All Categories

History

This section provides an overview for fatigue testing services as well as their applications and principles. Also, please take a look at the list of 12 fatigue testing service companies and their company rankings. Here are the top-ranked fatigue testing service companies as of February, 2026: 1.NTS, 2.Clark Testing, 3.TÜV Rheinland.

Table of Contents

Categories Related to Fatigue Testing Services

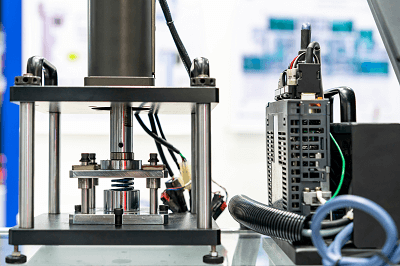

Fatigue testing is a test in which a load is repeatedly applied to a test sample to determine at what point this test sample is destroyed.

Even if a metal is subjected to a small load that does not break in one time, an invisible crack is generated by repeated application of the load. This is called "cracking."

If further load is applied while cracks have formed, the metal will eventually fracture. This is called "fatigue failure." Fatigue testing is used to investigate the number of times until fatigue failure occurs.

Fatigue testing is performed on almost all products in which metal is used. It is no exaggeration to say that fatigue testing is indispensable, especially for products that are expected to be used repeatedly, such as automobiles, cables, and overpasses.

Fatigue testing is also used to determine durability against bending operations. This is because metallic materials are often processed in long and narrow shapes and are prone to small cracks as a result of repeated bending.

In addition, although not to the same extent as metals, rubber and resins also have a lower rupture stress when subjected to repeated loading. Depending on the material and application, fatigue testing is recommended, as with metals.

Fatigue testing is performed in the following sequence:

The S-N diagram can be created by plotting the "magnitude of the load (stress)" on the vertical axis and the "number of times the load has ruptured" on the horizontal axis.

The S-N diagram shows that the load is horizontal after a certain stress. This stress is called the fatigue limit, which is the force at which fatigue failure does not occur, no matter how many times the load is repeated. By multiplying this fatigue limit by the safety factor, the allowable stress of the material can be calculated.

In order to create an accurate S-N diagram, it is important to test with a well-balanced set of large and small loads. It is recommended that at least six different loads be given and that as many points as possible be shaken to perform the test.

There are many types of fatigue testing. The type of test to be evaluated and the magnitude of the load will depend on the product and operating environment in which the test sample will be used.

Torsional fatigue testing is essential for automobile shafts because they are subjected to repeated torsional loading. In addition, there are two types of tension-compression fatigue testing: high-cycle fatigue testing, in which the entire surface of the specimen is subjected to loading, and low-cycle fatigue testing, in which loading is applied only to areas where stress is concentrated, such as steps.

For products that may be subjected to localized stress, it is recommended that both tests be performed.

The background of fatigue testing is that "metals are not always destroyed only when they are subjected to strong loads." Machines and structures are often broken by "repetitive loading" in which force is applied periodically, which is said to be about 80% of the time.

If fatigue testing is not used to make the correct assessment, serious accidents may result. For example, the 2007 "ExpoLand roller coaster rollover accident" is said to have been caused by destruction due to axle fatigue.

To prevent such a situation, it is important to conduct fatigue testing appropriate for the material and uses of the product, and to calculate the upper limit of stress (allowable stress) that can be used for the material.

*Including some distributors, etc.

Sort by Features

Sort by Area

Curtiss-Wright Corporation, founded in Davidson, North Carolina, in 1929 is a manufacturer of components for actuators, aircraft controls, valves, and surface-treatment services. The company's product portfolio includes aircraft components, including structural parts, engine components, landing gear components, and hydraulic systems, navigation systems, communication equipment, flight control systems, and cockpit displays. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. The company also offers customer services that include support, custom research projects and customized services.

Cambridge Materials Testing Limited, established in 1985 and based in Ontario, Canada, is a manufacturer of laboratory testing products. The company has ISO 17025 certification from A2LA as an independent testing laboratory and also accredited by Nadcap for material testing. The products are used in aerospace, automation, packaging, plastics, and also consumer products and toys. The company is specialised in producing tools for mar and abrasion testing, fade and colour testing, indoor air quality testing, and mould testing. The company’s accredited facilities are audited and approved in accordance with ASME Section III, Subsection NCA 3800, by the industry's suppliers.

FORCE Technology, in Brøndby, Denmark, in 2005 is a technology consultancy and service company that help companies with their technological transformation. The company provides services such as electronic product compliance and testing to ensure the reliability of the product and compliance with regulations, Calibration of meters and measuring instruments, integrity management, Hydrodynamic test for vessels and Aerodynamic services related to the operation of aircraft and planning of related facilities. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and IT.

Clark Testing is an independent, third-party testing and certification laboratory that is headquartered in Jefferson Hills, Pennsylvania and was established in 1992. The company offers a wide range of testing services, including environmental testing, electrical testing, mechanical testing, and materials testing. Clark Testing offers services such as analytical chemistry, coal and coke, corrosion, condition monitoring services, dynamometer testing, and electromagnetic compatibility (EMC). The company's customers include actuator testing, aerospace, amusement park, automotive and battery industries. Clark acquired Power and Propulsion Laboratory and is now simulating field operating conditions for light rail vehicles and people movers.

Element is a global supplier of materials testing and certification services headquartered in the US since 1827. They offer testing and inspection solutions worldwide, including tensile testing machines, impact testers, hardness testers, SEM, XRF analyzers, and environmental chambers, used to evaluate materials like metals, polymers, and composites in various sectors. including academic institutions, research labs, and industries. With a rich history spanning over a century, Element excels in precision instruments for scientific and engineering applications.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | NTS |

33.3%

|

| 2 | Clark Testing |

16.7%

|

| 3 | TÜV Rheinland |

16.7%

|

| 4 | Curtiss-Wright. IMR Test Labs |

11.1%

|

| 5 | Innovative Test Solutions, Inc. |

5.6%

|

| 6 | FORCE Technology |

5.6%

|

| 7 | Japan Testing Laboratories Co., Ltd. |

5.6%

|

| 8 | Shimadzu Seisakusho Co., Ltd. |

5.6%

|

Derivation Method

The ranking is calculated based on the click share within the fatigue testing service page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

3 | 27.3% |

Japan

Japan

|

2 | 18.2% |

Canada

Canada

|

1 | 9.1% |

Germany

Germany

|

1 | 9.1% |

Denmark

Denmark

|

1 | 9.1% |

Ireland

Ireland

|

1 | 9.1% |

Austria

Austria

|

1 | 9.1% |

United Kingdom

United Kingdom

|

1 | 9.1% |