All Categories

History

This section provides an overview for one-touch clamps as well as their applications and principles. Also, please take a look at the list of 6 one-touch clamp manufacturers and their company rankings. Here are the top-ranked one-touch clamp companies as of July, 2025: 1.IMAO Fixtureworks, 2.Imao, 3.Kouei Japan Trading Co., Ltd..

Table of Contents

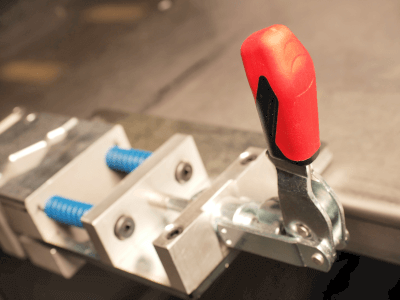

A one-touch clamp is a type of tool-less clamp that can be easily engaged and disengaged by operating a lever. This design not only reduces the time required for clamping but also eliminates the need for tools such as wrenches, thereby improving productivity and workability.

A one-touch clamp is a type of tool-less clamp that can be easily engaged and disengaged by operating a lever. This design not only reduces the time required for clamping but also eliminates the need for tools such as wrenches, thereby improving productivity and workability.

Compared to automated hydraulic or pneumatic clamps, one-touch clamps significantly reduce production costs and the burden of daily maintenance, such as addressing oil leaks.

One-touch clamps are commonly used in situations requiring frequent changes or securing of workpieces. They are particularly useful for clamping workpieces during machining processes or holding them steady with one hand. This is essential for operations in machining centers where the workpiece must be firmly held in place or pressed against a positioning pin for precise alignment. They are also advantageous in tight spaces where tool access is difficult.

These clamps allow workpieces to be secured easily and consistently with a simple lever rotation, eliminating the need for tools. The design enables the operator to hold the workpiece with one hand while securing it with the other, ensuring stability. Repeated engagement and release, even with considerable force, do not pose a risk of tampering or damage.

Variations include downward push type for top-down clamping, sideways push type for lateral hold, retract type for downward pulling, and push type for extending the shaft. Options are available in lever rotation direction, clamping direction, and force. Levers with torque adjustment are also available to minimize variation in clamping force by different operators and ensure consistent force application.

The clamping force required is considerably less than that of hydraulic or pneumatic clamps, making it suitable for confined spaces. One-touch clamps strike an optimal balance between workability and cost, positioning themselves between tool-operated and automated solutions.

*Including some distributors, etc.

Sort by Features

Sort by Area

IMAO Fixtureworks (IFW) is an American distributor of fixturing and machine components that was established in 2011 as a subsidiary of IMAO Corporation. Based in Fraser, Michigan, the company's product inventory includes standard machine elements and fixturing components such as knobs and grips, quick-release clamps, mechanical linear actuators, and pneumatic assisted work supports. IFW products are utilized by clients in industrial manufacturing, as well as for inspection, assembly, and machining applications. The company also offers custom solutions, technical support, and CAD model downloads via the company website.

Steel-Smith was founded in 1970 and is headquartered in Maharashtra, India, as a manufacturer and exporter of a wide range of toggle clamps and other industrial accessories. The design process at Steel-Smith entails converting a given requirement into a product that effectively fulfills such requirements. The company is driven by a singular dominant force that encompasses the entire process, from conceptualization to execution and from drawing to production. The company consistently introduces novel and inventive items while making ongoing enhancements to old offerings and providing clients with timely post-sales support.

Tsukatani Hamono Mfg. Co., Ltd., established in 1960, and based in Yao City, Osaka, Japan, is a manufacturer of industrial specialty blades. It offers a range of cutting tools that meet the specifications of printing machine manufacturers such as tools used to make perforations and punched holes in continuous business forms. Among its offerings are the flexible pinnacle die for cutting and stamping materials, punch parts for pouch used in perforating printed forms, and steel cutting rules for stamping out cardboards and paper packages.

Kouei Japan Trading Co. LTD., founded in 2016 and based in Tokyo, Japan, is a supplier of a wide range of steel materials, tools, and equipment. Its product range includes hand, lifting, hydraulic, safety, and cutting tools. It has branches in Vietnam, Myanmar, and Bangladesh, and it sources products from several manufacturers, including Tachibana Eletech Co. Ltd, Fuji Tool Co. Ltd., Skil Corporation, 3M Japan Group, and Koki Holdings Co. Ltd. The company mainly serves those in the construction industries like bridge, port, and plant construction, and even those working in steel factories.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | IMAO Fixtureworks |

30.2%

|

| 2 | Imao |

27.9%

|

| 3 | Kouei Japan Trading Co., Ltd. |

16.3%

|

| 4 | Steel-Smith |

11.6%

|

| 5 | Tsukatani Hamono Mfg. Co., Ltd. |

9.3%

|

| 6 | Consus Co., Ltd. |

4.7%

|

Derivation Method

The ranking is calculated based on the click share within the one-touch clamp page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

4 | 66.7% |

United States of America

United States of America

|

1 | 16.7% |

India

India

|

1 | 16.7% |

296 products found

296 products

Osaka Kakuda Kogyo Co., Ltd.

1260+ people viewing

Last viewed: 5 hours ago

■ Use ・ Temporary pushing of welding jig is the most popular way. It is also used for various processing and assembled jigs. ・ It is also used as...

10 models listed

Consus Co., Ltd.

280+ people viewing

Last viewed: 1 day ago

■Features - Clamp installation time is significantly shortened and work efficiency is increased. ・Compared to the screw-tight type, there is no ga...

Osaka Kakuda Kogyo Co., Ltd.

1040+ people viewing

Last viewed: 1 day ago

■ Use ・ Temporary pushing of welding jig is the most popular way. It is also used for various processing and assembled jigs. ・ It is also used as...

10 models listed

Miki Neturen Co., Ltd.

920+ people viewing

Last viewed: 9 hours ago

■Features 1. The structure is designed to engage with stronger force as the lifting load increases. 2. The cam can be closed or locked in the open ...

10 models listed

Osaka Kakuda Kogyo Co., Ltd.

810+ people viewing

■ Use ・ Temporary pushing of welding jig is the most popular way. It is also used for various processing and assembled jigs. ・ It is also used as...

4 models listed

Osaka Kakuda Kogyo Co., Ltd.

440+ people viewing

■ Use ・ Temporary pushing of welding jig is the most popular way. It is also used for various processing and assembled jigs. ・ It is also used as...

Miki Neturen Co., Ltd.

710+ people viewing

Last viewed: 15 hours ago

■Features 1. Clamps can be selected according to the thickness of the suspended object. 2. The structure is designed to engage with stronger force ...

7 models listed

Kanu Industries Co., Ltd.

240+ people viewing

Last viewed: 3 hours ago

■Push straight down with one action In conventional downward presser type toggle clamps, the presser arm moves in an arc, so the pressing direction...

Osaka Kakuda Kogyo Co., Ltd.

1040+ people viewing

Last viewed: 1 day ago

■ Use ・ Temporary pushing of welding jig is the most popular way. It is also used for various processing and assembled jigs. ・ It is also used as...

9 models listed

Tiuia Society Co., Ltd.

480+ people viewing

Last viewed: 22 hours ago

One -touch clamp with tools ・ Toolless ・ Easy clamp by lever operation ・ Speed up the setup for exchanges (lower type) ・ Die (lower type) de...

2 models listed

Osaka Kakuda Kogyo Co., Ltd.

850+ people viewing

Last viewed: 18 hours ago

■ Use ・ Temporary pushing of welding jig is the most popular way. It is also used for various processing and assembled jigs. ・ It is also used as...

7 models listed

Osaka Kakuda Kogyo Co., Ltd.

620+ people viewing

■ Characteristics ・ It is a type of clamp that you can use by welding in the angle and position you want by the customer. Bali clamps can determin...

3 models listed

Osaka Kakuda Kogyo Co., Ltd.

900+ people viewing

Last viewed: 5 hours ago

■ Characteristics ・ It is a type of clamp that you can use by welding in the angle and position you want by the customer. Bali clamps can determin...

9 models listed

Osaka Kakuda Kogyo Co., Ltd.

750+ people viewing

Last viewed: 13 hours ago

■ Characteristics ・ U -type and hook -type bars are hooked and clamped. ・ Especially adopted as mechanical parts and device parts. ・ The hook -t...

7 models listed

Osaka Kakuda Kogyo Co., Ltd.

740+ people viewing

■ Characteristics ・ It is a type of clamp that you can use by welding in the angle and position you want by the customer. Bali clamps can determin...

8 models listed

Osaka Kakuda Kogyo Co., Ltd.

760+ people viewing

■ Characteristics ・ It is a type of clamp that you can use by welding in the angle and position you want by the customer. Bali clamps can determin...

7 models listed

Osaka Kakuda Kogyo Co., Ltd.

550+ people viewing

Last viewed: 1 day ago

■ Characteristics ・ For fixing panels that are frequently replaced. ・ It is adopted as a pressed device and jigs using the great power in the occ...

3 models listed

Osaka Kakuda Kogyo Co., Ltd.

1050+ people viewing

Last viewed: 1 day ago

■ Characteristics ・ It is a type of clamp that you can use by welding in the angle and position you want by the customer. Bali clamps can determin...

10 models listed

Osaka Kakuda Kogyo Co., Ltd.

650+ people viewing

Last viewed: 1 day ago

■ Characteristics ・ For fixing panels that are frequently replaced. ・ It is adopted as a pressed device and jigs using the great power in the occ...

3 models listed

Osaka Kakuda Kogyo Co., Ltd.

1110+ people viewing

Last viewed: 18 hours ago

■ Characteristics ・ It is a type of clamp that you can use by welding in the angle and position you want by the customer. Bali clamps can determin...

9 models listed

Osaka Kakuda Kogyo Co., Ltd.

1280+ people viewing

Last viewed: 1 hour ago

■ Characteristics ・ It is a type of clamp that you can use by welding in the angle and position you want by the customer. Bali clamps can determin...

9 models listed

Osaka Kakuda Kogyo Co., Ltd.

660+ people viewing

Last viewed: 1 day ago

■ Characteristics ・ It is a type of clamp that you can use by welding in the angle and position you want by the customer. Bali clamps can determin...

3 models listed

Osaka Kakuda Kogyo Co., Ltd.

740+ people viewing

■ Characteristics ・ It is a type of clamp that you can use by welding in the angle and position you want by the customer. Bali clamps can determin...

8 models listed

Osaka Kakuda Kogyo Co., Ltd.

820+ people viewing

■ Characteristics ・ It is a type of clamp that you can use by welding in the angle and position you want by the customer. Bali clamps can determin...

5 models listed

Osaka Kakuda Kogyo Co., Ltd.

640+ people viewing

Last viewed: 1 day ago

■ Characteristics ・ For fixing panels that are frequently replaced. ・ It is adopted as a pressed device and jigs using the great power in the occ...

5 models listed

Osaka Kakuda Kogyo Co., Ltd.

980+ people viewing

Last viewed: 1 day ago

■ Characteristics ・ For fixing panels that are frequently replaced. ・ It is adopted as a pressed device and jigs using the great power in the occ...

10 models listed

Osaka Kakuda Kogyo Co., Ltd.

1050+ people viewing

Last viewed: 1 day ago

■ Characteristics ・ For fixing panels that are frequently replaced. ・ It is adopted as a pressed device and jigs using the great power in the occ...

9 models listed

Osaka Kakuda Kogyo Co., Ltd.

960+ people viewing

Last viewed: 8 hours ago

■ Characteristics ・ For fixing panels that are frequently replaced. ・ It is adopted as a pressed device and jigs using the great power in the occ...

8 models listed

Osaka Kakuda Kogyo Co., Ltd.

790+ people viewing

Last viewed: 3 hours ago

■ Characteristics ・ For fixing panels that are frequently replaced. ・ It is adopted as a pressed device and jigs using the great power in the occ...

6 models listed

Osaka Kakuda Kogyo Co., Ltd.

440+ people viewing

Last viewed: 12 hours ago

■ Characteristics ・ It is a type of clamp that you can use by welding in the angle and position you want by the customer. Bali clamps can determin...