All Categories

History

This section provides an overview for high frequency induction heating devices as well as their applications and principles. Also, please take a look at the list of 29 high frequency induction heating device manufacturers and their company rankings. Here are the top-ranked high frequency induction heating device companies as of February, 2026: 1.Miller Electric Mfg. LLC, 2.Ultraflex Power Technologies, 3.U.S. Solid.

Table of Contents

Categories Related to High Frequency Induction Heating Devices

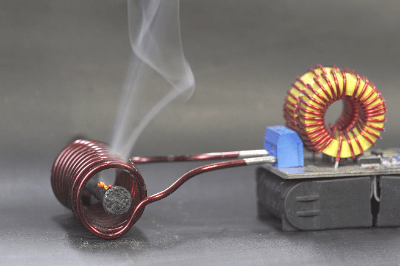

A high-frequency induction heating device is a device that heats by high-frequency induction.

A high-frequency induction heating device is a device that heats by high-frequency induction.

When alternating current is passed through a coil containing a metal body, a magnetic field is generated by the current flowing in the coil, causing induction loss, or hysteresis loss, which generates heat. At the same time, eddy currents, or eddy currents, are generated in the changing magnetic field due to electromagnetic induction. These eddy currents generate Joule heat, which causes eddy current losses.

High-frequency induction heating equipment utilizes the two heating principles of hysteresis loss and eddy current loss. The energy supplied to the object to be heated per unit area and unit time is large, making high-speed heating possible.

High-frequency induction heating is often used for melting, quenching, and brazing of metals because it can heat conductors such as metals without contact. A familiar example is the induction cooktop. Other applications include resins, wood, textiles, food, and medicine.

In the case of thermoplastic resins, induction heating can be used to weld resins while pressing them in a mold. In the case of food production, high-frequency induction heating equipment can be incorporated into factory lines to defrost food products rapidly when processing large quantities of food products.

In the medical field, high-frequency induction heating methods are also used in the development of cancer thermotherapy and other treatments.

High-frequency induction heating is a method of heating an object using electromagnetic induction. It can be classified as a direct heating method or an indirect heating method, depending on whether the object to be heated is heated by passing an electric current directly through it or through a conductive container.

The law of electromagnetic induction states that when an alternating current is applied to a coil, a magnetic flux is generated that passes through its center and surrounds the outside. Eddy currents are generated in the metal to prevent this magnetic flux from changing.

Depending on the magnitude of these eddy currents and the electrical resistance of the metal, Joule heat is generated in the metal. In the direct heating method, the object to be heated can be directly heated by generating eddy currents directly in the metal in this way.

The indirect heating method is used to heat insulators such as ceramics, which cannot generate eddy currents in the object to be heated. Therefore, indirect heating is possible by placing the object to be heated in a conductive container and heating the container.

To increase heating efficiency, the gap between the external shape of the object to be heated and the heating coil is reduced to increase the flux density transmitted. Furthermore, the heating is done by controlling the frequency of the AC power source between tens of Hz and hundreds of kHz.

Uniform Heating

The heat is generated by resistance heating against eddy currents generated by electromagnetic induction, so the heated object is uniformly heated from the inside.

Rapid Heating

By controlling the transmitter, high-frequency waves can be applied instantaneously to the object to be heated, and since the heating is internally self-heated, rapid heating is possible. Compared to heating furnaces that apply heat externally, this system is superior in productivity and requires no standby heating, making it a low-cost production method.

Selective Heating

Even for composite materials such as aluminum alloy and steel clad steel, only the portion of the material with high electrical resistivity can be selectively heated.

High Energy Efficiency

In general heating furnaces, external heating is done by combustion or heating elements, resulting in energy loss due to unnecessary heating of not only the object to be heated but also the furnace components and atmosphere. With high-frequency induction heating equipment, only the object to be heat-treated is heated by self-heating, thus eliminating waste and enabling heat treatment with high energy efficiency.

Expensive Capital Investment

High-frequency induction heating has the disadvantage that the initial capital investment is expensive because high-frequency induction heating equipment requires expensive high-frequency power supplies and control devices, as well as equipment to prevent electromagnetic radiation leakage to the surrounding environment.

Low Shape Selectivity

If the electric field of the object to be heated is non-uniform, the heat generation itself will also be non-uniform, resulting in uneven temperatures, which may lead to problems such as melting in the worst case. Therefore, the object to be heated should have a highly symmetrical shape, such as a cylinder. It is difficult to heat complexly shaped objects, such as square timbers or gears, evenly.

Individual and Partial Heating

High-frequency induction heating is a method of heating the whole or only a part of the object to be heated by means of an arbitrarily shaped coil designed to heat the object uniformly. For this reason, it is basically a one-piece flow process, and thus cannot perform batch-type mass simultaneous processing like external heating. Depending on the product and production conditions, this method has the disadvantage of reduced productivity.

*Including some distributors, etc.

Sort by Features

Sort by Area

Miller Electric Mfg. LLC (MEM) is an American manufacturer of arc welding and cutting equipment originally founded in 1929 before its acquisition by Illinois Tool Works (ITW) in 1993. Headquartered in Appleton, Wisconsin, the company produces various welders such as tungsten inert gas (TIG) and engine-driven models, wire feeders, and plasma cutters. It also offers related consumables and accessories, such as connector kits, spot welding tongs, safety equipment, and flux-cored wires. MEM products are commonly used in metal fabrication, manufacturing, and construction, as well as in the aviation industry.

U.S. Solid, founded in Cleveland, Ohio, in 2011 is a manufacturer of precision laboratory cuvettes, laboratory material and equipment. The company's product portfolio includes Valves Motorized Ball Valves, Solenoid Valves, Pneumatic Valves, ultrasonic cleaners and pipe connectors. The company serves markets including Medical and Healthcare, Home and Garden, Consumer Goods, Industrial Manufacturing and Construction and Building. They also offer services such as shipping, warranty, customer and technical support and Product Selection Guidance.

UltraFlex Power Technologies is a manufacturer of induction heating equipment that is headquartered in New York, USA, and was established in 1998. The company offers a wide range of induction heating products, including induction furnaces, induction heaters, and induction coils. UltraFlex also offers services including engineering, preventative maintenance, equipment start-up and training, on-site or in-house repairs, and extended warranties. The company's products are CE-marked and used in several industries, including manufacturing, metalworking, and plastics processing. UltraFlex meets the current WEEE, RoHS, and Reach directives and also has a global network of ISO 9001-certified factories, sales and support offices, and application labs.

Neturen Co. Ltd. is an ISO 9001-certified manufacturer of steel products and induction heating equipment established in 1946 and based in Tokyo, Japan. The company produces prestressed steel products for demanding construction projects, as well as heating equipment used for metal processing. These products include prestressed concrete (PC) steel bars, induction heating equipment for annealing or tempering steel, and steel wires. It also offers custom induction heat treatment products and services for clients with unique projects. The company’s products are mainly used by customers in the civil engineering, construction, and automotive sectors.

BIOBASE GROUP is a Chinese manufacturer of medical and laboratory equipment founded in 1999 and headquartered in Jinan, Shandong. The company offers over 200 different products including laboratory and medical cryogenic equipment, clinical analytical instruments, air protection devices, and specialized storage products. It also produces various medical consumables such as gloves, masks, and syringes. Biobase Group has branches in the US, India, Dubai, Singapore, and Kazakhstan. It offers global distribution and additional customization services to its clients in the biotechnology, environmental, cosmetic, and educational sectors.

Miwa Mfg Co., Ltd. established in 1980 and based in Osaka, Japan, is an ISO 9001 certified manufacturer and supplier of vacuum-type glove boxes and associated equipment. The company's product range includes Vacuum-type glove boxes, purge-type glove boxes, gas recycle purification systems, clean ovens, and high-frequency induction heaters. These products are used in various industrial processes that require controlled environments and specific temperature or purification conditions. They serve industries such as pharmaceuticals, electronics, research laboratories, and specialized manufacturing. Additionally, the company provides services like equipment customization, maintenance support, training, and technical consultation.

Chengdu Jinkezhi Electronic Co., Ltd., established in 1993 and located in Chengdu, Sichuan Province, China, is a manufacturer of induction heating machines. The company specializes in research, development, production, and sales, offering a product range that includes high-frequency, ultrasonic frequency, medium frequency, SWP ultra-high frequency induction, and induction annealing and normalizing machines. These products find applications in various industries, such as metal welding, hot forging, hardening, metal melting, and heat treating. It holds ISO9001-2008 quality and CE safety standards certifications.

Nippon Avionics Co., Ltd is a Japanese manufacturer of electronic aviation equipment and other office equipment. The incorporation is a result of merging NEC Corporation and Hughes Aircraft Company in 1960. Headquarters are located in Yokohama Japan. The company designs, manufactures, and sells items from three product lines: Information Systems, Joining Equipment, and Infrared Thermography. The products include communication devices used in aviation integrated circuit (IC) boards and media projectors for office use.

Eldec Induction GmbH is a manufacturer of induction heating and hardening systems established in 1982 and based in Dornstetten, Germany. The company primarily produces induction hardening machines for precision hardening or metal or alloy-fabricated parts, and induction heating systems for industrial heating processes such as annealing or brazing. It also offers customizable modular systems to suit unique client projects. The company mainly serves clients in the heavy machinery, aerospace, and automotive industries.

Termomacchine S.r.l., founded in 1976, is an induction machine manufacturer based in Rivalta di Torino, Turin, Italy. The company develops induction machines and spare parts for various capabilities, such as forging, press quenching, and welding. It also provides special applications for automobiles, cables and wires, and precious metals. The company's lineup includes in-line induction hardening systems for transmission shafts shaft hardening machines, and bearing hardening and tempering machines. It also manufactures insulated gate bipolar transistors (IGBTs), metal-oxide-semiconductor field-effect transistors (MOSFETs), and compact generators.

Ambrell Corporation., founded in Rochester, New York, in 1986 is a manufacturer of induction heating systems and tests to determine the right process and system in laborites. The company's product portfolio includes Induction heating coils, Precision heating solutions, Induction furnaces, Induction furnaces, and Heat treating. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. The company's production facility is ISO-certified and they has a national distribution network and a customer support center.

ENRX AS, founded in 1981 as ELVA Induksjon AS and acquired by Arendals Fossekompani ASA, is a manufacturer headquartered in Skien, Norway, developing induction heating, wireless charging and power supply solutions. The company's portfolio includes induction heating equipment and systems, such as bolt expansion and brazing products. It has executed over 20,000 installations of such solutions across 80 countries. The company also offers wireless charging and contactless power supply products protected by over 1,200 patents. Its charging products are developed for heavy-duty applications and electric vehicles, whereas its power supply products are designed for floor and rail applications.

Across International is a manufacturer of laboratory equipment and instruments based in the USA. Established in 2008, the company offers a wide range of products designed for scientific research, including laboratory ovens, vacuum pumps, rotary evaporators, and other essential equipment used in laboratories and research facilities. The equipment is used in scientific research and laboratory work across a range of fields, including chemistry, pharmaceuticals, materials science, and more. The company is ISO9001:2015 certified for quality management systems.

Shenzhen Double Ping Power Technology Co., Ltd., established in 1996 and based in Shenzhen, China, is a manufacturer and supplier of induction heating equipment. Specializing in small, portable, medium-frequency, and high-frequency induction heating equipment, the company offers a wide range of specifications suitable for various metal heating applications. Its products are utilized both domestically and internationally in regions such as Europe, North America, and Asia. Its headquarters covers an area of 600 square meters, with a production plant in Dongguan operating across approximately 8,480 square meters.

Schaeffler Group, founded in 1946 in Germany, is a manufacturer and supplier of precision-engineered components and systems for automotive and industrial applications. The company's product portfolio encompasses a wide range of solutions, including high-precision bearings, rolling and plain bearings, linear technology, and engine components. These products find applications in various industries, such as automotive, aerospace, industrial machinery, and renewable energy. The company continuous to develop advanced technologies that improve efficiency, sustainability, and performance across different sectors, remains a key player in shaping the future of mobility and industries.

Sirman SpA is an ISO 9001:2008-certified manufacturer of commercial kitchen appliances and equipment, established in Campo San Martino, Italy, in 1969. The company offers vacuum sealers for sous vide cooking or food preservation, soft cookers, and meat grinders for making stuffings or sausages. It also provides standard cooking hardware such as fryers, ovens, and toasters. Operating internationally, Sirman SpA has partner distributors and branch offices in over 100 countries across three continents.

Taipan Exim Co., Ltd, headquartered in Changshu City, Suzhou, Jiangsu Province, China, is a manfuacturer of induction heating machines. Its product line encompasses medium frequency, high frequency, ultra-high frequency induction machines, induction melting machines, and air-cooled induction machines. These machines cater to diverse industries including automotive, aerospace, medical, and energy, offering solutions for processes like hardening, tempering, annealing, heating, brazing, and melting. The company maintains adherence to ISO9000-2000 quality standards in its operations.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Miller Electric Mfg. LLC |

9.6%

|

| 2 | Ultraflex Power Technologies |

7.4%

|

| 3 | U.S. Solid |

7.4%

|

| 4 | Miwa Mfg Co., Ltd. |

5.3%

|

| 5 | Termomacchine S.r.l. |

4.3%

|

| 6 | HLQ INDUCTION EQUIPMENT CO.,LTD |

4.3%

|

| 7 | Malhotra Technologies |

4.3%

|

| 8 | Henan FOCO Machinery Co., Ltd |

4.3%

|

| 9 | Neturen Co., Ltd. |

4.3%

|

| 10 | Nippon Avionics Co., Ltd. |

4.3%

|

Derivation Method

The ranking is calculated based on the click share within the high frequency induction heating device page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

China

China

|

11 | 61.1% |

United States of America

United States of America

|

3 | 16.7% |

Japan

Japan

|

3 | 16.7% |

India

India

|

1 | 5.6% |

68 products found

68 products

S. workman-. Japan

1080+ people viewing

Last viewed: 4 hours ago

The TS series is a handheld type and is a very small model. The biggest feature is that the heated coil head can be moved freely, so you can aim at...

S. workman-. Japan

480+ people viewing

Last viewed: 4 hours ago

In a partnership with Italian CEIA, we will deliver a component type and the Power Cube series. Since the control unit, oscillation unit, and heati...

2 models listed

Denki Kogyo Co., Ltd.

410+ people viewing

Last viewed: 4 hours ago

■Features ・Achieved space savings by consolidating the oscillator, control panel, machinery, and water tank to the maximum extent possible (instal...

3 models listed

Seiwa Precision Machinery Co., Ltd.

610+ people viewing

Last viewed: 4 hours ago

The shrinking tooling system uses a high-frequency induction heating device to heat (approximately 300°C) and expand a shrinking holder in a short ...

SK Medical Electronics Co., Ltd.

480+ people viewing

Last viewed: 4 hours ago

■Small and lightweight Compact design saves installation space and supports inline installation ■Energy saving Highly efficient heating with a pow...

2 models listed

Denki Kogyo Co., Ltd.

450+ people viewing

Last viewed: 15 hours ago

■Features 1.Ultra-high temperature short-time heating using high-frequency induction heating (Max: 700℃) 2.Can be customized according to purpose a...

6 models listed

Seiwa Precision Machinery Co., Ltd.

640+ people viewing

Last viewed: 4 hours ago

The shrinking tooling system uses a high-frequency induction heating device to heat (approximately 300°C) and expand a shrinking holder in a short ...

TANNE INDUCTION JAPAN LIMITED.

560+ people viewing

Last viewed: 4 hours ago

■Technology overview New environmentally friendly technology This is the ultimate induction heating technology using ultra-high frequencies. By ins...

Daiichi Koshuha Industries Co., Ltd.

480+ people viewing

Last viewed: 4 hours ago

■DHF equipment and devices that meet your reliability ・DHF has developed new induction heating technologies such as high-frequency induction heati...

SK Medical Electronics Co., Ltd.

600+ people viewing

Last viewed: 2 hours ago

■Features ・Compact design does not take up space (460W × 390D × 700H) ・Rapid heating is possible using induction heating method (50g of pure iron...

Seiwa Precision Machinery Co., Ltd.

760+ people viewing

Last viewed: 1 hour ago

The shrinking tooling system uses a high-frequency induction heating device to heat (approximately 300°C) and expand a shrinking holder in a short ...

TANNE INDUCTION JAPAN LIMITED.

380+ people viewing

Last viewed: 3 hours ago

Daiichi Koshuha Industries Co., Ltd.

450+ people viewing

Last viewed: 4 hours ago

■DHF equipment and devices that meet your reliability ・DHF has developed new induction heating technologies such as high-frequency induction heati...

Daiichi Koshuha Industries Co., Ltd.

470+ people viewing

Last viewed: 4 hours ago

■DHF equipment and devices that meet your reliability ・DHF has developed new induction heating technologies such as high-frequency induction heati...

Daiichi Koshuha Industries Co., Ltd.

360+ people viewing

Last viewed: 3 hours ago

■DHF equipment and devices that meet your reliability ・DHF has developed new induction heating technologies such as high-frequency induction heati...

Daiichi Koshuha Industries Co., Ltd.

330+ people viewing

Last viewed: 3 hours ago

■DHF equipment and devices that meet your reliability ・DHF has developed new induction heating technologies such as high-frequency induction heati...

Daiichi Koshuha Industries Co., Ltd.

320+ people viewing

Last viewed: 3 hours ago

■DHF equipment and devices that meet your reliability ・DHF has developed new induction heating technologies such as high-frequency induction heati...

Daiichi Koshuha Industries Co., Ltd.

380+ people viewing

Last viewed: 4 hours ago

■DHF equipment and devices that meet your reliability ・DHF has developed new induction heating technologies such as high-frequency induction heati...

Daiichi Koshuha Industries Co., Ltd.

280+ people viewing

Last viewed: 3 hours ago

■DHF equipment and devices that meet your reliability ・DHF has developed new induction heating technologies such as high-frequency induction heati...

Daiichi Koshuha Industries Co., Ltd.

270+ people viewing

Last viewed: 3 hours ago

■DHF equipment and devices that meet your reliability ・DHF has developed new induction heating technologies such as high-frequency induction heati...

Daiichi Koshuha Industries Co., Ltd.

300+ people viewing

Last viewed: 3 hours ago

■DHF equipment and devices that meet your reliability ・DHF has developed new induction heating technologies such as high-frequency induction heati...

Daiichi Koshuha Industries Co., Ltd.

430+ people viewing

Last viewed: 4 hours ago

■DHF equipment and devices that meet your reliability ・DHF has developed new induction heating technologies such as high-frequency induction heati...

Daiichi Koshuha Industries Co., Ltd.

410+ people viewing

Last viewed: 4 hours ago

■DHF equipment and devices that meet your reliability ・DHF has developed new induction heating technologies such as high-frequency induction heati...

Daiichi Koshuha Industries Co., Ltd.

340+ people viewing

Last viewed: 3 hours ago

■DHF equipment and devices that meet your reliability ・DHF has developed new induction heating technologies such as high-frequency induction heati...

Daiichi Koshuha Industries Co., Ltd.

370+ people viewing

Last viewed: 3 hours ago

■DHF equipment and devices that meet your reliability ・DHF has developed new induction heating technologies such as high-frequency induction heati...

Daiichi Koshuha Industries Co., Ltd.

400+ people viewing

Last viewed: 3 hours ago

■DHF equipment and devices that meet your reliability ・DHF has developed new induction heating technologies such as high-frequency induction heati...

Daiichi Koshuha Industries Co., Ltd.

370+ people viewing

Last viewed: 3 hours ago

■DHF equipment and devices that meet your reliability ・DHF has developed new induction heating technologies such as high-frequency induction heati...

Daiichi Koshuha Industries Co., Ltd.

360+ people viewing

Last viewed: 3 hours ago

■Dependable DHF equipment and equipment ・DHF has developed new induction heating technologies such as high-frequency induction heating heat treatm...

Daiichi Koshuha Industries Co., Ltd.

440+ people viewing

Last viewed: 4 hours ago

■DHF equipment and devices that meet your reliability ・DHF has developed new induction heating technologies such as high-frequency induction heati...

Daiichi Koshuha Industries Co., Ltd.

400+ people viewing

Last viewed: 4 hours ago

■DHF equipment and devices that meet your reliability ・DHF has developed new induction heating technologies such as high-frequency induction heati...