All Categories

History

This section provides an overview for brake discs as well as their applications and principles. Also, please take a look at the list of 8 brake disc manufacturers and their company rankings. Here are the top-ranked brake disc companies as of February, 2026: 1.Ferodo, 2.TRW, 3.SHW.

Table of Contents

Categories Related to Brake Discs

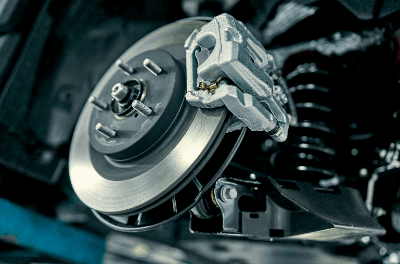

A brake disc is a disc-shaped component used in the braking system to decelerate and stop a vehicle.

There are several types of braking systems used in vehicles, and the disc brake is one of the prominent ones, alongside drum brakes. It comprises the brake disc, brake caliper, piston, and other components.

Also known as a disc rotor, it rotates along with the wheel. During braking, the brake pads inside the brake caliper, driven by force from the piston, clamp strongly on both sides of the brake disc, generating braking force.

The brake disc is mounted on the axle as part of the disc brake system and is used for the vehicle's braking. Due to the exposed nature of the brake disc in the disc brake system, the heat generated during braking can dissipate to the external environment through the brake disc.

This characteristic makes disc brakes less prone to a decrease in braking force (fade phenomenon) caused by the heat of the brake pads, which can be an issue during abrupt braking from high speeds or continuous use. Additionally, even when the brake disc surface is wet, such as in the rain, the rotating disc helps repel water droplets, minimizing the reduction in braking power in wet conditions.

Disc brakes were initially introduced in aircraft and later became widely used in automobiles, motorcycles, trains, and other vehicles. They are now employed in many automobiles.

The brake disc is a crucial component of the disc brake, and it is a disc attached to the axle, rotating together with the wheel. Brake discs made of cast iron, known for their wear resistance and high heat dissipation, are predominant.

During braking, the force applied to the piston is used to sandwich the brake pads on both sides of the brake disc, creating friction between them and generating braking force. This action applies the brake to the wheel rotating as a unit.

The lever principle comes into play with the brake disc, and the larger the diameter, the greater the braking force obtained when the brake disc is sandwiched from the outer periphery. However, the brake disc and brake caliper must fit within limits to avoid interference with other components such as the wheel's interior, suspension, and wheelhouse.

Generally, high-performance or sports vehicles tend to use larger-diameter brake discs.

Brake discs are classified into solid discs and vented discs based on their shape.

Solid discs consist of a single disc-shaped plate. They are lightweight, providing the advantage of high maneuverability. However, compared to vented discs, the surface temperature of solid discs tends to rise more, making them more susceptible to the fade phenomenon. Therefore, they are used in wheels where braking loads are relatively low, such as the rear wheels of ordinary cars or the front wheels of lightweight vehicles.

Vented discs have a structure where two disc-shaped plates with heat-dissipating cavities on the inside are overlaid with a space in between. While vented discs become heavier compared to solid discs, they offer excellent cooling effects and are less prone to the fade phenomenon, making them suitable for sports driving.

Vented discs are commonly used in vehicles with high braking loads during driving, including sports cars. Additionally, in vehicles where the braking load on the front wheels is greater than the rear wheels due to weight transfer during braking, vented discs are often used in the front wheels, with solid discs in the rear.

In addition to cast iron, brake discs can be made of carbon ceramic. Brake discs made of carbon ceramic are high-priced products manufactured through complex processes. However, due to their lightweight nature and resistance to performance degradation even under full-throttle driving, they have found adoption in high-priced sports cars and racing cars, among other limited automobile types.

*Including some distributors, etc.

Sort by Features

Sort by Area

Ferodo was established in 1897 and is based in High Peak, Derbyshire as the first and foremost manufacturer of brake components for almost all types of vehicles. The product portfolio includes brake pads, brake discs, calipers, brake fluids and other related accessories. These products are used in drum brake, disc brake, ABS brake and hydraulic brake depending upon the nature of braking system. The company is manufacturing brake components for automotive industry giants like Mercedes, Ford and Volkswagen.

Shandong Frontech Auto Parts Co., Ltd, established in 2004 and based in Dongying, Shandong, China, is a manufacturer and supplier of brake components. The company's product range includes brake pads, brake discs, brake shoes, brake drums, and brake sensors. These products play crucial roles in ensuring vehicle safety and enhancing braking performance. It serves the automotive industry, particularly in the production and supply of OEM brake pads. The company also offers services related to technology development, product testing, and customer support.

TRW was launched in 2002 in Livonia, Michigan and is a manufacturer and supplier of automotive safety products for the personal cars, motorcycles and commercial vehicles markets It supplies braking equipment such as disks, calipers, steering racks and pumps, stabilizer links and shock absorbers. Its motorcycle products catalog includes motor clutch, footrest, handlebars, brakes and chassis systems. The company also stocks brake calipers, shock absorbers, steering gears, and linkage and suspensions for the commercial vehicle industry.

MAT Foundry Group Ltd, established in 2000 and based in Poole, Dorset, United Kingdom, is a manufacturer and supplier of cast iron products. The company's product range includes brake discs, caliper housing, differential cases, diesel injection pump housing, and camshaft & balancing shafts. These products are primarily utilized in passenger cars, commercial vehicles, and various industrial applications. It serves passenger vehicles, commercial vehicles, heavy-duty vehicles, and industrial markets. The company is also used in iron casting, research & development, manufacturing, and product engineering support.

Project Mu Co., Ltd., established in March 1988, and based in Shuunan-shi, Yamaguchi, Japan, is a manufacturer and supplier of racing brake systems. Its offerings include genuine repair models, low noise and low dust pads, and pads for hybrid vehicles. It also offers street sports models, pads for rear inner-drum equipped vehicles, and rear pads for drifting. These are designed to improve the performance of vehicles, enhancing initial braking force, and ensuring a comfortable feeling through the pedal.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Ferodo |

78.3%

|

| 2 | TRW |

4.6%

|

| 3 | SHW |

4.1%

|

| 4 | Fagor Ederlan |

3.2%

|

| 5 | MAT Foundry Group Ltd. |

2.8%

|

| 6 | Shandong Frontech Auto Parts Co.,Ltd. |

2.8%

|

| 7 | Supfina |

2.3%

|

| 8 | Project Mu Co., Ltd. |

1.8%

|

Derivation Method

The ranking is calculated based on the click share within the brake disc page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United Kingdom

United Kingdom

|

2 | 50.0% |

China

China

|

1 | 25.0% |

Japan

Japan

|

1 | 25.0% |

6 products found

6 products

Hamakita Kogyo Co., Ltd.

200+ people viewing

The strength of important safety parts in the suspension is guaranteed using an Amsler testing machine. ■Features In-house annealing stress relief...