’s products are used to support efficient production, customization, and quality control of plastic components and assemblies. The company has also been awarded ISO 9001:2015 certification for quality management systems.

CEW, established in Baldwyn, MS, USA, is a manufacturer of wheeler products such as Custom Plastic Wheels, Flat Free PU Wheels, Tread Cap Wheels, Pneumatic Wheels, and Foam Filled Wheels since 1976. The company is ISO 9001:2019 certified and offers polyethylene (PE), polypropylene (PP), PVC, and nylon-made products used in lawn & garden, medical & mobility, waste & recycling, lightweight material, and bicycle applications. The company also offers microcellular polyurethane tires and products to varied sectors of medical, manufacturing, and industrial markets.

Wilmington Machinery, Inc. was established in 1972 and is a manufacturer of specialized and regular high-speed rotary blow molding equipment and structural plastic machines. The available machinery is utilized for injection molding, blow molding, stock, and custom machinery for applications such as big plastic parts, plastic pallets, miniature bottles, and handle ware bottles. The firm offers product design, development, pilot production, sumo molding equipment, lab work, training, and machine retrofitting and rebuilding.

BOLE Machinery Inc., since 1998, has been a manufacturer and researcher of precision injection molding machinery in Hudson Drive Stow, OH. The products include hydraulic servo EKS series, two-platen DK series, FE(fully electric), special machine series, and application-specific machines. The parts of the machines are air break switches, back pressure valves, mould adjust motors, and high-pressure oil hoses. The machines are used in household appliances, automotive, and industrial markets, as the company has offices in the US, Europe, Korea, and India.

Tabata Industrial Machinery CO., LTD., established in 1947 and headquartered in Tokyo, Japan, is a manufacturer that specializes in processing equipment for the plastics industry. The company's processing systems include blending, preforming, extrusion, and oven systems for the production of PTFE tubing and coated wire. It also produces small injection molding machines, exhaust gas treatment devices, cleaning ovens, and pelletizers. Its product offers high-intensity interval training (HIIT) that can be performed using various exercises. It serves the plastics industry, specifically for the production of PTFE tubing and coated wire.

Matsuda Seisakusho Co., Ltd., established in 1925 is a manufacturer based in Kuki-shi, Saitama, Japan that specializes in the production and sales of injection molding machines for both rubber and plastics. They offer test machines for construction and civil engineering industries and related equipment. Their product range includes large and small injection molding machines, vacuum presses, compression molding machines, and transfer molding machines. Matsuda Seisakusho acquires CE Marking, which is a mandatory safety certification for the import and transportation of their machines to European countries, to ensure compliance with European manufacturing standards.

Gusu Food Processing Machinery Suzhou Co. Ltd. is a manufacturer of machinery and related equipment for producing chocolate established in 1969 in Suzhou, Jiangsu, China. The company offers conche machines for concentrating or developing the flavor of chocolate, chocolate enrobers for coating ingredients with chocolate, and standard chocolate machines for production processes. It also offers complete candy bar lines built to customer specifications for mass production operations. The company’s products are commonly used in the confectionery, food processing, and snack food industries.

Pascal Corporation, founded in 1974 and based in Hyogo, Japan, is a manufacturer of automation equipment and systems. Its product range includes work clamping systems, gas springs, injection mold machines, and pallet clamps, catering to various industrial applications. Additionally, it offers die casting machines, press machines, auto couplers, and a selection of robot products, including expansion clamps, gas balancers, and tool changers. Its offerings find utility across industries, enhancing manufacturing processes, ensuring precision, and optimizing efficiency in workholding, and material handling. Since 1999, the company has maintained ISO9001 certification for its quality management system.

Sodick Co., Ltd, founded in 1976 and headquartered in Yokohama, Japan, is a manufacturer and supplier of machine tools, injection molding machines, food machines, and LED products. The company's product portfolio includes nano-level precision machines, magnesium alloy injection machines, noodle steam sterilizers, LED products, and electronic components. These products are utilized in various industries, including food processing, electronics, LED and lighting, manufacturing and machining, and the plastics and injection molding industry. The company has development, production, and service locations in different countries, including the United States, China, Thailand, India, and Singapore.

The Japan Steel Works, LTD., founded in Tokyo, Japan, in 1907 is a manufacturer of plastic machinery products and plastic molding machines, as well as IT and defense products. The company's product portfolio includes Spinning Extruders, Film and Sheet Manufacturing Equipment, Polyolefin Pelletizers, Magnesium Injection Molding Machines and hot presses. The company serves markets including Automotive and Electric Vehicles, Renewable Energy and Energy Storage and Electronics and IT Infrastructure. The company has a national distribution network and a customer support center.

Initially established in 1938, Shibaura Machine has three-quarters of a century providing Comprehensive technology and supporting the “monozukuri” of the world. With the technical and development capabilities of the Shibaura Machine Group, various machines and services create rich value and contribute to the creation of an industrial base. Working on the eight technical platforms, they develop and manufacture a wide range of production devices that meet the needs of the times, delivering the best solutions by combining our accumulated excellent know-how and the latest technology. Shibaura Machine uses its knowledge of modern global standards of advanced technology to support Japan and the world.

Sumitomo Heavy Industries, Ltd. (SHI) was established in 1888. SHI offers complete solutions for industrial machinery production and operations, heavy machinery for infrastructure, logistics, and construction, power generation systems as well as systems to reduce pollution, water purification, and ship construction. In addition, SHI also offers various software services including IT solutions.

Key Plastics, founded in 1986 and located in Wicklow, Ireland, is a supplier and manufacturer of metal and plastic molding solutions. The company offers a broad range of services and capabilities that include prototyping, injection molding, tooling transfers, mold manufacture, and moldflow analysis. These services and capabilities are used for creating functional and visual models, maintaining production continuity, producing consistent plastic parts, and predicting how molten plastic will flow and behave inside molds. The company’s services are utilized in automotive, electronics, consumer goods, medical devices, and industrial manufacturing. The company is also ISO 13485, AS 9100, and ISO 9001 certified.

Fecoatec, S.L. is a manufacturer engaging in food processing solutions, founded in 1907 and based in Madrid, Spain. The company offers a range of products under various brands, including ENROULTRA, automatic machines designed for enrobing chocolate, compound, and fat masses. In addition, it produces DOMBO, automatic coating pans for chocolate and syrup coating of food products. It also manufactures DAHU, automatic machines that generate filtered humidity and controlled temperature for air handling and drying solutions in food processing. Automatic machines for sugar syrup preparation are offered under the DISSOLPLUS brand, as well as automatic forming rollers known as FORMINGPLUS.

Selmi Group SRL, founded in 1965 and headquartered in Pollenzo, Italy, is a manufacturer of Selmi chocolate machinery and equipment for the manufacture of chocolate. The company's products include chocolate tempering machines, one-shot depositor chocolate dispensing machines, and cluster machines for agglomerates of dried nuts and chocolate. Other than individual machines, it offers complete turnkey chocolate production lines, which are customized to client needs. It also offers used and reconditioned machinery at discounted prices, as well as training on the use of its machinery for client teams.

BE Machinery Inc. was established in 1978 and is a manufacturer of big injection molding machines, aluminum extrusion presses, and die-casting equipment. Types of injection molding equipment are available: an electric 2 platen, a servo-hydraulic 2 platen, and all-electric toggles. The extrusion presses for aluminum and copper are indirect & direct single-action and short-stroke hybrid direct. The machines for die-casting come in medium, large, and hybrid sizes. The business offers controller upgrades, machine retrofits, and specialized training programs. The corporation has offices in the USA, Mexico, Brazil, Japan, India, and Germany.

ARBURG, founded in 1923 and headquartered in Lossburg, Germany, is a manufacturer of molding machines. The company offers a diverse range of products that includes hydraulic machines, hybrid machines, electric machines, cube-mold machines, and vertical machines. These machines are used to generate force and pressure for the molding process, for high-precision applications, for precision and energy efficiency, to produce complex and multi-component plastic parts, and for producing components with vertical parting lines. These machines are utilized across industries such as automotive, consumer goods, and packaging.

KraussMaffe, founded in 1838 and headquartered in Munich, Germany, is a manufacturer of machines and systems for producing and processing plastics and rubber. Its broad range of products includes additive manufacturing, extrusion technology, injection molding machinery, and reaction process machinery. These products are utilized across industries to create and shape plastic and rubber materials for applications such as prototyping, the production of complex components, packaging, and automotive parts. The company caters to an array of industries, including construction, consumer goods, electronics, medical, and industrial manufacturing.

Mazzetti Renato S.r.l., founded in 1972, is a chocolate production machinery manufacturer based in Tribiano, Milan, Italy. The company holds a patent for ball mills used in mixing, refining, and conching chocolate, which previously required three separate machines. Its also offers machinery for producing chocolate bars with inclusions and fillings, chocolate centers for sugar-coated dragees, and chocolate drops for bakery products and ice cream coating. These products feature stainless steel structures and food-grade aluminum alloy parts with electric, mechanical, and pneumatic components from primary suppliers.

DESMA USA, Inc., founded in 1965 and headquartered in Fridingen, Germany, is a supplier of injection molding solutions. The company’s diverse range of products includes vertical machines, horizontal machines, alpha and sigma machines, and rebuilt and used machinery. These injection molding solutions are used for manufacturing products, producing a range of plastic parts and products, and ensuring optimal performance and longevity. The company’s products cater to industries including automotive, consumer goods, footwear, medical, and packaging.

Meadoworks, LLC, founded in 1969 and headquartered in Chicago, Illinois, is a supplier of equipment and services to the global plastics industry. Its diverse range of products includes blow molding machinery, converting equipment, extrusion machinery, general inspection equipment, and plant support equipment. The company’s products are used to create hollow plastic products, transform raw materials into finished plastic products, shape and form plastic materials, assess the quality and integrity of plastic products, and perform material handling, storage, and maintenance. These products cater to the plastics industry, encompassing processes such as blow molding, converting, extrusion, quality inspection, and overall plant support.

Ranking as of January 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Wabash Plastics, Incorporated |

12.7%

|

| 2 | Wilmington Machinery, Incorporated |

7.9%

|

| 3 | BOLE Machinery Inc. |

7.7%

|

| 4 | BE Machinery Inc. |

6.9%

|

| 5 | CEW |

6.7%

|

| 6 | Matsuda Seisakusho Co.,Ltd. |

4.4%

|

| 7 | TABATA INDUSTRIAL MACHINERY CO., LTD. |

4.4%

|

| 8 | KraussMaffe |

4.2%

|

| 9 | Sodick Co., Ltd |

4.2%

|

| 10 | Key Plastics |

3.8%

|

Derivation Method

The ranking is calculated based on the click share within the molding machinery page as of January 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

8 | 53.3% |

United States of America

United States of America

|

4 | 26.7% |

China

China

|

1 | 6.7% |

Ireland

Ireland

|

1 | 6.7% |

Italy

Italy

|

1 | 6.7% |

371 products found - Page 2

371 products - Page 2

Shibaura Machine

510+ people viewing

Last viewed: 15 hours ago

In order to realize a decarbonized society, which has been attracting attention in recent years, we have added to our lineup the ultra-large all-el...

Katahisado Co., Ltd.

380+ people viewing

Last viewed: 1 day ago

Imported product made by Chocolate World, headquartered in Belgium. ■Applications automatic tempering ■Features ・Easy tempering ・Easy molding ...

Yamanaka Eng Co.,Ltd.

420+ people viewing

Last viewed: 1 day ago

Precision forming tools and molds manufactured by strip winding technology. Because it boasts high strength, it has a long service life and can be ...

Wakisaka Engineering Co., Ltd.

380+ people viewing

■Features ・Various data input and display Display on LCD screen and input using touch panel method. ・The vertical drive of the mold is a direct d...

Mori Machinery Co., Ltd.

250+ people viewing

The one-of-a-kind technology that has been perfected for copper pipes is also useful for aluminum pipes.

Shibaura Machine

590+ people viewing

Last viewed: 22 hours ago

The EC-SXIII series is equipped with the new controller "INJECTVISOR-V70", which has dramatically improved functionality compared to the previous s...

Ecold Japan Co., Ltd.

370+ people viewing

■Hand former HF 100 An indispensable unit for sheet metal work Ecold Handformer makes even the most arduous hammering work a breeze. It is possible...

Takahama Industries Co., Ltd.

710+ people viewing

Last viewed: 1 day ago

■Development concept This roller machine was developed by gathering the best of KAJISEKI's technology in line with the trend of high-variety, low-v...

Takahama Industries Co., Ltd.

430+ people viewing

■Development concept The BCP series has developed into various shapes as a tile press (clay shaper). The long-standing original press technology ha...

5 models listed

Wakisaka Engineering Co., Ltd.

390+ people viewing

Last viewed: 1 hour ago

■Features ・Various data input and display Display on LCD screen and input using touch panel method. ・The vertical drive of the mold is a direct d...

Labnect Co., Ltd.

460+ people viewing

■For sample molding of ceramics, metal powders, food powders, pharmaceuticals, etc. The powder sample molding machines "Mini Lab Press" and "Lab Pr...

Labnect Co., Ltd.

520+ people viewing

Last viewed: 1 day ago

■For sample molding of ceramics, metal powders, food powders, pharmaceuticals, etc. The powder sample molding machines "Mini Lab Press" and "Lab Pr...

Labnect Co., Ltd.

560+ people viewing

Last viewed: 1 day ago

■Compact and capable of pressure molding up to 200Mpa (2 tons of surface pressure) This is a small manual cold isostatic press machine with a simpl...

Labnect Co., Ltd.

310+ people viewing

Last viewed: 5 hours ago

■A maximum load of 5,000N can be applied by simply turning the handle. A screw press is a low-load forming machine. A maximum load of 5,000N (500kg...

THANK METAL

270+ people viewing

Last viewed: 13 hours ago

Pouch forming equipment Air-driven automatic type. Continuous processing of pouch formation using roll-to-roll ■Device configuration Unwinding dev...

THANK METAL

280+ people viewing

■Pouch forming equipment Motor-driven single-wafer type Easy to use with only 100V power supply

Shibaura Machine

450+ people viewing

Last viewed: 22 hours ago

The measurement stability and filling stability required for special silicone rubber molding are achieved using an electric molding machine, and ou...

Shibaura Machine

630+ people viewing

Last viewed: 13 hours ago

■Achieving even more precise molding of thermosetting resin This is an injection molding machine dedicated to thermosetting resin molding and rubbe...

Shibaura Machine

450+ people viewing

Last viewed: 22 hours ago

■We respond to improvements in the quality and physical properties of molded products. This series is equipped with a vent type injection device. T...

Shibaura Machine

360+ people viewing

Last viewed: 22 hours ago

■Gathering the know-how necessary for light guide plate molding We bring together the optimal know-how for light guide plate molding. We will achie...

Shibaura Machine

490+ people viewing

Last viewed: 13 hours ago

■Sandwich molding attracting attention for resource recycling This is an injection molding machine equipped with two injection devices for the purp...

Shibaura Machine

410+ people viewing

Last viewed: 22 hours ago

■You can save labor in the assembly process and insert molding. This is a two-material molding machine based on the all-electric injection molding ...

Labnect Co., Ltd.

550+ people viewing

Last viewed: 9 hours ago

■For sample molding of ceramics, metal powders, food powders, pharmaceuticals, etc. The powder sample molding machines "Mini Lab Press" and "Lab Pr...

Shibaura Machine

480+ people viewing

Last viewed: 15 hours ago

■Achieve high value-added molding By combining an electric injection molding machine/hydraulic injection molding machine with an electric sub-injec...

Labnect Co., Ltd.

490+ people viewing

■For sample molding of ceramics, metal powders, food powders, pharmaceuticals, etc. The powder sample molding machines "Mini Lab Press" and "Lab Pr...

Labnect Co., Ltd.

480+ people viewing

Last viewed: 9 hours ago

■For sample molding of ceramics, metal powders, food powders, pharmaceuticals, etc. The powder sample molding machines "Mini Lab Press" and "Lab Pr...

Ecold Japan Co., Ltd.

270+ people viewing

■Hand former HF 100 PA allows you to use both hands freely With this machine, you can use both hands freely to control the workpiece, and the press...

Kyowa Green Co., Ltd.

270+ people viewing

Last viewed: 1 day ago

We manufacture substrate pots from φ50mm to φ80mm. *A separate compressor is required.

Kyowa Green Co., Ltd.

230+ people viewing

Last viewed: 23 hours ago

We manufacture substrate pots from φ20mm to φ50mm. *A separate compressor is required.

Wakisaka Engineering Co., Ltd.

410+ people viewing

Last viewed: 10 hours ago

■Features ・This is an ultra-compact vacuum forming machine developed for test molding, and uses cut sheets for molding. ・The vertical movement of...