All Categories

History

This section provides an overview for test sockets as well as their applications and principles. Also, please take a look at the list of 6 test socket manufacturers and their company rankings. Here are the top-ranked test socket companies as of December, 2025: 1.SNOW Co., Ltd., 2.Ensinger, 3.Robson Technologies, Inc..

Table of Contents

Categories Related to Test Sockets

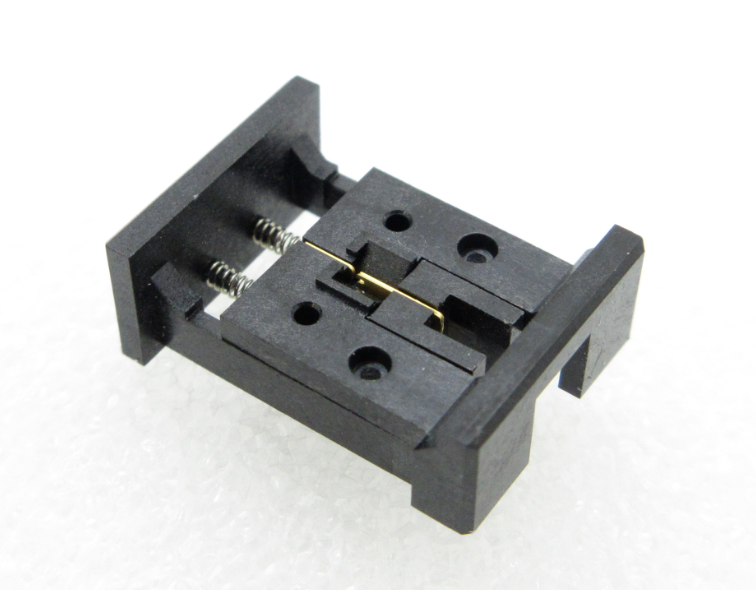

A Test Socket is a tool used in the development process or pre-shipment inspection of electronic device packages and semiconductor device packages (hereinafter referred to as devices).

Designed to match the pinout of the package under test, it can be inserted into the socket to establish necessary connections and measurements. This allows for the rapid execution of device testing and development evaluation. The device insertion and removal are straightforward, enabling development evaluation and testing without soldering to the substrate.

The connection between the test socket and the device package is made using electrodes called probes. The mechanism involves the pins of the device package making contact with the probes, and establishing a circuit. The arrangement of probes varies between sockets, and various types are available for different applications.

The primary uses of test sockets include mass production testing and evaluation development testing of device packages.

Mass production testing is conducted to evaluate the operation and performance of devices and detect defects. The test socket, by inserting the device and making contact with the pins, serves as a tool for executing device testing. Using test sockets enables the efficient testing of a large number of ICs, allowing the identification of defective products. This process is a critical step in quality management, essential for ensuring the reliability of products.

Evaluation development testing involves performance testing when developing device packages. At the development stage, semiconductor chips are processed into their final packages. It is necessary to confirm whether the device operates correctly in this form and obtains the required characteristics at the development stage. Evaluation development is carried out using test sockets without directly implementing on the substrate, confirming characteristics and operations.

Both are used in testing device packages. Here are examples of items evaluated using test sockets during testing:

1. Pin Configuration Evaluation

Ensures that the pin configuration inside the package matches the design. It is also essential to check for any external damage to the package based on its appearance.

2. Electrical Characteristic Evaluation

Measures voltage, current, and frequency characteristics, and evaluates whether they are within specified values. Insulation resistance may also be measured and evaluated.

3. Mechanical Evaluation

Conducts mechanical evaluations such as the device's impact resistance and the impact of vibrations.

4. Temperature Evaluation

For some applications, it is necessary to evaluate the temperature characteristics of the device. This is an example of applications used in automobiles or aircraft. Using a test socket, the device's operation is tested in high-temperature environments.

The principle of the test socket focuses on facilitating the connection and testing of electronic devices and ICs. The test socket is designed to correspond to the pinout information of a specific IC or device, and the contacts of the test socket are arranged based on the pinout information of the IC. This establishes a connection between each pin of the IC and the test socket.

Designed for easy insertion and removal of the device under test for testing purposes, it allows different devices to be tested using the same test socket, enabling quick testing and debugging. It plays a role in transmitting signals at each pin, connecting the internal signals of the device to external test equipment.

Some products can be customized to accommodate different ICs or semiconductor devices. This may involve changing the pinout to match a specific IC package or adjusting the design to meet special requirements.

Test sockets come in various types depending on the contact method. Here are some examples of types of test sockets:

These are probes with a structure that holds a spring inside a barrel (pipe) and allows the plunger to operate (stroke) vertically by tilting it inside the barrel. They are also called Pogo pins or spring probes. Probe pins are generally categorized into two types: double-ended movable type and single-ended movable type. Additionally, there are variations such as internal spring type and external spring type, depending on how the spring is implemented.

Manufactured by different companies with unique structures, they generally use the elasticity of metal springs or rubber to achieve the stroke required for probing.

*Including some distributors, etc.

Sort by Features

Sort by Area

Robson Technologies, Inc. is an American manufacturer of custom test interfaces that was established in Morgan Hill, California in 1989. The company primarily produces test interfaces for the semiconductor industry, including test presses, sockets, and fixtures, as well as burn-in sockets and boards using stainless steel pogo pins. It also offers device-under-test (DUT) boards for ensuring consistency between performance and specification requirements, and curve tracing systems for DC parametric testing. The company’s products are mainly used in the semiconductor, consumer electronics, defense, and aerospace industries.

Ensinger, founded in 1966 in Germany as solely a manufacturer of plastics for commercial customers, has grown to manufacture performance and engineering thermoplastics for numerous industries worldwide. The company's products include plastic compounds, extruded semi-finished products, injection-molded finished parts, as well as compressed and cast-formed parts. Ensinger serves the plant engineering, building construction, automotive, aerospace, medical, and food markets, among many other industries. The company has over 30 international production and sales locations, serving customers across the globe.

Smiths Interconnect Canada Inc., headquartered in London, England, is a manufacturer of connectivity solutions. The company provides technically differentiated electronic components, subsystems, optical and radio frequency products that connect, protect and control critical applications in mainly energy, defence, aerospace and industrial market segments. Its product portfolio includes connectors, board test fixture probes and defence antenna systems. It has 21 sales, R&D and manufacturing locations in 12 countries, including Canada, US and UK. The company complies with multiple quality, safety and environmental standards including ISO, RoHS and REACH.

FEINMETALL GmbH, founded in 1964 by the Kreidler company and headquartered in Herrenberg, Germany, is a manufacturer and distributor of contact probes, probe cards, and special contacts used in semiconductor, automotive, and electrical industries. The contact probe product segment includes radio frequency, fine pitch, high current, switch, and wire harness probes. The company also manufactures standard components and customer-specific special contacting units such as test heads, test sockets, or interface blocks. FEINMETTAL operates production and subsidiaries in Europe, Asia, and America, including Tunisia, China, Taiwan, the Czech Republic, Mexico, Singapore, and the USA.

Ranking as of December 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | SNOW Co., Ltd. |

33.3%

|

| 2 | Ensinger |

18.7%

|

| 3 | Robson Technologies, Inc. |

14.7%

|

| 4 | Smiths Interconnect Canada Inc. |

12.7%

|

| 5 | FEINMETALL GmbH |

10.7%

|

| 6 | MiS Technologies Corporation |

10.0%

|

Derivation Method

The ranking is calculated based on the click share within the test socket page as of December 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Germany

Germany

|

2 | 50.0% |

Japan

Japan

|

1 | 25.0% |

United States of America

United States of America

|

1 | 25.0% |

147 products found - Page 2

147 products - Page 2

Japan Connect Industry Co., Ltd.

110+ people viewing

Last viewed: 12 hours ago

When the test socket reaches the end of its lifespan, you can immediately replace it by using an IC conversion adapter. (Solder the IC conversion a...

2 models listed

Japan Connect Industry Co., Ltd.

110+ people viewing

Last viewed: 40 minutes ago

Nippon Connect Kogyo's power transistor sockets are available in a variety of TO packages and are compatible with high current (large current), hig...

10 models listed

Japan Connect Industry Co., Ltd.

70+ people viewing

Last viewed: 42 minutes ago

Nippon Connect Kogyo's power transistor sockets are available in a variety of TO packages and are compatible with high current (large current), hig...

8 models listed

Japan Connect Industry Co., Ltd.

150+ people viewing

Last viewed: 1 day ago

Nippon Connect Kogyo's power transistor sockets are available in a variety of TO packages and are compatible with high current (large current), hig...

10 models listed

Japan Connect Industry Co., Ltd.

130+ people viewing

Last viewed: 12 hours ago

Nippon Connect Kogyo's power transistor sockets are available in a variety of TO packages and are compatible with high current (large current), hig...

4 models listed