All Categories

History

This section provides an overview for compression reducers as well as their applications and principles. Also, please take a look at the list of 22 compression reducer manufacturers and their company rankings. Here are the top-ranked compression reducer companies as of February, 2026: 1.Wastequip, LLC, 2.Global Trash Solutions, 3.Wessco Waste & Recycling Equipment.

Table of Contents

Categories Related to Compression Reducers

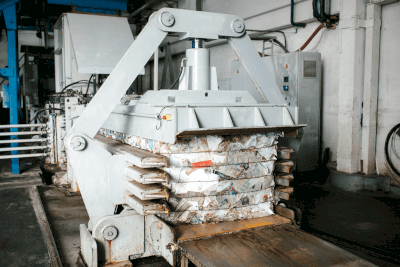

A compression reducer is a device that compresses waste by applying high pressure to reduce its volume. By applying high hydraulic pressure, refuse that would otherwise take up a lot of space can be compacted. In addition to reducing waste storage space, it can also reduce the cost of waste collection and transportation. They are especially used at food processing sites, construction sites, and plastic product factories where large amounts of waste are generated. In addition, large size machines are used in direct connection with production lines.

Compression reducers are used in places where large amounts of waste are generated. An example is a building materials processing plant. The site generates a large amount of lumber and wood waste, making waste disposal very difficult. However, by using compression reducers, the volume of waste is reduced and costs are reduced. They are also widely used in plastic product manufacturing plants.

Plastic and Styrofoam can be greatly reduced in volume by compressing them. In addition, since they can be compacted without heat treatment, they can be recycled.

Compression reducers are used to compress and reduce the volume of refuse. Here, we introduce the principles and features of compressing various types of refuse.

Refuse placed in a sealed space is compressed by tens of tons of high hydraulic pressure. The principle is simple: the volume is reduced by being crushed by the compression plates. Large-scale equipment is capable of compressing more than 500 kg of refuse at a time, and is directly connected to the production line of a factory.

Brittle refuse such as styrofoam is crushed before being compacted. The waste is broken into small pieces by passing through a crushing section with large blades and is then compacted. After compaction, the waste is evenly distributed, making it easier to transport and process. This method is also environmentally friendly, as it does not interfere with recycling because it is processed without the addition of heat. However, some heat is generated by friction during compression, so cooling water must be used.

In addition, there are smaller devices that can be used easily. These devices can compress paper, plastic bottles, cans, etc., and are installed in offices and commercial facilities.

*Including some distributors, etc.

Sort by Features

Sort by Area

SP Industries, Inc., founded in 1996 and located in Hopkins, Michigan, is a designer and manufacturer of compactors, pre-crushers, transfer station equipment, and cart dumpers. The company offers a broad range of products that include trash compactors, food waste compactors, box dumpers, wet waste pre-crushers, and transfer stations. These products are used for waste reduction, minimizing food waste in food service and agricultural contexts, material handling, handling wet waste materials, and ensuring environmentally responsible waste transfer. The company’s products cater to industries such as commercial waste management, food service, agriculture, material handling, and municipal waste optimization.

Wastequip, established in 1989, is a manufacturer of waste management equipment based in North Carolina, United States. The company's catalog includes hoists, refuse trucks, compactors, tarping systems, and carts used by recyclers, haulers, municipalities, maintenance professionals and OEMs. It also has Wastequip WRX Service Centres to offer services like installing, maintaining and repairing Wastequip brands like Amrep, Mountain Tarp, Pioneer, Wastebuilt and Galbreath. The company has also introduced sustainable methods production like Project 25 to reduce virgin resin usage by 25%, andTower EVR -Green to recycle 100% cart body.

Weima America, Inc., established in 1980 and based in Ilsfeld, Germany, is a manufacturer and supplier of shredding and briquetting machinery. The company's product range includes single-shaft shredders, four-shaft shredders, cutting mills, briquette presses, and draining presses. These products are utilized in plastics recycling, wood waste shredding, metal recycling, waste-to-energy processes, and paper & cardboard recycling. The machinery primarily serves industries such as plastics, wood processing, metal recycling, and waste management. As part of its service offerings, it provides preventative maintenance, machine upgrades, retrofitting, and specialized training for its machinery's optimal use.

Global Trash Solutions, started in 2008 and based in Florida, United States, is a manufacturer of waste management equipment. The company's products include compactors and balers. It also offers consultancy services to businesses across the US on waste management strategies by providing waste stream analysis and advice on how to minimize waste and recycling costs. The company deals with different waste types, including plastic, paper, municipal solids, metal and textiles and it also repairs faulty compactors and balers.

Mark-Costello Co., founded in 1956 with headquarters in Paramount, California, USA, is a manufacturer and distributor of waste, material handling, and recycling equipment. The company's product line includes hydraulic waste cart dumpers, shredders, medical waste sterilizers, MRF (material recovery facility) conveyor systems, and balers. These products are used for various applications, including recycling systems, cardboard crushing and bailing, and paper, plastic, tire, and wood shredding equipment. The company serves various industries, including food processing, chemical processing, logistics and warehousing, and automotive.

Wessco Waste & Recycling Equipment, in the United States in 1987, is a supplier of waste and recycling equipment. The company offers a variety of waste compactors designed for reducing the volume of waste materials, optimizing storage space, and simplifying disposal, advanced conveyors and sorting systems for streamlining material handling and separation in recycling facilities, and shredders and crushers are ideal for reducing the size of waste materials and preparing them for recycling or disposal.

RUNI A/S, founded in Denmark in 1973 is a manufacturer of waste compactors. The company offers a comprehensive range of waste compactors, including models designed for general waste, recyclables, hazardous materials, and specialized applications and tailored compactor solutions to meet specific needs. Its products are used by factories and production facilities to efficiently handle waste generated during their manufacturing processes and by medical facilities to safely manage regulated medical waste.

Orwak, founded in 1971 and based in Sävsjö, Sweden, is a manufacturer of balers and waste compactors. The company provides compaction and baling solutions for solid waste materials. Its range of compactors, baling and briquetting systems promote sorting at source and makes waste management more profitable. Its compactors can reduce the waste down to 10 % of its original volume. The company has obtained ISO 9001 and 14001 certifications for quality and environmental management, as well as ISO 3834 certification for fusion welding.

YUKEN KOGYO CO., LTD. established in 1929 and incorporated in 1956, based in Ayase, Kanagawa, Japan, is a manufacturer and supplier of hydraulic equipment. The company's product range includes Piston Pumps, Vane Pumps, Pressure Controls, Flow Controls, and Directional Controls. These products are used in hydraulic systems for control and optimization. The industries it serves include construction, manufacturing, automotive, and industrial machinery. In addition to its product offerings, the company provides services such as product customization, technical support, product training, and maintenance.

KenBay, founded in the United States in 2003 is a manufacturer of industrial trash compactors designed to provide maximum compaction in a minimum space. The company offers commercial garbage compactors for an oil rig, that is designed to the rigid specifications of the food industry, or a compactor that can withstand hazardous materials or explosives. It also provides customized compactor solutions tailored to the specific needs of the clients and offers consulting services to help businesses optimize their waste management processes.

COMPACTORS INC, established in 1987 in the United States, is a manufacturer specializing in waste management equipment. The company designs and produces a range of compactors and balers for efficient waste handling. With a devotion to environmental sustainability, COMPACTORS INC serves various industries, including hospitality, retail, and healthcare, addressing waste disposal challenges with inventive solutions. COMPACTORS INC's extraordinary approach lies in their devotion to creating custom waste management systems tailored to each client's needs. For instance, their vertical balers efficiently compress recyclable materials, aiding companies in reducing waste volume and promoting recycling efforts.

Marathon Equipment Co., founded in 1967 and headquartered in USA, is a manufacturer of waste compaction machines and units. The company's product line includes stationary compactors, compaction containers, self-contained compactor containers, transfer systems, and compactor monitoring systems. The company also offers consultation, design, engineering, and fabrication of full turnkey compaction systems, as well as rental and lease systems. It serves various customers including grocery stores, hospitals, restaurants, logistics and distribution centers, as well as manufacturing plants.

KIMURA Group, founded in 1988 and based in Kure City, Hiroshima Prefecture, is a manufacturer of environmental and industrial machinery. The company produces crushers, presses, and cutting machines for waste management and recycling. Its offerings include a patented REC aluminum casting method for part production at the Higashi Hiroshima Plant. Its machinery caters to industries like automobile recycling and shipbuilding. The company's portfolio also encompasses packing machines for PET bottles and industrial equipment. It also offers OEM and ODM services based on customer specifications, from design to development.

Safran, a French company founded in 2005, is a manufacturer and maintenance of civilian and military aircraft engines. The company's main areas of operation include space systems, engines and propulsion, aerospace equipment, avionics and electronics, defense, and security. Its products are applied in the aerospace, defense, and security industries, including surveillance systems, propulsion systems, landing gear, and thrust reversers for commercial and military aircraft engines. The company embraces innovation and safety standards to meet customer satisfaction.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Wastequip, LLC |

10.5%

|

| 2 | Global Trash Solutions |

7.9%

|

| 3 | Wessco Waste & Recycling Equipment |

7.9%

|

| 4 | Custom Manufacturing Inc., |

5.3%

|

| 5 | BACE, LLC |

5.3%

|

| 6 | RUNI A/S |

5.3%

|

| 7 | KenBay |

5.3%

|

| 8 | SP Industries, Inc. |

5.3%

|

| 9 | Orwak |

5.3%

|

| 10 | Waste Management, Inc. |

5.3%

|

Derivation Method

The ranking is calculated based on the click share within the compression reducer page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

11 | 68.8% |

Denmark

Denmark

|

1 | 6.3% |

Sweden

Sweden

|

1 | 6.3% |

Japan

Japan

|

1 | 6.3% |

South Africa

South Africa

|

1 | 6.3% |

Republic of Korea

Republic of Korea

|

1 | 6.3% |

116 products found

116 products

Fujitex Co., Ltd.

1050+ people viewing

Last viewed: 16 hours ago

For the final disposal site management company with a landfill. Compress the waste and extend the remaining years of landfills. 5 points ■ "Full w...

Horitomi Commerce and Industry

550+ people viewing

Last viewed: 3 minutes ago

(1) With a compact design, it can be installed in the same location as the content of the flexible bag contents, and can be operated on the current...

2 models listed

Eco Friend Co., Ltd.

720+ people viewing

Last viewed: 22 hours ago

■Features ・Information transmission function (55-inch large monitor) and deposit function using mobile phone. ・Stores 500mm PET bottles (approx. ...

Eco Friend Co., Ltd.

360+ people viewing

Last viewed: 22 hours ago

■Features ・Information transmission function (55-inch large monitor) and deposit function using mobile phone. ・Stores 500mm PET bottles (approx. ...

Wintex Co., Ltd.

380+ people viewing

Last viewed: 3 minutes ago

■Features Movable ■Compaction volume reduction target flexible container bag Wintex Co., Ltd. "Flexible container compression equipment

Technolinks Co., Ltd.

470+ people viewing

Last viewed: 17 hours ago

A simple unit for empty can sorting and compression equipment. It is possible to freely combine the sorting workbench, magnetic separator, aluminum...

Yamamoto Manufacturing Co., Ltd.

370+ people viewing

Last viewed: 15 minutes ago

500kg/h ■PET bottle pre-processing machine for "removal of residual liquid" and "simple compression". ・Even leftover plastic bottles, which are d...

Technolinks Co., Ltd.

280+ people viewing

Last viewed: 22 hours ago

This is an empty can press machine that closes on one side. This model has been improved over many years and is used in many recycling facilities. ...

Japan Packaging Machinery Co., Ltd.

570+ people viewing

Last viewed: 3 minutes ago

The chain is made of reinforced steel and compresses tightly. Features ■More functional... Omnipress is a new roll compactor. The input port of th...

Fujitex Co., Ltd.

480+ people viewing

Last viewed: 22 hours ago

■Multi-compression for everything from soft plastics to beverage cans Compress, reduce volume, and package bulky waste. This series reduces install...

3 models listed

Fujitex Co., Ltd.

510+ people viewing

Last viewed: 3 minutes ago

■Compresses and packs all kinds of waste with one machine This is a multi-baler that compresses and packs all kinds of waste such as used paper, PE...

2 models listed

Fujitex Co., Ltd.

750+ people viewing

Last viewed: 22 hours ago

■Improve storage and transportation efficiency by reducing volume The compressor has no daily processing limit, and can efficiently process waste p...

Fujitex Co., Ltd.

700+ people viewing

Last viewed: 22 hours ago

■Compress the filled plastic bottle The filled plastic bottle is dehydrated and compressed. Selected by customers in beverage factories and waste t...

Fujitex Co., Ltd.

280+ people viewing

Last viewed: 39 minutes ago

■Compress and reduce the volume of PET bottles to approximately 1/10 and bundle them. - Fully automatic machine is equipped with a graphic operatio...

5 models listed

Hocos Co., Ltd.

390+ people viewing

Last viewed: 1 hour ago

■Improvement of factory environment Compress chips to reduce wasted space. Solidification creates a clean working environment. ■Reducing transport...

TAIYO Co., Ltd.

520+ people viewing

Last viewed: 3 minutes ago

Efficiently compresses empty cans.

Moriya Sangyo Co., Ltd.

650+ people viewing

Last viewed: 3 minutes ago

Reasonable compression process The X30 is ideal for locations where large amounts of waste are generated, such as distribution bases and various f...

Technolinks Co., Ltd.

310+ people viewing

Last viewed: 1 day ago

This is a two-way alligator type hydraulic press machine that consists of a charging case, a top cover, a main press plate, and a shutter. By using...

Moriya Sangyo Co., Ltd.

620+ people viewing

Last viewed: 3 minutes ago

Fusion of mass processing and space saving The X50 is ideal for large retail stores, businesses, and municipal recycling plants that generate larg...

Moriya Sangyo Co., Ltd.

670+ people viewing

Last viewed: 3 minutes ago

Separate body designed for increased separation, expandability, and versatility By using a separation box, it can be easily moved to the waste sto...

Moriya Sangyo Co., Ltd.

800+ people viewing

Last viewed: 3 minutes ago

Features ■Compact firmly even when filled with plenty We have achieved ``the smallest size and packaging as is'', which was not possible with previ...

Moriya Sangyo Co., Ltd.

500+ people viewing

Last viewed: 13 hours ago

Features ■Achieving high cost performance We have achieved high cost performance by adopting a simple and sturdy structure and manual operation. ■...

Moriya Sangyo Co., Ltd.

400+ people viewing

Last viewed: 22 hours ago

The design does not look like a garbage disposal, making it ideal for installation in offices, etc. Although the pressurizing force is 0.7 tons, t...

Moriya Sangyo Co., Ltd.

490+ people viewing

Last viewed: 6 hours ago

The design does not look like a garbage disposal, making it ideal for installation in offices, etc. Although the pressurizing force is 0.7 tons, t...

Moriya Sangyo Co., Ltd.

440+ people viewing

Last viewed: 7 hours ago

It has been introduced in a variety of industries including hospitals, restaurants, commercial facilities, hotels, and offices. Although the press...

Yukos Co., Ltd.

420+ people viewing

Last viewed: 22 hours ago

Strong clamping force provides a sharp finish.The perfect partner for drawing folding machines. ■Product features - Compresses with a strong tight...

Moriya Sangyo Co., Ltd.

460+ people viewing

Last viewed: 22 hours ago

Ideal for areas and facilities where discharging in plastic containers is possible. The Premo 750 has a pressurizing force of 1.3 tons and a pushe...

Moriya Sangyo Co., Ltd.

520+ people viewing

Last viewed: 21 hours ago

Achieving a clean work environment by reducing vibration, noise, paper dust, and electricity Introducing a machine that can crush cardboard boxes ...

San-ai Ecosystem Co., Ltd.

330+ people viewing

Last viewed: 6 hours ago

■Product description Compresses and solidifies chips. During compression, the adhering cutting fluid is squeezed out. Ideal for processing machines...

San-ai Ecosystem Co., Ltd.

260+ people viewing

Last viewed: 22 hours ago

■Product description - Compression and solidification of various chips such as iron, SUS, aluminum, etc. A compressor that can also process badges....