All Categories

History

This section provides an overview for photo etching as well as their applications and principles. Also, please take a look at the list of 14 photo etching companies and their company rankings. Here are the top-ranked photo etching companies as of March, 2026: 1.Dongguan TMN Electronics Co., Limited, 2.Advanced Metal Etching, Inc., 3.Kraftetch Industries.

Table of Contents

Categories Related to Photo Etching

A photoetching process is a processing technology that combines the principle of photography (photoengraving technology) and etching technology to remove unnecessary parts.

It can form complex and fine patterns on materials, such as substrates.

The photoetching process has the following applications:

It is used to produce printed circuit boards that are built into most electronic devices. Printed circuit boards consist of copper foil attached to a base made of ceramics or resin. Unnecessary portions of the copper foil are removed by photoetching to produce electronic circuits.

Other uses include the production of flexible circuit boards (FPCs) and rigid circuit boards used in electrical products and cell phones. Components are used in circuit boards for touch sensors, temperature sensors, antennas, heaters, and camera sensors.

It is used for fine patterning of semiconductors and liquid crystal displays.

Used as a metal mask (stencil) to print solder paste on printed circuit boards in the surface mounting process where many electronic components are mounted.

The photoetching process generally involves the following steps:

Draw mask patterns on glass and other materials.

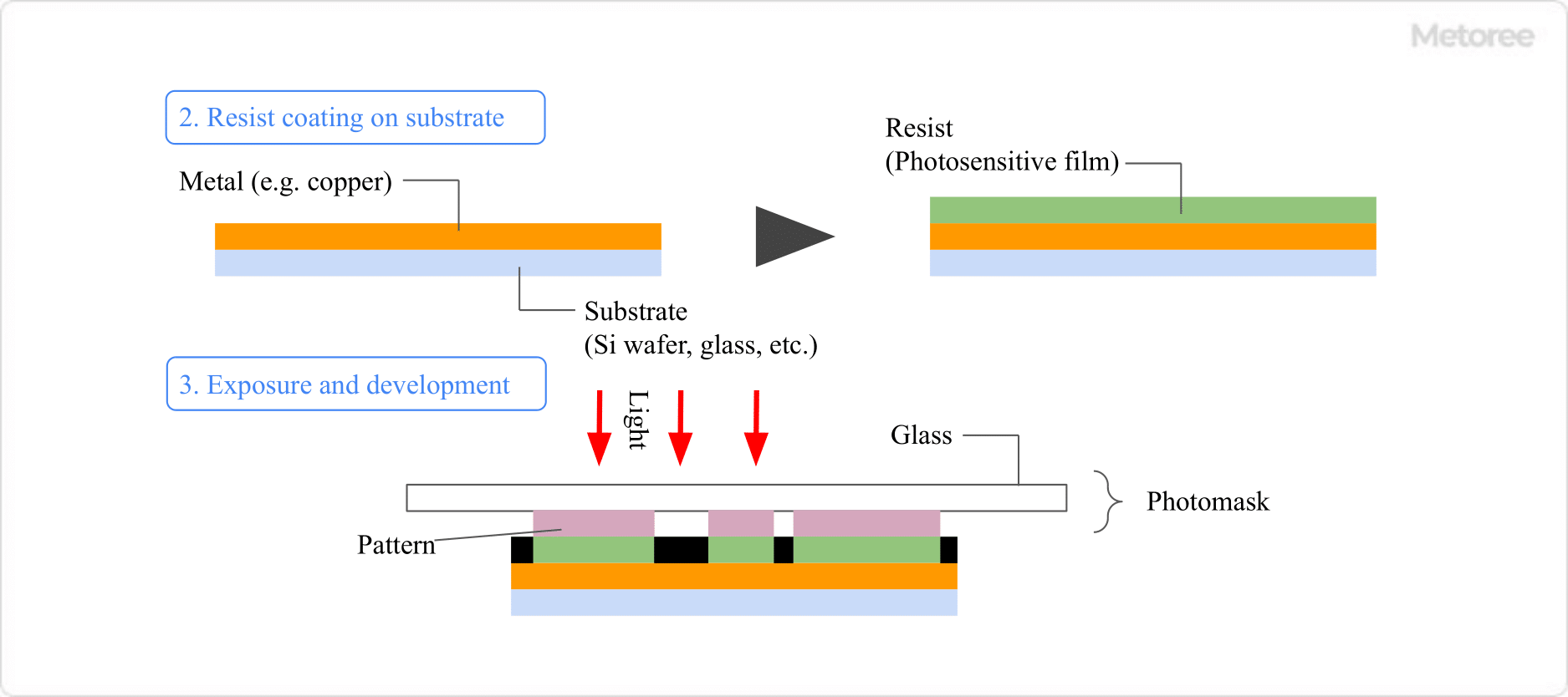

A resist (photosensitive film) is applied to the substrate to be etched. Resist must be coated in a dark room, as it is altered by light.

Figure 1. Resist coating on substrate and exposure/developing

Expose with the mask created in step 1 placed on the resist coat. The area not covered by the mask is transformed and can be removed by the developer (only in the case of positive type. In the case of negative type, the unexposed areas will be removed by the developer).

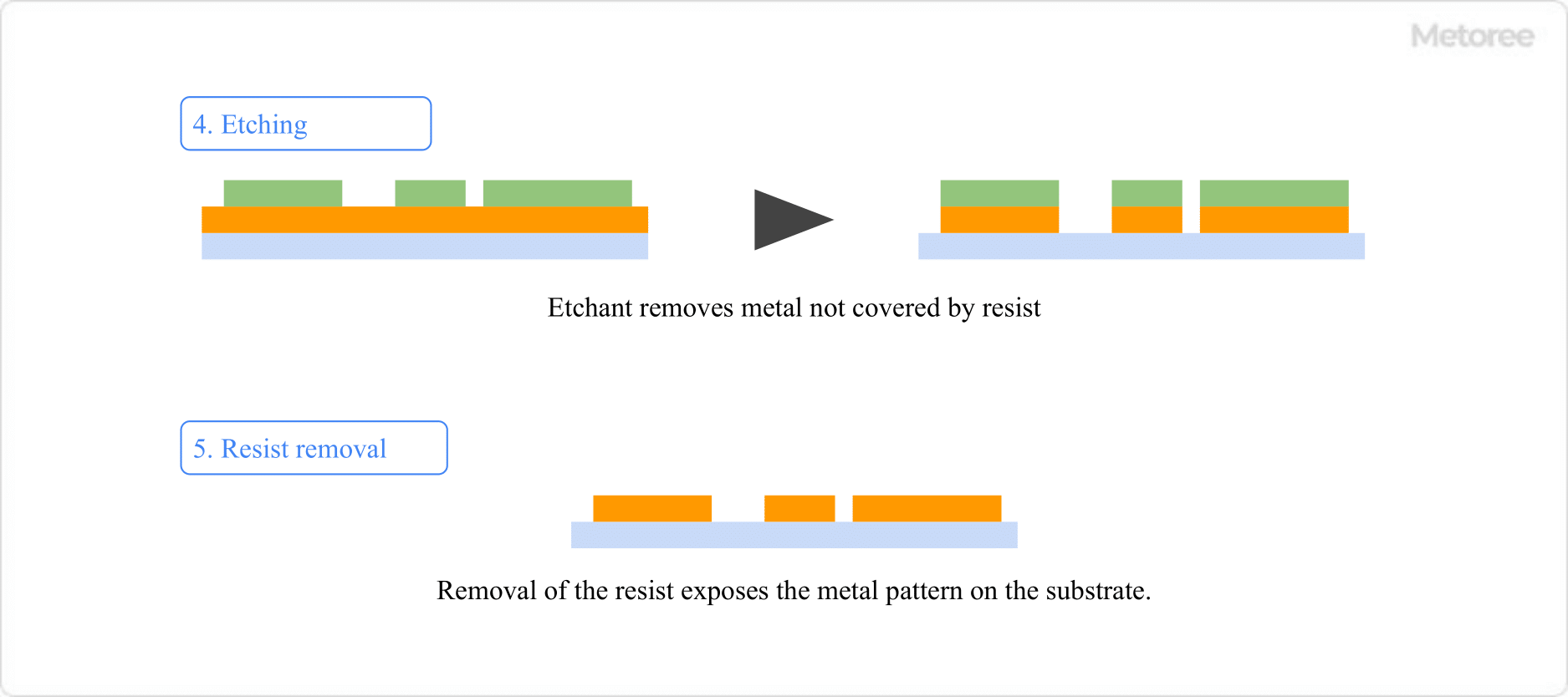

The metal in the area where the resist was removed in step 3 is removed with an etchant. Etching on silicon substrates, for example, uses highly corrosive hydrofluoric acid as the etchant, so care must be taken when handling it.

Figure 2. Etching and resist removal

The resist is removed and cleaned to complete the process.

After removing dirt from the material to be processed (stainless steel, copper, nickel, etc.), photoresist is applied to the reverse side of the material. After masking with a photomask, the photoresist is exposed to UV light to sensitize the photoresist.

Next, the photoresist is removed from the areas that were not illuminated by the photomask using specified chemicals. Finally, a metal-dissolving chemical (etchant) is used to dissolve the unmasked areas to obtain the pattern as designed.

This is a processing technique that combines etching and electroforming (a technique to create a model opposite to the master product). This processing technology makes it possible to manufacture precision products.

This method is used to etch very hard metals such as molybdenum and titanium.

This is a method of etching three-dimensional or curved surfaces. Etching is performed on the inside of cylindrical products and on the outside of bar-shaped products.

This is a method for etching thin metal films (ITO, Al, Cu, Ni, Cr, etc.) formed by vapor deposition or sputtering using a chemical process to form patterns with high processing accuracy.

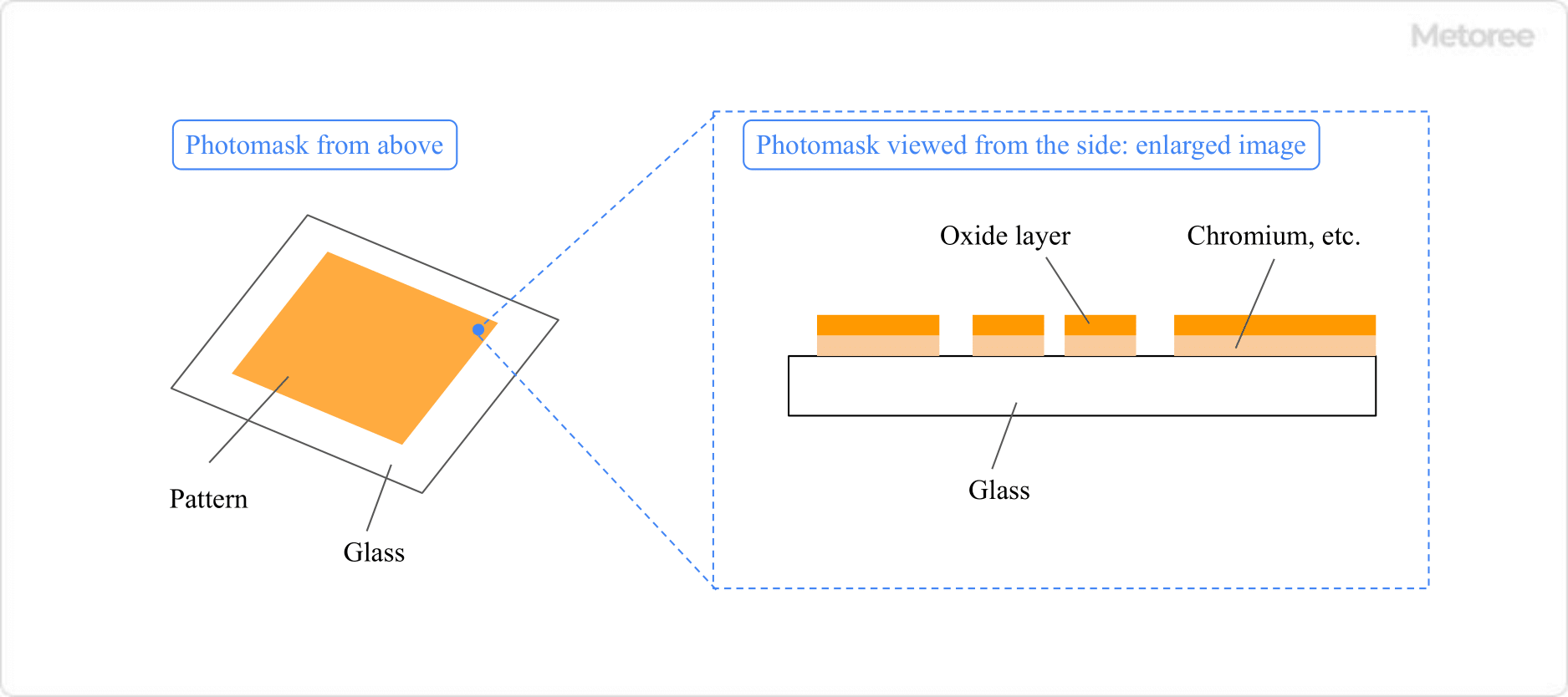

Figure 3. Photomask Structure

The photomask fabrication process is similar to that of photoetching. First, a pattern is drawn by CAD or other means. Next, a substrate with some kind of light-shielding film on a glass substrate is prepared.

There are three types of light shielding films: chrome mask, glass mask, and film mask, in order of processing accuracy. These substrates are called photomask blanks.

Next, resist is applied to the photomask blanks, and an electron beam or other means is used to draw the original mask that will become the basis of the product. Thereafter, in a process similar to photoetching, the light-shielding film is removed by a developer solution, and finally the resist is removed and washed.

*Including some distributors, etc.

Sort by Features

Sort by Area

PMA Photometal, a corporation established in 1982 and headquartered in Phoenix, Arizona, operates as a commercial and industrial sector of PMA Companies. The company offers precision etched components, nameplates, graphic overlays, signages among others catering to various sectors such as aerospace, medical, electronics, manufacturing, and utility industries. The organization comprises of highly skilled individuals who create superior and advanced items for global customers. Furthermore, the company implements a rigorous inspection process that covers all stages of design, production, and timely delivery to meet the requirements of its clients.

VACCO Industries, Precision Etched Parts, founded in 1954 as Vacuum and Air Components Company and currently a subsidiary of ESCO Technologies Inc., is an American manufacturer based in El Monte, California, specializing in commercial photo etching components. The company’s capabilities include photo chemical etching process to produce various components from carbon and spring steel, brass, copper, stainless steel, and titanium. It also provides metal diffusion bonding and metal adhesive bonding services. Additionally, the company offers electroforming and micro laser services for precision laser cutting, micro welding, and marking. The company serves diverse industries, including automotive, avionics and space, electronics, and life science.

Cadence Design Systems, Inc., founded in 1988 in San Jose, California, USA, is a manufacturer of electronic design automation (EDA) software, hardware, and IP. It offers digital integrated circuits, custom ICs, and system-level verification. The software solutions streamline and optimize the development of complex electronic systems, ensuring faster time-to-market, improved performance, and reduced costs for customers. These tools find extensive use in industries such as semiconductor manufacturing, electronics, and telecommunications. It plays a pivotal role in driving innovation by enabling the creation of advanced electronics, from smartphones and IoT devices to advanced automotive systems and data centers.

Advanced Metal Etching, Inc., founded in 1993, is manufacturer based in Ligonier, Indiana, specializing in photochemical etching and laser cutting. The company offers photo chemical etching for manufacturing metals and material products such as aluminum, copper, and stainless steel etching. It also provides fiber laser cutting products to produce sheet metal parts with various dimensions and thickness, along with in-house plating. The company offers hybrid manufacturing, combining chemical etching and laser cutting processes. The company serves various industries, including aerospace, military, automotive, electronics, mechanical manufacturing as well as medical, microelectronics, and radio frequency (RF).

Hirai Seimitsu Kogyo Corporation, established in 1967 and headquartered in Osaka, is a manufacturer and supplier of photo-etched products. The company's product range spans household appliances, manufacturing jigs, automotive electronic components, and metal parts for ceramic packages in communication base stations. These products serve various sectors, including the household appliance industry, manufacturing, automotive, and telecommunications. Beyond products, the company provides services such as photo chemical etching, surface finishing, machining, ceramic processing, and lamination.

Kyodo International, Inc. established in 1970 and based in Kawasaki-shi, Japan, is a manufacturer and distributor of microfabrication tools and equipment. The company's product range includes deposition tools, photolithography equipment, etching machines, CMP processing units, and nanoimprinting tools. These products are used for the development and manufacturing of electronic components and systems. The company serves industries such as electronics manufacturing, microelectromechanical systems (MEMS) production, and life sciences, it ensures the delivery of high-precision tools for intricate manufacturing processes. Its services span the sale, repair, and overhaul of consumable parts.

Mekoprint, founded in 1954 and based in Stovring, Denmark, is an ISO 9001 certified manufacturer and supplier of solutions for industrial and electronics companies. The company designs and provides comprehensive solutions in the areas of printed electronics, cable harnesses, metal components, precision solutions, and graphic solutions. These products find various applications in green tech, automation, medical, professional equipment, and household appliances. Approximately 500 people work for the firm at its 40,000-square-meter European production facilities.

AEM & Forge, LLC is a distributor and custom manufacturer of metal raw materials based out of Houston, Texas. The company serves the aerospace, manufacturing, construction, and other industries. The company utilizes various alloys including aircraft standard, nickel, cobalt, copper alloys, and mil-spec materials. The company also provides services including consulting, electropolishing, EMI and RFI shielding, and photo etching. Customized annealing, beveling, deburring, and water jet cutting customizations are also available.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Dongguan TMN Electronics Co., Limited |

16.3%

|

| 2 | Advanced Metal Etching, Inc. |

10.9%

|

| 3 | Kraftetch Industries |

9.8%

|

| 4 | PMA Photometals |

8.2%

|

| 5 | AEM & Forge, LLC |

7.6%

|

| 6 | Tecomet Inc. |

6.5%

|

| 7 | Cadence |

6.0%

|

| 8 | Hirai Seimitsu Kogyo Corporation |

6.0%

|

| 9 | Kyodo International, Inc. |

6.0%

|

| 10 | KYOSEI Factory Thailand Co., Ltd. |

5.4%

|

Derivation Method

The ranking is calculated based on the click share within the photo etching page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

7 | 53.8% |

Japan

Japan

|

2 | 15.4% |

Denmark

Denmark

|

1 | 7.7% |

India

India

|

1 | 7.7% |

China

China

|

1 | 7.7% |

Thailand

Thailand

|

1 | 7.7% |