All Categories

History

This section provides an overview for ultrasonic metal welders as well as their applications and principles. Also, please take a look at the list of 10 ultrasonic metal welder manufacturers and their company rankings. Here are the top-ranked ultrasonic metal welder companies as of February, 2026: 1.TELSONIC AG, 2.UltrasonicEngineering Co.,Ltd., 3.Sonics & Materials, Inc..

Table of Contents

Categories Related to Ultrasonic Metal Welders

Ultrasonic metal joining machines are machines that use air vibrations generated by ultrasonic waves to join metals together.

Normally, heat is used to melt metals when joining metals, but ultrasonic metal joining machines do not use heat. Ultrasonic joining machines, however, do not use heat. Ultrasonic waves cause metal atoms to vibrate, making it possible to join metals with different melting points.

On the other hand, the disadvantage is that the joining strength is weak because the metal is not melted once and then joined completely, as is the case with heat. Therefore, care must be taken when seeking high strength.

Metal joining can be broadly classified into three categories. Specifically, there are three types of metal joining: fusion welding, in which the joint is heated and melted; solid phase welding, in which mechanical pressure is applied to cause plastic deformation of the joint; and brazing, in which a solder material with a low melting point is applied to the joint. Ultrasonic bonding is classified as solid phase bonding.

Ultrasonic metal joining machines are used to join items that should not be affected by their surroundings, such as foil lamination of battery electrodes and joining copper wires to connector terminals. Ultrasonic Metal Joining Machines do not melt metal with heat, so the material itself is not subjected to intense heat.

Therefore, there is little effect of heat on other parts of the joint. However, since the connection strength is not high, it is not suitable for large moving parts.

When metals are exposed to air, an oxide film is formed on the surface or foreign matter adheres to the surface. When these materials are adhered, joining is not possible unless the bonding surface is melted once.

However, when ultrasonic vibrations are applied parallel to the bonding surface while pressure is applied vertically to the metal, the ultrasonic vibrations cause the metals to rub against each other, peeling off the oxide film and adhesions to expose the metal surface. The interatomic force enables atoms to bond to each other without melting the metal.

Once the metal is melted, if the metal surface is thin, the shape itself may be deformed or shrink. However, with ultrasonic metal joining, the force acts on only a small layer of the joining surface, so the shape is not greatly disrupted.

Also, since only ultrasonic energy is used, no gas is consumed. The consumption of electrical energy is also greatly reduced, making it an environmentally friendly joining method.

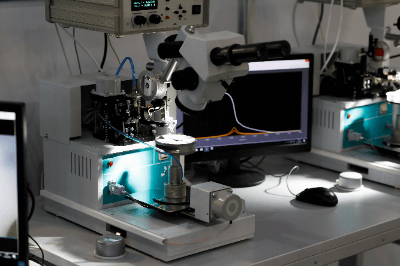

Ultrasonic metal joining machines consist of an oscillator, a vibration unit, and an ultrasonic horn.

It provides high-frequency power and controls the frequency. Since the frequency varies with each ultrasonic horn used and fluctuates depending on the temperature and pressure conditions during operation and operation, a frequency tracking circuit is included to adjust the frequency to the optimum level.

The vibration section consists of a transducer and a fixed horn. The frequency sent from the oscillator is transmitted through the transducer to the fixed horn, which amplifies the amplitude.

In the ultrasonic horn, the ultrasonic vibration from the vibrating section and the applied pressure cause instantaneous frictional heat on the workpiece joining surface, which melts the contact surface of the workpiece and bonds the molecules to each other. When the ultrasonic vibration stops, the molten workpiece rapidly cools and solidifies.

If pressure is applied continuously during cooling, the bonded surfaces will solidify in a denser state, resulting in a stronger bond.

Ultrasonic metal joining machines are safer, quicker, and more accurate than other joining methods. Joining by ultrasonic waves is a spot joining process, which allows for precise processing. In addition, it takes only a few seconds to join.

Except for the spot portion, there is little effect on the metal, and damage or deformation is unlikely to occur. Due to solid phase bonding by ultrasonic waves, the temperature rise to the base metal is slow, and bonding is possible at a relatively low temperature of 35% to 50% of the base metal's melting temperature.

Therefore, there are no sparks or smoke, and excellent strength and conductivity can be ensured.

*Including some distributors, etc.

Sort by Features

Sort by Area

Sonitek Corporation is a manufacturer and supplier of heat staking and ultrasonic welding systems and tooling that was established in 1989 and is headquartered in Milford, Connecticut. The company produces a wide range of heat staking and ultrasonic welding systems, including benchtop systems, automated systems, and custom systems. Its products, such as TS-100 Benchtop Heat Staking System, USW-2000 Automated Ultrasonic Welding System, and Custom Heat Staking and Ultrasonic Welding Systems, are used by a number of industries, such as electronics, medical, and automotive. The company also provides a range of services, including system integration, tooling design and fabrication, and training.

Sonics & Materials Inc., founded in 1969 with headquarters in the USA, is a manufacturer of a broad range of plastic welding equipment, tooling, and components. The company's manufacturing is divided into four divisions: plastics assembly, liquid processing, metal welding, and ultrasonic cutting and sealing. Sonics & Materials Inc.'s products include ultrasonic plastic welders, vibration welders, hand-held units, bench model presses, and ultrasonic kits for OEM installation. The company holds ISO 9001 certification and also offers custom design, tooling, and production of equipment for client-specific requirements.

Closed Loop Technology, Inc., established in 1946 and headquartered in Danbury, Connecticut, is a manufacturer that specializes in the design and development of plastics joining and metal welding equipment. The company offers a range of products such as ultrasonic plastic welding, ultrasonic metal welding, and ultrasonic cleaning. It also offers ultrasonic/sonic driller/corer and ultrasonic machining. Its product allows for the production of clean welds in minimal time with uniform joints. The company has achieved ISO 14001 certification and the CBIA Award of Excellence for its environmental success. It serves industries such as automotive, electronics, medical, manufacturing, and laboratory.

SONOBOND ULTRASONICS, INC., founded in the United States in 1960, is a supplier of ultrasonic metal welding and textile bonding equipment. The company offers a range of textile bonding machines for applications like nonwoven fabric bonding and embossing, ultrasonic metal welding machines are capable of welding various metals with speed and precision, and ustomized equipment and solutions to meet the specific needs. It serves industries such as electronic, environmental, filtration, HVAC, photovoltaic, and medical.

Xiamen Lith Machine Limited, founded in 1998 and headquartered in Xiamen, Fujian, China, is a manufacturer of battery laboratory and production equipment. Its product offerings encompass lithium battery production line machines and battery pack assembly line machines for battery manufacturing, laboratory machines for research and testing, battery materials for production, prismatic cell production machines, and cylindrical cell laboratory machines. The company has been verified on-site by SGS Group, an inspection company, and holds more than 16 patent rights.

Ultrasonic Engineering Co.,Ltd., founded in 1956 and based in Tokyo, Japan, is a manufacturer of electrical equipment, machinery, and supplies among others. The company has 186 patents and offers a wide range of products including cltrasonic wire bonders, ultrasonic cleaners, ultrasonic plastic welders, ultrasonic metal bonders, and ultrasonic measuring instruments among others. The company serves various industries including chemicals & pharmaceuticals, paper & printing, transport & logistics, textiles, and many more.

Founded in 1890 in Missouri, Emerson Electric Co., is a technology and engineering company that provides various solutions for customers in industrial, commercial, and consumer markets globally. Business segments include automation solutions, AspenTech, and commercial & residential solutions segments. The Automation Solutions segment offers measurement and analytical instrumentation, industrial valves and equipment, and process control software and systems. The AspenTech segment provides asset optimization software for enhancing performance through a combination of modeling, simulation, and optimization capabilities. The Commercial & Residential Solutions segment offers residential and commercial HVAC products, system protector and flow control devices, and IoT thermostats.

Telsonic AG, based in Bronschhofen, St. Gallen, Switzerland, has been a manufacturer of industrial ultrasonic solutions since its inception in 1966. The company maintains individual affiliates in strategic locations such as Germany, Serbia, England, America, and China, with specialized distributors worldwide providing technical documentation that complies with ISO/DIS 17100 standards. The product range includes ultrasonic presses and generators, sonotrodes, ultrasound control systems, sieving resonators, and hand welding units. The company has built affiliations with the Schleuniger Group and the Baumer Group for research and advancement in ultrasonic technology.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Emerson Electric Co. |

26.8%

|

| 2 | TELSONIC AG |

17.1%

|

| 3 | UltrasonicEngineering Co.,Ltd. |

17.1%

|

| 4 | Sonics & Materials, Inc. |

12.2%

|

| 5 | Closed Loop Technology, Inc. |

9.8%

|

| 6 | SONOBOND ULTRASONICS, INC. |

7.3%

|

| 7 | Adwells Co., Ltd. |

4.9%

|

| 8 | Shanghai Yangmi Intelligent Technology Co., Ltd. |

2.4%

|

| 9 | Sonitek Corporation |

2.4%

|

Derivation Method

The ranking is calculated based on the click share within the ultrasonic metal welder page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

4 | 57.1% |

China

China

|

1 | 14.3% |

Switzerland

Switzerland

|

1 | 14.3% |

Japan

Japan

|

1 | 14.3% |