All Categories

History

This section provides an overview for honing machines as well as their applications and principles. Also, please take a look at the list of 23 honing machine manufacturers and their company rankings. Here are the top-ranked honing machine companies as of February, 2026: 1.delapena droup Ltd., 2.Hardinge Inc, 3.Barnes Honing.

Table of Contents

Categories Related to Honing Machines

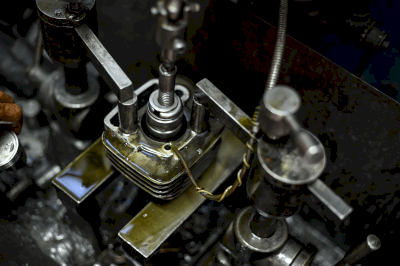

A honing machine is one of the machines used for surface finishing. The machine rotates while crushing the inner surface of a cylindrical workpiece with multiple grinding wheels attached in the shape of sticks to finish the inner surface.

Since it is not possible to cut a large number of pieces at once, honing machines are generally used for final finishing after cylindrical cutting with boring machines or other machines.

Although honing machines are similar to internal grinding machines, they are capable of machining more precise hole accuracy, roundness, and higher surface roughness.

Honing machines are often used for machining the internal surfaces of engine cylinders, which require extremely high precision in order to achieve the final finish on cylindrical workpieces.

The surface roughness is almost mirror finish, but if you look closely, you can see small scratches in the form of crossed lines, which adhere to the engine oil and keep the oil film to protect the cylinder from friction with the piston, so it is ideal for machining engine cylinders that constantly circulate high pressure oil.

Most honing machines are vertical machines, and the bore is machined by the up-and-down motion of a grinding wheel attached to the stick-shaped tip.

Other types of honing machines include the parallel flat honing machine, which sandwiches the workpiece between two disk-shaped grinding wheels and uses a reciprocating motion to align multiple workpieces to a uniform height; the CNC multi-axis honing machine, which performs the entire process automatically, eliminating the need to use separate grinding wheels for intermediate and final finishing operations; and the honing machine with a water and abrasive grain mixture sprayed onto the workpiece. Liquid honing, in which a mixture of water and abrasive grains is sprayed onto the workpiece to create a matte finish on the surface, and other types of honing.

Both of these processes do not apply heat or load to the workpiece as in the cutting process, and they do not affect the accuracy of heat-sensitive workpieces. However, the honing process is based on the shape created by the grinding process prior to honing, so the quality of the previous process is important to achieve high accuracy.

In addition, honing cannot exceed the outside diameter of the stick on which the grinding wheels are mounted, because the multiple grinding wheels are all attached to each other in close contact. Therefore, it is necessary to prepare separate sticks for the inner diameter of each workpiece and separate grinding wheels to be attached to the sticks, which has the disadvantage of being very costly.

A fine mesh of scratches created by honing is called a cross hatch.

Cross-hatches are formed gradually by the repetitive back-and-forth motion of a rotating horn that creates a fine mesh of scratches at different angles when moving downward and upward.

First, a coarse grindstone is used in roughing to create a large-angle mesh at a relatively slow rotation speed, followed by finishing with a fine grindstone at a higher rotation speed to create small-angle scratches, and finally cross-hatching is formed with an angle of about 20° to 60°.

By creating cross hatches in this way, oil can enter the grooves of the cross hatches where metals slide against each other, preventing the oil film from running out.

Examples of this process include engine parts such as cylinders, rocker arms, and connecting rods.

Honing and polishing (internal grinding) can both be used for hole drilling with high precision as finishing processes, but the machining methods are different.

Honing involves pressing multiple cylindrically mounted grinding wheels together in a reciprocating motion, whereas internal grinding involves placing only one point of the grinding wheel on the workpiece and rotating the workpiece and grinding wheel together.

Honing can produce a higher roundness and surface roughness than internal grinding, but it has the disadvantage that it cannot be corrected because it follows the hole drilled in the previous process, whereas internal grinding can be corrected to some extent and is determined by the accuracy of the centering process.

In addition, cross hatches can only be produced by honing, which cannot be done with internal grinding.

Incidentally, one of the hole finishing tools often used on milling machines is a reamer, which is also used for hole finishing, but has the disadvantage that it is more difficult to handle hardened, high-hardness steel than grinding.

*Including some distributors, etc.

Sort by Features

Sort by Area

Ohio Tool Works (OTW) is an American manufacturer based in Ashland, Ohio, specializing in vertical and horizontal honing machines, as well as related tooling, abrasives, and supplies. Since its establishment in 2004, OTW serves various industrial sectors, including oil and gas, aerospace, automotive, medical device, and metalworking industries. OTW offers its services to honing companies, regardless of the machine brands used. These services include initial machine assessment, installation, maintenance, repair recommendations, custom solutions, and worker training. Additionally, OTW's Inventory on Demand program enables honing companies to reduce inventory costs while ensuring access to necessary tooling and abrasives.

Brush Research Manufacturing Co., Inc., a manufacturer established in 1958 and headquartered in Los Angeles, California, specializes in producing abrasive surface finishing products. The company's product portfolio includes the Flex-Hone Tool, a tool for deburring, edge blending, and also for surface finishing. The company also manufactures abrasive nylon brushes that is designed for an array of surface finishing and deburring applications. With ISO 9001:2015 certification, the company demonstrates adherence to quality its QMS.

Little Swede Industries established in 1977 serves as a manufacturer of custom surface treatment machinery and metal finishing/cleaning products and its manufacturing facility is based in Wichita, Kansas. The company's product line includes Washers, Shakers, and Blasters used in the aerospace, metal fabrication, and oil and gas industries and it offers a 12-month warranty for its products. It provides support from the product selection stage through the life-cycle of the machines and manufactures automated cleaning systems.

HTT USA Inc., established in 1997 and headquartered in Grayslake, USA, is a manufacturer of deep-hole drilling machines. The company's products include horizontal honing, deep hole drilling, and BTA deep hole boring machines. Its horizontal honing machines are used for refining cylinder bores in engines, and deep hole drilling machines for precision drilling of engine valves in automotive manufacturing. It also offers solutions for gear shafts, fuel injection parts, and mold making for the aerospace, automotive, and medical instruments industries. The company also provides technical consulting, machine repair, and upgrade services, ensuring tailored configurations to meet specific customer needs.

Sunnen Products Company, founded in 1924, is an American manufacturer and supplier headquartered in St. Louis, Missouri, specializing in of high-precision and bore sizing machines, tools, and abrasives. Joe Sunnen, founder of the company, invented the first manual cylinder hone in 1928. Over the years, Sunnen has developed industrial honing machines, tools, and abrasives with bore sizing and finishing systems, lapping machines, deep hole drilling machines and tools, bore gaging and roller burnishing systems. These products find applications in various industries, such as honing solutions in the automotive sector, as well as a line of machines, tools, and abrasives for energy drilling.

Hardinge, a company established in 1890, based in Berwyn, Pennsylvania, USA, is a manufacturer and exporter of precision machine tools and accessories. The company’s product solutions for various industrial and research applications such as turning, milling, grinding, workholding, and automation. It has a range of products such as CNC lathes, machining centers, cylindrical grinders, collets, chucks, indexers, and rotary tables. These products are designed to operate with high accuracy, quality, and reliability. It is a chief supplier of precision machine tools and accessories in the US and abroad.

Rottler Manufacturing has been a symbol of cutting-edge technology since 1923. They offer a comprehensive machinery range catering to all engine builders. From custom machine shops to high-volume remanufacturing, Rottler has the perfect machine. Renowned for innovation, their advanced designs meet global engineering demands. Operating from Kent, Washington, their facility, dedicated solely to the automotive aftermarket, boasts state-of-the-art equipment. With in-house quality control, Rottler ensures premium standards. Their ability to engineer, manufacture, and customize tooling gives them a competitive edge.

Zhengzhou Sino-Crystal Diamond Co. Ltd., established in 2004 and based in Zhengzhou, China, is a manufacturer of synthetic diamonds and related products. The company has CNAS-authorized labs and has set up a tech center that partners with nine R&D institutes and colleges in China to conduct research around synthetic diamonds. In 2008, it changed into an incorporated company, and in 2010, it was first listed on the Shenzhen Stock Exchange. It has ten subsidiaries and is ISO 14001 and ISO 9001 certified.

Toyo Advanced Technologies Co., Ltd., established in 1950, is a Japanese manufacturer and supplier headquartered in Minami-ku, Hiroshima, specializing in machinery and hard coating solutions. The company offers various computerized numerical control (CNC) internal and external grinding machines as well as gear and multi-profile grinding machines. Additionally, it provides CNC honing machines, cylinder block bore finishers, multi-wire saws for power semiconductors, and scroll cutting machines. These machines find applications in various industries, including automobile, bearing, and electric household appliance. The company also offers hard coating solutions such as chemical vapor deposition (CVD), physical vapor deposition (PVD), and diamond-like carbon (DLC) coatings.

delapena Group Ltd, founded in 1927 by Leslie delapena, is a designer and manufacturer of honing, abrasives, and toolings headquartered in Cheltenham, Gloucestershire, UK. It offers vertical and horizontal, honing mandrels, and icon-based honing machines used in the automotive, aerospace, pharmaceutical, oil & gas, and other manufacturing sectors The company also has a service department offering honing consultancy, complete tooling refurbishment, and process engineering services. It also has a tooling refurbishment facility which offers tool refurbishment to all major honing manufacturers including Jones & Shipman, Ohio Tool Works, Gehring, Animex, and Kadia.

Chris-Marine AB, founded in 1962 with headquarters in Denmark, is a manufacturer of maintenance equipment for four-stroke and two-stroke engines. The company's products include electronic cylinder pressure indicators, spray washing machines, injector test fuel valve test rigs, honing machines, grinding machines, and lathes for valves, seats, and seat recess surfaces. Chris-Marine machines are used by trade professionals in power plants, marine servicing businesses, and workshops. The company also provides accessories and after-sales service for all of its products.

Gehring Technologies GmbH is a manufacturer of fine machine technologies for conventional and electrified drive trains as well as precision honing, laser, and surface processing technologies. Headquartered in Ostfildern, Germany, the company was established in 1926. Gehring Technologies specializes in delivering cutting-edge solutions for precision manufacturing, including honing systems, laser solutions, and surface coatings. These technologies find applications across industries such as automotive, aerospace, and energy. The company's comprehensive services encompass process wage honing, aligning, engineering and digital solutions, optimization, and technical consulting.

Pemamo SA, founded in 1988, is a manufacturer of high-precision honing machines and tools based in La Neuveville, Switzerland. The company's product line includes automatic and semi-automatic machines, such as horizontal and vertical honing machines. It also produces hones for blind and through bores with galvanic and metallic bonds, hand hones, and segment hones. In addition, it offers a range of apparatus and accessories, such as adapters and friction-clutch systems. Supported by a network of 30 agents in 25 countries, the company serves various industries, including aeronautics, automotive, and healthcare.

Anhui Union Brush Industry Co. Ltd., established in 2001 and headquartered in Hefei, China, is a manufacturer of industrial brushes. The company produces road sweeping, snow sweeping, and floor machine brushes. It also offers strip brushes, roller brushes, and solar panel cleaning brushes. Its brush solutions serve food processing, automotive, and glass processing industries. The company collaborates with Hotani, DuPont, and Tory companies to enhance the quality and range of its products.

Osborn GmbH., founded in 1887 and based in Burgwald, Germany, is a supplier of tools and application solutions for surface treatment and finishing. Its product portfolio ranges from technical brushes, polishing tools, and grinding discs used in applications like metal processing, deburring, and weld seam preparation. The company has 13 production facilities worldwide, over 100,000 custom-made tools, and over 10,000 standard products. It owns several brands, including Broomate, DIALUX, and Load Runners, and supplies customers in over 120 countries. It is also ISO 50001, ISO 9001, and ISO 14000 certified and has over 700 TÜV-SÜD certified products.

PSS-Abrasives & Tool Division, established as Bates Technologies Inc. in 1985 and headquartered in Noblesville, Indiana, United States, is an industrial surfacing tool and equipment manufacturer and B2B supplier. The company's products include vertical and horizontal bore honing production machines, CNC micro-hone systems, and gagging and size control systems.Its services include the production of custom honing stones and tooling, a test drive trial program, and tool reconditioning. In 2005, the company acquired the tooling and abrasive line of products from Micromatic, adding to its legacy of 80 years of honing and bore finishing experience.

KADIA, a part of Nagel Group established in 1959, is a manufacturer of honing and mechanical deburring technology headquartered in Nürtingen, Baden-Württemberg, Germany with locations in Europe, USA, China, India, and Brazil The company offers new and pre-owned honing machines, honing tools, honing abrasives, deburring machines, and deburring tools for high-precision finishing. It has attained the ISO 9001, ISO 14001, and VDA 6.4 and 6.1 certificates and its customers include vehicle manufacturers and their suppliers, as well as players in the hydraulic industry and aerospace technology.

Amc-Schou AS, established in 1925 and based in Skanderborg, Denmark, is a supplier of engine rebuilding and cylindrical grinding machinery. Some of the machines it stocks include cylinder honing machines, line boring machines, and crack detectors. The company’s crankshaft grinders feature hydraulically operated wheel slide movement and face plate locking pins capable of up to 3700mm/145.6 inch. The company also delivers machines engineered to suit individual needs, like having extra-large swings. The first engine rebuilding machine was manufactured in 1938, and the company has delivered approximately 16,000 machines to over 100 countries.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | delapena droup Ltd. |

9.0%

|

| 2 | Hardinge Inc |

7.4%

|

| 3 | Barnes Honing |

6.6%

|

| 4 | Ohio Tool Works |

6.2%

|

| 5 | Toyo Advanced Technologies |

5.5%

|

| 6 | HTT USA Inc. |

5.3%

|

| 7 | Little Swede Industries |

5.1%

|

| 8 | Gehring Technologies GmbH |

4.8%

|

| 9 | Osborn |

4.8%

|

| 10 | PEMAMO SA |

4.8%

|

Derivation Method

The ranking is calculated based on the click share within the honing machine page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

8 | 47.1% |

Japan

Japan

|

3 | 17.6% |

Germany

Germany

|

2 | 11.8% |

China

China

|

1 | 5.9% |

United Kingdom

United Kingdom

|

1 | 5.9% |

Sweden

Sweden

|

1 | 5.9% |

Denmark

Denmark

|

1 | 5.9% |

37 products found

37 products

Utsunomiya Manufacturing Co., Ltd.

810+ people viewing

Last viewed: 14 hours ago

■TGR-016 series The TGR-016 series is a CNC tool grinder developed specifically for "tool edge polishing". It comes standard with the interactive p...

Fuji Honing Industry Co., Ltd.

670+ people viewing

Last viewed: 18 hours ago

■2021 Good Design Award Winner SMART, SMALL, SIMPLE IoT compatible smart machine. Space-saving machine for small diameter machining. Simple & easy ...

Nagel Aoba Precision Co., Ltd.

1080+ people viewing

Last viewed: 1 hour ago

◎ Energy saving, ◎ Space saving, ◎ Sound saving, ◎ Maintenance saving. Reduces CO2 emissions by approximately 40%. *Compared to the conventional hy...

Nissin Seisakusho Co., Ltd.

700+ people viewing

Last viewed: 16 hours ago

■Mechanical double expansion (servo control) + process integration using air-in process measurement A medium-diameter honing machine that inherits ...

Nissin Seisakusho Co., Ltd.

790+ people viewing

Last viewed: 1 day ago

■A servo-controlled mechanical expansion method is used for the grindstone expansion method, which is the heart of the honing machine. The vertical...

Fuji Honing Industry Co., Ltd.

580+ people viewing

Last viewed: 9 hours ago

New generation honing machine with newly developed spindle structure High performance & multifunctional flagship model ■Summary ・Supports various...

Nissin Seisakusho Co., Ltd.

910+ people viewing

Last viewed: 1 day ago

■A servo-controlled mechanical expansion method is used for the grindstone expansion method, which is the heart of the honing machine. The vertical...

Fuji Honing Industry Co., Ltd.

520+ people viewing

Last viewed: 1 day ago

A new generation honing machine with a newly developed main shaft structure.An economy model that combines economy and performance. ■Summary ・Ach...

Nagel Aoba Precision Co., Ltd.

920+ people viewing

Last viewed: 18 hours ago

◎ Energy saving, ◎ Space saving, ◎ Sound saving, ◎ Maintenance saving. Approximately 40% reduction in CO2 emissions *Compared to the conventional h...

Nissin Seisakusho Co., Ltd.

540+ people viewing

Last viewed: 1 day ago

■Adopts main/sub double slide function on the main shaft part The long stroke model is a general-purpose series commercialized for machining long h...

Cyber RC Co., Ltd.

430+ people viewing

Last viewed: 5 hours ago

■Summary It is mainly used for carbide drills, but when resharpening the cutting edge, chipping is likely to occur if the cutting edge is too pinne...

Nissin Seisakusho Co., Ltd.

630+ people viewing

Last viewed: 1 day ago

■Free combination of "3 cells" possible. flexible honing machine Cell-type honing machines can be combined flexibly according to the purpose. This ...

Cyber RC Co., Ltd.

420+ people viewing

■Summary It is mainly used for carbide drills, but when resharpening the cutting edge, chipping is likely to occur if the cutting edge is too pinne...

Fuji Honing Industry Co., Ltd.

780+ people viewing

Last viewed: 1 day ago

A best-selling model that is faithful to the basics and has a solid design that has endured for generations. The history of our honing machine star...

Nagel Aoba Precision Co., Ltd.

730+ people viewing

Last viewed: 9 hours ago

◎ Energy saving, ◎ Space saving, ◎ Sound saving, ◎ Maintenance saving. Approximately 40% reduction in CO2 emissions *Compared to the conventional h...

Nissin Seisakusho Co., Ltd.

800+ people viewing

Last viewed: 1 day ago

■Free combination of "3 cells" possible. flexible honing machine Cell-type honing machines can be combined flexibly according to the purpose. This ...

Kashifuji Co., Ltd.

500+ people viewing

■Typical workpieces to be processed Spur gears, helical gears, gears with shafts, etc. ■Product features With KGH250, you can easily and inexpensi...

Toyo Advanced Technologies

400+ people viewing

A high-speed honing cell that demonstrates its power in highly efficient, high-precision honing of cylinder blocks. High-speed honing stroke improv...

Toyo Advanced Technologies

450+ people viewing

TVH-05 is a compact honing machine that helps shorten production lines. With a width of 750mm and a depth of 1,540mm, the installation area is redu...

NK Works Co., Ltd.

780+ people viewing

Last viewed: 11 hours ago

■Product overview A honing machine is a bore sizing and finishing system that can finish geometric tolerances and surface roughness of various meta...

NK Works Co., Ltd.

750+ people viewing

■Product overview A honing machine is a bore sizing and finishing system that can finish geometric tolerances and surface roughness of various meta...

NK Works Co., Ltd.

550+ people viewing

Last viewed: 9 hours ago

■Product overview A honing machine is a bore sizing and finishing system that can finish geometric tolerances and surface roughness of various meta...

NK Works Co., Ltd.

430+ people viewing

■Product overview A honing machine is a bore sizing and finishing system that can finish geometric tolerances and surface roughness of various meta...

NK Works Co., Ltd.

440+ people viewing

Last viewed: 1 day ago

■Product overview A honing machine is a bore sizing and finishing system that can finish geometric tolerances and surface roughness of various meta...

NK Works Co., Ltd.

650+ people viewing

■Product overview Horizontal honing machines are designed for speed, precision, and convenience, and are ideal for factories that process a wide va...

NK Works Co., Ltd.

610+ people viewing

■Product overview Horizontal honing machines are designed for speed, precision, and convenience, and are ideal for factories that process a wide va...

NK Works Co., Ltd.

350+ people viewing

Last viewed: 1 day ago

■Product overview Horizontal honing machines are designed for speed, precision, and convenience, and are ideal for factories that process a wide va...

NK Works Co., Ltd.

350+ people viewing

Last viewed: 1 day ago

■Product overview Horizontal honing machines are designed for speed, precision, and convenience, and are ideal for factories that process a wide va...

NK Works Co., Ltd.

370+ people viewing

■Product overview Horizontal honing machines are designed for speed, precision, and convenience, and are ideal for factories that process a wide va...

NK Works Co., Ltd.

550+ people viewing

■Product overview Tube horns perform precise finishing on the inner diameter by rotating a horn head equipped with a grindstone. It is easy to oper...