All Categories

History

This section provides an overview for conductive mats as well as their applications and principles. Also, please take a look at the list of 11 conductive mat manufacturers and their company rankings. Here are the top-ranked conductive mat companies as of February, 2026: 1.Mats, Inc., 2.Kinetic Polymers, 3.Prouction Automation Corporation.

Table of Contents

Categories Related to Conductive Mats

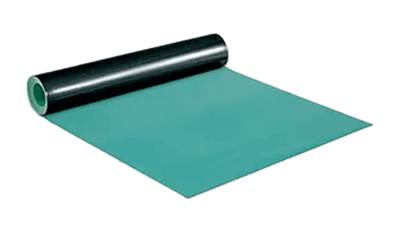

Conductive mats are used to discharge static electricity gradually that has been charged on the human body.

They are often laid on the floor and used in workshops, factories, laboratories, and clean rooms. In some cases, durability and abrasion resistance are required, and regular maintenance is necessary.

Conductive mats are made of conductive materials and are used to discharge static electricity, seal electromagnetic waves, and prevent damage to equipment caused by static electricity.

Conductive mats are placed on floors to reduce the risk of static electricity generation and discharge. They are especially used in workshops, factories, and clean rooms to facilitate the discharge of static electricity from people and equipment.

Conductive mats are placed around electronic and precision equipment to block the entry of electromagnetic waves from the outside. This protects the proper operation of the equipment and reduces electromagnetic interference (EMI) problems.

Conductive mats may be used in potentially explosive environments. In areas where explosive gases or vapors are present, the generation and discharge of static electricity must be suppressed. Conductive mats can reduce the risk of ignition due to electrical discharge.

Conductive mats, when connected to the ground or grounding system, provide a safe grounding condition for people and equipment. Secure grounding improves safety by reducing the risk of electric shock and equipment failure.

Conductive mats may also be used in certain environments, such as laboratories and clean rooms. In environments where static control and electromagnetic shielding are important factors, conductive mats can be expected to play a part.

Conductive mats promote the discharge of static electricity by means of conductive materials. The following is a brief description of the principle of conductive mats.

Conductive mats are typically made of conductive materials. These materials include conductive fibers, conductive rubbers, and conductive polymers. The resistivity of these materials is generally around 10-6 Ωm to 10-4 Ωm, which is one to three orders of magnitude greater than that of iron.

Since a small resistance value is dangerous due to the large electric current that flows when static electricity is discharged, we dare to use materials with a larger resistance value. Conductive mats have conductive materials woven into their surfaces and interiors, and electric charges and currents flow to ground through these materials.

Conductive mats serve to facilitate the discharge of static electricity from charged objects. Static electricity builds up (is charged) on objects and the human body, but is quickly discharged when it comes into contact with the conductive material woven into the conductive mat.

Conductive mats are effective when connected to the ground or the grounding system. Static electricity (charge) on a person or object flows to the ground through the ground wire the moment it touches the conductive mat.

As described above, the effect of conductive mats is due to the conductive material's ability to conduct electricity and discharge static electricity. This allows the mats to achieve their intended purposes, such as static electricity suppression, safety improvement, and electromagnetic shielding.

There are several types of conductive mats available, but the following factors should be considered in selecting the appropriate conductive mat

Conductive materials used for conductive mats vary widely, with conductive fibers, conductive rubbers, and conductive polymers being the most common. Depending on the application and requirements, the properties of the material (durability, antimicrobial properties, heat resistance, etc.) should be taken into consideration when selecting the appropriate material.

The electrical performance of conductive mats is also important. The resistivity of the material should be checked and its ability to discharge static electricity and grounding should be considered.

Conductive mats come in a variety of sizes and shapes, and the appropriate size should be selected to suit the work space and installation location. There are also types that can be cut on site and can be processed into appropriate shapes to suit the installation environment.

The durability of conductive mats is also important. If abrasion or chemical resistance is required, a mat with corresponding durability should be selected. It is also important to select mats that can be easily cleaned and regularly inspected based on ease of maintenance.

Certain industries and environments may have specific standards or regulatory requirements for conductive mats (e.g., regulations, fire codes, etc.). Please review applicable standards and requirements and select mats that comply with them.

*Including some distributors, etc.

Sort by Features

Sort by Area

Mats, Inc., established in 1971 and headquartered in Stoughton, Massachusetts, USA, is a manufacturer of various flooring products. The company specializes in manufacturing a diverse range of advanced products, including commercial floor mats, modular carpet tiles, and entrance matting systems. These products are designed to enhance safety, comfort, and aesthetics in various indoor and outdoor spaces. It caters to a wide array of industries, including hospitality, healthcare, education, and commercial real estate, providing flooring solutions that improve the overall environment and functionality of spaces while allowing environmental responsibility and product durability.

Durable Corporation, founded in 1923 and based in Norwalk, United States of America, is a manufacturer of loading dock bumpers, industrial & material handling mats, anti-fatigue mats, and flooring. The company provides molded dock bumpers and wall and corner guards. It also offers anti-fatigue mats, anti-static/conductive mats, and metal wheel chocks. Dock bumpers are used to provide protection by absorbing impact damage. Mats’ function is to increase comfort underfoot and reduce slip accidents. These products are capable of meeting the specific needs of a diverse customer base.

Production Automation Corporation (PAC), located in Minnetonka, MN, USA, is a full-service stocking distributor and manufacturer’s representative, established in 1973. The company supports technical products that solve manufacturing problems, is a distributor of products, tools, and furniture for the electronics, medical device manufacturing, lab, and healthcare industries. Customers turn to it when they need expertise on product selection, require help sourcing an alternate/unavailable product, or when an existing supplier becomes difficult to work with. It helps the customer business grow, which means it is continually adding new product lines and brands by popular demand.

HOZAN TOOL INDUSTRIAL CO., LTD., established in 1946 in Naniwa-ku, Osaka, Japan, is a manufacturer and supplier of electronics and bicycle tools. Their product range includes soldering irons for electronics assembly, various types of multimeters for electrical measurements, pliers for wire manipulation, diverse screwdrivers for fastening tasks, and wire strippers for precise wire preparation. Additionally, they also offer chemical products such as anti-rust oils, freezer sprays, cutting oil, and dusters.

Dou Yee Enterprises, in operation since 1982, is a manufacturer and industrial solutions provider catering to the semiconductor, data storage, electronics, and biomedical sectors. It offers a wide array of products, including cleanroom materials and equipment for electrostatic discharge control, micro contamination control solutions, static shielding bags to protect electronics, moisture barrier bags for safeguarding sensitive equipment from moisture, and desiccants. The company has over 45 strategically located international branch offices, and its manufacturing facilities in Singapore, Malaysia (Seremban), China (Suzhou), France, and Poland adhere to stringent quality standards, holding ISO 9001 and ISO 14001 certifications.

Kinetic Polymers, established in Rangareddy, Telangana, India, is a manufacturer of multiple conductive compounds and anti static products and solutions since 2000. The company offers ESD safe products like anti static, conductive products also fabricates the ESD furniture like work stations/ tables, ESD chairs, trolleys, shelves, matching stringent technical demands and customized products. It also produces conductive products for explosives, chemicals and pharma industries for fire safety. It is equipped with the latest technologies for testing and calibration of different instruments, and latest machineries and R&D infrastructure to meet certification demands from customers.

Wearwell, established in 1950 and headquartered in Smyrna, USA, is a manufacturer of ergonomic solutions. The company specializes in industrial and commercial ergonomic matting and flooring, including pharmaceutical, healthcare, and retail sectors. Its products include anti-fatigue mats, cable and hose protection, and flooring tape. Its ergodeck features a secure interlocking system for creating customizable, ergonomic flooring solutions in industrial settings, while its grit shield offers a high-traction surface for oily environments. The company also provides ROI calculator, site survey, and sketchbook tools to optimize ergonomic solutions. Its products are used in automotive manufacturing, hospitality, and food processing industries.

RAVASCO TRANSMISSION AND PACKING PRIVATE LIMITED, established in 1991 and headquartered in Mumbai, Maharashtra, India is a manufacturer, supplier, and exporter of industrial rubber products The company’s production line involves the manufacturing of various products including rubber sheets, EPDM roofing membranes, rubber transmission belts, industrial rubber roofing, and vulcanized rubber sold under the Indus brand. The products are widely used in the construction field, semiconductor, computer & electronic parts factories, agricultural field, and electronic industries. The products undergo a manufacturing process involving a number of steps, including compounding, molding, calendering and finishing.

UNIQUE SAFETY SERVICES was started in 2014 and is based in Maharashtra, India, and is a manufacturer and supplier of Fire Safety equipment and personal protective equipment, under the Brand Name U-Safe for various safety applications. The company's product line consists of portable gas detectors, oil & chemical spill kits, safety showers, Eyewash Stations, and, Bright Star flameproof Torches that are crucial in Iron and Steel, Construction, Petrochemicals, Fabrication, and, Power Plants. The company also offers emergency protection equipment such as Pilot Ladders, Fire Fighter Boots, and, Fire Blankets for Paper & glass manufacturing, mining, and, medical sectors.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Mats, Inc. |

25.0%

|

| 2 | Kinetic Polymers |

25.0%

|

| 3 | Prouction Automation Corporation |

25.0%

|

| 4 | HOZAN TOOL INDUSTRIAL CO., LTD. |

25.0%

|

Derivation Method

The ranking is calculated based on the click share within the conductive mat page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

4 | 44.4% |

India

India

|

3 | 33.3% |

Japan

Japan

|

1 | 11.1% |

Singapore

Singapore

|

1 | 11.1% |

50 products found

50 products

Yagyu Shokai Co., Ltd.

540+ people viewing

Last viewed: 1 day ago

■Summary - Convenient as a countermeasure against static electricity when using a computer or in a small space. - Prevents dust from adhering to co...

Yagyu Shokai Co., Ltd.

460+ people viewing

Last viewed: 1 day ago

■Summary ・The mat surface has been treated with an anti-slip coating. ・The antistatic performance does not deteriorate easily even after washing ...

Yagyu Shokai Co., Ltd.

490+ people viewing

Last viewed: 1 day ago

■Summary - Suitable for soldering applications, and can also be used for assembly in the semiconductor field and repair of EUC circuits. - Comes wi...

Yagyu Shokai Co., Ltd.

510+ people viewing

Last viewed: 3 hours ago

■Summary ・It is resistant to heat and suitable for soldering applications, and can also be used for assembly in the semiconductor field and repair...

Yagyu Shokai Co., Ltd.

470+ people viewing

Last viewed: 1 day ago

■Summary ・There is a sloping parts storage area, which is convenient for temporary storage of small parts. - It is possible to store screwdrivers ...

Yagyu Shokai Co., Ltd.

490+ people viewing

Last viewed: 1 day ago

■Summary - Cut marks are less noticeable even after using a cutter knife. ・Since it is double-sided, it is a great value type that can be used twi...

Yagyu Shokai Co., Ltd.

460+ people viewing

Last viewed: 1 day ago

■Summary - A felt-like mat that uses acrylic organic conductive fibers and has excellent conductive performance and static electricity removal func...

Yagyu Shokai Co., Ltd.

440+ people viewing

Last viewed: 1 hour ago

■Summary ・The front side has a static electricity dissipation layer and the back side has a conductive layer to prevent problems caused by static ...

Yagyu Shokai Co., Ltd.

430+ people viewing

Last viewed: 1 day ago

■Summary -The embossed surface is a non-glare type that reflects less light.

Custom Co., Ltd.

500+ people viewing

Last viewed: 1 day ago

■ Conductive rubber flo armat ・ Surface resistance (table): 104-106 ω ・ Surface resistance (back): 104-106 ω ・ Made of synthetic rubber ・ Condu...

Engineer

360+ people viewing

Last viewed: 1 day ago

■ Features ・ A color mat for static electricity measures that protects electronic components and electronic devices that are vulnerable to static e...

4 models listed

Engineer

300+ people viewing

Last viewed: 1 day ago

■ Features ・ A4 size compact tabletop conductive mat. ・ Protects electronic components and electronic devices that are vulnerable to static electri...

2 models listed

Cowboy Co., Ltd.

330+ people viewing

Last viewed: 1 day ago

■Features ・Conductive material is used. ・Excellent cushioning reduces weight burden. - Oil and water resistant specifications. Water absorption r...

GUARDNER Corporation

320+ people viewing

Last viewed: 1 hour ago

■Features Electrostatic type undermat ・Electrical resistance value 1.0×10^9 or less ・With double-sided tape for fixing on the back side ・Materia...

GUARDNER Corporation

280+ people viewing

Last viewed: 1 day ago

■Features ・We focused on cost benefits and maintained the basic performance of conductive mats. ・Electrical resistance value: 1×10^6≦R≦1×10^8Ω (w...

GUARDNER Corporation

220+ people viewing

Last viewed: 1 day ago

■Features ・Because it is conductive, it does not attract dust ・Because it is ST treated, there is no need to worry about it sticking to the soles...

JS Cube Co., Ltd.

280+ people viewing

Last viewed: 1 day ago

◼︎Product overview - Fatigue-reducing mat with anti-static function. -Relieve foot fatigue when working while standing. - Not fluffy, perfect for o...