All Categories

History

This section provides an overview for die casting machines as well as their applications and principles. Also, please take a look at the list of 12 die casting machine manufacturers and their company rankings. Here are the top-ranked die casting machine companies as of February, 2026: 1.Messer Cutting Systems, Inc., 2.Pascal Corporation., 3.Bühler AG.

Table of Contents

Categories Related to Die Casting Machines

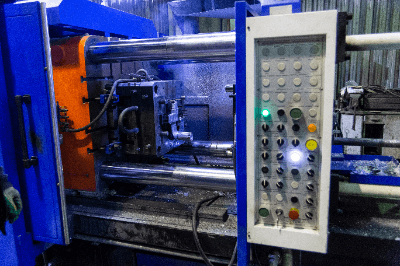

A die casting machine is a piece of equipment that melts a metal or alloy at high speed and pours it into a mold for casting.

Die casting machines can mass-produce products of the same shape with high precision, thus reducing the workload of workers. They are also effective when using low-melting-point metals such as aluminum and zinc, since low-melting-point metals are easy to melt and pour into the die.

However, it is difficult to use die casting machines for metals with high melting points, necessitating the use of other casting methods. Another advantage of die casting machine casting is that the surface of the product is very smooth, so the polishing process can be omitted.

Omission of the polishing process leads to reductions in product manufacturing time and cost.

Die casting machines are used in a variety of industries. Specifically, they are used in the manufacture of automotive parts, electronic devices, and construction materials. Recently, die casting machines have been developed that use environmentally friendly materials to reduce product waste and increase sustainability.

In automotive, aluminum is used to manufacture a wide variety of parts, from engine blocks, cylinder heads, and other components to emblems, door handles, and other small decorative items. In particular, the use of lightweight and highly rigid aluminum alloys can improve vehicle fuel efficiency and safety.

In electronics, aluminum alloys are used to manufacture metal parts used in smartphones, tablet devices, and digital cameras. Examples include camera lens holders, shutter buttons, and aluminum frames for smartphones.

In building materials, die-casting machines are used to manufacture small to large and complex shaped parts such as door knobs, handles, shutter hinges, and curtain walls and facade panels that decorate the exterior of buildings.

The principle of making a product with a die casting machine consists of creating a mold that matches the shape and pouring liquid metal into it. Die casting machines use pistons that utilize hydraulic pressure, which must be above a certain level.

Liquid metal such as aluminum alloy, called molten metal, is poured into the die connected to the die casting machine. Since the die into which molten metal is poured is subject to internal pressure, care must be taken to ensure that the die is not tightly sealed or the molten metal may leak from the gaps in the die.

For example, a die casting machine during casting will hold the mold under high pressure. When the liquid metal poured into the mold is cooled, a hardened product conforming to the shape of the mold is completed.

Die casting machines are classified into two types:

The hot chamber system is named after the injection section, which injects molten metal, and the molten metal storage furnace, which are integrated into a single unit, and the injection section is constantly heated. Since the injection part is always heated, it is used for casting materials with low melting temperatures from the viewpoint of safety and durability of parts. The major advantage is that molten metal can be injected efficiently.

The cold chamber system is named after the fact that the injection section, where molten metal is injected, and the molten metal storage channel are separated and the injection section is not heated at all times. Since the molten-metal storage furnace is independent, it is used for casting materials with high melting temperatures; molten-metal injection is required for each product, and the production time tends to be long.

Die casting machine molds are mainly responsible for determining the shape and changing the temperature.

1. Shape Determination

Since products are manufactured according to the die, the die determines the general and detailed shape of the product, as well as small grooves and holes. The accuracy of the mold's shape is an important point because it directly affects the quality of the product.

The position of the gate for pouring molten metal and the flow of molten metal in the mold are determined according to the shape of the product and the number of products to be manufactured at one time. If the mold is in the way and the product cannot be taken out, a mechanism is added to move the mold at an angle or a hydraulic cylinder is pushed out to take the product out.

2. Temperature Change

Die-cast products are manufactured by cooling and solidifying molten metal. The die, which determines the quality of the product, is a very important component of the die casting machine. In addition, the creation of a die takes months and the cost of creating a die is a large part of the manufacturing process.

If a die fails or is damaged during mass production, production must be halted. It is important to note that along with a significant reduction in production capacity, there are additional costs associated with mold maintenance.

*Including some distributors, etc.

Sort by Features

Sort by Area

Messer Cutting Systems, established in 1898 in Frankfurt, Germany, is a manufacturer and supplier of cutting-edge cutting machines and technology. The company's product portfolio includes a wide range of cutting systems, plasma and oxyfuel cutting machines, as well as related software and services. These new solutions are utilized across industries such as metal fabrication, automotive, and aerospace. Messer Cutting Systems aims to empower its customers with precise, efficient, and quality cutting solutions. The company teams up with technology partners to develop predictive maintenance software and automation technologies, thus making them the partner of choice for cutting systems solutions worldwide.

SKC, Inc. is a manufacturer and supplier based in the United States, established in 1962, specializing in quality products for air sampling and environmental monitoring. SKC offers a comprehensive range of products including air sampling pumps, monitoring instruments, and sampling media. These solutions cater to industries like industrial hygiene, occupational safety, and environmental assessment. SKC's is devoted to promoting the well-being of individuals and communities by delivering accurate tools for air quality analysis.

Pascal Corporation, founded in 1974 and based in Hyogo, Japan, is a manufacturer of automation equipment and systems. Its product range includes work clamping systems, gas springs, injection mold machines, and pallet clamps, catering to various industrial applications. Additionally, it offers die casting machines, press machines, auto couplers, and a selection of robot products, including expansion clamps, gas balancers, and tool changers. Its offerings find utility across industries, enhancing manufacturing processes, ensuring precision, and optimizing efficiency in workholding, and material handling. Since 1999, the company has maintained ISO9001 certification for its quality management system.

Changzhou New District JinKang Precision Mechanism Co., Ltd., established in 2005, is headquartered in Bengaluru, Karnataka, India, as a manufacturer specializing in the design and production of winding machinery and related solutions. The company’s product range includes winding machines designed for manufacturing coils used in applications like electric motors and transformers. The company received the Industry Pioneer Award in 2016. Certified with ISO 9001:2015, it maintains quality standards in manufacturing. The company's target markets span automotive, electronics, aerospace, renewable energy, and industrial manufacturing. And also collaborate internationally, forming partnerships in the United States, Germany, China, and Japan.

Sodick Co., Ltd, founded in 1976 and headquartered in Yokohama, Japan, is a manufacturer and supplier of machine tools, injection molding machines, food machines, and LED products. The company's product portfolio includes nano-level precision machines, magnesium alloy injection machines, noodle steam sterilizers, LED products, and electronic components. These products are utilized in various industries, including food processing, electronics, LED and lighting, manufacturing and machining, and the plastics and injection molding industry. The company has development, production, and service locations in different countries, including the United States, China, Thailand, India, and Singapore.

Initially established in 1938, Shibaura Machine has three-quarters of a century providing Comprehensive technology and supporting the “monozukuri” of the world. With the technical and development capabilities of the Shibaura Machine Group, various machines and services create rich value and contribute to the creation of an industrial base. Working on the eight technical platforms, they develop and manufacture a wide range of production devices that meet the needs of the times, delivering the best solutions by combining our accumulated excellent know-how and the latest technology. Shibaura Machine uses its knowledge of modern global standards of advanced technology to support Japan and the world.

Optic Technology (Shenzhen) Co., Ltd is a manufacturer based in China, established in 2005, specializing in designing and producing optical and imaging products. Optic Technology delivers quality optical solutions globally. Their range includes digital microscopes, endoscopes, and industrial cameras. They wish to empower scientific and industrial advancements, the company prioritizes precision, innovation, and reliability. Optic Technology's products find applications in research, healthcare, and manufacturing, contributing to enhanced visual analysis and diagnostics.

Bühler AG is a Swiss multinational food and beverage processing machinery and equipment manufacturer that was established in 1860 and is headquartered in Uzwil, Switzerland. The company produces a wide range of food and beverage processing machinery and equipment, including mills, dryers, and extruders. Its products, such as Winnower, Roller Mill, and Extrusion System, are used by a number of industries, as diverse as cereals, coffee, and chocolate industries. The company also provides a range of services, including process engineering, plant construction, and training.

Flex Films is a manufacturer based in India, established in 1981, specializing in the production of flexible packaging solutions and films. Flex Films is a pioneer in the flexible packaging business. They offer an extensive range of packaging solutions that cater to various industries, including food and beverages, pharmaceuticals, and consumer goods. Their devotion to sustainability is evident through their eco-friendly products and manufacturing processes. Flex Films' selling point lies in their cutting-edge technology, product quality, and devotion to customer satisfaction.

KOLON Industries is a manufacturer headquartered in South Korea and it was established in 1957. The company is a principal player in various industries, including textiles, chemicals, films, and sustainable technologies. KOLON Industries has evolved into a global innovator. Their product range spans from performance fabrics and industrial materials to advanced chemical solutions and sustainable technologies. Their strengths lie in extensive research capabilities, strategic partnerships, and a devotion to driving sustainable growth.

Mitsubishi Chemical America, Inc. (MCA) is a chemical products manufacturer and distributor based in Greer, South Carolina. The company was established in 2017 as one of four regional headquarters of the Mitsubishi Chemical Corporation (MCC), which supplies North American companies like Boeing, Tesla, and Bemis Company, Ltd. The company produces, imports, and distributes MCC products such as ion exchange resins used for metals recovery or water processing, optical reflective sheets used in liquid crystal backlights, and various monomers and polymers used in infrastructure and transportation. MCA serves a wide range of industries including aerospace and defense, energy, and construction.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Bühler AG |

22.6%

|

| 2 | Messer Cutting Systems, Inc. |

15.8%

|

| 3 | Pascal Corporation. |

9.0%

|

| 4 | SKC, INC. |

7.5%

|

| 5 | Mitsubishi Chemical America, Inc. |

6.8%

|

| 6 | Optic Technology(Shenzhen) Co., Ltd |

6.5%

|

| 7 | Changzhou New District JinKang Precision Mechanism Co., Ltd. |

6.1%

|

| 8 | Shibaura Machine |

5.7%

|

| 9 | KOLON Industries |

5.4%

|

| 10 | Sodick Co., Ltd |

5.4%

|

Derivation Method

The ranking is calculated based on the click share within the die casting machine page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

3 | 37.5% |

United States of America

United States of America

|

2 | 25.0% |

China

China

|

2 | 25.0% |

Switzerland

Switzerland

|

1 | 12.5% |

29 products found

29 products

Shibaura Machine

570+ people viewing

Last viewed: 1 day ago

■Equipped with total control system “TOSCAST-999” High production/low environmental impact electric mold clamping machine (E type) ■Shibaura Machi...

Maebashimoto Alloy Co., Ltd.

930+ people viewing

Last viewed: 14 hours ago

■ Complex shape of pipes & high airtightness ・ Casting stainless steel pipes in aluminum alloy casting while maintaining high airtightness. ・ Pip...

Fujimoto Kogyo Co., Ltd.

440+ people viewing

Last viewed: 1 day ago

Because the shape of aluminum die-cast parts is complex, deburring requires a lot of manpower, and it was thought that it would be difficult to sav...

Fujimoto Kogyo Co., Ltd.

390+ people viewing

Last viewed: 1 day ago

Because the shape of aluminum die-cast parts is complex, deburring requires a lot of manpower, and it was thought that it would be difficult to sav...

Fujimoto Kogyo Co., Ltd.

410+ people viewing

Last viewed: 1 day ago

Because the shape of aluminum die-cast parts is complex, deburring requires a lot of manpower, and it was thought that it would be difficult to sav...

Sigma Industries Co., Ltd.

630+ people viewing

Last viewed: 17 hours ago

If the leak test is negative, the water tank at the bottom of the device will rise. After being immersed in water, test air is applied to the workp...

Sigma Industries Co., Ltd.

560+ people viewing

Last viewed: 5 hours ago

When the inspection pressure is high, a clamp structure using a preload pressure intensifier is used.

Sigma Industries Co., Ltd.

440+ people viewing

Last viewed: 23 hours ago

Holes are drilled with high precision using two self feeders. Equipped with a cutting oil circulation system.

SK Medical Electronics Co., Ltd.

540+ people viewing

Last viewed: 8 hours ago

■Features ・Precision casting machine using lost wax method ・High-speed temperature rise using high frequency is possible ・High dimensional accur...

Shibaura Machine

480+ people viewing

Last viewed: 49 minutes ago

Shibaura Machine's unique technology and rich experience include a highly rigid mold clamping device, an injection device equipped with a select ro...

Shibaura Machine

510+ people viewing

Last viewed: 51 minutes ago

With the theme of a new era die-casting machine, Shibaura Machine has realized energy saving, cleanliness, high cycle, and shockless. This is the i...

Shibaura Machine

420+ people viewing

Last viewed: 37 minutes ago

This is a high quality die casting machine that requires high strength and pressure resistance. A new casting system that uses an electromagnetic p...

Shibaura Machine

450+ people viewing

Last viewed: 46 minutes ago

Magnesium alloy is the lightest and has the highest specific strength among commonly used structural materials, so it is attracting attention as an...

Shibaura Machine

620+ people viewing

Last viewed: 45 minutes ago

■We pursued usability by adopting a large touch panel and combining functionality. TOSCAST-999 is a control device installed in large die casting m...

Shibaura Machine

500+ people viewing

Last viewed: 38 minutes ago

Shibaura Machine's environmental impact reduction machine for the future of carbon neutrality. The concept is "New 3S" ■Equipped with electric mol...

Shibaura Machine

510+ people viewing

Last viewed: 35 minutes ago

R series equipped with ultra-high-speed hydraulic servo injection and electric mold clamping mechanism. The standard model achieves acceleration pe...

Shibaura Machine

570+ people viewing

Last viewed: 50 minutes ago

■Features ・The mold opening/closing time is shortened by adopting a toggle mechanism driven by an electric servo motor, and the cycle is shortened...

Shibaura Machine

450+ people viewing

Last viewed: 41 minutes ago

■Full-time high production The concept of DC135J-T2 is to improve reliability and expand the casting area. It guarantees stable production even und...

Hikari Hydraulic Machinery

480+ people viewing

Last viewed: 6 hours ago