13 Bearing Holder Manufacturers in 2024

This section provides an overview for bearing holders as well as their applications and principles. Also, please take a look at the list of 13 bearing holder manufacturers and their company rankings. Here are the top-ranked bearing holder companies as of October, 2024: 1.Midwest Super Cub, 2.Wahl Bros. Racing, 3.Ozak Seiko Co., Ltd..

Table of Contents

What Is a Bearing Holder?

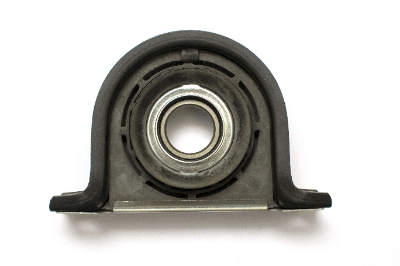

A bearing holder is a device used in various machines to support bearings in the correct position to receive the load and rotation of a rotating shaft. It is attached to the machine's body and holds the bearings by fitting them. The design of a bearing holder must match the load that the bearing is subjected to, and it should have sufficient rigidity based on the bearing size.

Uses of Bearing Holders

Bearing holders are predominantly used in industrial machinery. They must be rigid enough to withstand the load received by the rotating shaft. Considerations such as surface roughness of the bore and corner radii size are important. Bearing holders simplify the design and manufacturing of the housing part that holds the bearing. They are typically mounted as single or double bearing holders for deep groove ball bearings. For angular contact bearings, they can be used with a back-mounted double bearing or with an additional deep groove ball bearing.

Principle of Bearing Holders

Bearing holders serve the following functions:

1. Rigidity

Rigidity is crucial to ensure that the rotating shaft remains in position under load and maintains smooth rotation. Misalignment can cause issues such as gear meshing inaccuracies, noise, or gear damage.

2. Positional Accuracy

Bearing holders are typically screwed to the machine body. Precise alignment of screw holes and bearing holding holes is vital for correct shaft positioning. The housing hole size that holds the bearing is also important to prevent rattling between the bearing and the housing. The housing bore should typically be finished to a tolerance grade of about H7 for a clearance fit.

3. Heat Dissipation

Heat dissipation is especially important when the rotating shaft is under high loads and speeds. Bearing holders play a crucial role in dissipating heat generated by bearings to prevent overheating.

Other Information on Bearing Holders

How to Use Bearing Holders

Correct usage of bearing holders is key to maintaining bearing performance. Methods of mounting bearings, such as flange seizures, retaining rings, and free-running bearings, must be chosen based on the application:

- Flange Holder: Uses a flange to hold and fix the bearing axially. Suitable for applications where axial movement is undesirable.

- Retaining Ring: A groove in the housing holds a retaining ring to prevent the bearing from loosening. Used when axial force is minimal and slight axial movement is acceptable.

- Free-standing: No axial restriction, allowing free movement of the bearing. Typically used to support the free end of a ball screw.

List of 13 Bearing Holder Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- Germany

- Japan

- Netherlands

- Sweden

-

-

-

Midwest Super Cub

Top Shaft Bearing Holder

Manufacturer Overview

Midwest Super Cub, founded in 1995 in Welton, Iowa, USA, is a manufacturer specializing in performance parts for various vehicles. The company offers advanced-performance garden tractor pulling parts, complete tractors, transmissions and parts, chassis parts, and motors specifically designed for Cub Cadets. It is ISO 9001 certified with products offering precision engineering and performance enhancement. Its offerings serve the niche industry of garden tractor pulling, providing racers and enthusiasts with the essential components to modify and optimize Cub Cadet tractors for competitive and recreational use.

-

-

-

-

-

Vogel Manufacturin

Top Shaft Bearing Holder

Manufacturer Overview

Vogel Manufacturing, headquartered in Oshkosh, Wisconsin, USA, has been a manufacturer of garden tractor pulling parts and related solutions since 1975. The company provides a wide range of products for garden tractor pulling, such as pistons, camshafts, connecting rods, carburetors, air filters, tires, wheels, and more. These products are designed to enhance the performance and durability of garden tractors for various racing applications. The company also provides custom fabrication and engineering services to meet the specific needs of its customers.

-

-

-

-

-

-

-

NACHI-FUJIKOSHI CORP.

Plummer Block Housing

Manufacturer Overview

NACHI-FUJIKOSHI CORP. is a Japanese manufacturer of industrial machinery and tools, such as bearings, hydraulic equipment, robots, and cutting tools. They also provide services such as machine maintenance and repair. The company's products are used in automotive, aerospace, construction, and electronics. One of NACHI-FUJIKOSHI's renowned products is their robotic arm, the "MZR series," which is designed for precision assembly and inspection tasks in industries. They received several awards for their technological advancements and contributions to the industry, including the 2021 Japan Society of Mechanical Engineers Medal for new hydraulic equipment technology and the 2020 Nikkan Kogyo Shimbun Grand Technology Award.

-

-

-

-

-

NSK Ltd.

Bearing Units

Manufacturer Overview

NSK Ltd., based in Japan, is a manufacturer of precision bearings and motion control solutions which started its journey in 1916. The company has established itself as a major supplier for multiple industries, including automotive, industrial machinery, and aerospace. Their extensive product portfolio encompasses ball bearings, roller bearings, and linear motion components. Their Motion & Control products and technologies support the motion that brings comfort and convenience in cars, planes, wind turbines, satellites, and almost anything with moving parts.

-

-

-

-

-

TBK Co., Ltd.

Bearing Housings

Manufacturer Overview

TBK Co., Ltd., established in 1949 with headquarters in Tokyo, Japan, is a manufacturer of brakes and engine components for road load-transporting trucks. The company's product line includes brakes for trucks and buses, water pumps for engine cooling systems, oil pumps for lubrication systems, and replacement parts. Its extended portfolio of products includes engine camshafts, cylinder heads, engine units, engine assist systems, and crankcases. Isuzu Motors Ltd., Mitsubishi Fuso Truck and Bus Corp., UD Trucks Corporation, Hino Motors Ltd., and Mitsubishi Motors Corporation are only some of the clients the company serves.

-

-

-

-

-

Rodon International

Bearing housings

Manufacturer Overview

Rodon International BV is based in the Netherlands and was founded in 2014 as the manufacturer and supplier of poultry processing spare parts. the company not only supplies various spare parts for machinery used in the poultry industry but can also modify and adapt parts to suit the customer's specific needs. They deal in parts for overhead conveyors, and in de-feathering and cropping machines. there is also equipment such as blades and knives, openers, an Inside bird washer, and brushes available for immediate delivery.

-

-

-

-

-

SKF

Bearing housings

Manufacturer Overview

SKF UK is the British division of SKF, originally founded in 1907 and headquartered in Gothenburg, Sweden. SKF designs, develops, and manufacturers bearings, seals, lubrication systems, and services worldwide, with industrial and automotive segments, providing solutions for industries including aerospace, agriculture, transportation, food and beverage, general machinery, material handling, mining, energy, paper, and wind energy. SKF UK offers rolling bearings, mounted bearings, automotive seals, lubrication management, vehicle aftermarket services, waste electric products, and electronic equipment products as well as services including maintenance, remanufacturing, customization, and training.

-

-

-

-

-

CREATION MODEL LTD

ALU ECCENTRIC BEARING HOLDER 0.5MM (BLACK/2PCS)

Manufacturer Overview

CREATION MODEL LTD, established in 2006 and headquartered in Shizouka, Japan, is a manufacturer of race-oriented suspension geometry for Infinity nitro on-road models and accessories. The company ensures the quality and precision of its products through rigorous quality control and adheres to ISO 9001 certification, offering precision, durability, and performance. Its suspension geometry components are specifically designed for the competitive racing industry, enhancing the handling and performance of the Infinity nitro on-road models. It offers numerous chassis, accessories, touring cars, racing cars, and components serving the specific demands of professional and amateur racers, to achieve optimal results on the track.

-

-

-

-

-

D&E Bearings

Bearing housings

Manufacturer Overview

D&E Bearings, established in 1966 in Stockholm, Sweden, is a manufacturer specializing in the production of slide bearings, plain bearings, and roller bearings. The company holds ISO 9001 & 14001 certifications, ensuring accuracy, durability, and sustainability in the products. Its product portfolio offers a broad array of solutions for various industries, including automotive, industrial machinery, construction, and renewable energy. These advanced bearings are instrumental in reducing friction and wear, thereby extending the lifespan and performance of machinery and equipment in applications ranging from automotive engines to wind turbines.

-

-

-

-

-

NTN-SNR

NTN-SNR BEARING HOUSINGS

Manufacturer Overview

NTN-SNR, established in 1916 and headquartered in Annecy, France, is a manufacturer of industrial machinery spare parts and bearings. The company specializes in manufacturing various products, including bearings, linear modules, constant velocity joints, tensioners, vehicle spare parts, and servicing equipment. It adheres to ISO 9001 and ISO/TS 16949 certifications for precision, stability, and extended product lifespans. Its comprehensive product offerings serve various industries, including automotive, aerospace, railway, agriculture, and industrial manufacturing, providing essential components and solutions that play a critical role in the performance and efficiency of machinery and vehicles worldwide.

-

-

-

-

-

Wahl Bros. Racing

Bearing Holders & Accessories

Manufacturer Overview

Wahl Bros. Racing, established in 1981 in Greenbush, Minnesota, USA, is a manufacturer of racing car parts, accessories, chassis, and various performance parts. The company’s product range includes a comprehensive variety of items such as snowmobile and ATV parts, suspension components, advanced-performance clutches, and lightweight chassis components. It offers streamlined quality and holds ISO 9001 certification, ensuring the products are used for precision, durability, and optimal performance. It serves the motorsport industry, offering solutions for snowmobile and ATV racing, as well as other competitive motorsports with premium, specialized equipment, serving the varying needs of professional racers and motorsport hobbyists.

-

-

-

-

-

LFD Wälzlager GmbH

Bearing housings

Distributor Overview

LFD Wälzlager GmbH, founded in 1978, is a mechanical engineering supplier that specialize in spherical plain bearings, rod ends, and hydraulic cylinders, headquartered in Dortmund, Nordrhein-Westfalen, Germany. It serves customers worldwide and is part of the engine, turbine, and power transmission equipment manufacturing industry. It has 7 companies in its corporate family. Whether it’s conveyor or drive technology, mechanical and plant engineering, pumps and compressors, automotive and agricultural technology, or the sports and leisure sectors – all industries around the globe use its products, manufactured according to German standards.

-

-

Bearing Holder Manufacturer Ranking

*Including some distributors, etc.Ranking as of October 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Midwest Super Cub |

40.0%

|

| 2 | Wahl Bros. Racing |

20.0%

|

| 3 | Ozak Seiko Co., Ltd. |

20.0%

|

| 4 | NACHI-FUJIKOSHI CORP. |

20.0%

|

Derivation Method

The ranking is calculated based on the click share within the bearing holder page as of October 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- NSK Ltd.: 30,577

- NACHI-FUJIKOSHI CORP.: 7,205

- Ozak Seiko Co., Ltd.: 138

Newly Established Company

- LFD Wälzlager GmbH: 1978 (46 years ago)

- Ozak Seiko Co., Ltd.: 1976 (48 years ago)

- Vogel Manufacturin: 1975 (49 years ago)

Company with a History

- SKF: 1907 (117 years ago)

- NSK Ltd.: 1916 (108 years ago)

- NACHI-FUJIKOSHI CORP.: 1928 (96 years ago)

Bearing Holder Manufacturers in United States

*Including some distributors, etc.

Global Distribution of Bearing Holder Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

5 | 50.0% |

United States of America

United States of America

|

2 | 20.0% |

Netherlands

Netherlands

|

1 | 10.0% |

Sweden

Sweden

|

1 | 10.0% |

Germany

Germany

|

1 | 10.0% |

List of Bearing Holder Products

7 products are listed.

Ozak Seiko Co., Ltd.

Compact and easy mounting lead screw support unit SUH (fixed side) series

30+ people viewing

There is no need to design sending screws ■ Characteristics ・ Block type ・ Recommended axis diameter: φ8 ~ φ32 ・ Compatible with collective ord...