All Categories

History

This section provides an overview for sheet metal testers as well as their applications and principles. Also, please take a look at the list of 10 sheet metal tester companies and their company rankings. Here are the top-ranked sheet metal tester companies as of February, 2026: 1.ERICHSEN INC, 2.S.C. SARTOROM IMPEX S.R.L, 3.Arotec Colombiana S.A.S.

Table of Contents

Categories Related to Sheet Metal Testers

A sheet metal tester is a process to check whether sheet metal has been created according to specifications and drawings before shipment.

A sheet metal tester is a process to check whether sheet metal has been created according to specifications and drawings before shipment.

Sheet metal, also known as sheet metal, is thin, flattened metal. Sheet metal is also called sheet metal, or sheet metal, when the material is plastically processed at room temperature. Inspectors check inspection standards based on drawings and specifications, and inspect the sheet metal tester's dimensions, weight, color, thickness, and appearance to make a pass/fail decision as the final product. When aesthetics are involved in the appearance, it is difficult for the inspectors to make a judgment.

Typically, sheet metal tester quality inspections check the following two points:

Quality control methods are used to prevent defective products. However, it is difficult to introduce quality control methods unless you are familiar with them on a daily basis. Quality control awareness can solve familiar problems. For example, when a defect is found on a product, the worker considers whether the defect could have been caused by his or her own work methods. As a result, they can find and implement improvements in their daily work. Once you are familiar with the above, you can systemize your quality control measures in the following flow.

Mechanical sheet metal testers require products to be machined to a relatively high degree of accuracy and to be finished to a good condition with no scratches or burrs. In terms of dimensional accuracy, many of the product drawings are digitized electronically using CAD and other methods, making it difficult for errors to occur. However, mistakes can still occur during the blank removal (disassembly) stage, which is necessary for processing, due to the oversight of sheet thickness and elongation caused by processing.

On the other hand, scratches on sheet metal are more likely to occur during the transportation and processing stages when obtaining materials. Even scratches that are difficult to notice at the part fabrication stage may become apparent in the paint finish and result in a defective product.

The occurrence of burrs in sheet metal is mainly caused by forgetting to perform human deburring operations and variations in quality. The occurrence of defective products leads to loss of processing costs, including material costs and painting, and delays in product delivery, so companies need to take countermeasures. Sheet metal tester is important in daily operations to prevent the occurrence of defective products.

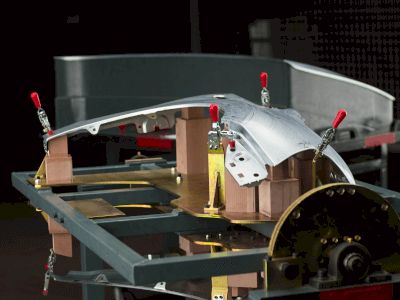

A wide variety of sheet metal testers are available to check the dimensional accuracy of sheet metal.

To meet safety requirements in sheet metal design, various performance requirements, such as required strength, weight, cost, ease of repair, and quality, are designed into the appropriate part shape through all kinds of analysis and simulation. As a result, sheet metal parts have many complex configurations, and it is very difficult to create each one in the designed shape and ensure the necessary dimensional accuracy by combining parts with each other.

Sheet metal testers are always on site to show the exact shape of sheet metal parts, which is necessary to shorten development time and ensure quality. A wide variety of inspection tools are available for different part sizes and configurations.

Depending on the application and measurement accuracy, the right measuring tool should be used for sheet metal tester applications. For length measurement, a steel straightedge, steel tape measure, caliper, micrometer, or height gauge is used. For angle measurements, right angle rulers and protractors can be used.

Dial gauges measure the accuracy of machines and products. Narrow gaps that cannot be measured with calipers can be measured with a thickness gauge. Pin gauges are rods made to a given size. It is inserted into a hole in a product to check if the hole diameter is in accordance with the standard.

To maintain high product quality, inspection software for precision sheet metal testers is available. Specifically, inspection software can evaluate unbent, BR unbent, wrong bending dimensions, reverse bending, drilling unbent, press-fit nut misalignment, press-fit nut presence, etc. When detection and judgment are achieved through simple verification, judgment accuracy and processing time can also be evaluated.

*Including some distributors, etc.

Sort by Features

Sort by Area

ERICHSEN INC., founded in 1910 and based in Westlake, is a manufacturer of testing equipment and machines. The company's products are used in sheet metal testing, surface testing, corrosion testing, and material testing. The products meet global requirements for testing technology and exceed international demands for accuracy. It is specialised in testing tools for sheet metal, surfaces, corrosion, and materials. The company holds DAkkS-accredited calibrations according to DIN EN ISO/IEC 17025:2018 in the fields of mechanical measurands (mass, pressure, and force) and dimensional measurands.

Labortech s.r.o., established in 1995 and headquartered in the Czech Republic, China, is a manufacturer of testing machines, equipment, and automatons. The company specializes in impact machines, hardness testers, and special test equipment. Its offerings include testing systems, software, and accessories, serving diverse testing needs in the automotive, aerospace, and education sectors. The company's machines and equipment are also utilized for mechanical testing and balancing, providing solutions for materials and product evaluation.

ABS Instruments Pvt.Ltd., established in 1989 and based in Chennai, India, is a supplier of testing equipment materials. The company has NABL (ISO 17025) accreditation for the calibration of speed, displacement, extensometers, hardness testers, and impact testers. The products are applied to testing of hardness, fatigue, sheet metal, visual inspection, and rebound. The products are used in industries like automotive, defence, polymer, aerospace, and pharmaceuticals. The company specialised in making accelerated weathering instrument bandols, ageing ovens, automatic hardness and density testers, and automatic cupping test machines.

ZwickRoell Corporation, founded in 1935 and based in Ulm, Germany, is a global supplier of static materials testing machines. Its offerings include static materials testing machines, dynamic and fatigue testing machines, and automated testing systems, used in research and development, and quality assurance across various industries. Its machines run approximately 80,000,000 materials and component tests annually. The company operates a calibration laboratory accredited to ISO/IEC 17025 and is certified to ISO 9001 and ISO 14001.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | ERICHSEN INC |

33.3%

|

| 2 | S.C. SARTOROM IMPEX S.R.L |

22.2%

|

| 3 | Arotec Colombiana S.A.S |

11.1%

|

| 4 | Cromocol Scandinavia AB |

11.1%

|

| 5 | LABORTECH s.r.o. |

11.1%

|

| 6 | ZwickRoell Corporation |

11.1%

|

Derivation Method

The ranking is calculated based on the click share within the sheet metal tester page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

India

India

|

2 | 20.0% |

China

China

|

2 | 20.0% |

United States of America

United States of America

|

1 | 10.0% |

Czech Republic

Czech Republic

|

1 | 10.0% |

| Romania | 1 | 10.0% |

| Colombia | 1 | 10.0% |

Sweden

Sweden

|

1 | 10.0% |

Germany

Germany

|

1 | 10.0% |