All Categories

History

This section provides an overview for wire edms as well as their applications and principles. Also, please take a look at the list of 7 wire edm companies and their company rankings. Here are the top-ranked wire edm companies as of February, 2026: 1.Marshall Manufacturing Company, 2.Absolute Machine Tools, 3.Sodick.

Table of Contents

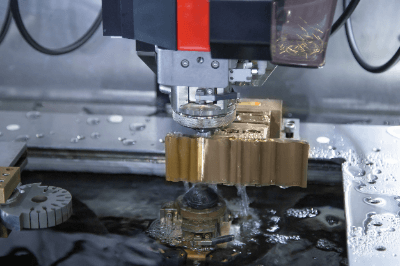

Wire electrical discharge machining (EDM) is a method where an electrical current passes through a brass wire to cut materials using discharge heat. This technique does not involve direct contact between the wire and material, resulting in clean cuts and enabling precision machining to a few micrometers. It accommodates cutting widths in materials ranging from as thick as 400 mm to as thin as 0.02 mm.

Suitable for cutting conductive materials like iron, stainless steel, copper, brass, and aluminum, Wire EDM cannot process non-conductive materials.

Wire EDM is used in metal cutting and precision machining for a variety of thicknesses. It’s applied in fabricating small components in devices like smartphones and household appliances, as well as in larger machinery parts.

Its precision makes it ideal for mold manufacturing and intricate shapes. The wire-cutting process streamlines steps compared to traditional machining, allowing for efficient one-stroke cutting in sheet metal processing.

Wire EDM operates in a tank filled with insulating water or oil to cool the wire and prevent it from being cut by heat. The electrical discharges between the electrified wire and the material enable melting and cutting without direct contact at extremely high temperatures.

This method offers the advantages of precision cutting across a wide range of conductive material thicknesses, using wires typically between 0.10 mm and 0.30 mm in diameter. It produces no burrs or chips, reducing the need for additional processing. However, limitations include slow processing speeds and the inability to process non-conductive materials or perform certain machining tasks like groove or pocket machining due to the vertical stretching of the wire during processing.

*Including some distributors, etc.

Sort by Features

Sort by Area

Absolute Machine Tools, established in 1988 and headquartered in Lorain, Ohio, USA, is a manufacturer and supplier of CNC machine tools. The company's product range includes horizontal & vertical machining centers, bridge mills, mill & turn centers, Swiss-type lathes, and wire EDM machines, serving industries such as aerospace, agriculture, automotive, construction & mining, energy, and medical sectors. The company also offers automation solutions, installation, service maintenance, and training services. With an emphasis on cutting-edge engineered solutions in their ISO 9001:2015 and ITAR accreditations, the company, with decades of experience, consistently exceeds expectations in quality and service.

Marshall Manufacturing Company is a manufacturer of precision machined parts, founded in 1951 and located in Minneapolis, Minnesota. The company provides medical components, devices and surgical instruments to customers throughout the US and Europe. Its capabilities include CNC Swiss & Micro-Swiss machining, laser tube cutting, CNC Turning, CNC wire EDM, and CNC 3D bending of small diameter wire and tubing. These services cater to industries such as medical, biomedical, and related device fields. The company is registered to ISO 13485:2016, ensuring the implementation and maintenance of its quality system.

GF Machining Solutions is a manufacturer of complete solutions for precision components and the mold-making factory. GF Machining Solutions was established in USA and came to inception in 1802. The company portfolio includes Electronic dance music, laser texture, laser micromachine, and additive manufactured machines. Additionally, the company offers spindles, automation, tooling, and digitalized solutions backed by unrivaled customer services and support. They provide solutions, the advances energy-efficient and clean manufacturing of diverse product.

ONA, founded in 1952 and headquartered in Durango, Bizkaia, Spain, is a manufacturer of EDM machines and precision assemblies. The company offers compact, modular, and double-head wire and die-sinking EDMs. In addition to these standard products, it offers integral customized solutions for the design and manufacture of customized machines using EDM technology or a combination of processes. It serves various industries including automotive, turbines, microelectronics, and mold. The company also offers a wide range of digital services and software solutions including smart programming, automation, control and supervision, security, and software.

Sodick, founded in 1976 and headquartered in Schaumburg, Illinois, is a manufacturer and supplier specializing in EDM machines. The company offers a diverse product portfolio, including Wire EDM, Sinker EDM, Small Hole EDM, Metal 3D Printing, and High-Speed Milling. Sodick also provides technologies in additive manufacturing, automation, and EDM, serving industries such as aerospace, automotive, energy, and the medical sector. With four locations across the U.S., the company delivers EDM machine solutions, technical support, and parts to customers nationwide.

MAKINO INC., founded in 1981 and based in Mason, Ohio, USA, is a manufacturer and supplier of machining solutions. They offer a wide range of products, including horizontal machining centers, vertical machining centers, machining centers, graphite machining centers, and wire and sinker EDMs. These machining solutions enable precise and efficient metal cutting and shaping processes, catering to diverse industries, including aerospace, automotive, medical, and die/mold manufacturing, for increased productivity and quality production of industrial products such as bolts, sheet metals, and more.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Marshall Manufacturing Company |

23.6%

|

| 2 | Absolute Machine Tools |

21.8%

|

| 3 | Sodick |

12.7%

|

| 4 | GF Machining Solutions LLC |

12.7%

|

| 5 | ONA |

10.9%

|

| 6 | Prototype & Short-Run Services, Inc. |

9.1%

|

| 7 | MAKINO INC. |

9.1%

|

Derivation Method

The ranking is calculated based on the click share within the wire edm page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

4 | 80.0% |

Spain

Spain

|

1 | 20.0% |