All Categories

History

This section provides an overview for lcd modules as well as their applications and principles. Also, please take a look at the list of 35 lcd module manufacturers and their company rankings. Here are the top-ranked lcd module companies as of July, 2025: 1.TRU-VU Monitors, Inc., 2.Kopin, 3.EARTH COMPUTER TECHNOLOGIES dba EarthLCD.

Table of Contents

Categories Related to LCD Modules

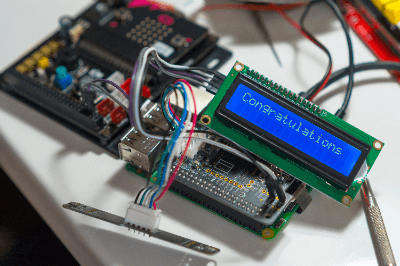

An LCD Module is an LCD panel, which constitutes of an LCD display, and a driver/controller for displaying images.

Because they are relatively inexpensive, thin, and have low power consumption, they are incorporated into a wide variety of electronic devices. In addition to embedded devices, they are often used as components for electronic crafts.

There are two main types of LCD modules: character LCD modules, which specialize in displaying text, and graphic LCD modules, which can also display graphics and illustrations.

The range of applications for LCD Modules is expanding day by day, and there are no limits to the number of uses for LCD Modules.

In portable devices such as smartphones, tablets, and laptops, LCD Modules are a central component of the user interface. They receive the user's touch input and display information clearly, greatly enhancing the usability of these devices.

LCD Modules are used in home appliances such as televisions, refrigerators, air conditioners, and washing machines to display information and provide operational guidance. For example, in televisions they are used to display images, and in refrigerators and air conditioners they are used to display temperature and setting modes.

LCD Modules are also used in the operation panels of industrial equipment such as factory production lines, agricultural machinery, and construction equipment. They provide the operator with necessary information to enable safer and more efficient equipment operation.

LCD Modules also play an important role in the medical field. They are installed in devices that monitor vital signs of patients, ultrasound machines, MRI scanners, etc., and provide necessary information visually to medical personnel.

In modern automobiles, LCD Modules are used to display information such as vehicle speed, engine status, and navigation information.

To understand how Liquid Crystal Display (LCD) Modules work, one must first understand the properties of liquid crystals. Liquid crystals are substances in a state between that of a solid and a liquid, and can be oriented by temperature or an electric field. This property is the core principle behind LCDs.

Some liquid crystals have the ability to change the polarization of light, and LCDs use this ability to produce images. Specifically, applying voltage to a liquid crystal cell (consisting of a liquid crystal layer and electrodes on both sides) changes the orientation of the liquid crystal, resulting in a change in light transmittance.

The LCD Module consists of the display part based on the liquid crystal cell and the electronic circuits that control it. The electronic circuit applies a voltage to each liquid crystal cell in response to an input signal and controls the light transmittance of each cell. This creates a complex image when viewed as a whole display.

For color display, this is usually achieved by combining backlight and color filters for the three primary colors of red, green, and blue. Each pixel consists of three liquid crystal cells (corresponding to red, green, and blue respectively), and the transmittance of each cell can be controlled to produce any desired color.

LCD Modules are broadly classified into three types according to their construction and assembly methods. They are called COB type, COG type, and COF type, respectively, and have different characteristics and application fields.

Each of the three types is selected based on factors such as product characteristics, field of application, and manufacturing cost.

The COB type refers to a type in which the LCD panel and IC chip are mounted on the same printed circuit board. All functions can be mounted in a single unit, but this type has the disadvantage that it tends to be large in size.

The COG type refers to a type in which the IC chip is directly mounted on a glass substrate (LCD panel). This enables thinner and smaller modules. However, passive components are externally mounted.

COF type refers to a type in which IC chips are mounted on a flexible film substrate. COF type, like COG type, can be made thinner and smaller, and can also be applied to curved surfaces.

Major components of liquid crystal displays (LCDs) include polarizing filters, glass substrates, transparent electrodes, alignment films, and color filters.

There are three display methods for LCD Modules:

In color display, RGB color filters are applied to each display unit, and various colors are expressed by combining them.

*Including some distributors, etc.

Sort by Features

Sort by Area

TRU-VU Monitors, Inc., founded in Arlington Hts., IL, in 1990 is a manufacturer of industrial-grade LCD monitors and touch screens. The company's product portfolio includes high brightness Sunlight Readable monitors, outdoor waterproof monitors, industrial touch screens, panel mount monitors, and waterproof LCD displays. Their products are used in markets such as aviation, inspection systems, sports stadiums, amusement parks, and oil and gas. The company provides services such as Product Selection Guidance, Engineering Support, and Custom Manufacturing.

EARTH COMPUTER TECHNOLOGIES dba EarthLCD, established in Santa Ana, CA, in 1994, is a manufacturer of LCD equipment used in medical devices, embedded systems, airplanes, and factories worldwide. Their product portfolio includes LCD solutions for factory automation, offering displays that withstand harsh environments and ensure efficient operation in industrial settings and LCD panels, including TFT-LCDs, OLED displays, and custom-designed displays, used in, industrial automation, aviation, and more. The company provides global distribution and technical support.

Fema Electronics Corporation, founded in 1980 and headquartered in the United States, is a manufacturer and supplier of quality display products. The company offers cutting-edge touchscreen displays catering to various industries, from consumer electronics to medical devices and industrial automation. These displays enhance user interactions and experiences, providing seamless touch control for diverse applications. to empower customers by manufacturing great display solutions and providing unparalleled customer service. Since its inception, the company has been empowering customers by manufacturing quality display solutions and providing unparalleled customer service.

P-tec Corporation is a manufacturing and supplying company with headquarters in Alamosa, Colorado. The company was established in 1986 and has since been in the business of manufacturing, and supplying light-emitting diode, and liquid crystal display products such as graphic and character LCDs, SMD displays, LED displays, UV/IR LEDs, and CBI LEDs. P-tec serves large, to small-scale manufacturers in industries like automotive, aerospace & defense, food & beverage equipment, electronic signs & displays, networking & communication devices, industrial controls & automation to test & measurement devices companies.

Kopin Corporation is a manufacturer of liquid crystal microdisplays for wearable computing devices and was established in 1984 in Westborough, Massachusetts. The company collaborates with Fujitsu, Motorola, Google, RealWear, and Vuzix for offering critical components and customized optical display systems. The products range from ultra-small LCD, Ferroelectric LCoS, OLED, and energy-efficient ASICs to optical modules. Microdisplays are used in industrial, military, enterprise, consumer, and healthcare applications for advanced imaging and better sustainability. They employ game-changing technologies such as heterojunction bipolar transistors that power billions of cellphones as well as microdisplays. Forth Dimension Displays & NVIS Inc are their subsidiaries.

Vishay Intertechnology, Inc. (Vishay) was incorporated in 1962 and is headquartered in Malvern, Pennsylvania. The company serves the industrial, automotive, telecommunications, consumer products, and medical end markets and sells its products under numerous brand names inlcuding Siliconix, Draloric, Beyschlag, UltraSource, and Applied Thin-Film Products. The company manufactures and sells discrete semiconductors and passive electronic components in globally while operating in six market segments: MOSFETs, diodes, optoelectronic components, resistors, inductors, and capacitors.

San Technology also known as Santek is a manufacturer company founded in May 2000, situated in San Diego Carlifonia and is specialized in displays. The company offer products such as LED panel, printed circuit board and other related products. The company has achieved to establish four factories in Mexico and China. In addition It has subsidiaries in Japan and Germany to ensure its products are distributed across the globe to cater the needs of their customers. The company provides technology for high and low volume productions.

American Portwell Technology is a global company that specializes in designing and manufacturing a wide range of embedded computing solutions, including single-board computers and industrial motherboards. Established in 1993, it has provided embedded computing solutions to various industries, including automation, gaming, medical, and military. The Company has received several industry recognitions for its quality products and services. Its products are proven by customers around the world for their reliability, scalability, and flexibility. The company's aim on research, development and technology has enabled it to stay ahead in the fast-paced and rapidly evolving embedded computing industry.

Toshin Kogyo CO., LTD., established in 1951 and headquartered in Tokyo, Japan, is a manufacturer that manufactures, imports and sells electronic components. The company produces electronic components such as aluminum electrolytic capacitors, capacitors for audio equipment, film capacitors, and liquid crystal modules. It also released an aluminum electrolytic capacitor series for acoustic applications called the UTJH series. The UTJH series has a wide temperature range of -40°C to +85°C, which makes it suitable for use in various environments. The company has achieved ISO-14001 and ISO-9001 certification. It serves industries such as electronic components, printing, and fabric industry.

Clover Display Limited was established in 1983 with its headquarters in Kowloon, Hong Kong, and is a manufacturer of LCDs and chemical engineering products for various industrial applications. The company has received ISO 9001 & ISO 14001 certifications and provides standard LCD modules, standard LCD panels, EBTN, and TFT Displays that have uses in control units, energy meters, automotive, health & medical equipment, and home appliances, as well as in fax machines, feature phones, sports coaching meters, and, thermostats.

Hsintek was founded in 1989 with its headquarters in Taoyuan, Taiwan is a manufacturer of multiple-function display solution products and associated accessories for various industries. The company has received ISO9001-2015 & ISO13485-2016 certifications and provides OEM & ODM touch modules, LCD modules, medical monitors, metallic touch monitors, and, industrial metallic monitors, along with video monitors, car rear vision systems, CRT monitors, AHD camera / DVR, special accessories for Covid-19 that have applications in CCTV surveillance, media, medical, broadcasting, and transportation fields.

Innovative Sensor Technology IST AG was founded in 1991 and is headquartered in Ebnat-Kappel, Switzerland. The company is a manufacturer of physical, chemical, and biological sensors that serve industries including automotive, fuel cell, renewable energy, and medical devices. The company has 4 product segments. Micro heaters are used for laser manufacturing, humidification, 3D printing, and other specialty uses. Customized sensor solutions are offered across many customer fields, and designed for quality, accuracy, and compatibility.

Applied Green Light (AGL) was founded in 2008, is located in Hsinchu Science Park, Taiwan, and is a manufacturer of digital display products, including TFT LCD displays, for a wide range of customers. Originally, Applied Green Light (AGL) only manufactured high-brightness TFT LCDs for outdoor use but has extended their product line to include LCD-related control systems and professional digital displays for general commercial use, industrial use, medical applications, vehicles, and military applications. The company's displays have been used on millions of devices worldwide.

Bona Fide Technology is a supplier and manufacturer specializing in the design and development of electronic products and solutions. Established in 1992, the company is headquartered in Hong Kong and providing a wide range of electronic components like connectors, cables, and switches. They offer a diverse lineup of consumer electronics, including headphones, earphones, and audio accessories. Their products is the "BFM88" Bluetooth headphones, renowned for their sound quality, seamless wireless connectivity, and ergonomic design, ensuring a comfortable listening experience.

Display Elektroniks GmbH is a liquid crystal display (LCDs) and LC modules manufacturer and supplier established in 1984. They are an ISO9001-manufacturer that partners with manufacturing equipped with Class-1000 and Class-100 clean room conditions to deliver a fully-automated LCD/TFT production line. Display Elektronix produces OCA technology on module production lines using Surface Mount PCBA, COB, COF, and heat-seal techniques. The company’s standard portfolio includes LCD panels, digital modules, alphanumeric modules, monochrome graphic modules, TFT, OLED, e-Paper, LED displays, customized membrane switches, and rubber keypads. In addition, Display Elektronix offers over 5,000 customized LCD and LC module designs.

Evervision Electronics, established in 1998 and based in New Taipei City, Taipei, is a manufacturer of LCD and LCM technology modules. Aside from LCD and LCM, the company also manufactures TFT modules. These integrated products of the company are customizable and configurable according to client modifications and requirements. Therefore, the company also provides additional accessories that customers may need, such as controller boards. Evervision Electronics's products are applicable to industrail equipment, medical products, large electrical goods, and POS systems.

Shenzhen AV-Display (AVD) is a supplier and manufacturer of a wide range of display products for various industries. Established in 2004, a company based in China that specializes in the design, development, and manufacturing of display solutions. They offers an extensive product portfolio that includes TFT LCD displays, OLED displays, touch panels, and LCD modules. These displays are used in applications such as consumer electronics, industrial equipment, medical devices, automotive systems, and more. Thei product is the "AVD-TW101" TFT LCD display.

Stanley Electric Co., Ltd is a Japanese manufacturer of electric lights established in the year 1933. Stanley Electric Co Ltd makes LED ignited products and operates under three business segments: automotive equipment, electronic components, and applied electronic products. In its automotive equipment business, Stanley Electric produces and sells LED and HID headlamps, rear combination lamps, fog lamps, and automotive and LED bulbs. In its other segments, Stanley Electric makes LEDs, infrared LED lamps, optical sensors, LCDs, subminiature lamps, backlight units for LCDs, flash units for cameras, and operation panels. The largest end markets include Japan, China and Asia-Pacific, and the Americas.

Sunlike Display is a manufacturer and supplier of LCD modules and displays for various industries. The company is Taiwan-based that was established in 1998. They offer a wide range of products, including graphic LCD modules, character LCD modules, TFT LCD modules, OLED displays, and touch panels. These display modules are used in applications such as industrial equipment, consumer electronics, medical devices, automotive systems, and more. One sample product from Sunlike Display is the "SLG1602A" character LCD module. It features a 16x2 character display with LED backlighting, offering clear and easy-to-read text.

Yeebo is a supplier and manufacturer and company based in Hong Kong that specializes in the design and development of electronic products and accessories. Established in 2000, they offer a diverse range of electronic products and accessories. They produce items such as power banks, USB chargers, wireless chargers, audio devices, smart home devices, and mobile phone accessories. One sample product from Yeebo is the "YB-8038" power bank. It features a high-capacity battery, multiple USB ports for charging multiple devices simultaneously, and compact design for easy portability. This power bank provides a dependable power source for mobile devices on the go.

Winstar Display, established in 1998 in Taiwan, Japan is a manufacturer of LCD display modules and panels. The company operates worldwide and manufactures advanced displays and modules for LCD, LCM and TFT screens. Their product categories have LCM modules along with monochrome FSTN LCM, TFT LCM / TFT panels, OLED display modules (PMOLED), custom LCD displays and panels. These products find use in transportation, entertainment, architecture and retail sectors. These displays are ideal for higher resolution pictures and can showcase information, images or other requirements on the screen with crystal clarity. Customized sizes and panels are available on request.

Japan Display, founded in 2012 in Minato City in Tokyo, is a manufacturer of medium and small-sized displays for mobile and automotive devices. The company was formed by merging the liquid crystal display ventures of Sony, Toshiba, and Hitachi to create a sustainable, high-definition, and environmentally-friendly display. The products include Lithographic OLED, VR displays, double-sided LED displays, mobile displays, and industrial applications. Their business spans across Europe, America, Korea, China, Hong Kong, and the Philippines. The products find use in industrial imaging, aerospace, healthcare, automotive and personal devices. Using proprietary LTPS transistors on glass, they make energy-efficient and high-definition displays.

Litemax Electronics Inc. is a manufacturer of LED displays and industrial computing, established in 2000, with its headquarters located in New Taipei, Taiwan. They offer sunlight-readable LCDs, boards and modules, embedded boxes, AI edge computing, and more. These are used for visual communication, industrial computing, embedded systems, and mobile computing. The company caters to transportation, industrial, marine, digital signage, and data mining industries and can customize solutions based on specific industry requirements.

EarthLCD, a division of Earth Computer Technologies, Inc. founded in 1984 and based in Irvine, California, is a manufacturer that specializes in liquid crystal display (LCD) solutions. The company has introduced a wide range of LCD products, including portable monitors, video graphics array (VGA) and thin film transistor (TFT) LCD kits, as well as smart color LCDs. Its current offerings feature open-frame, enclosed, and touchscreen industrial LCD monitors, complemented by LCD controllers and mounting hardware. EarthLCD's products are widely used in the retail sector for digital signage, and kiosks, as well as in medical equipment and factory automation settings.

Orient Display, founded in 1996, is a Chinese-American joint ventured manufacturer and supplier headquartered in Bellevue, Washington, specializing in display technology solutions. The company's product line includes thin-film transistor (TFT) displays and panels, liquid-crystal displays (LCDs), organic light-emitting diode (OLED) displays, as well as embedded LCD and TFT modules. Among its featured product variants are LCD glass panels and backlights, graphic and character LCDs, vertical alignment (VTN) LCDs, touch panels, and demo boards. Additionally, the company provides LCD parts, such as connectors and controllers. These products find applications across diverse sectors, including airport information boards, gym equipment, servers, and electronic price tags.

Pro-face America (PFA) is an American manufacturer of industrial personal computer (IPC) and human machine interface (HMI) products that was originally established as Digital Electronics Corporation in 1988 before its rebrand in 2013. The company primarily produces HMI products such as operator interfaces and graphic terminals, as well as IPC products including panel, embedded, and box PCs. It also offers HMI and IPC data management software, as well as custom assembly and repair services to customers requiring additional support. PFA operates as a subsidiary of Schneider Electric, which serves clients in the food and beverage, consumer electronics, automotive, and pharmaceutical sectors.

Lumex-ITW, founded in 1916 in North America, is a manufacturer of electronic switch components, photonics, LEDs, and LCDs. The company offers a wide range of products that include surface-mount LEDs, through-hole LEDs, LED bulb replacements, color TFT LCDs, and push-button switches. Lumex-ITW offers original equipment manufacturers a wide range of custom production options, including semi-custom, fully custom, and plug-and-play solutions for LED/LCD displays, backlighting, light arrays, and LED indicators. Some examples include customized colors and specific wavelengths in LED indicators and special graphics and colors on LCD displays.

Tianma Europe GmbH, a subsidiary of Tianma Microelectronics Co., Ltd., established as TIANMA NLT Europe GmbH in 2004 and renamed Tianma Europe GmbH in 2017, has headquarters in Düsseldorf, Germany, and is a distributor of Tianma displays across multiple markets, including automotive, medical, and industrial. The company's products include high-luminance displays, resistive and capacitive touch displays, customized displays, passive LCDs, and automotive-use displays. Tianma Europe GmbH displays use technologies developed by Tianma that include Super Fine TFT, Reflective TFT, and Transmissive EVT for wider-angle viewing and easier reading in bright and high-sunlight environments.

Flat Display Technology Corporation, a supplier of electronics equipment, was established in 1989 and is based in Taichung, Taiwan. Its product catalog ranges from e-paper kits, TFT display modules, full flat industrial open frames, μC-HMI, and GUI TFT modules. The company has obtained several certifications, such as ISO 9001:2000, ISO 14001:2015, and D-U-N-S certificates. Its products are utilized for electronics, automation, automotive, and telecommunication sectors across several regions, including the Czech Republic, France, Germany, Italy, and Japan.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Kopin |

6.1%

|

| 2 | TRU-VU Monitors, Inc. |

5.4%

|

| 3 | Display Elektronik GmbH |

4.9%

|

| 4 | EARTH COMPUTER TECHNOLOGIES dba EarthLCD |

4.7%

|

| 5 | P-tec |

4.5%

|

| 6 | ZETTLER |

4.2%

|

| 7 | Innovative Sensor Technology IST AG |

4.2%

|

| 8 | FEMA Electronics |

3.8%

|

| 9 | San Technology, Inc. |

3.8%

|

| 10 | Vishay Intertechnology, Inc., |

3.5%

|

Derivation Method

The ranking is calculated based on the click share within the lcd module page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Taiwan

Taiwan

|

10 | 34.5% |

United States of America

United States of America

|

8 | 27.6% |

Japan

Japan

|

3 | 10.3% |

China

China

|

3 | 10.3% |

Germany

Germany

|

3 | 10.3% |

Hong Kong

Hong Kong

|

1 | 3.4% |

Switzerland

Switzerland

|

1 | 3.4% |

604 products found

604 products

CLOVER JAPAN Co., Ltd.

1280+ people viewing

Last viewed: 4 hours ago

The monochrome LCD modules manufactured by ZETLLER come in character and graphic types. The character type is suitable for displaying numbers, alph...

10 models listed

Teidec Co., Ltd.

1070+ people viewing

Last viewed: 1 hour ago

■Features Monochrome LCD displays are still widely used, such as in remote control displays. Both the unit price and development cost are extremely...

10 models listed

CLOVER JAPAN Co., Ltd.

670+ people viewing

Last viewed: 8 hours ago

We have 30 types of standard 7-segment type LCD panels with no development costs, ranging from 2 digits to 16 digits, and most can be delivered in ...

10 models listed

CLOVER JAPAN Co., Ltd.

740+ people viewing

Last viewed: 4 hours ago

Standard LCD modules are available in character type, graphic type, etc. We recommend COG (Chip on Glass), which is the current mainstream. Detaile...

10 models listed

Teidec Co., Ltd.

970+ people viewing

Last viewed: 1 day ago

■Features Monochrome LCD displays are still widely used, such as in remote control displays. Both the unit price and development cost are extremely...

7 models listed

Teidec Co., Ltd.

840+ people viewing

Last viewed: 3 minutes ago

■Features Monochrome LCD displays are still widely used, such as in remote control displays. Both the unit price and development cost are extremely...

10 models listed

CLOVER JAPAN Co., Ltd.

780+ people viewing

Last viewed: 26 minutes ago

It has a stylish circular shape that is suitable for home appliances, smart homes, medical equipment, control equipment, etc. It also uses an IPS l...

5 models listed

Pico Systems Co., Ltd.

230+ people viewing

Last viewed: 12 hours ago

■LCD touch panel module This is a module that includes an LCD touch panel for various devices and a CPU board for control. Develop display software...

Kernel Hard Engineering Co., Ltd.

540+ people viewing

Last viewed: 9 hours ago

■ Overview ・ WT32-SC01 Plus is a product with a 16MB SPI flash memory and an LCD display equipped with a WT32-S3-WROVER module. ・ WT32-S3-WROVER ...

Teidec Co., Ltd.

920+ people viewing

Last viewed: 22 hours ago

■Features Monochrome LCD displays are still widely used, such as in remote control displays. Both the unit price and development cost are extremely...

9 models listed

Teidec Co., Ltd.

1300+ people viewing

Last viewed: 15 hours ago

■Features Monochrome LCD displays are still widely used, such as in remote control displays. Both the unit price and development cost are extremely...

10 models listed

Christage Co., Ltd.

360+ people viewing

Product Description ■"Touch Panel Module" is provided as a set of the following three items. ① "Operation screen (UI) design software" that allows ...

5 models listed

Rocky Co., Ltd.

560+ people viewing

Last viewed: 1 day ago

Intelligent touch panel display control board that summarizes display/input/control/communication functions compactly

3 models listed

Nagano Techtron Co., Ltd.

880+ people viewing

Last viewed: 1 day ago

■Summary This product allows customers to easily develop software. Equipped with RS232 and SPI interfaces, it is possible to directly control backl...

8 models listed

Nagano Techtron Co., Ltd.

830+ people viewing

Last viewed: 20 hours ago

■Summary This product allows customers to easily develop software. Equipped with RS232 and SPI interfaces, it is possible to directly control backl...

10 models listed

Nagano Techtron Co., Ltd.

840+ people viewing

Last viewed: 3 hours ago

■Summary This product has improved visibility under direct sunlight. We provide LCD monitors with a brightness of 800 to 1,000 nits as standard. It...

10 models listed

Nagano Techtron Co., Ltd.

850+ people viewing

■Summary Many TFT LCD modules are available as standard products. In addition to standard products, we also have high-brightness, monochrome TFT, a...

10 models listed

Nagano Techtron Co., Ltd.

860+ people viewing

Last viewed: 1 hour ago

■Summary We offer a wide variety of standard Chip-on-Glass (COG) LCD displays. Backlights and glass can be freely combined according to customer sp...

10 models listed

Nagano Techtron Co., Ltd.

1030+ people viewing

Last viewed: 10 hours ago

■Summary Organic EL (Organic Light Emitting Diode, OLED) is self-luminous and has superior performance compared to conventional products, including...

10 models listed

DWIN Technology

1010+ people viewing

Last viewed: 15 hours ago

Can be developed without any coding skills required. Easy-to-use DWIN DGUS tool for creating GUIs

4 models listed

Nagano Techtron Co., Ltd.

640+ people viewing

■Summary We offer a variety of high-resolution graphic LCD modules, and you can freely select the combination of backlight and glass to suit your n...

10 models listed

Nagano Techtron Co., Ltd.

1310+ people viewing

Last viewed: 1 hour ago

■Summary You can now easily upgrade your existing display to an organic EL type with excellent visibility. Organic EL products with character displ...

10 models listed

Nagano Techtron Co., Ltd.

930+ people viewing

Last viewed: 6 hours ago

■Summary We have a large number of STN LCD character display modules available as standard products. You can choose the font and supported language...

10 models listed

Nagano Techtron Co., Ltd.

320+ people viewing

Last viewed: 1 day ago

■Summary The NT-POSM82W floor type is an all-in-one floor-mounted full self-checkout register equipped with the touch panel PC ``NT-POS-M82W-J641.'...

Christage Co., Ltd.

190+ people viewing

Last viewed: 11 hours ago

Features of HDMI compatible products ■"IPS liquid crystal" that is easy to see from all directions It uses an IPS LCD panel and is highly visible f...

Christage Co., Ltd.

190+ people viewing

Last viewed: 12 hours ago

■What is organic EL display (OLED)? This is a self-luminous display product that uses organic EL materials that emit light when electricity is pass...

Yagyu Shokai Co., Ltd.

190+ people viewing

Last viewed: 12 hours ago

■Features ・Transmission and reception are possible at a distance of up to 300m line of sight. - Up to 4 cameras can be added. - The camera has a d...

Christage Co., Ltd.

200+ people viewing

Last viewed: 4 hours ago

Features of HDMI compatible products ■"IPS liquid crystal" that is easy to see from all directions It uses an IPS LCD panel and is highly visible f...

Christage Co., Ltd.

180+ people viewing

Last viewed: 22 hours ago

■What is organic EL display (OLED)? This is a self-luminous display product that uses organic EL materials that emit light when electricity is pass...

Yagyu Shokai Co., Ltd.

170+ people viewing

Last viewed: 1 day ago

■Features - High-definition 920,000 pixel camera and monitor set. ・Remote monitoring is possible using a smartphone. ・It is easy to operate with ...