All Categories

History

This section provides an overview for hydraulic presses as well as their applications and principles. Also, please take a look at the list of 23 hydraulic presse manufacturers and their company rankings. Here are the top-ranked hydraulic presse companies as of December, 2024: 1.Schuler Inc., 2.F P Miller Company, 3.SIMPAC America Co. Ltd..

Table of Contents

Categories Related to Hydraulic Presses

Postdoctoral researcher, conducting research on the production of cathode composite particles for solid-state batteries in the Equipment Engineering Group of Osaka Prefecture University.

Belongs to the Resource and Energy Recycling Laboratory, Nagaoka University of Technology, and conducts research on the development of DDR-type zeolite membranes for CO2 separation and the capture of CO2 from digestion gas generated from sewage treatment plants.

https://researchmap.jp/eiji-hayakawa

Thesis

https://doi.org/10.3390/membranes11080623

http://www.ijcea.org/index.php?m=content&c=index&a=show&catid=109&id=1177

https://www.sciencedirect.com/science/article/abs/pii/S1387181119305529?via%3Dihub

https://www.sciencedirect.com/science/article/abs/pii/S138358661833154X?via%3Dihub

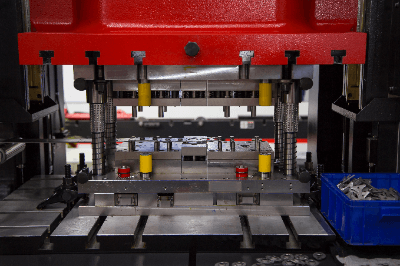

A hydraulic press is a device that uses hydraulic pressure as its power source to apply pressure to thin sheet metal and process it into the shape of a die.

The hydraulic motor sends oil to the hydraulic cylinder, and the piston in the hydraulic cylinder slides the die up and down to press it. Hydraulic presses are characterized by the speed of the slide, the pressure at the time of operation, and the long stroke. On the other hand, there is a risk of falling accidents due to oil leakage, etc., which must be considered when using hydraulic presses.

Presses are available in mechanical and servo motor types, depending on the operating system.

Although hydraulic presses have relatively slow production speeds, they can handle a wide range of materials and allow precise control of press speed, acceleration, force, and stroke length. In addition, large compression capacity can be obtained on a relatively small scale. These features make them suitable for small-scale production, drawing, and bending.

Hydraulic presses are mainly used in the processing of sheet metal materials for automobiles, home appliances, and electrical equipment. The types of presses available include cutting presses, deep drawing presses, injection presses, forming presses, punching presses, and forging presses. When selecting a press, it is necessary to consider the amount of press pressure, length of stroke, size of the press to be handled, and safety aspects. Examples of hydraulic presses in use are shown below.

Hydraulic presses use Pascal's principle to produce a large force with a small force. Pascal's principle states that fluid in a closed container, regardless of the shape of the container, transmits the pressure per unit area received at one point directly to all other parts of the fluid. For example, in the figure below, F1/A1 = F2/A2 because the pressures on both sides are balanced, and F2 = F1 × A2/A1. In other words, the larger the area ratio, the more force can be generated.

Also, the principle of leverage allows the force (f) at the force point of the lever to be transmitted as a larger force (F1) at the point of action. By utilizing these two principles, a very large force can be generated even by human power.

It is important to note here that the larger the area ratio of the two sides, the greater the force that can be generated, but at the same time, the length that can be moved (stroke) becomes shorter. The stroke is determined by the amount of oil that is pushed out, and the larger the area ratio, the smaller the amount of oil that can be pushed out, resulting in a shorter stroke.

In the explanation of the principle, the manual method using a lever is briefly explained. However, hydraulic presses used industrially need to apply very large force precisely, so they use a hydraulic pump to push out oil. The following is an explanation of the operating principle of a hydraulic press.

A hydraulic press consists of a hydraulic pump, hydraulic cylinder, pressure control valve, flow control valve, directional valve, hydraulic tank, and a press section. The hydraulic pump, pressure control valve, and hydraulic cylinder are connected to the hydraulic tank. The pipe extending from the hydraulic pump is connected to the pressure control valve, flow control valve, and hydraulic cylinder.

When the hydraulic press is in operation, oil is transported from the hydraulic tank to the hydraulic cylinder by the hydraulic pump through pipes. At that time, the pressure and flow of the oil are adjusted by the pressure control valve and flow control valve to achieve the target pressure and stroke speed. The hydraulic cylinder is then pushed by the oil to operate the cylinder press. When the press is completed for the set time, the oil used is sent from the hydraulic cylinder to the hydraulic tank. It is possible to control compression by the cylinder, stop, and return the cylinder by means of a directional valve.

*Including some distributors, etc.

Sort by Features

Sort by Area

SIMPAC America Co. Ltd. (SAC) is a manufacturer of hydraulic, mechanical, and servo presses as well as automation solutions that was established in 2016 as the North American subsidiary of the South Korean company SIMPAC, Inc. Based in Troy, Michigan, the company produces mechanical, servo, and hydraulic presses, automation solutions, and tandem lines for furniture and automotive manufacturers, as well as for clients in the aerospace and defense industries. Along with their products, SAC offers additional services including design and engineering, consultation, and onsite training of client personnel.

Schuler Incorporated Canton, founded in Canton, MI, in 1978 is a manufacturer of System solutions for the automotive components industry. The company's product portfolio includes Automotive Press Technology, Stamping and cutting Technology, Hydraulic Press Technology, Forging Technology, and Minting Technology. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. The company provides services such as Product Selection Guidance, Engineering Support, New Product Design and Development and Custom Manufacturing.

Savage Engineering was founded in 1963 in Ohio as a hydraulic press manufacturer. Some of the custom presses manufactured by the company include Cold Header Die Repair Presses that have applications in the bolt-making industry, along with Compression Presses that has uses in the aerospace, automotive and consumer products market as it is used to mold fiberglass and composite parts. There are also Die Spotting Press, Hydraulic Hot Press for manufacture of aircraft components from titanium or stainless steel alloys and Metalworking Hydraulic Press which has extensive applications.

Magnum Press, founded in Adamsville, Tennessee, in 1996 is a manufacturer of high speed production hydraulic presses suitable for operations including assembly, blanking, and coining The company's product portfolio includes space-saving presses ideal for applications such as bending, forming, and punching, Robust and heavy-duty presses suitable for deep drawing and stamping, and Precision presses and Custom Hydraulic Presses. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation.

Trinks Inc., established in 1935, is a manufacturer and supplier headquartered in De Pere, Wisconsin, United States. Trinks Inc offers a range of products, such as compression molding presses, transfer molding presses, vacuum molding presses, and custom presses, among others. The products are crucial components in various industries, such as rubber, plastic, composite, and metal. The products are used for various purposes, such as molding complex and precise parts with high quality and efficiency. The company also provides engineering, installation, training, and maintenance services for its clients.

GlobePharma, incorporated in 1993, is a manufacturer of pharmaceutical sampling equipment, laboratory and pilot scale blending systems, milling machines, cleaning validation tools and coupons, high-shear granulators, and tablet presses. The company is a supplier of particle size-reducing equipment, sundry equipment, and cGMP valves used in the pharmaceutical, nutraceutical, food, cosmetic, and automotive industries. The company in New Brunswick, New Jersey, offers services such as equipment maintenance, training, documentation services, repair, and refurbishment of equipment.

INNOVO Corporation, founded in 1996, is a designer and manufacturer of toolings and systems for notching, cutting, slotting, piercing, and assembling tube and pipe applications. Hydraulic double-notch units, piercing dies, specialized cut-offs, benders, and fence panels are among the products offered. The company is located in Elk Grove Village, Illinois, and provides in-house engineering utilizing solidworks, programming, electrical engineering, complete hydraulic systems, and training. The company has manufacturing facilities such as CNC machining centers and wire EDM machines.

SparTek Industries began in 1971 as Superior Plywood in Portland, Oregon. The company is a manufacturer of process machinery used in pressing, gluing, and material handling industries including wood, rubber, and composite panels. The company has three segments: Configured Solutions, Parts & Supplies, and Services. Configured Solutions produces machines used in material handling, machines used for sawing and clipping, hydraulic presses, and gluing & extrusion equipment. Parts & Supplies cover replacement parts and consumables. Services include engineering services, product and design evaluation, as well as consulting with ROI analysis.

F.P. Miller Company opened for business in Chicago, Illinois in the 1950s. F.P. Miller is a distributor for new and used machinery sales, rebuilding, and machine repair services including on-site repairs for parts, machines, and systems used in manufacturing. F.P. Miller’s offerings of new equipment includes many models of air hydraulic presses, air compressors, and grinders, as well as accessories including dust & mist collectors and digital readouts. Used equipment includes heavy machinery such as vertical spindle rotary surface grinders as well as systems such as pallet racks.

Jaygo Incorporated was incorporated in 1971 in the State of New Jersey. Originally, Jaygo was a distributor of equipment for chemical, pharmaceutical, cosmetic, coating, and petroleum industries. Today, Jaygo is also a manufacturer of equipment including conical screw processors, double planetary mixers, and all types of grinding media. Jaygo serves both large Fortune 500 companies and startups. Jaygo sells both new and used equipment. Jaygo’s product offerings include agitated filtration & drying systems, double arm mixer extruders, batch mills, and pressure vessel clamps. Jagyo also offers equipment rental and testing facilities.

KOJIMA IRON WORKS CO., LTD. established in 1809 in Gunma, Japan, is a manufacturer and supplier of specialized industrial presses and machinery. The company's product range includes Ring Rolling Mill, Hydraulic Forging Press, Hydraulic Long-Plate Forming Press, Plate Forming Press, and Hydraulic Straightening Press. These machines are used in metal forging, pressing, shaping, and straightening processes. They primarily serve industries like automotive, aerospace, metallurgy, manufacturing, and construction. Beyond manufacturing, it offers after-sales support, machine maintenance, custom engineering solutions, and technical consulting.

DEKUMA, established in 2004 and headquartered in China, is a manufacturer of rubber and plastic processing technologies. The company specializes in rubber injection molding machines, extrusion lines, and hydraulic presses. Its designs are guided by German technologies, ensuring precision in main components like injection and extrusion units, screws, and cold runner blocks. The company caters to diverse industries such as automotive, electricity power, and pipe solutions, including PE/PPR and PVC, while addressing the demands for rubber tracks, press-on solid tires, and liquid silicone rubber products.

Japan Automatic Machine Co. (JAM) primarily serves the automotive industry and related industries. JAM provides development, manufacturing and sales of automatic wire processing machines, terminals, connectors, electronic components, precision vices, precision presses, precision tools and instruments, progressive die and injection mold tooling, and other related products. JAM is headquartered in Japan and has offices globally.

Iwaki Industry Co. Ltd., founded in 1980 and headquartered in Aichi Prefecture, Japan, is a manufacturer and supplier of hydraulic press machines and related equipment. The company's products include vacuum press molding machines, metal press molding machines, and resin press molding machines. It also manufactures custom machines as well as offering used and reconditioned machines. Its products are used in various manufacturing applications to deform workpieces under high pressure. It serves industries that include consumer product manufacturing, marine, and automotive.

Carell Corporation, founded in Stapleton, AL in 1992 is a manufacturer of industrial metal working machines. The company's product portfolio includes Grinding Machines, Milling Machines, Turning Lathes, bending and shearing machines that offer precise metal forming and cutting capabilities for sheet metal and structural components and punching and press machines that deliver high-speed and efficient operations for metal punching. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation.

ProSys Servo Filling Systems, founded in Webb City, MO, in 1985 is a manufacturer of filling machinery for filling cartridges, squeeze tubes, unit dose tubes, and single & dual barrel syringes. The company's product portfolio includes tube filling, cartridge filling, syringe filling and airless pump applications. The company serves industries such as Cosmetic, Pharmaceutical, Food, Chemical, Adhesive, Sealant and Grease. The company also provides services including national distribution, product selection, customized services, technical support and customer service.

Coal Iron Works, founded in 2015 and located in Anderson, Indiana, is a Manufacturer of hydraulic forging presses. Their product line includes tabletop presses, c-frame presses, double-sided presses, a digital press controller, and a 120-ton press. These hydraulic forging presses are used in the metalworking and blacksmithing industries for shaping and forming metal materials. They provide the force needed to shape and manipulate metal into desired shapes and sizes. The presses can be used for forging applications, including bending, drawing, embossing, and stamping metal parts. They are essential tools in metalworking workshops and blacksmithing operations, enabling efficient and precise metal-forming processes.

Ranking as of December 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Schuler Inc. |

80.9%

|

| 2 | F P Miller Company |

2.6%

|

| 3 | SIMPAC America Co. Ltd. |

2.6%

|

| 4 | Wabash Metal Products Inc |

1.7%

|

| 5 | Coal Iron Works |

1.7%

|

| 6 | Carell Corporation |

1.7%

|

| 7 | Dongguan DEKUMA-WELLTEC Machinery Ltd |

0.9%

|

| 8 | INNOVO Corporation |

0.9%

|

| 9 | Reliable Rubber & Plastic Machinery Company |

0.9%

|

| 10 | ProSys Servo Filling Systems |

0.9%

|

Derivation Method

The ranking is calculated based on the click share within the hydraulic presse page as of December 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

11 | 68.8% |

Japan

Japan

|

4 | 25.0% |

China

China

|

1 | 6.3% |

91 products found - Page 3

91 products - Page 3

Iwaki Kogyo

270+ people viewing

Last viewed: 3 hours ago

This is a hydraulic press made to use it for components pressing. ◼︎ Characteristics In order to emphasize workability, it has a structure that ca...

Iwaki Kogyo

330+ people viewing

Last viewed: 3 hours ago

It is a hydraulic press molding machine made to correspond to horizontal products, not a square shape. ◼︎ Characteristics 1. Because the thermal b...

CGC Co., Ltd.

60+ people viewing

Last viewed: 8 hours ago

This is a highly reliable, high-performance, high-speed hydraulic bench press machine developed by making full use of hydraulic technology and prod...

CGC Co., Ltd.

50+ people viewing

Last viewed: 8 hours ago

This is a highly reliable, high-performance, high-speed hydraulic bench press machine developed by making full use of hydraulic technology and prod...

CGC Co., Ltd.

60+ people viewing

Last viewed: 6 hours ago

This is a highly reliable, high-performance, high-speed hydraulic bench press machine developed by making full use of hydraulic technology and prod...

CGC Co., Ltd.

50+ people viewing

Last viewed: 8 minutes ago

This is a highly reliable, high-performance, high-speed hydraulic bench press machine developed by making full use of hydraulic technology and prod...

CGC Co., Ltd.

70+ people viewing

Last viewed: 10 hours ago

This is a highly reliable, high-performance, high-speed hydraulic bench press machine developed by making full use of hydraulic technology and prod...

Taiyo Machinery

230+ people viewing

Last viewed: 20 hours ago

It is a continuous automatic press machine that can be united by pressing button operation and continuous automatic processing by automatic / optic...

Taiyo Machinery

200+ people viewing

Last viewed: 3 hours ago

It is a continuous automatic press machine that can be united by pressing button operation and continuous automatic processing by automatic / optic...

Taiyo Machinery

290+ people viewing

Last viewed: 3 hours ago

The two -sided tightening press has a wide range of models, from 44TON to 240 ton. TP2-40 It is easy to replace the knife and the wear plate in th...

Taiyo Machinery

200+ people viewing

Last viewed: 3 hours ago

The two -sided tightening press has a wide range of models, from 44TON to 240 ton. TP2-80 Lock cylinder can be attached to prevent the upper lid f...

Taiyo Machinery

240+ people viewing

Last viewed: 3 hours ago

It is a continuous triple tightening press machine that is easy to replace the knife and wear plate. There is an example of a listed product. We h...

Taiyo Machinery

190+ people viewing

Last viewed: 3 hours ago

The two -sided tightening press has a wide range of models, from 44TON to 240 ton. TP2-210 Hopper mounting is also possible according to your requ...

Taiyo Machinery

250+ people viewing

Last viewed: 3 hours ago

It is a continuous triple tightening press machine that is easy to replace the knife and wear plate. There is an example of a listed product. We h...