All Categories

History

This section provides an overview for counterboring services as well as their applications and principles. Also, please take a look at the list of 4 counterboring service companies and their company rankings. Here are the top-ranked counterboring service companies as of March, 2026: 1.Bevel Tech Group, Inc., 2.Universal Steel America, Inc., 3.Vischer & Bolli AG Machining and workholding.

Table of Contents

Categories Related to Counterboring Services

Counterboring services are the process of making a hole larger in diameter than the initial hole or screw at the entrance to a threaded or drilled hole.

Counterboring services are the process of making a hole larger in diameter than the initial hole or screw at the entrance to a threaded or drilled hole.

It is a stepped structure when viewed from the cross section. It is used to process metal or wood, and its main purpose is to prevent the bolt head from protruding beyond the mounting surface.

Counterboring services are used to prevent bolts and screws from loosening, improve aesthetics, and prevent injury. Specifically, the following types of processing are performed.

To install a bolt so that its head does not protrude from the face, use a hexagon socket head bolt or other bolt that does not require a wrench. If the head of the bolt is conical, counterboring services are performed on the edge of the hole to form a conical shape.

Counterboring services are performed by drilling a hole and then machining it to the desired size and depth with an end mill. There are also counterbore drills that can perform drilling and endmilling at the same time.

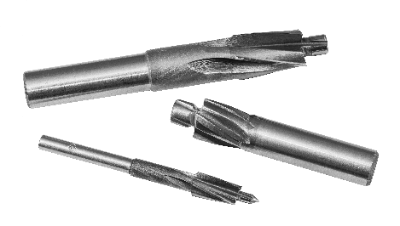

A counterbore drill is a drill with a stepped shape. The thin shaft at the tip of the drill is used for drilling holes, and the thick shaft at the base of the drill is used for counterboring services.

Counterboring services must be performed by using a counterboring drill of a shape that allows the desired drill hole and the counterboring services to be performed by passing the counterboring drill to the desired counterboring depth.

Counterboring services can be broadly classified into the following four types:

Counterboring is a process that only touches the surface of the hole. This is done to secure the bolt's tightening force.

The depth of the counterbore is specified so that the head of the bolt is hidden. Counterboring services are usually about 1mm deep, but deeper counterboring services are called deep counterboring.

This is done when using countersunk screws. A conical hole is drilled to match the shape of the screw head. Some sites call this process "flat firings."

Counterboring services are performed on the opposite side of the thread direction.

The following points should be noted when performing counterboring services.

Area Required for the Process

The distance from the edge must be considered for the location of the counterbored edge. If the distance between the edge and the radius of the counterbore is almost the same, a thin stepped shape will remain, which is undesirable in use.

Tools

There is a special tool for counterboring called a counterbore drill. It has a narrow, stepped tip and is capable of simultaneous counterboring services and drilling in a single rotation. The counterbore drill is mounted on a drilling machine.

For back counterboring, in which counterboring is done from the opposite side, use a tool with an eccentric tip that protrudes on one side. The structure is such that the tool does not interfere with the first drilled hole when inserted.

Machining Machine

A drilling machine, milling machine, or lathe is used as the processing machine.

*Including some distributors, etc.

Sort by Features

Sort by Area

Founded in 2001, and based in Houston, Texas, U.S, Universal Steel America, Inc. is a specialty steel plate distributor and manufacturer. The company manufactures ASTM Structural Plate, ASME Pressure Vessel Plates (PVQ), Marine & Offshore Plate, Abrasion Resistant Plates, and Die Steel Plates. Their products have applications in the oil and gas, construction, mining, energy, and machinery industries. Their services include Plate Cutting, Beveling, Rolling, Welding, and, Plate Finishing. They also offer Drilling, Counterboring & Countersinking, and, Additional Testing & Specifications that are needed by various industrial sectors.

Vischer & Bolli AG Machining and workholding, founded in Germany in 1957, is a supplier of drilling, deburring, and milling machines. The company's product portfolio includes flat drills, step drills, 3-lip drills, deep hole drills, and micro drills for every application of materials such as steel, cast iron, aluminum, stainless materials, stainless steel, and titanium. It also offers clamping products such as MasterGrips, Workpiece stops, Deflection clamping jaw, and Wedge clamping elements.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Bevel Tech Group, Inc. |

33.3%

|

| 2 | Universal Steel America, Inc. |

33.3%

|

| 3 | Vischer & Bolli AG Machining and workholding |

22.2%

|

| 4 | HEULE Precision Tools |

11.1%

|

Derivation Method

The ranking is calculated based on the click share within the counterboring service page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

1 | 50.0% |

Switzerland

Switzerland

|

1 | 50.0% |