All Categories

History

This section provides an overview for vacuum pads as well as their applications and principles. Also, please take a look at the list of 19 vacuum pad manufacturers and their company rankings. Here are the top-ranked vacuum pad companies as of February, 2026: 1.GINIER, 2.Anver Corp., 3.Pearse Bertram+ Streamline Contract Manufacturing.

Table of Contents

Categories Related to Vacuum Pads

1987~1991: Engaged in research on wire covering materials at Polymer Materials Laboratory.

1991~1997: Worked as a patent Engineer at Koike International Patent Office.

1997~2005 Worked as an intellectual property member at GE Yokogawa Medical System, currently working as a writer.

Linkedinhttps://www.linkedin.com/in/%E8%A3%95%E5%AD%90-%E9%88%B4%E6%9C%A8-92b21a234/

researchmap

https://researchmap.jp/0315rs2017

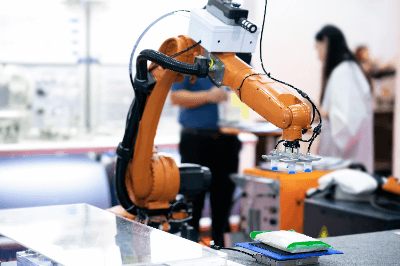

A vacuum pad is a component in a conveying system that absorbs and conveys an object to be conveyed (hereinafter referred to as a "workpiece").

The vacuum pad is connected to a vacuum generator. With the suction surface of the vacuum pad in contact with the workpiece, the vacuum generator creates a lower pressure (vacuum) in the space between the pad and the workpiece than the ambient air pressure. This causes the vacuum pad to pick up the workpiece for transport. Vacuum pads are used in a variety of fields to improve production efficiency because they require only a vacuum pad and a vacuum generator.

Vacuum pads are used in various fields because they are available in the configuration of a vacuum pad and a vacuum generator.

For example, they are used to convey relatively heavy metals such as car body pressed steel plates and hot stamping forged steel plates, plate glass, film, plastic, and other plate-like objects, as well as objects with surface roughness such as cardboard boxes and wood.

It can also be used to convey foods such as confectionery and electronic components, such as silicon wafers and cells.

Vacuum pads are suctioned by creating a vacuum in the space between the pad and the workpiece using a connected vacuum generator. In other words, the principle of the vacuum pad is that suction occurs when the pressure in the space between the pad and the workpiece is lower than the ambient air pressure (usually atmospheric pressure). The suction force of the vacuum pad is directly proportional to the pressure difference between the atmospheric pressure and the pressure inside the pad.

When the vacuum level of the pad, which is controlled by the vacuum generator, is lowered, suction stops when the pad can no longer support the weight of the workpiece. The pad and the workpiece are separated.

There are three types of vacuum generators: ejectors that use the Venturi effect, vacuum pumps that use motor rotation to rotate vanes and suction gas, and vacuum blowers that use impeller rotation to suction surrounding gas.

Vacuum pads are manufactured in various sizes, materials, and shapes in consideration of the operating environment, holding power, and durability to touch various shapes and types of workpieces.

Vacuum pads come in three main shapes: flat, oval, and bellows. The flat type is used for workpieces with flat surfaces.

The ellipsoidal type is used for long, narrow workpieces and is suitable for small areas, such as pipes. The oval shape is flat and has a small volume inside the Vacuum pad, so it can vacuum a workpiece in a short period. The bellows type is used when the height of the workpiece varies due to its bellows shape, and the height needs to be compensated as necessary.

Typical materials for vacuum pads are nitrile rubber, silicone rubber, polyurethane, and special high-temperature materials. For example, a silicone rubber vacuum pad is used for food products, which does not affect food products. An oil-resistant, silicone-free vacuum pad is used for automobile bodies.

Vacuum pad material should be matched not only to the material of the workpiece but also to the environment in which it is used. For example, if durability and high-speed transfer are required, a highly durable material that requires less frequent replacement should be used.

The first step in selecting a vacuum pad is to determine the conditions of use. The main operating conditions include the weight of the workpiece, suction posture, vacuum pressure used, acceleration when lifting the workpiece, acceleration when moving the workpiece, and the coefficient of friction between the workpiece and vacuum pad.

Here, we will use the example of lifting and picking up a workpiece vertically and then moving it horizontally.

The theoretical suction force of an individual vacuum pad is the difference between the atmospheric pressure and the pressure of the pad divided by the atmospheric pressure, multiplied by the suction area and the force due to atmospheric pressure. When using a single pad, select a vacuum pad whose value is greater than the theoretical holding force. When multiple pads are used, the Vacuum pads should be selected so that the value obtained by multiplying the Vacuum pad force of each pad by the number of pads is greater than the theoretical holding force.

Nitrile rubber is often used as the material for Vacuum pads in general applications, but selection should be made according to the Uses of the application and the material of the workpiece, such as using fluorine rubber in clean environments where conductive nitrile rubber or conductive silicon rubber is used in environments where static electricity is not desired.

Vacuum pads are made of rubber, so the suction surface wears out with use. Wear conditions vary depending on the frequency of use and vacuum pressure, but severe wear can cause air leakage, reduced suction power, longer suction time, and other problems.

Vacuum pads are usually treated as consumable items and need to be replaced periodically, considering the wear of the suction surface. Although the replacement time varies depending on the operating environment, if the required suction force cannot be obtained due to air leakage caused by wear, it may lead to a major accident, such as a workpiece falling off, so a replacement time should be set well in advance.

For example, the vacuum pressure drop due to leakage at the vacuum pad is measured, and if the pressure drops below a specified value, the pad should be replaced.

*Including some distributors, etc.

Sort by Features

Sort by Area

COVAL, established in 1986 in Raleigh, North Carolina, USA, is a manufacturer of vacuum handling solutions and vacuum management automation products. The product range includes vacuum pumps, suction cups, vacuum accessories, and intelligent vacuum managers that offer benefits such as improved productivity, reduced energy consumption, and enhanced safety in material handling processes. These products find applications in various industries, including packaging, automotive, plastics, and food processing, where they streamline operations, increase efficiency, and ensure the gentle and secure handling of delicate or irregularly shaped objects.

ANVER Vacuum Material Handling Specialists, established in 1975 and located in Elk Grove Village, Illinois, USA, is a manufacturer and supplier of vacuum tube lifting systems and vacuum lifting equipment. The company's product range includes vacuum tube lifters, lifting pads, grippers, generators, and system components, catering to diverse industries such as manufacturing, aerospace, automotive, food and beverage, and material handling. The company’s services entail, testing and certification, supply chain management, and technical support. The company also holds ISO 9001:2015 certification, an indication that it exceeds expectations in quality and service.

Pearse Betram+ was founded in 1947 in Bloomfield, Connecticut. Today Pearse Bertram+ is an end-to-end solutions provider for the manufacturing industry. Pearse Bertram+ is ISO 9001:2015 certified and also UL508A (industrial control panels), IPC 620 (wire harness assemblies), and IPC-A-610, J-STD-001, and IPC-7711 certified for soldering. Pearse Bertram+ operates in both contract manufacturing and engineering support. The manufacturing segment includes electrical, pneumatic, robotic, hydraulic, and process systems. Engineering support includes support for operation of robotics, machinery design and usage, industrial automation, value engineering, and auditing.

Nihon Pisco Co. Ltd., founded in 1976 and based in Nagano, Japan, is a manufacturer and distributor of pneumatic equipment and is ISO 9001 and ISO 14001 certified. The company stocks various products like valves, actuators, and vacuum accessories used in several industries, including semiconductor, medicine, and rechargeable battery. The company started selling push-in fitting for pneumatic piping in 1977 and launched the industry’s first push-in fitting built-in type speed controller in 1981. In 1993, it launched a few products, including a quick exhaust valve, a digital pressure sensor, and a vacuum generator with a digital pressure sensor.

CKD Corporation, established in 1943 under the name of Japan Aircraft Electric Co., Ltd., is a Japanese manufacturer of automation machinery and manufacturing components, headquartered in Komaki, Aichi. Their diverse portfolio includes pneumatic and fluid control components, fine system components, drive components, and labor-saving components. The company has also developed various types of automation machinery, such as transparent object inspection systems, pharmaceutical products packaging machines, and more. These products find applications in various industries, for example their automated food packaging systems are designed for maintaining food quality and hygienic conditions. Their fluid control components are used in the solar cell manufacturing process.

Advance Micro Solutions, founded in 2006 in Bernang, Malaysia, is a manufacturer of rubber and vacuum cups. The company specializes in the manufacturing of various products, including rubber gaskets, seals, O-rings, rubber pick up tools,, and various other vacuum cups. These products offer benefits such as optimum sealing properties, durability, and accuracy in diverse applications. The products serve various industries, including automotive, pharmaceuticals, aerospace, and packaging, where the rubber components ensure effective sealing and vacuum cups provide secure handling and automation solutions.

GINIER, established in 2010 in Suzhou, Jiangsu Province, China, is a manufacturer of various suction cups and vacuum suction cups. The company specializes in manufacturing various suction cups, including flat suction cups, bellows suction cups, and foam pads. These optimal-quality vacuum suction cups have robust durability, optimum suction performance, and resistance to wear and tear, allowing stable and long-lasting use. The suction cups cater to industries such as automotive, glass handling, packaging, and robotics, offering secure and efficient object handling solutions. The patented technology an d advanced vacuum suction cups production techniques make it a global manufacturer of domestic vacuum industry.

Dart Vacuum, founded in 2002 in Bromley, Kent, UK, is a manufacturer of vacuum cups and pads. The company specializes in manufacturing advanced products such as regular cups, bellows cups, threaded cups, oblong cups, and other custom silicone cups tailored to meet various industrial needs. These vacuum cups and pads are made to lift and grasp objects with optimum efficiency, allowing safe handling of materials. They are available in various materials and shapes to help with a multitude of tasks, from delicate glass dealing to heavy-duty metalwork in fields like automotive manufacture, the packaging industry, carpentry, and robotics.

Suction Cups, founded in 2001 and headquartered in Shenzhen, China, is a manufacturer of rubber products and silicone cups. The ISO 9001 certified company specializes in manufacturing various types of suction cups, including vacuum suction cups, silicone suction cups, flat rubber suction cups, and custom-designed suction cups. These suction cups offer robust grip and suction power, making them ideal for various applications. They are equipped with optimal durability, flexibility, and resistance to wear and tear, ensuring longevity and cost-effectiveness for users. The suction cups find applications in industries such as manufacturing, robotics, packaging, and material handling for multiple industrial needs.

Xiamen Better Silicone Co., Ltd, established in 1998 and based in Xiamen, China, is a manufacturer of mold tools, rubber, and plastic products. The company specializes in manufacturing various silicone rubber products, including silicone seals, gaskets, keypads, and custom silicone parts that come with optimal resistance to extreme temperatures, chemicals, and weathering for long-lasting performance and stability. The offerings find applications across various industries, such as automotive, electronics, medical devices, and household appliances, where the need for robust silicone components is important. It is ISO 9001, FDA, RoHS, and LFGB certified and uses injection molding technique for optimal molds.

Wood’s Powr-Grip Co., Inc. is a manufacturer of vacuum lifting equipment. Established in 1964, the company is based in Laurel, Montana, USA. The company specializes in designing and producing vacuum lifters and components for material handling. Its product range includes hand-held vacuum cups, vacuum lifters, mounting cups, and accessories, serving industries such as construction, glass handling, and manufacturing. Powr-Grip tools helps in handling smooth and nonporous materials such as glass, plastics, engine valves, sheet metal, and solid surfacing as well as laminates, stone slabs and appliances Wood’s Powr-Grip offers services like technical consultation, exchanges, repairs, warranties and customization.

William B. Rudow, Inc. was founded in 1946 and located in Sarasota, Florida, as a manufacturer of rubber & vinyl suckers, vacuum cups, and suction cups for the printing, packaging, baking, robotics, and parts handling industries. The company produces vacuum cups using materials such as rubber, vinyl, silicone, polyurethane, and neoprene with a variety of fittings and styles. They also offer spare parts and fittings such as discs, vertical washers, metal caps, paper stop deflectors, and adapters that have applications in the automobile, aerospace, construction, machinery manufacturing, and foundry industries.

Scorpion Manufacturing, established in 1987 and headquartered in Canada, is a manufacturer and supplier of pneumatic and vacuum components. The company's product range includes pneumatic products, vacuum components, automotive power clamps, vacuum pumps, and industrial process valves, catering to industries such as automation, aerospace, and automotive. The company’s services entail technical representation, product distribution, and engineered solutions. Devoted to first-hand technologies and fast delivery, Scorpion Manufacturing ensures customer satisfaction through its extensive inventory and skilled team. With over three decades of experience, it consistently exceeds expectations in quality and service.

SMC Corporation of America, established in 1977 and located in Noblesville, Indiana, is a manufacturer of pneumatic equipment and motion control products used in the automation, controls, and process industries. It is the North American subsidiary of Japan’s SMC Corporation, and it offers a broad range of products, including actuators, directional control valves, and airline equipment. The company is ISO 14001 and ISO 9001 certified and has an education division that teaches technical skills and the latest developments in industrial automation. It also runs a sales development program for training outside sales at the company.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | GINIER |

15.9%

|

| 2 | Anver Corp. |

10.6%

|

| 3 | Pearse Bertram+ Streamline Contract Manufacturing |

8.8%

|

| 4 | Dart Vacuum |

8.0%

|

| 5 | Advance Micro Solutions |

6.2%

|

| 6 | SUCTION CUPS |

6.2%

|

| 7 | William B. Rudow, Inc. |

6.2%

|

| 8 | COVAL |

5.3%

|

| 9 | Hirotaka Seiki Co., Ltd. |

5.3%

|

| 10 | Wood’s Powr-Grip Co., Inc. |

4.4%

|

Derivation Method

The ranking is calculated based on the click share within the vacuum pad page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

5 | 33.3% |

United States of America

United States of America

|

3 | 20.0% |

China

China

|

2 | 13.3% |

Malaysia

Malaysia

|

1 | 6.7% |

United Kingdom

United Kingdom

|

1 | 6.7% |

| NULl | 1 | 6.7% |

Canada

Canada

|

1 | 6.7% |

Italy

Italy

|

1 | 6.7% |

544 products found

544 products

Otani Giken Co., Ltd.

190+ people viewing

Last viewed: 3 hours ago

This is a standard suction pad. Especially suitable for suctioning flat workpieces.

10 models listed

Otani Giken Co., Ltd.

180+ people viewing

Last viewed: 2 hours ago

This is a 1.5 step bellows-like suction pad. It is also possible to pick up tilted workpieces. It can also absorb variations in the height directio...

10 models listed

Otani Giken Co., Ltd.

220+ people viewing

Last viewed: 1 day ago

A 2.5 step bellows-like suction pad. It is also possible to pick up tilted workpieces. It can also absorb variations in the height direction of the...

10 models listed

Combum Co., Ltd.

340+ people viewing

Last viewed: 8 hours ago

Wide variety: Φ20, 40, 60, 80, 100mm, can be selected according to the size of the workpiece Features ■Using Bernoulli's theorem, workpieces are t...

5 models listed

Orte Corporation Co., Ltd.

230+ people viewing

Last viewed: 21 hours ago

■ Use ・ We recommend that you scratch the surface of the chip with a collet such as metal, heat -resistant resin, or have problems with chips. ・ ...

10 models listed

Otani Giken Co., Ltd.

210+ people viewing

Last viewed: 4 hours ago

A 3.5 step bellows-like suction pad. It is also possible to pick up tilted workpieces. It can also absorb variations in the height direction of the...

4 models listed

Orte Corporation Co., Ltd.

200+ people viewing

Last viewed: 1 day ago

■ Use ・ We recommend that you scratch the surface of the chip with a collet such as metal, heat -resistant resin, or have problems with chips. ・ ...

10 models listed

Otani Giken Co., Ltd.

210+ people viewing

Last viewed: 23 hours ago

This suction pad has a thin lip, so it adheres well to the workpiece, and can also suction workpieces that are tilted or uneven.

3 models listed

Gunkyo Seisakusho Co., Ltd.

410+ people viewing

Last viewed: 15 hours ago

Is it expensive to replace pads? Keep the cost of consumables as low as possible.

Orte Corporation Co., Ltd.

200+ people viewing

Last viewed: 12 hours ago

■ Use ・ We recommend that you scratch the surface of the chip with a collet such as metal, heat -resistant resin, or have problems with chips. ・ ...

10 models listed

Otani Giken Co., Ltd.

200+ people viewing

Last viewed: 15 hours ago

Increases the effective suction area for rectangular workpieces such as lead frames and ICs, allowing for proper suction. This is an oval suction pad.

10 models listed

Combum Co., Ltd.

390+ people viewing

Last viewed: 3 hours ago

■Features ・The star-shaped lip shape can freely follow soft bodies and bag-shaped workpieces. ・The materials used are FDA compliant. ・In additio...

4 models listed

Orte Corporation Co., Ltd.

260+ people viewing

Last viewed: 1 day ago

■ Use ・ We recommend that you scratch the surface of the chip with a collet such as metal, heat -resistant resin, or have problems with chips. ・ ...

8 models listed

Otani Giken Co., Ltd.

170+ people viewing

Last viewed: 1 day ago

This suction pad has a very thin lip and a flat pad surface, making it difficult for thin workpieces to wrinkle. This is a suction pad suitable for...

3 models listed

Orte Corporation Co., Ltd.

200+ people viewing

Last viewed: 1 day ago

■ Use ・ We recommend that you scratch the surface of the chip with a collet such as metal, heat -resistant resin, or have problems with chips. ・ ...

7 models listed

Combum Co., Ltd.

230+ people viewing

Last viewed: 5 hours ago

■New materials have been added to the suction pad. ・Suction pad made of silicone rubber material mixed with metal components. ・If there is any co...

6 models listed

Otani Giken Co., Ltd.

230+ people viewing

Last viewed: 1 day ago

This suction pad is made of soft material, which prevents wrinkles from forming on thin workpieces. This is a suction pad suitable for paper and th...

2 models listed

Orte Corporation Co., Ltd.

180+ people viewing

Last viewed: 1 day ago

■ Use ・ We recommend that you scratch the surface of the chip with a collet such as metal, heat -resistant resin, or have problems with chips. ・ ...

10 models listed

Daiki Sangyo Co., Ltd.

150+ people viewing

Last viewed: 1 day ago

■A wide variety of pad sizes, pad materials, and holder shapes. Suitable for thick and flat workpieces. Our lineup includes "vacuum pads for packag...

6 models listed

Combum Co., Ltd.

220+ people viewing

Last viewed: 1 day ago

■New materials have been added to the suction pad. ・Suction pad made of silicone rubber material mixed with metal components. ・If there is any co...

8 models listed

Otani Giken Co., Ltd.

140+ people viewing

Last viewed: 8 hours ago

This suction pad is flexible due to its long neck and recess on the top of the cup, making it suitable for suctioning fragile workpieces. Φ6 size.

10 models listed

Tatsuta Co., Ltd.

380+ people viewing

Last viewed: 1 day ago

■Features ・Uses basic bellows cartridge. - Easy handling of lightweight workpieces. -Easy to use in narrow spaces. ・For workpieces whose height i...

Orte Corporation Co., Ltd.

170+ people viewing

Last viewed: 1 day ago

■ Use ・ We recommend that you scratch the surface of the chip with a collet such as metal, heat -resistant resin, or have problems with chips. ・ ...

5 models listed

TAIYO Co., Ltd.

430+ people viewing

Last viewed: 1 day ago

Ideal for transporting heavy round objects such as concrete piles and steel pipes. ■Features ・Easy to replace pads. ・The lip is long and easily ...

Orte Corporation Co., Ltd.

200+ people viewing

Last viewed: 21 hours ago

■ Use ・ We recommend that you scratch the surface of the chip with a collet such as metal, heat -resistant resin, or have problems with chips. ・ ...

10 models listed

Orte Corporation Co., Ltd.

210+ people viewing

Last viewed: 1 day ago

■ Use ・ We recommend that you scratch the surface of the chip with a collet such as metal, heat -resistant resin, or have problems with chips. ・ ...

7 models listed

Orte Corporation Co., Ltd.

180+ people viewing

Last viewed: 8 hours ago

■ Use ・ We recommend that you scratch the surface of the chip with a collet such as metal, heat -resistant resin, or have problems with chips. ・ ...

10 models listed

Orte Corporation Co., Ltd.

130+ people viewing

Last viewed: 1 day ago

■ Use ・ We recommend that you scratch the surface of the chip with a collet such as metal, heat -resistant resin, or have problems with chips. ・ ...

6 models listed

Orte Corporation Co., Ltd.

210+ people viewing

Last viewed: 36 minutes ago

■ Use ・ We recommend that you scratch the surface of the chip with a collet such as metal, heat -resistant resin, or have problems with chips. ・ ...

10 models listed

Orte Corporation Co., Ltd.

260+ people viewing

Last viewed: 2 hours ago

■ Use ・ We recommend that you scratch the surface of the chip with a collet such as metal, heat -resistant resin, or have problems with chips. ・ ...

6 models listed