All Categories

History

This section provides an overview for stamping dies as well as their applications and principles. Also, please take a look at the list of 11 stamping die companies and their company rankings. Here are the top-ranked stamping die companies as of February, 2026: 1.IQ Manufacturing, 2.Keats Manufacturing Co., 3.Reich Tool & Design, Inc..

Table of Contents

Categories Related to Stamping Dies

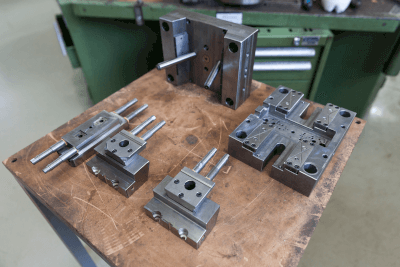

A stamping die is a tool used in the stamping process to shape products.

A stamping die is a tool used in the stamping process to shape products.

It comprises a pair of upper and lower dies designed to interlock. When combined, these dies form the desired shape. Set in a stamping press, the dies apply pressure to the metal being processed, causing plastic deformation and shaping the metal.

There are two main types of stamping dies: dies, which press flat metal sheets between upper and lower dies, and molds, used for casting and plastic molding, where molten material is poured into the die.

The type of press machine used can vary, with some being manually operated and others capable of automated, complex shape formation using multiple dies.

Stamping dies enable bending, shearing, and drawing - key processes in metal product fabrication. Specific dies like bending dies, shearing dies, and drawing dies are used for these respective processes.

Stamping dies are vital in manufacturing various products due to their ability to mass-produce identical shapes quickly. They are commonly used in making parts for automobiles, motorcycles, medical equipment, and construction materials, all requiring precision and efficiency in their production.

Different stamping dies are designed for various processes like shearing and bending.

The press machine's pressure is crucial in stamping, where the die is pressed against the metal to induce plastic deformation. Note that while higher press performance facilitates easier forming, it also increases press forming efficiency and operational electricity costs.

Stamping dies are manufactured using machining centers, where the desired shape is cut and heat-treated. Die fabrication typically takes 3 to 6 months, depending on the product's size and complexity.

Materials like alloy tool steel, known for its toughness, and high-speed tool steel, recognized for heat and wear resistance, are used for stamping dies due to the high pressure involved.

Stamping dies can be broadly categorized into two types based on their operation during stamping. However, it's important to note that the definitions of these categories can vary.

Dies are primarily used for processing metal sheets. In these dies, the metal is placed between the open upper and lower dies, and then the upper die is pressed into the lower one to form the shape.

Molds are mainly used for processing plastics. Molten resin is poured into the closed upper and lower molds, and then allowed to cool and harden before the formed product is removed.

Stamping dies come in three main types:

A single-shot mold performs one type of stamping process continuously. It's the most common among the three types and can handle one to several stamping processes. Its simplicity makes it cost-effective, though it is less efficient due to manual operation.

A progressive die houses multiple stamping processes within a single die. It automatically transfers metal to the next process, enabling efficient, high-precision production. Though complex and costly to produce, it's the fastest among the three types and accommodates complex shapes.

A transfer die links single-shot dies for each process via a transfer mechanism. It combines the large processing capability of single-shot molds with the automation of progressive molds. While production costs are higher and processing time slower than progressive dies, it offers high versatility.

*Including some distributors, etc.

Sort by Features

Sort by Area

IQ Manufacturing, founded in June 2015 and headquartered in Auburn Hills, MI is an AS-9100 and ISO-9001-certified manufacturer and machine shop. The company offers various machining services, including but not limited to CNC machining, wire EDM, prototyping, injection molding, and surface grinding. Dies, molds, and parts are also readily available. The company offers turnkey services and custom manufacturing solutions for several industries and applications, including automotive, aviation, aerospace, defense, automation parts, and more.

Keats Manufacturing Co., established in 1958 and headquartered in Illinois, USA, is a manufacturer of stampings, metalforms, and assemblies. It offers a range of products including custom metal stampings, brackets, and shields. These products are used in various industries, including the automotive, aerospace, and general manufacturing sectors. It also offers a wide range of custom and stock medical device components such as implants and prosthetics, temperature probes, and surgical devices. The company holds several certifications such as the ISO:9001, ISO:14001, and IATF:16949 certificates.

Reich Tool & Design, Inc. (RTD) is a contract manufacturer specializing in tool and die design based in Wisconsin. Founded in 1965, the company operates out of two facilities in Menomonee Falls with a combined floor space of 72,000 sq ft, serving manufacturers of consumer appliances, automotive, firearms, and medical devices. The company offers various services including CNC turning and machining, laser marking and welding, 3D printing, and multi-sonic washing. RTD is compliant with ISO 9001:2015, ISO 13485:2016, and AS9100 standards, and functions as a partnered solutions provider for clients like Harley Davidson, Ruger, and Milwaukee Electric Tool.

WALKER TOOL & DIE Inc., established in 1959 and headquartered in Grand Rapids, Michigan, is a manufacturer specializing in metal stamping dies and metal stamping tool systems. The company provides solutions in the field of metal stamping through services like die simulation, 3D CAD modeling, and die design. It offers metal stamping die products, including progressive dies, transfer dies, line dies, die repair, and part validation. These products serve industries like automotive, appliances, office furniture, and aerospace. The company also offers value-added services such as CNC machining, wire EDM, laser trimming, prototyping, and low-volume production stamping.

Ashing Machine & Tool Co., established in 1986 and based in Grinnell, Iowa, is a stamping die supplier. The company offers a range of services, including progressive stamping dies, progressive die design, metal stamping dies, steel stamping dies, and line dies. These products support various industries, including automotive, appliance, HVAC, transportation, off-road, commercial, and agricultural sectors. Its capabilities encompass the entire lifecycle of stamping dies, from quotation and design to building, qualification, and ongoing support.

AAPICO, established in 1996 and headquartered in Ayuthaya, Thailand, is a manufacturer specializing in OEM automotive parts. The company operates in three distinct business sectors: OEM auto parts manufacturing, car dealerships, and IoT connectivity & mobility solutions. In the OEM Auto Parts Manufacturing segment, it produces a wide range of components, including stamped and welded assemblies, chassis frame components, stamping dies, assembly jigs, and more. In the car dealership business, it represents brands like Mitsubishi, Ford, Honda, Proton, Hyundai, and more. In the IoT Connectivity & Mobility Business, it offers car accessories, telematics, logistics systems, and Oracle ERP consultancy.

Dongguan Orienson Hardware Electrical Co., Ltd., established in 2000 and located in Dongguan City, Guangdong, is a China stainless steel stamping parts manufacturer specializing in metal stamping solutions. The company's expertise extends to designing and producing production molds tailored to customer needs, encompassing soft molds, fixture molds, and engineering sample molds. The company's metal stamping services cover a wide spectrum, including fine blanking parts, deep drawing parts, copper stamping, stainless steel stamping, steel stamping, and more. It serves diverse industries such as automotive, electrical and electronic accessories, optical fiber communication, medical devices, and energy development.

Kunshan Feiya Precision Moulding Co., Ltd., established in 2004 and located in Kunshan City, Jiangsu, is a manufacturer specializing in plastic injection molding & stamping die service. The company offers a diverse range of services, including plastic injection molding, progressive stamping die manufacturing, CNC machining, and the production of plastic and metal parts. It provides precision molding solutions to various industries, including automotive, electronics, medical, and more. The company excels in producing automotive interior plastic parts molds, precision electronic digital plastic parts molds, precision medical equipment parts molds, bending dies, metal stamping tools, and more.

Yamaoka Seisakusho Co., Ltd., headquartered in Joyo City, Kyoto, Japan, and established in 1954, is a manufacturer of production equipment. The company specializes in addressing various demands in press manufacturing, including molds and production equipment design. Its capabilities extend to producing dies suitable for punching processes of ultrathin, complex, or multilayer special-material films, such as those required for digital household goods or mobile phones. The company is well-equipped for mass production of press parts and resin products. Its in-house production lines offer flexibility to accommodate requests of different lot sizes and product configurations without restrictions.

Quality Stamping & Tube Corp. was founded in 1982 in Jackson, Wisconsin, USA, as a manufacturer of metal stampings, aluminum extrusions, and heat transfer products. Offering various products, the company provides OEM radiators such as The Successor One-Piece Core Radiator, Aluminum Extrusion Molding, Aluminum Extrusion Circle, and Aluminum Extrusion Fins. Additionally, the company provides services including progressive stamping, OEM stamping, aluminum stamping, and aluminum extrusion finishes. The products are used in cooling systems and in manufacturing for creating intricate shapes and designs, whereas the services improve the functionality of components. The company serves various industries, including automotive, aerospace, manufacturing, and electronics.

Founded in 1948, and, located in Tarentum, PA, Oberg Industries is a manufacturer of stamped metal components and precision tooling. The company offers surgical instruments, Automation systems, special devices, and, finishing solutions for the medical sector along with stamped metal components for jet engines, submarines, munitions, firearms, and rotary-wing aircraft. that are used in the defense sector. They also offer Precision Grinding, Special / Secondary Processes, and Assembly Cells for the construction industry besides automotive parts including Clutch plates. Fuel injectors. Staked motor laminations, Airbag components that have applications in the Automotive industry.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | IQ Manufacturing |

14.9%

|

| 2 | Keats Manufacturing Co. |

13.9%

|

| 3 | Reich Tool & Design, Inc. |

12.9%

|

| 4 | WALKER TOOL & DIE, INC. |

11.9%

|

| 5 | Ashing Machine & Tool Co. |

9.5%

|

| 6 | Oberg Industries |

8.5%

|

| 7 | Quality Stamping & Tube Corp |

7.0%

|

| 8 | AAPICO |

6.5%

|

| 9 | Dongguan Orienson Hardware Electrical Co., Ltd. |

6.5%

|

| 10 | Yamaoka Seisakusho |

4.5%

|

Derivation Method

The ranking is calculated based on the click share within the stamping die page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

5 | 62.5% |

China

China

|

2 | 25.0% |

Thailand

Thailand

|

1 | 12.5% |