All Categories

History

This section provides an overview for metal sawing as well as their applications and principles. Also, please take a look at the list of 16 metal sawing manufacturers and their company rankings. Here are the top-ranked metal sawing companies as of February, 2026: 1.B & Z Manufacturing Co. Inc., 2.Sparky, 3.Hasan Mohamed Hasan Almahroos (SPC) L.L.C..

Table of Contents

Categories Related to Metal Sawing

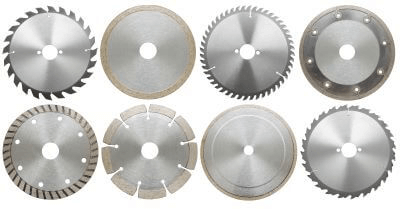

A metal sawing is a doughnut-shaped saw blade attached to a cutting machine and used to cut materials or process grooves.

The material is made of high-speed tool steel (HSS), making it possible to process various materials.

Since it can be reground and used, it can be used as many times as necessary until the circular diameter of the blade becomes smaller than the limit of the cutting machine. Since the rotational speed is slower than that of a high-speed cutting machine using a cutting wheel, it can process while reducing spark dispersion and dust generation.

In addition to cutting round, square, and L-shaped angle materials, metal sawing cut materials vulnerable to frictional heat, such as vinyl chloride pipe and aluminum, are unsuitable for high-speed cutting machines.

However, for materials such as nonferrous metals and PVC pipes, selecting a blade suitable for each material is necessary.

Since they are less likely to generate sparks, they are suitable for use in places where fire must be avoided.

Also, depending on the type, the angle of the vise or clamp that holds the material in place can be freely changed, allowing angled cutting.

Although they are the same cutting machine, their features are significantly different from high-speed cutting machines that use cutting wheels.

First, metal sawing does not rotate as fast as high-speed cutting machines, which reduces dust generation. Still, the blades wear out more quickly than grinding wheels, so they need to be resharpened more often, and if the blade diameter becomes too small after repeated grinding, replacing it is costly and time-consuming.

The grinding wheel has a relatively long life and can continue cutting for a long time. Still, the processing speed is slightly slower than that of a metal sawing, and because the grinding wheel rotates at high speed, sparks and dust are generated in large quantities, so sufficient care must be taken in the work environment before operation.

In addition, metal sawing is less affected by heat, so burrs are less likely to appear on the cross-section after cutting, and the cut surface has the advantage of a clean finish.

In both cases, if the blade is applied too forcefully to the material, it can lead to blade breakage, which is very dangerous, so work with caution.

A hand saw is a so-called "saw," a metal strip with a cutting edge.

While metal sawing is made entirely of hard materials such as HSS, hand saws use HSS only for the cutting edge. The metal band is elastic and becomes flexible when force is applied. The metal is attached to the handle, cutting the object manually.

The cutting edge is the most significant difference between metal and hand sawing. The hand saw has "clippers" on both sides of the blade to improve cutting performance. Metal sawing does not have this "clam."

Cutting conditions for metal sawing vary depending on the type of material to be cut, the fabric of the metal sawing, and the work performed in each process.

Cutting speed is adjusted using the following guidelines.

Cases of Slow Cutting Speed

Cases for Higher Cutting Speeds

The following guidelines are used to adjust the feed rate per blade.

Cases Requiring a Smaller Feed Rate

Case of Increasing The Feed Rate

When metal sawing blades are repeatedly sharpened, they gradually become smaller in diameter. As long as the blade can reach the material to be cut, it can be reground and used repeatedly. However, the metal sawing must be replaced if the blade can no longer reach the material needing cutting.

If regrinding is performed as soon as possible, it will avoid problems such as cracks in the metal sawing. In addition, the maintenance of chips on the cutting machine can extend the life of the metal sawing and reduce running costs.

*Including some distributors, etc.

Sort by Features

Sort by Area

B&Z Manufacturing, started in 1960 and based in San Jose, California, is an ISO 9001-certified manufacturer of ultra-precision components made using multi-axis milling, turning, and ultra-precision machining. Some of its products include instruments for the dental industry, face bows, and articulators used in facial reconstructions, and it works with several materials, including stainless steel, aluminum, and brass. It’s UL-registered, and its other capabilities include vertical milling, precision sawing, and surface grinding. It also provides supplemental CNC machining services such as fixture building, bead blasting, and CAD engineering.

Machine Plus LLC, founded in 2011 with headquarters in the USA, is a custom manufacturer of machined parts. The company provides custom milling, turning, welding, fabrication, and quality control services for the production of custom parts for manufacturers in various industries, including automotive, aerospace, manufacturing, medical, packaging, and many more. The company works with materials including aluminum, stainless steel, hardened steel, plastic, and titanium, among others. It specializes in zero-defect, low-medium-volume manufacturing, and high-tolerance machining.

ACCURATE METAL SAWING SERVICE Co. was founded in 1955 in the USA and is a manufacturer that offers tailored metal cutting services for fabrication and metalworking purposes. The company also provides material sawing and finishing services, as well as a range of products including round, square, and steel pipes. It offers precise material cutting with minimal waste and maintains a production tolerance while accommodating bar materials up to 50 feet in length. It possesses manual, semi-automatic, and fully automatic saws, and boasts extensive experience working with challenging materials such as iron, colored materials, pipes, and plastics.

Behringer Saws, Inc. is a Pennsylvania-based manufacturer of sawing systems and structural fabricating equipment. Founded in 1988 as an independent branch of Behringer GmbH in Germany, the company produces circular saws and bandsaws, as well as profile machining centers for beams, plates and angles. The company serves various industries with demanding sawing and fabricating requirements such as the aerospace, automotive, and construction sectors. Behringer Saws, Inc. also offers training, tech support, and spare parts to their clients, along with custom solutions and service contracts covering maintenance and calibration for their products.

Northern Metal Products, founded in 1959, is a manufacturer of Point Of Purchase(POP) display and Original Equipment Manufacturer (OEM) services for agriculture, medical, plumbing, automotive, and construction industries. The St. Cloud, Minnesota facility offers services such as wire forming and assembly, laser cutting, and wood laminating performed onsite. Additionally, the POP displays are used for brand and product visibility by creating a way to make the products stand out. The company is ISO 9001:2015 certified; thus, its OEM products meet stringent industry standards using diverse technologies.

Metal Sawing Technology, founded in 1988 with headquarters in the USA, is a manufacturer and distributor of bandsaws, blades, and parts. The company's bandsaw blade product line includes bandsaw blades for metal, bandsaw blades for wood, circular saw blades for metal, and circular saw blades for wood. Machines available include heavy-duty miter bandsaws, horizontal utility bandsaws, and heavy-cast vise-base bandsaws. It also offers an extensive range of upgrades that include aftermarket bandsaw parts, bandsaw tires, and cutting fluids.

Baileigh Industrial Holdings LLC., founded in 1999 and now a subsidiary of JPW Industries, Inc., is an American manufacturer and distributor of industrial metalworking and woodworking products, headquartered in Manitowoc, Wisconsin. The company offers metalworking machines, including electric plates and pipe bevellers, hydraulic punches and break presses, multi-process welders, variable speed drill presses, and magnetic boxes and pan brakes. They also provide woodworking machines like benchtop planers, benchtop wood jointers, desktop computer numerical control (CNC) engravers, and drum sanders. With over 500 products, Baileigh Industrial serves various companies, including Advanced Energy Industries, Inc., AMETEK, Inc., BP p.l.c., and 3M.

Sutton Garten Co.’s history dates back to1916 in Indianapolis, Indiana. Sutton Garten is an independent welding distributor, providing products and services. Sutton Garten’s product offerings include welding abrasives, dry ice & blast equipment, electric welding equipment & supplies, filler metals, flux and chemicals, fume extraction equipment, gases, cylinders, dewars, gas equipment for welding, welding hand tools, plasma cutting equipment, metal cutting sawing grinding tools, welding safety equipment, and weld accessories. Sutton Garten’s service offerings include bulk gas installations, carbon dioxide gas fill service, rental welding & cutting equipment as well as repairs.

TCI Precision Metals was founded in 1956 and is headquartered in Gardena, California, United States, as a distributor of precision-cut parts and machine-ready blanks. The company offers diverse products, including aluminum strip blanks, 2-sided precision blanks, precision saw-cut blanks, and round precision blanks, among others. These products are essential for ensuring precise dimensions and quality in manufacturing processes across various sectors, including the creation of intricate shapes and meeting tight tolerances. The company serves various industries, including aerospace, medical, defence, energy, transportation, and food processing.

Metkraft Ltd., a Fisher Barton company established in 1995 and headquartered in Ho Chi Minh City, Vietnam, is a manufacturer of industrial knives and wear components. The company's products include wood chipper blades, shredder knives, and pelletizers. Its wood chipper blades and shredder knives are used for processing wood and tree care, while pelletizers and granulator blades are used in plastic production and recycling. It incorporates CNC machining, milling, and heat-treating processes, including cryogenics, induction, and annealing, in its products. The company knives are used in the construction, corrugation, and forestry industries.

ZPS - FRÉZOVACÍ NÁSTROJE a.s., founded in 1990 in Zlin, Czech Republic, is a manufacturer of machine tools and hardening products. The company specializes in manufacturing a diverse range of cutting tools, including milling cutters, drills, reamers, and threading tools. The products are acclaimed for precision engineering, optimal-performance capabilities, and durability, which are essential for metalworking and machining applications. It serves a wide spectrum of industries, including automotive, aerospace, and general manufacturing, where precision and stability are paramount. With over seven decades of expertise in cutting tool production, it offers advanced cutting tools for various industrial applications.

Sparky, established in 1994 in Sofia, Bulgaria, is a manufacturer of concrete, metal cutting, woodworking, and special power tools and accessories. The company makes power tools such as large angle grinders, circular and miter saws, cord drill sets, drywall screwdrivers, and rotary hammers, which it ships to Russia, Bulgaria, Poland, Ukraine, and the United Kingdom. It also provides the following accessories: drill bits for concrete, diamond sanding discs, jig saw blades, sanding and finishing discs, and safety guards.

TSUNE SEIKI CO., LTD., founded in Toyama, Japan, in 1917 is a manufacturer of sawing machines and inspection machines & tools. The company's product portfolio includes circular, band, hack sawing machines, tube cutting machines, saw blade grinding machines, chamfering machines and saw blades. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. They also offer custom packaging, warehousing, and distribution services.

Tokyo Seimitsu Co. Ltd., established in 1949 and headquartered in Tokyo, Japan, is a manufacturer of semiconductor production equipment and precision measuring instruments. Its product portfolio includes optical measuring instruments, probing machines, polish grinders, X-ray CT systems, and coordinate measuring machines. In 1952, the company developed Japan’s first high-pressure flow-type air micrometer, and in 1958, it created the world’s first germanium pellet automatic thickness sorting machine. It also developed Japan’s first coordinate measuring machine in 1969, followed by Japan’s first wafer-dicing machine in 1970. The company is the industry’s only semiconductor equipment manufacturer with measurement technology.

Maxmen Metal Sawing Co., founded in 1960 with headquarters in India, is a manufacturer, wholesaler, and supplier of bandsaw cutting machines. The company's product line includes pivot-type and double-column-type bandsaw cutting machines available with three modes of operation: manual, semi-automatic, and fully automatic, giving clients six combinations and 20 different models to choose from. These products are used for cutting both wood and metal stock and can also be used for cutting meat and bones.

M. H. Al Mahroos, founded in 1930 with headquarters in Bahrain, the UAE, and Saudi Arabia, is a distributor and supplier of construction and building equipment. The company's product portfolio comprises five main categories: construction equipment, compaction machinery, concrete technology, earth-moving machines, and industrial tools and equipment. The company serves numerous commercial, retail, and industrial market segments, and has been commissioned to provide equipment for several projects, including Canal View, Bahrain's LNG Import Terminal, and the Gulf Hotel Bahrain. It also provides a range of after-sales services, including installation, tailored training programs, preventative maintenance, and equipment and machine renovations.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | B & Z Manufacturing Co. Inc. |

14.5%

|

| 2 | Sparky |

8.1%

|

| 3 | Hasan Mohamed Hasan Almahroos (SPC) L.L.C. |

8.1%

|

| 4 | Metal Sawing Technology |

8.1%

|

| 5 | TCI Precision |

8.1%

|

| 6 | Machine Plus LLC |

6.5%

|

| 7 | ACCURATE METAL SAWING SERVICE CO. |

6.5%

|

| 8 | Baileigh Industrial Holdings LLC. |

6.5%

|

| 9 | METKRAFT LTD. |

4.8%

|

| 10 | ZPS - FRÉZOVACÍ NÁSTROJE a.s. |

4.8%

|

Derivation Method

The ranking is calculated based on the click share within the metal sawing page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

9 | 56.3% |

Japan

Japan

|

2 | 12.5% |

Vietnam

Vietnam

|

1 | 6.3% |

Czech Republic

Czech Republic

|

1 | 6.3% |

Bulgaria

Bulgaria

|

1 | 6.3% |

India

India

|

1 | 6.3% |

| Bahrain | 1 | 6.3% |

268 products found

268 products

Sanko Hamono Seisakusho Co., Ltd.

510+ people viewing

Last viewed: 22 hours ago

Chip saws and metal saws are mainly used for grooving and cutting workpieces. We process workpieces (processed materials) such as wood, resin, and ...

Kouken Nippon Co., Ltd.

510+ people viewing

Last viewed: 22 hours ago

■Features - Laser welding for all sizes. ・Bond mixing and molding are manufactured on a fully automatic line. ・There is little variation and the ...

Hamakita Seiki Co., Ltd.

440+ people viewing

Last viewed: 22 hours ago

■Features ・A product that pursues cost performance ・Lightweight type, light burden ・Excellent durability due to thicker chip width and diagonal ...

MATO Tool Co., Ltd.

270+ people viewing

Last viewed: 22 hours ago

Carbide solid metal saw [Sharp Saw-S] is designed exclusively to specifications such as blade shapes according to the processing conditions of the ...

5 models listed

Revau Labor Japan Co., Ltd.

480+ people viewing

Last viewed: 16 hours ago

■ Speedy and consistently consistent top quality We respond to customer needs with a basic product lineup, including "HSS Special," which has been ...

Kouken Nippon Co., Ltd.

490+ people viewing

Last viewed: 22 hours ago

■Features - Laser welding for all sizes. ・Bond mixing and molding are manufactured on a fully automatic line. ・There is little variation and the ...

Kato Saw Co., Ltd.

420+ people viewing

Last viewed: 22 hours ago

Suitable for pitches of 5 mm or more and thick workpieces of 15 mm or more. ■Details ・Chidori blade ・BG blade ・Three-stage blade ・Uneven pitch...

Hamakita Seiki Co., Ltd.

470+ people viewing

Last viewed: 22 hours ago

■Features ・Tipped saw for general wood and laminated wood ・Uses a highly durable chip that lasts a long time ・Excellent sharpness due to unique ...

Revau Labor Japan Co., Ltd.

480+ people viewing

Last viewed: 22 hours ago

■ Speedy and consistently consistent top quality We respond to customer needs with a basic product lineup, including "HSS Special," which has been ...

Kouken Nippon Co., Ltd.

530+ people viewing

Last viewed: 14 hours ago

■Features - Laser welding for all sizes. ・Bond mixing and molding are manufactured on a fully automatic line. ・There is little variation and the ...

Hamakita Seiki Co., Ltd.

440+ people viewing

Last viewed: 16 hours ago

■Features ・Tipped saw for general wood and laminated wood ・Ideal for tabletop and slide use ・Uses a highly durable chip that lasts a long time ...

MATO Tool Co., Ltd.

810+ people viewing

Last viewed: 22 hours ago

Special tools for aluminum groove processing and precision cutting processing appear. Have you ever experienced burrs or rough processing, even tho...

Revau Labor Japan Co., Ltd.

330+ people viewing

Last viewed: 22 hours ago

As for other metal saw products, we carry the following high-quality products that will surely satisfy you with the true value of German-made high ...

Kouken Nippon Co., Ltd.

480+ people viewing

Last viewed: 22 hours ago

■Features - Laser welding for all sizes. ・Bond mixing and molding are manufactured on a fully automatic line. ・There is little variation and the ...

Hamakita Seiki Co., Ltd.

340+ people viewing

Last viewed: 14 hours ago

■Features ・Tipped saw for general wood and laminated wood ・Ideal for cutting plywood ・Uses a highly durable chip that lasts a long time ・Excell...

MATO Tool Co., Ltd.

710+ people viewing

Last viewed: 22 hours ago

Difficult shaving materials such as stainless steel alloys and titanium alloys are cut quickly. In the groove processing of SUS304, it can be proce...

Revau Labor Japan Co., Ltd.

400+ people viewing

Last viewed: 14 hours ago

We keep a variety of sizes in stock that are compatible with the chip saw manual cutting machines that are popular in the domestic market, and we w...

Revau Labor Japan Co., Ltd.

390+ people viewing

Last viewed: 16 hours ago

We keep a variety of sizes in stock that are compatible with the chip saw manual cutting machines that are popular in the domestic market, and we w...

Kouken Nippon Co., Ltd.

480+ people viewing

Last viewed: 22 hours ago

■Features - Laser welding for all sizes. ・Bond mixing and molding are manufactured on a fully automatic line. ・There is little variation and the ...

Hamakita Seiki Co., Ltd.

380+ people viewing

Last viewed: 14 hours ago

■Features ・Tipped saw for general wood and laminated wood ・Ideal for vertical pulling ・Uses a highly durable chip that lasts a long time ・Excel...

MATO Tool Co., Ltd.

250+ people viewing

Last viewed: 17 hours ago

Carbide solid metal saw is easier to use and high performance with a machineing machine. [SHARP SAW FZ] was developed with the concept. Until now,...

3 models listed

Revau Labor Japan Co., Ltd.

380+ people viewing

Last viewed: 16 hours ago

We keep a variety of sizes in stock that are compatible with the chip saw manual cutting machines that are popular in the domestic market, and we w...

Kouken Nippon Co., Ltd.

480+ people viewing

Last viewed: 22 hours ago

■Features - Laser welding for all sizes. ・Bond mixing and molding are manufactured on a fully automatic line. ・There is little variation and the ...

Hamakita Seiki Co., Ltd.

430+ people viewing

Last viewed: 14 hours ago

■Features ・Ideal for cutting aluminum ・Excellent sharpness due to unique polishing angle ・Uses a highly durable chip that lasts a long time

YSK Industry Co., Ltd.

270+ people viewing

Last viewed: 22 hours ago

■ Characteristics ・ Less resistance due to ultra -thin blade with a blade thickness of 1.6 mm. ・ Because it is laser slit, low noise and low vibr...

10 models listed

Kouken Nippon Co., Ltd.

430+ people viewing

Last viewed: 22 hours ago

■Features - Laser welding for all sizes. ・Bond mixing and molding are manufactured on a fully automatic line. ・There is little variation and the ...

Hamakita Seiki Co., Ltd.

410+ people viewing

Last viewed: 22 hours ago

■Features ・For both iron and stainless steel ・Long life due to the use of highly wear-resistant tips ・Excellent sharpness due to unique polishin...

Revau Labor Japan Co., Ltd.

370+ people viewing

Last viewed: 16 hours ago

This is a high-quality chip saw that minimizes body vibration and pursues cutting accuracy. We offer optimal products from a variety of sizes and m...

Daido Kogyo Co., Ltd.

280+ people viewing

Last viewed: 1 hour ago

The low-friction PVD coating provides a clean cut surface, less vibration and burr, and reduces the risk of pipe deformation at the end of the cut....

Daido Kogyo Co., Ltd.

280+ people viewing

Last viewed: 1 hour ago

The low-friction PVD coating provides a clean cut surface, less vibration and burr, and reduces the risk of pipe deformation at the end of the cut....