All Categories

History

This section provides an overview for polyphenylene sulfide (pps) resins as well as their applications and principles. Also, please take a look at the list of 10 polyphenylene sulfide (pps) resin manufacturers and their company rankings. Here are the top-ranked polyphenylene sulfide (pps) resin companies as of March, 2026: 1.Prochase Enterprise Co., Ltd., 2.CS Hyde Company, 3.Poly Fluoro Ltd..

Table of Contents

Categories Related to Polyphenylene Sulfide (PPS) Resins

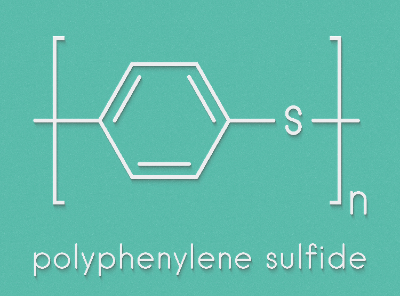

Polyphenylene sulfide (PPS) resin is a thermoplastic resin characterized by a structure of alternating benzene and sulfur bonds. It is esteemed as a super engineering plastic due to its outstanding properties. The mechanical strength and other characteristics of PPS can be modified with different fillers, leading to its widespread use as a reinforced resin, typically with about 30% glass fiber composites.

Its growing popularity across various industries stems from its well-balanced properties, including excellent moldability, processability, heat resistance, mechanical strength, dimensional stability, flame resistance, and chemical resistance.

PPS resin, a super engineering plastic, is utilized in automotive parts, electronic parts, and medical equipment parts, among other high-performance applications. Notably, nearly half of the PPS resin market is dedicated to automotive parts.

As hybrid vehicles increasingly employ PPS resin components, its demand is expected to rise. In non-automotive sectors, PPS is essential for electronic components like IC chips, due to its superior dimensional stability and insulation properties. Its excellent heat and flame resistance makes it ideal for filter manufacturing as well.

PPS resin is typically produced by a polycondensation reaction of paradichlorobenzene and sodium sulfide in a polar solvent, under high temperature and pressure. The polymerization process involves dehydration and dephosphorization reactions. Cross-linking in the resulting polymer greatly influences its properties, making the distinction between cross-linked and linear PPS resin critical for various applications.

Crosslinked PPS resin, formed by heat treatment in an oxygen atmosphere during synthesis, allows molecular weight control by incorporating oxygen into the polymer chain. This results in a cross-linked structure with high rigidity and creep deformation resistance, even in high-temperature environments.

Linear-chain PPS resin retains its linear structure without undergoing special heat treatment. This type of PPS has lower rigidity but improved toughness and elongation compared to cross-linked PPS. It allows for high-purity synthesis and achieves superior moisture absorption resistance, electrical insulation, and dimensional stability.

Unreinforced PPS consists purely of PPS resin without additional reinforcing materials like glass or carbon fiber. It's widely used across various industries thanks to its impressive properties, especially its remarkable heat resistance. Unreinforced PPS maintains stable performance even under high temperatures, making it suitable for high-temperature industrial applications such as engine parts, exhaust system components, and boiler parts.

Reinforced PPS resin, created by adding materials like glass or carbon fiber to PPS, offers enhanced strength and rigidity. It's ideal for components needing impact resistance. In the automotive sector, it's used for engine parts, exterior parts, and suspension components, where durability and rigidity are paramount. Its excellent performance under severe conditions like high temperatures, vibration, and friction makes it especially valuable.

This type of PPS resin, known for high electrical insulation, is crucial in the electrical and electronics fields. It's used in printed circuit boards, connectors, terminal blocks, motor parts, transistors, and IC packages. Suitable for high-temperature operations, it maintains stable electrical properties under such conditions and offers excellent chemical resistance.

Alloy-reinforced PPS is a blend of PPS with other materials to enhance specific properties, making it suitable for applications that require lubricity and wear resistance. By incorporating elements like graphite and mineral fillers, this variant improves friction and wear resistance. It's particularly effective in automotive and mechanical parts that endure high friction and temperatures.

*Including some distributors, etc.

Sort by Features

Sort by Area

RTP Company (RTPC) is an American private manufacturer of custom thermoplastic compounds that was established in Winona, Minnesota in 1982. The company produces various compounds for industrial applications, including conductive, anti-static, flame retardant, and high temperature resistant formulations. It also offers friction resistant and TPE compounds, as well as color solution compounds with metallic or glow-in-the-dark features. RTPC products are used in intensive industrial processes, such as structural reinforcement, chemical resistance treatment, and thermal stabilization. Its notable clients include Lockheed Martin, NASA, and Becton Dickinson.

CS Hyde, Company was founded in 1996 and is headquartered in Lake Villa, Illinois. The company is a manufacturer of high-end materials including adhesives, films, and rubber for customers from numerous industries including automotive, electronics, and large batteries. The company’s main products include pressure-sensitive tapes, silicone rubber sheets, threading, and 3D printing surface materials. The company also provides numerous services such as slitting, die and dieless cutting, sheeting, and belting. Other services include material conversion such as applying adhesives to films.

APSX LLC, established in 2006 and headquartered in Blue Ash, Ohio, is a manufacturer of advanced production solutions. The company mainly specializes in producing plastic injection machines, CNC machines, molds, machine parts, and motor control accessories, in which their products are employed in the low-volume production of plastic and metal parts as well as in prototype and testing processes. APSX's offerings enable efficient manufacturing processes, quality end products, and improved automation capabilities.

Prochase Enterprise Co., Ltd., founded in 1992 in Taichung City, Taiwan, is a manufacturer of various engineered plastics and protective films. The company specializes in temperature resistant & optimal performance engineering plastic resins, thermoplastic elastomer (TPE) compounds, and coated PET films. It boasts ISO 9001 and ISO 14001 certifications for optimal quality standards and the products offer robust heat resistance, mechanical properties, and adaptability, making them ideal for various applications across industries such as automotive, electronics, packaging, and construction. The engineering plastic resins and TPE compounds enhance product performance, while the coated PET films serve in packaging and printing applications.

Poly Fluoro Ltd., established in 1985 and headquartered in Bangalore, India, is a manufacturer of precision machined polymer components. The company specializes in producing a broad range of optimal-quality products, including PTFE (Teflon) tubes, expanded PTFE (ePTFE) joint sealants, lubricating slideways (Tucite B), bridge bearing pads, PTFE slide bearings, and expanded PTFE (ePTFE) membranes. It holds certifications like ISO 9001:2015 and ISO 14001:2015 for the durability and performance of its offerings. The products offer numerous advantages, such as optimal chemical resistance, low friction properties, and robust durability. The products find applications across industries like chemical processing, automotive, construction, and pharmaceuticals.

DIC, established in 1908 in Japan, is a manufacturer and supplier of printing inks, organic pigments, and PPS compounds. The company's product portfolio includes different printing inks, such as offset inks used for quality printing, gravure inks for packaging materials, and UV-curable inks for various applications. They also offer organic pigments used in automotive coatings, and PPS compounds, used in electronic and automotive components. DIC's products are used in industries like automotive, electronics, food, and housing. They provide quality products and services that meet societal needs while addressing local and global challenges.

KUREHA AMERICA, INC., founded in 1976 and based in New York, USA, is a manufacturer of specialty products for industrial uses. The company specializes in manufacturing a broad array of products, including specialty chemicals, resins, piezoelectric and pyroelectric films, and advanced materials. It holds certifications such as ISO 9001 and ISO 14001 for the durability and consistency of its product offerings. The products are used for robust properties such as optimal heat resistance, chemical stability, and electrical insulation. These qualities make its products ideal for various industries, including automotive, electronics, packaging, and medical devices.

Vaisala, established in 1936 in Finland, is a technology company that is a manufacturer of electronic measurement systems and equipment for meteorology, environmental sciences, traffic safety, and industry worldwide. The Company's products include radiosondes, barometric pressure measurements, weather stations, lighting detection systems, and moisture measurement solutions. Vaisala also sells a large selection of its products directly to consumers via the company's online store. The company also provides commercial clients with the XWeather subscription service, which offers numerous options for industrial-grade environmental measurement.

ChemPoint, established in 1999 and a subsidiary of Univar Solutions Inc., is a fine and specialty chemical distributor headquartered in Bellevue, Washington. The company runs ChemPoint, a personalized e-distribution platform that enables the marketing and sales of specialty and fine chemicals in North America, Europe, the Middle East, and Africa. The platform features MarketConnect, a web-based tool that offers market transparency to customers and allows producers to review sales processes. ChemPoint offers a diverse range of specialty chemical products, including adhesives, lubricating fluids, polymers, sealants, and thermoplastics.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Prochase Enterprise Co., Ltd. |

17.3%

|

| 2 | CS Hyde Company |

13.4%

|

| 3 | Poly Fluoro Ltd. |

11.8%

|

| 4 | ChemPoint |

9.4%

|

| 5 | APSX LLC. |

9.4%

|

| 6 | Vaisala Oyj |

9.1%

|

| 7 | RTP Company |

8.3%

|

| 8 | KUREHA AMERICA, INC. |

7.9%

|

| 9 | Merchant Research & Consulting, Ltd. |

7.1%

|

| 10 | DIC CORPORATION |

6.3%

|

Derivation Method

The ranking is calculated based on the click share within the polyphenylene sulfide (pps) resin page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

3 | 42.9% |

Taiwan

Taiwan

|

1 | 14.3% |

India

India

|

1 | 14.3% |

Japan

Japan

|

1 | 14.3% |

United Kingdom

United Kingdom

|

1 | 14.3% |

108 products found

108 products

Takahashi Kasei Ltd.

390+ people viewing

Last viewed: 13 hours ago

Hotty Polymer Co., Ltd.

600+ people viewing

Last viewed: 11 hours ago

■ Overview This is a MEX (material extraction layer system) 3D printer made of PPS (polyphenylEK Faid) resin with excellent cost, chemical resistan...

TAKAI SEIKI CO., LTD

640+ people viewing

Last viewed: 14 hours ago

■Cage (retainer) The cage is built into the gap between the inner and outer rings, and its role is to keep the balls at the same distance to preven...

Kotec

800+ people viewing

Last viewed: 12 hours ago

"KOTEX" has been established in various fields as a high -quality recycled recycled carbonate resin brand. We offer a wide variety of grades to sup...

Plus Seiko Co., Ltd.

520+ people viewing

Last viewed: 12 hours ago

PPS resin: Resin with excellent heat resistance, chemical resistance, and dimensional stability Polyphenylene sulfide (PPS) is a thermoplastic res...

Ensinger

530+ people viewing

Last viewed: 11 hours ago

■Summary A sliding PPS material containing 10% each of PTFE, carbon fiber, and graphite. It is ideal as a high-performance bearing due to its wide ...

KB Seiren Co., Ltd.

480+ people viewing

Last viewed: 1 day ago

■Polyphenylene sulfide fiber with excellent heat resistance KB Seiren Co., Ltd. has developed Gladio®, a polyphenylene sulfide fiber with excellent...

Tokiwa Co., Ltd.

240+ people viewing

Last viewed: 11 hours ago

This material has excellent heat resistance, chemical resistance, mechanical strength, rigidity, flame retardancy, and dimensional stability.

5 models listed

TAKAI SEIKI CO., LTD

590+ people viewing

Last viewed: 10 hours ago

■Cage (retainer) The cage is built into the gap between the inner and outer rings, and its role is to keep the balls at the same distance to preven...

Hirose Paper Co., Ltd.

770+ people viewing

Last viewed: 11 hours ago

This is the world's first wet non -woven fabric made of 100 % PPS fiber (polyphenylene salons). PPS fibers are crystalline high -functional heat -p...

Azumaneji Co., Ltd.

930+ people viewing

Last viewed: 11 hours ago

■Screw with hexalobular hole A hexalobular hole is a star-shaped hexagonal recess developed by Textron in the United States in 1971, and is also ca...

Takahashi Kasei Ltd.

230+ people viewing

Last viewed: 1 day ago

A product using super engineering plastic PPS resin (polyphenylene sulfide) that has strong strength and can withstand high temperatures of 220℃. ...

10 models listed

Ensinger

480+ people viewing

Last viewed: 11 hours ago

■Summary PPS (polyphenylene sulfide) material. It has high mechanical strength and rigidity even at temperatures exceeding 200℃. It also has excell...

Wilco Co., Ltd.

380+ people viewing

Last viewed: 15 hours ago

■Features - Mainly used when stacking electronic boards and fixing them. We offer a lineup of PEEK, PPS, and integrally molded products with metal ...

10 models listed

Takahashi Kasei Ltd.

280+ people viewing

Last viewed: 10 minutes ago

A product using super engineering plastic PPS resin (polyphenylene sulfide) that has strong strength and can withstand high temperatures of 220℃. ...

10 models listed

TAKAI SEIKI CO., LTD

530+ people viewing

Last viewed: 14 hours ago

■Cage (retainer) The cage is built into the gap between the inner and outer rings, and its role is to keep the balls at the same distance to preven...

Ensinger

480+ people viewing

Last viewed: 11 hours ago

■Summary Compression molded sliding PPS material containing 15% carbon fiber, 10% graphite, and 10% PTFE. Compared to extruded materials, it has lo...

Engineer

240+ people viewing

Last viewed: 11 hours ago

■ Features -Sideline countermeasures that are suitable for handling delicate electronic components on static electricity. ・ Control static electric...

5 models listed

Nitto El Material Co., Ltd.

430+ people viewing

Last viewed: 1 day ago

The PPS (polyphenylene salfide) adhesive tape No.320A is a tape based on PPS film with excellent heat resistance. It is used for the application of...

2 models listed

TAKAI SEIKI CO., LTD

580+ people viewing

Last viewed: 14 hours ago

■Cage (retainer) The cage is built into the gap between the inner and outer rings, and its role is to keep the balls at the same distance to preven...

Ensinger

410+ people viewing

Last viewed: 3 hours ago

■Summary Compression molded reinforced PPS material containing 40% glass fiber. Compared to extruded materials, it has lower internal stress and su...

TAKAI SEIKI CO., LTD

550+ people viewing

Last viewed: 7 hours ago

■Cage (retainer) The cage is built into the gap between the inner and outer rings, and its role is to keep the balls at the same distance to preven...

Ensinger

570+ people viewing

Last viewed: 11 hours ago

■Summary PPS material containing 40% glass fiber. Reinforced with glass fiber for high stiffness and creep strength. It also has excellent heat res...

TAKAI SEIKI CO., LTD

450+ people viewing

Last viewed: 14 hours ago

■Cage (retainer) The cage is built into the gap between the inner and outer rings, and its role is to keep the balls at the same distance to preven...

Ensinger

520+ people viewing

Last viewed: 7 hours ago

■Summary Black PPS material containing 40% glass fiber. Reinforced with glass fiber for high stiffness and creep strength. It also has excellent he...

TAKAI SEIKI CO., LTD

480+ people viewing

Last viewed: 5 hours ago

■Cage (retainer) The cage is built into the gap between the inner and outer rings, and its role is to keep the balls at the same distance to preven...

TAKAI SEIKI CO., LTD

530+ people viewing

Last viewed: 14 hours ago

■Cage (retainer) The cage is built into the gap between the inner and outer rings, and its role is to keep the balls at the same distance to preven...

TAKAI SEIKI CO., LTD

590+ people viewing

Last viewed: 14 hours ago

■Cage (retainer) The cage is built into the gap between the inner and outer rings, and its role is to keep the balls at the same distance to preven...

TAKAI SEIKI CO., LTD

480+ people viewing

Last viewed: 11 hours ago

■Material ・PP ・ETFE ・PPS Minimum order lot: 10 pieces

Takeuchi Industries Co., Ltd.

190+ people viewing

Last viewed: 11 hours ago

■Features - PPS is used as the material and has not only wear resistance but also chemical resistance and high heat resistance. -Since it expands t...

6 models listed