All Categories

History

This section provides an overview for internal grinders as well as their applications and principles. Also, please take a look at the list of 10 internal grinder manufacturers and their company rankings. Here are the top-ranked internal grinder companies as of March, 2026: 1.Aerospace Manufacturing & Design, 2.Toyo Advanced Technologies, 3.I Machine Tools Corp..

Table of Contents

Categories Related to Internal Grinders

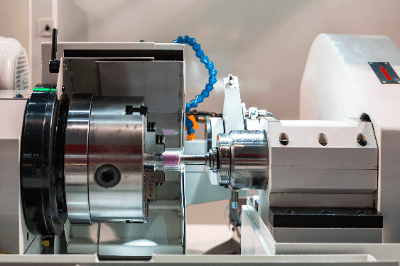

An internal grinder is a machine designed to grind the internal surfaces of primarily cylindrical workpieces.

Grinding is a machining process that utilizes grinding wheels.

Grinding wheels consist of tough abrasive grains, such as aluminum oxide and silicon carbide, bonded together with a bonding agent.

Grinding is not suitable for rough machining due to the shallow depth of cut compared to cutting processes.

However, it is highly effective for precision machining, delivering excellent dimensional accuracy and surface finish roughness.

Internal grinders employ a small-diameter internal grinding wheel attached to a spindle referred to as a wheelhead.

The workpiece is secured using an external jaw chuck or an electromagnetic chuck attached to the spindle.

Internal grinders are broadly categorized into two types based on the grinding method: rotary workpiece type and planetary type.

In the workpiece rotary type, the wheel spindle and the main axis rotate relative to each other, while the grinding wheel on the wheel spindle oscillates back and forth as it cuts into the workpiece mounted on the main axis.

The planetary grinding method is employed when the workpiece is large or challenging to balance during rotation.

While rotating the wheel spindle, the spindle itself is given a planetary motion to grind along the internal surface.

To maintain the sharpness, accuracy, and shape of the grinding wheel, dressing is necessary when changing the wheel or after each grinding cycle.

Grinding wheel dressing involves placing the rotating grinding wheel on the diamond dresser installed on the machine.

In basic workpiece-turned internal grinders, the wheel head with the grinding wheel attached has a sliding mechanism relative to the spindle, allowing the grinding wheel to enter the hole.

Internal grinders are used to grind the internal surface of cylindrical shapes, but by adjusting the slide position, they can also grind the end face perpendicular to the shaft center of the hole.

Simultaneous grinding in a single process enables high-precision machining.

The hole's diameter and length that can be ground depend on the grinding wheel's outside diameter and the machine's stroke.

Various bore diameters can be accommodated by selecting a grinding wheel that matches the bore diameter.

However, as bore deflection tends to be higher due to the wheel spindle's small size, it is advisable to choose a grinding wheel with the largest possible diameter for the bore and mount it on the wheel spindle head using a short-shafted wheel spindle.

The machine can also handle stepped bore diameters, and coaxiality of the bore diameter can be achieved in a single process, ensuring high precision. Taper grinding can also be performed by angling the spindle.

When grinding workpieces with a grinding wheel, a low peripheral speed can cause abrasive grains to detach along with the bonding agent.

Typically, the wheel spindle head rotates at 2000 to 3000 rpm under standard grinding conditions to achieve the desired peripheral velocity due to the grinding wheel's small diameter.

The spindle workpiece speed is set to maintain a peripheral speed of about 35 to 45 m/min for the grinding surface.

*Including some distributors, etc.

Sort by Features

Sort by Area

JTET Machine System, established in 1961 and headquartered in Osaka, Japan, is a manufacturer and supplier of machine tools, FA systems, and precision apparatuses. The company's product portfolio includes FA systems, drive shafts, machine tool grinders, precision mechanical equipment, and intermediate shafts for vehicles. These products find applications in various industries, including the automobile, information technology, home appliances, space technology, and medical devices. The company is ISO 14001 certified and has offices in South Korea, China, Thailand, and Mexico, establishing a global network.

Toyo Advanced Technologies Co., Ltd., established in 1950, is a Japanese manufacturer and supplier headquartered in Minami-ku, Hiroshima, specializing in machinery and hard coating solutions. The company offers various computerized numerical control (CNC) internal and external grinding machines as well as gear and multi-profile grinding machines. Additionally, it provides CNC honing machines, cylinder block bore finishers, multi-wire saws for power semiconductors, and scroll cutting machines. These machines find applications in various industries, including automobile, bearing, and electric household appliance. The company also offers hard coating solutions such as chemical vapor deposition (CVD), physical vapor deposition (PVD), and diamond-like carbon (DLC) coatings.

As a high-precision grinding machine manufacturer in Taiwan since 1982, Jainnher Machine owns more than 40 years of experience and has developed a complete machine series to fulfill various grinding requests. Our machine series including: Centerless, Cylindrical, Internal, Plunge, Angular, Center hole, Double spindle (ID & OD), Vertical and Thread grinding machine. Grinding machines are widely used in precision aerospace and other transportation industries, cutting tools, medical parts, mold & machining parts, consumer goods. We have successful cases of customized solutions with different industries. The company holds ISO 9001:2015 certification and CE/UKCA certifications , not only to meet customer requirements for quality assurance but also to enhance customer confidence and satisfaction in our grinding machine products Jainnher has global service net to conquer the language and time zone difference. And we’re able to provide the fully technical support, field training which can benefit our dealers communicate with their customers.

Okamoto has been a manufacturer of Total Abrasive Process Machine in Japan since 1926. The company offers a range of Griding machines, including Precision Cylindrical, Double Column Type, Specialized, Ultra Precision Form, and CNC Precision Surface Grinding Machines, as well as Semiconductor equipment devices such as polishing, lapping, and slicing machines, along with special consumer-designed devices. These products provide abrasive processing for the automotive, IT, digital consumer electronics, and semiconductor industries.

Palmary Machinery Co., Ltd., established in 1998 and based in Taichung, Taiwan, is a manufacturer of precision grinding machines. Its product range encompasses centerless grinders, cylindrical grinders, internal grinders, vertical grinders, and surface grinders, serving a diverse array of industries such as automotive, aerospace, mechanical components, and more. The company holds CE certification and ISO9001:2015 certification, highlighting its adherence to quality standards. The company has also achieved several accolades, including the Gold Medal Award at the 89th Poland Mach-Tool Show 2017 and the 14th National Brand Yushan Award 2017.

Okuma Corporation is a Japanese machine tool manufacturer that was founded in 1898 as the Okuma Noodle Machine Company before rebranding in 1918. Based in Oguchi, Aichi Prefecture, the company produces a wide selection of machines including CNC lathes, multi-axis machining centers, grinders, and multitasking machines. It also offers software and automation solutions that can be customized to improve the performance and functionality of its products. Okuma Corp. maintains a global support network via 28 subsidiaries located throughout Asia, the Americas, Europe, and the Pacific regions.

I Machine Tools Corp. is a manufacturer and exporter of various kinds of CNC machines and machine tools based in Taichung City, Taiwan. The company specializes in the production of metal cutting machines, CNC milling machines, grinding machines, and machining centers. I Machine Tools Corp. also offers various Vertical and Horizontal CNC Turning Lathe such as High-Speed Turning Lathe and CNC Swiss Type Turning Lathe designed for hard materials machining.

Pitroda Utility Industries, established in 1960 and headquartered in Wadhwan, India, is a manufacturer and supplier specializing in the field of grinding technologies. The company offers a wide range of grinding machines catering to various industrial needs, which include hydraulic cylindrical grinding machines, internal bore grinding machines, SPM cylindrical grinding machines, CNC/PLC cylindrical grinding machines, and more. Its products are applicable in various industries, including metal product manufacturing, automotive, defense, pharmaceutical, agriculture, and more.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Aerospace Manufacturing & Design |

19.8%

|

| 2 | Toyo Advanced Technologies |

14.3%

|

| 3 | I Machine Tools Corp. |

11.9%

|

| 4 | JAINNHER MACHINE CO., LTD. |

11.9%

|

| 5 | UNITED GRINDING North America |

11.1%

|

| 6 | Okuma Corporation |

7.9%

|

| 7 | JTET Machine System |

7.9%

|

| 8 | Okamoto Machine Tool Works,Ltd. |

5.6%

|

| 9 | PITRODA UTILITY INDUSTRIES |

4.8%

|

| 10 | PALMARY MACHINERY CO., LTD. |

4.8%

|

Derivation Method

The ranking is calculated based on the click share within the internal grinder page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

4 | 44.4% |

United States of America

United States of America

|

2 | 22.2% |

Taiwan

Taiwan

|

2 | 22.2% |

India

India

|

1 | 11.1% |

49 products found

49 products

Toyo Advanced Technologies

510+ people viewing

Last viewed: 15 minutes ago

This internal grinding machine is ideal for machining bearings that require concentricity between the outer and inner diameters. It also supports a...

JTET Machine System

620+ people viewing

"High -precision, high -speed grinding, and mechanical miniaturization" required for the inner grinding of bearings are realized. The workhead is "...

JTET Machine System

370+ people viewing

Last viewed: 6 hours ago

This is a composite grinder that achieves high rigidity and low heat displacement with a composite platform. The grinding area is 600mm, and the ne...

2 models listed

Toyo Advanced Technologies

570+ people viewing

Last viewed: 19 hours ago

An internal grinder that can handle workpieces with an inner diameter of up to 100mm. Equipped with the latest technology to stably process a varie...

Toyo Advanced Technologies

440+ people viewing

Last viewed: 2 hours ago

Large internal grinding machine compatible with outer diameters of 140 to 320 mm. The high machine rigidity and workpiece support system using two ...

Toyo Advanced Technologies

420+ people viewing

Last viewed: 1 day ago

Medium-sized internal grinding machine compatible with outer diameters of 90 to 240 mm. The high machine rigidity and workpiece support system usin...

Toyo Advanced Technologies

490+ people viewing

An internal grinder for small diameter workpieces with an inner diameter of 1.5 mm or more. Adopts a workpiece support system of 1 shoe and 2 rolle...

Toyo Advanced Technologies

520+ people viewing

Last viewed: 1 day ago

A large internal grinder that supports large diameter sizes up to 610 mm (φ440 for T-1354N). A wide variety of options such as a turret device (up ...

Toyo Advanced Technologies

640+ people viewing

Last viewed: 1 day ago

A medium-sized internal grinding machine that supports medium diameter sizes up to 250 mm (φ200 for T-1254N) and is suitable for high-precision mac...

Toyo Advanced Technologies

610+ people viewing

Last viewed: 17 seconds ago

A general-purpose internal grinder that can handle workpieces with an inner diameter of up to 170mm. With a wide work range and abundant options, i...

JTET Machine System

450+ people viewing

Last viewed: 4 hours ago

It is a composite grinder that allows high accuracy grinding of the inside and outside diameter and end surface with one chauck.

2 models listed

JTET Machine System

940+ people viewing

Last viewed: 17 hours ago

It is a stand -shaped grinder that can be grinded, internal and terminal grinding.

JTET Machine System

680+ people viewing

Last viewed: 1 day ago

VGF series large processed product (Max.φ400) compatible type With a newly developed special chuck, horizontal transportation immediately after gri...