All Categories

History

This section provides an overview for zeolites as well as their applications and principles. Also, please take a look at the list of 6 zeolite manufacturers and their company rankings. Here are the top-ranked zeolite companies as of February, 2026: 1.Protech Minerals, LLC, 2.TOMOE Engineering Co., Ltd., 3.Reade Advanced Materials.

Table of Contents

Categories Related to Zeolites

Postdoctoral researcher, conducting research on the production of cathode composite particles for solid-state batteries in the Equipment Engineering Group of Osaka Prefecture University.

Belongs to the Resource and Energy Recycling Laboratory, Nagaoka University of Technology, and conducts research on the development of DDR-type zeolite membranes for CO2 separation and the capture of CO2 from digestion gas generated from sewage treatment plants.

https://researchmap.jp/eiji-hayakawa

Thesis

https://doi.org/10.3390/membranes11080623

http://www.ijcea.org/index.php?m=content&c=index&a=show&catid=109&id=1177

https://www.sciencedirect.com/science/article/abs/pii/S1387181119305529?via%3Dihub

https://www.sciencedirect.com/science/article/abs/pii/S138358661833154X?via%3Dihub

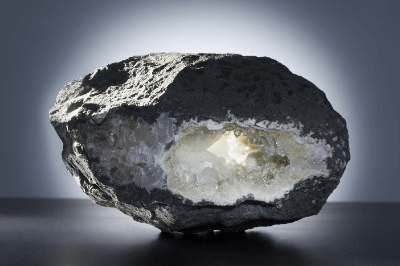

Zeolite is a crystalline aluminosilicate. Its main components are silicon, aluminum, and oxygen, forming a porous crystal structure. The smallest basic unit of zeolite is the SiO4 tetrahedron, which is assembled into a three-dimensional structure. Some of the silicon is replaced by aluminum, and cations exist around it to regulate the charge.

In general, zeolites have ion exchange and adsorption capacities that derive from their unique crystal structure. This property is applied to gas adsorption, cation exchange, and catalysis.

Zeolites have a myriad of pores at the molecular level and depending on their structure, they possess various properties such as adsorption, ion exchange, and catalytic properties.

Zeolites are also called molecular sieves and can sieve molecules according to pore size. This property is used to remove water and impurities from gases and solvents. Zeolites are also used as soil conditioners, water treatment agents, carbon dioxide and nitrogen adsorbents, and are catalysts for petrochemical products.

Zeolite is a porous crystalline aluminosilicate composed of SiO4 and AlO4 tetrahedra. Zeolites are composed of SiO4 tetrahedra and AlO4 tetrahedra.

Zeolites are composed of SiO4 and AlO4 tetrahedra in a wide variety of crystal structures, and currently, more than 240 different structures have been found. Each of these differs greatly in pore size and adsorption capacity.

Zeolites are classified into three main types: natural zeolite, synthetic zeolite, and artificial zeolite. There are many types of natural zeolites, including borite, mordenite, and clinoptilolite. Most of them do not have a uniform crystal structure and occur together with quartz and carbonates. Synthetic zeolites are artificially synthesized zeolites. Synthetic zeolites have higher adsorption and ion exchange capacities than natural zeolites, but the cost of synthesis is higher. Artificial zeolite is a zeolite synthesized without the high cost of synthetic zeolite. It can be synthesized by reacting coal ash with caustic soda. By changing the formulation and conditions, artificial zeolite with high functionality can be synthesized.

Zeolite has been used as a material for the separation of membranes. Zeolite can be processed into inorganic membranes called reverse osmosis membranes to dehydrate organic solvents, remove water vapor from gases, and remove salt from seawater. For example, in the dehydration of organic solvents, water is removed by taking advantage of the slight difference in molecular weight between organic solvent molecules and water molecules. Hydrophilic organic solvents such as ethanol, isopropyl alcohol, butanol, ethyl acetate, and acetone can also be dehydrated.

There are three advantages to using zeolites for water treatment.

The first is that zeolites have uniform pores, enabling separation by molecular sieving with high precision. Zeolites are called molecular sieves because they have numerous pores at the molecular level and can sieve at the molecular level.

Second, because of its heat resistance and chemical resistance, zeolite can be used under high-temperature conditions and applied to various substances. It can be used for chemicals that are harmful to the human body, such as those used in chemical plants and paint factories.

Third, zeolite itself is available in a wide variety of types, each with various compositions and pore sizes. This allows for a much greater degree of freedom in the treatment process, as materials can be selected according to the object to be treated and the application.

As the composition of the zeolite changes, the properties of the water treatment also change. For example, zeolite contains a large amount of silicon (Si) and aluminum (Al). When the Si/Al ratio is low, the zeolite becomes more hydrophilic and shows high water adsorption properties, making it suitable for the dehydration of solvents. Conversely, when the Si/Al ratio is increased, hydrophobicity increases and chemical resistance to acids and other substances is high, making zeolite suitable for treating highly acidic chemicals.

Zeolites are attracting attention for their use in agriculture and environmental conservation due to their adsorption and ion exchange capacities.

Zeolites can be applied to ponds, swamps, and soil to adsorb heavy metals and eutrophication-causing components, thereby protecting the water and soil environment. Zeolite is also an excellent material for the deodorization and decomposition of toxic components of automobile exhaust gas to maintain normal air, water, and soil environments.

Additionally, zeolites are used in agricultural and horticultural applications. Zeolite has regular pores that allow for adequate aeration. Mixing soil with zeolite creates soil that provides sufficient oxygen to the roots and improves plant growth. It can also adsorb a variety of substances, allowing it to retain some of the fertilizer components while supplying an adequate amount to the plants. It can also purify the soil by adsorbing impurities contained in the soil. Minerals dissolved in zeolite can also have the effect of being used as plant nutrients. Examples of applications in the horticultural field include potted plants, vases, and hydroponics.

Zeolite is one of the indispensable catalytic materials in the petrochemical field. Zeolites are used for isomerization, cracking, and aromatization of hydrocarbons, and to produce fuel oils such as gasoline from methanol. Fluidized bed catalytic cracking (FCC) is one of the most typical examples. This is a reaction that breaks down the components obtained from the upstream of crude oil into molecules with lower carbon numbers. A method used to produce higher value-added components such as gasoline and is indispensable to our current way of life.

In recent years, zeolite separation membranes have also been developed to remove carbon dioxide from biogas, natural gas, and coal gasification combined cycle power generation, etc. These are attracting attention as energy sources with less environmental impact, and zeolites are also very important in the energy and environmental fields.

*Including some distributors, etc.

Sort by Features

Sort by Area

Protech Minerals, LLC is a manufacturer and supplier of natural minerals, with its headquarters located in Victorville, California. The company offers a diverse range of natural minerals, including Gypsum, Montmorillonite clay, bentonite clay, sepiolite clay, and kaolin clay. These minerals serve various purposes across industries such as agriculture, construction, and personal care. Protech Minerals ensures the quality and organic compliance of their products, as they are certified by the Organic Materials Review Institute (OMRI) and approved for use in organic farming.

READE was originally established in Wolverhampton, England in 1773 as a pharmaceutical chemical and varnish manufacturer. Today READE is based in Riverside, Rhode Island in the United States and is an ISO 9001-certified distributor of specialty chemical solids. READE Advanced Materials offers a selection of hundreds of materials and compounds ranging from alloys in various forms to oxides, sulfides, individual elements, and specialty compounds. READE offers global sourcing, custom toll chemical processing, and custom toll packaging from metallurgical grade to pharmaceutical and food grade.

Bisley International, LLC is a multinational marketer and distributor of industrial raw materials, with offices in Australia, New Zealand, Asia, the Middle East, and North America. The company serves several industries including agrochemicals, metallurgy, construction, food & beverage, and oil well drilling. The company produces trace elements and additives for the agrochemical industry. For metallurgy, the company produces specialty allows, raw materials, and consumables. For construction, the company produces raw materials for concrete and plaster. For oil well drilling, the company produces products for extracting and well cementing.

CB Minerals LLC, established in 1897 and headquartered in Mamaroneck, New York, is a global mineral supplier and distributor. The company represents many mining and mineral producers both in the United States and throughout the world offering over 40 different industrial minerals of many different grades. It carries minerals for the cosmetics industry, the environmental industry, the paints industry, and many more. Some of its offerings include alumina, bentonite, calcium sulfate, mica, and more. It adheres to ISO 9000 standards and is registered with the U.S. General Services Administration.

Tomoe Engineering Co., Ltd., established in 1941 and located in Tokyo, Japan, is a manufacturer of decanter type centrifugal separators. The company offers a range of products, including gravity belt thickeners, HED-type dewatering centrifuges, disc-type centrifuges, rotary snails, and ASM tubular centrifuges, which cater to pharmaceuticals, food, chemistry, ships, electric power, and water treatment. The products are used in sludge dewatering, oil-water separation, clarification processes, liquid-liquid separation, and solids removal. The company’s expertise extends across diverse sectors, such as oil and gas and power generation.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Protech Minerals, LLC |

26.8%

|

| 2 | TOMOE Engineering Co., Ltd. |

24.2%

|

| 3 | Reade Advanced Materials |

15.1%

|

| 4 | CB Minerals LLC |

13.4%

|

| 5 | Bisley International LLC |

12.5%

|

| 6 | Nakamura Choukou Co., Ltd. |

8.0%

|

Derivation Method

The ranking is calculated based on the click share within the zeolite page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

4 | 66.7% |

Japan

Japan

|

2 | 33.3% |

20 products found

20 products

Hokuei Co., Ltd.

590+ people viewing

Last viewed: 8 hours ago

The ``soil'' that grows crops is screaming. Because he is sick. The role of ``Klino Zeolite'' is to improve the soil and grow healthy crops. Japane...

️Nature Grace Ltd.

300+ people viewing

Last viewed: 8 hours ago

■Health recovery/environmental purification “eco housing” project Natural antioxidant, redox, and water/air quality purification effects protect bu...

Yamajin Pharmaceutical Co., Ltd.

450+ people viewing

Last viewed: 8 hours ago

Zeolite has pores at the molecular level, and has the property of adsorbing various substances within these pores. It can adsorb molecules smaller ...

Kawai Fertilizer Co., Ltd.

390+ people viewing

Last viewed: 1 hour ago

■Fertilizer piggy bank Hohiup, produced in Shimane Prefecture, is a natural clay mineral whose main component is mordenite, which is formed by alte...

Technos Nakata Co., Ltd.

410+ people viewing

Last viewed: 8 hours ago

■Features Zeolite (variety mordenite) is fired and pelletized into a cylindrical shape. Zeolite's excellent adsorption capacity has been further im...

Technos Nakata Co., Ltd.

410+ people viewing

Raw materials used ■Domestic natural zeolite <calcination processing> It is a metamorphosed ore made from accumulated volcanic ash, and its interio...

Technos Nakata Co., Ltd.

340+ people viewing

Last viewed: 1 day ago

■Dehumidifier product information Domestic household dehumidifiers were launched in 1979, and 12 years later, in 1991, the market size exceeded the...

Moriya Sangyo Co., Ltd.

660+ people viewing

Last viewed: 7 hours ago

This is an ethylene gas/VOC adsorption/decomposition agent that is effective in preserving freshness and inhibiting mold during long-term storage o...

Moriya Sangyo Co., Ltd.

390+ people viewing

Last viewed: 8 hours ago

This is an ethylene gas/VOC adsorption/decomposition agent that is effective in preserving freshness and inhibiting mold during long-term storage o...

Moriya Sangyo Co., Ltd.

380+ people viewing

Last viewed: 1 day ago

This is an ethylene gas/VOC adsorption/decomposition agent that is effective in preserving freshness and inhibiting mold during long-term storage o...

Act Biz Co., Ltd.

310+ people viewing

Last viewed: 8 hours ago

■Humidity control effect using porous mineral “Zeophil” - Zeofil has a humidity control function that absorbs moisture when the air is humid and re...

Nakamura Choukou Co., Ltd.

840+ people viewing

Last viewed: 5 hours ago

■Nano-sized zeolite “Zeoal” which is a miniaturized version of zeolite Zeolites are crystalline compounds whose main components are silica (silicon...