All Categories

History

This section provides an overview for ball end mills as well as their applications and principles. Also, please take a look at the list of 22 ball end mill manufacturers and their company rankings. Here are the top-ranked ball end mill companies as of February, 2026: 1.NACHI-FUJIKOSHI CORP., 2.HG TECHNOLOGY CO., LTD., 3.CERATIZIT Sacramento LP.

Table of Contents

Categories Related to Ball End Mills

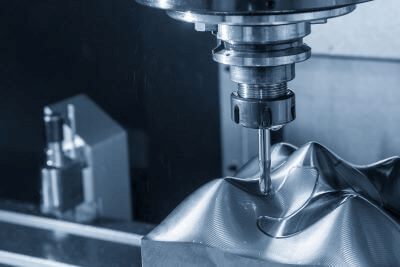

A Ball Nose Mill is a cutting tool used in machine tools that has a spherical tip.

A Ball Nose Mill is a cutting tool used in machine tools that has a spherical tip.

The cross-sectional shape of the cutting surface of an ordinary nose mill is right-angled because of its flat shape, whereas the cross-sectional shape of a ball nose mill can be curved when cutting with a ball nose mill.

By using a ball nose mill, a curved surface can be freely formed as long as the radius of curvature is equal to or greater than the ball radius of the ball nose mill, without using a 5-axis machining center with a mechanism to tilt the cutting tool.

Since Ball Nose Mills are suitable for cutting to form curved surfaces, they are used to cut fillet sections to prevent parts and debris from accumulating in the corners of the bottom surface.

In addition, by cutting with numerical control using NC milling machines, etc. based on the shape designed with CAD software, smooth curved surfaces that are difficult to form with ordinary square nose mills can be formed if the radius of curvature is greater than the ball radius of the ball nose mill.

Ball Nose Mills can be used in conjunction with NC machine tools to easily cut curved surface shapes. However, there are several disadvantages compared to square nose mills.

Ball Nose Mills have a small cross-sectional area of the cutting edge, which makes them less rigid and more prone to spills.

The cross-section of a ball nose mill's blade is curved, and the tool diameter varies greatly depending on the position of contact with the material to be cut.

Even when the feed rate and rotation speed are set at a constant level, excessive load applied to the tip of the nosemill due to the levelness or surface roughness of the workpiece surface can result in edge spills.

Other disadvantages include the inability to machine right-angled corners on the bottom surface and poor cutting swarf discharge, making the square nose mill superior as a general-purpose nose mill.

The quality of the machined surface varies greatly depending on the position of contact with the material to be machined, so the use of machining equipment with high-precision positioning accuracy and surface treatment after machining are necessary if smooth curved surfaces are to be formed.

Since the cutting edge is shaped like a round ball, ball nose mills are used to cut not only flat surfaces and sides, but also spherical surfaces and any other shapes, as well as for corner radiusing using the radius of the nose mill. Due to the spherical shape, the tool diameter gradually increases from the tip of the blade to the outside, and the rotational speed also changes.

Since the tool diameter at the tip is zero, the rotation speed remains zero no matter how fast the tool is rotated. Therefore, machining only at the tip where the rotation is zero will not produce good results for either the cutter or the workpiece, such as a dirty surface or spilled edges.

To achieve good machining results with a ball nose mill, it is important to use as much of the outside of the cutting surface as possible and to contact the workpiece at a high rotational speed.

With a 5-axis machine that can freely change the angle of the table and spindle, the nose mill or table can be tilted to any angle to cut to obtain good accuracy.

It is not impossible to machine a flat surface with a ball nose mill. Although it takes more time than with a milling cutter, it is possible to machine a flat surface by shifting the ball diameter by half (10 mm for 20 mm) and machining it as if it were filled with a flat surface.

In this case, the surface will be noticeably uneven and not clean. Although it is limited to roughing applications only, a single ball nose mill can be used universally for machining complex surface shapes to flat surfaces and side machining.

For large-diameter ball nose mills with a diameter larger than 20 mm, in addition to the solid type, there are other types of mills with two removable inserts. The replaceable inserts cannot be reground and used again, as is the case with solid mills.

However, it is easy and time-saving to change blades, as they can simply be replaced when the sharpness deteriorates. There are two types of tips, one for roughing and the other for finishing.

For roughing, one tip is symmetrical at the top and bottom. In many cases, one tip can be used for two machining operations if the tip is turned over and mounted after use. Balls for finishing are one-piece inserts shaped like a half-moon and cannot be re-machined by rearranging the cutting edges as in the case of roughing.

The main types of machines used in conjunction with ball nose mills are 3-axis CNC routers, 4-axis CNC routers, and 5-axis CNC routers. Each CNC router reads 3D data created by CAD/CAM software and performs machining using ball nose mills.

Machining accuracy can be adjusted by the radius of the ball nose mill's cutting edge, the number of revolutions, and the speed of progression. Recently, machines equipped with high-speed cutting functions have also been introduced specifically for high-speed machining.

3-Axis CNC Router

The 3-axis CNC router is controlled by the X, Y, and Z axes and is suitable for flat surface machining and shallow grooving.

4-Axis CNC Router

The 4-axis CNC router has a rotary axis in addition to the X, Y, and Z axes, and can process while rotating, making it suitable for three-dimensional machining and engraving.

5-Axis CNC Router

The 5-axis CNC router has an inclined axis in addition to the 4-axis CNC router and can process more complex shapes.

*Including some distributors, etc.

Sort by Features

Sort by Area

Melin Tool Company, a company founded in 1940, based in Cleveland, Ohio, is a manufacturer and supplier of quality end mills and cutting tools. The company offers a range of products such as carbide drills, thread mills, countersinks, and custom tools. These products are designed for high performance applications in aerospace, medical, and mold and die fields. It also provides after-sales service and warranty for its products and it is ISO 9001-2008 certified and has a strong status in the US market.

Dapra Corporation, founded in 1955, and headquartered in Bloomfield, Connecticut, USA, is a supplier and a manufacturer of manufacturing tools and equipment. The company offers a broad range of products, including indexable milling tools, workholding vises, pneumatic power tools, dot peen, and lasers. The company also offers DataMatrix reading and verification solutions, as well as high-feed square shoulder button, face ball nose, and back draft tools. These products are widely used across various manufacturing sectors, including aerospace, automotive, mold and die, and firearms. It offers USA certified service in-house for all warranty repairs.

Interstate Abrasives is based in Chicago, Illinois. Interstate abrasives is a distributor for manufacturing including grinding and machining applications. Interstate Abrasives operates in 4 product categories, abrasives, coolants, diamonds/CBN, and general industrial supplies. Interstate abrasives works with grain types such as aluminum oxide, silicon carbide, ceramic, zirconia, glass, slurries, and finishing compounds. Bond types include vitrified, resinoid, rubber, plastic, epoxy, and shellac bonds. Cutting and carbide tools include saw blades, diamond and dressing tools, honing sticks and stones, steel and nylon brushes, and filter systems. Metal working fluids include coolants, cleaners, lubricants, and rust preventatives.

ARCH Cutting Tools, a producer firm based in America, was created in 1983 and is headquartered in Warren, Michigan, and centers on creating and engineering efficient instruments to assist its clientele in meeting their specific requirements. The company specializes in producing spherical metal tools that can be indexed for easy removal. The company produces various items, such as indexable drillers, millers, spotting drills, center drills, titanium nitride, countersinks, center bores, and other related products. The company prioritizes the demands of its customers by ensuring timely delivery of manufactured products following provided estimates.

UNION Tool Co., established in 1955 is a manufacturer and retailer of cutting tools, linear motion products, sensor products, and measuring instruments based in Tokyo, Japan. The company offers tungsten carbide-made cutting tools such as MDP drill pointer, OPTECH-M non-contact drill diameter, and ring setting machines. The company also has a rolling dies/ forging tools/ coating rods product segment which includes various products including screw manufacturing dies, rack dies, rolled products, and roll dies & incremental dies. Their products are used in PCB drill development, and machine tools & semiconductor manufacturing applications.

NACHI-FUJIKOSHI CORP. is a Japanese manufacturer of industrial machinery and tools, such as bearings, hydraulic equipment, robots, and cutting tools. They also provide services such as machine maintenance and repair. The company's products are used in automotive, aerospace, construction, and electronics. One of NACHI-FUJIKOSHI's renowned products is their robotic arm, the "MZR series," which is designed for precision assembly and inspection tasks in industries. They received several awards for their technological advancements and contributions to the industry, including the 2021 Japan Society of Mechanical Engineers Medal for new hydraulic equipment technology and the 2020 Nikkan Kogyo Shimbun Grand Technology Award.

OSG Corporation., founded in 1938 and headquartered in Toyokawa, Japan, is a manufacturer of various cutting tools, including end mills, drills, taps, rolling dies, and gauges. The cutting tools are engineered for an array of industries, including energy, automotive, aerospace, die/mold, and heavy. The company also has an academy that it uses as an innovation hub for researching, designing, and developing new products. It established its first overseas subsidiary in the U.S. in 1968, and since then, it has continued to build a network of manufacturing, sales, and technical support locations spanning 33 countries.

Shivam Tools & Steels, established in 1988 and located in Maharashtra, India, is an ISO 9001:2008 certified manufacturer and supplier of various CNC tools and milling accessories. The company’s product line includes various CNC tools, CNC milling accessories, carbide inserts, dies and mold accessories, and industrial cutting tools. Others include VMC toolings, HSS cutting tools, and measuring instruments. Industries served include automotive, aerospace, health care, and consumer products, to name but a few.

MOLDINO Tool Engineering, Ltd, established in 1928, is a manufacturer and retailer of tips and cutting tools made of steels, and carbide alloys. The product line is divided into end mills, indexable tools, and drilling, threading, & chamfering tools. The end mills and indexable tools are offered in various forms, including square, replaceable head, odd-shaped, and radius, whereas the drilling, threading, and chamfering tools include stepped borers, counterbores, non-step borers, and hard drills. Theproducts are used for die-sinking, slotting, helical cutting, taper cutting, side cutting, and many others. The company in Sumida-ku, Tokyo operates as a subsidiary of Mitsubishi Materials Corporation.

Wey Juan Technology Co. Ltd, founded in 2000 in Taichung City, Taiwan is a manufacturer of carbide cutting tools, including square end mills, corner radius end mills, miniature end mills, roughing end mills, and related accessories for metalworking, aerospace, automotive, and industrial supply purposes. The company’s products are made from carbide ross sourced from Japan Sumi Tool and Germany KFC, and made through CNC machining. The company serves both local and international clients for high precision and machining processes.

Towa Corporation, established in 1979 in Kyoto, Japan, is a manufacturer of semiconductor molding equipment and precision molds. The company manufactures various semiconductor precision molds, equipment, and fine plastic molded parts. Products include molding equipment, singulation equipment, ultra-precision molds, end mills, and drill series for use in mainly industrial applications. They make fingerprint sensors, floating image technology, and head-up displays as well. These are used for multiple packaging purposes, including leadframe ICs, transistors, and diodes. Their proprietary transfer folding method and resin molding technique ensure the semiconductor molds are temperature- and chemical-resistant, offering immense performance with leakproof and resilient properties.

Tissenbach Precision Tools, established in 2014 and located in Istanbul, Turkey, is a manufacturer and supplier of precision tools, such as tungsten carbide end mills, reamers, drills, saw blades, and other special cutting tools. The company’s products are made from various materials, including cast iron, stainless steel, hardened steel, heat-resistant alloys/titanium, and non-ferrous materials. These products benefit industries, such as aerospace, power generation, marine, electronics, and precision engineering, among others.

HG TECHNOLOGY CO. LTD, established in 2002 and based in Changhua County, Taiwan, is a manufacturer of solid carbide tools including end mills, drills, and reamers. Solid carbide tools can be used to work on a wide range of materials such as stainless steel, aluminum, titanium, graphite, alloy steel, and more. The company’s product portfolio includes various types of carbide end mills such as square, corner radius, and ball nose. These products are commonly used for machining in diverse industries, including electrical, electronics, dental and healthcare equipment, aerospace, and precision molding.

DIC TOOLS, established in Patiala, Punjab in 2012 is a manufacturer of cutting tools which include HSS Cutting Tools and Gear Cutting Tools. Their product portfolio includes solid carbide end mills used for precise milling, high-speed steel (HSS) and HSS-Co drills, high-speed steel (HSS) and HSS-Co drills used in turning and milling operations, and boring bars and tool holders for hole machining. The company serves industries such as Electronics and Semiconductors, Metalworking and Fabrication and Precision Engineering.

NS Tool Co., Ltd., founded in 1954 with headquarters in Tokyo City, Japan, is a manufacturer of original coatings and CNC machining tooling under the NS Tool brand. The company's product line includes end mills, original coated toolings, ultra micro end mills, and 2-flute long neck ball end mills for hardened steel. These products are used for precision machining of alloys, hardened steel, and other materials to create components and parts. The company serves markets that include electronics product manufacturing, aerospace, appliance manufacturing, and industrial parts manufacturing.

Universal Cutting Tools, Inc, an American company founded in 1971 and based in Warren, Michigan, is a manufacturer and supplier specializing in cutting tools. The company's product portfolio includes stub screw machine drills, straight pipe taps, and Silver and Deming drill sets. These products find applications in various industries, including electronics manufacturing, metalworking, and the oil and gas industry. The company provides services, including detailed product catalogs and shipping of its tools to clients in various countries, including Australia, China, and Canada.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | NACHI-FUJIKOSHI CORP. |

23.8%

|

| 2 | HG TECHNOLOGY CO., LTD. |

19.0%

|

| 3 | CERATIZIT Sacramento LP |

9.5%

|

| 4 | TOWA Corporation |

9.5%

|

| 5 | MOLDINO Tool Engineering, Ltd. |

9.5%

|

| 6 | UNION TOOL CO. |

9.5%

|

| 7 | Greenleaf Corporation |

4.8%

|

| 8 | Tissenbach Precision Tools |

4.8%

|

| 9 | DIC TOOLS |

4.8%

|

| 10 | OSG Corporation |

4.8%

|

Derivation Method

The ranking is calculated based on the click share within the ball end mill page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

7 | 41.2% |

United States of America

United States of America

|

5 | 29.4% |

India

India

|

2 | 11.8% |

Taiwan

Taiwan

|

2 | 11.8% |

Turkey

Turkey

|

1 | 5.9% |

295 products found

295 products

Rinos Co., Ltd.

290+ people viewing

Last viewed: 3 hours ago

It is a long type of No.67.

3 models listed

Banishing Tool Co., Ltd.

330+ people viewing

Last viewed: 3 hours ago

■ Specialist for improving productivity ・ The latest blade type is both high -speed sending and good finish. ・ Heat and wear resistance is greatl...

8 models listed

Fujiki Corporation Co., Ltd.

430+ people viewing

Last viewed: 4 hours ago

■Features ・Stable cutting due to strong negative shape ・High ball R accuracy ±0.01 ・Supports a wide range of processing methods with 2 types ・A...

Green Tool Co., Ltd.

440+ people viewing

Last viewed: 3 hours ago

We offer a 3D type ball end mill. GT ball end mill based on proven technology. The blade shape has been set to be optimal for high-hardness steel,...

Daijet Industries Co., Ltd.

200+ people viewing

Last viewed: 3 hours ago

Indexable ball end mill With a main body key, this tool can be used for everything from rough machining, such as overlaying mold materials, to sem...

2 models listed

Rinos Co., Ltd.

310+ people viewing

Last viewed: 3 hours ago

It is a long type of No.T67.

3 models listed

Asahi Tool Manufacturing Co., Ltd.

340+ people viewing

Last viewed: 1 day ago

■ Features ・ Twin head tip * Realizes cost per corner with small chip material ・ Long life and high precision processing can be made by the super...

10 models listed

Kyowa Seiko Co., Ltd.

260+ people viewing

Last viewed: 1 day ago

Cubic boron nitride is a diamond crystal structure material composed of boron and nitrogen. It is used for machining ferrous metals and specializes...

Banishing Tool Co., Ltd.

410+ people viewing

Last viewed: 3 hours ago

■ Specialist for improving productivity ・ The latest blade type is both high -speed sending and good finish. ・ Heat and wear resistance is greatl...

9 models listed

NS TOOL Co., Ltd.

390+ people viewing

Last viewed: 3 hours ago

X-coated 2-flute ball end mill with ball radius less than R1. A versatile type that can process a wide range of work materials from roughing to fin...

Saito Manufacturing Co., Ltd.

120+ people viewing

Small diameter taper ball end mill with standardized maximum taper angle of 15°. *Other product numbers are available.

10 models listed

EISEN Co.Ltd.

320+ people viewing

Last viewed: 2 minutes ago

■Special tools for machining cemented carbide and die steel (die sack mill) Die Sac Mill is Eisen's original diamond/CBN electroplated tool that ca...

Rinos Co., Ltd.

450+ people viewing

Last viewed: 3 hours ago

It is a long type of No.67. * There are other part numbers.

10 models listed

Asahi Tool Manufacturing Co., Ltd.

350+ people viewing

Last viewed: 1 day ago

■ Features ・ 2 -blade ball end mill long shank type ・ Ideal for R processing of the corner ■ Selected table by coating material ・ Carbon steel ...

10 models listed

Fujiki Corporation Co., Ltd.

370+ people viewing

Last viewed: 4 hours ago

■Features ・Achieves outstanding machinability and durability by using a base material that can withstand ultra-positive shapes. ・High ball R accu...

Fukuda Seiko Co., Ltd.

1570+ people viewing

Last viewed: 3 hours ago

A long shank type ball end mill that can handle a wide range of mold machining.

3 models listed

Rinos Co., Ltd.

600+ people viewing

Last viewed: 3 hours ago

■ Characteristics ・ It is a long type of No.T67. ・ Used for rough shaving such as molds.

10 models listed

Asahi Tool Manufacturing Co., Ltd.

240+ people viewing

Last viewed: 21 hours ago

■ Features ・ 2 -blade ball end mill long shank type ・ Ideal for R processing of the corner ■ Selected table by coaching material G2 ・ Carbon st...

10 models listed

Kyowa Seiko Co., Ltd.

290+ people viewing

Cubic boron nitride is a diamond crystal structure material composed of boron and nitrogen. It is used for machining ferrous metals and specializes...

NS TOOL Co., Ltd.

370+ people viewing

Last viewed: 8 hours ago

・2-flute long neck ball end mill for non-ferrous metals ・Flute shape with high cutting performance improves machined surface quality even with de...

Saito Manufacturing Co., Ltd.

190+ people viewing

Last viewed: 3 hours ago

A wide range of applications are possible, from general steel to non-ferrous materials and resins. The sharp, uncoated cutting edge provides high p...

10 models listed

Rinos Co., Ltd.

390+ people viewing

Last viewed: 3 hours ago

Used for rough shaving such as molds. * There are other part numbers.

10 models listed

Asahi Tool Manufacturing Co., Ltd.

350+ people viewing

■ Features ・ 2 -blade ball end mill long shank type ・ Ideal for R processing of the corner ■ Selected table by coaching material G2 ・ Carbon st...

10 models listed

Fukuda Seiko Co., Ltd.

1300+ people viewing

Last viewed: 3 hours ago

Most widely used for general profiling and corner radius finishing. A general-purpose ball end mill.

4 models listed

NS TOOL Co., Ltd.

290+ people viewing

Last viewed: 8 hours ago

・2-flute ball end mill for non-ferrous metals ・High cutting performance blade shape improves machined surface quality

Saito Manufacturing Co., Ltd.

240+ people viewing

Last viewed: 3 hours ago

The good surface roughness of the cutting edge provides a high-quality finished surface. *Other product numbers are available.

10 models listed

Rinos Co., Ltd.

410+ people viewing

Last viewed: 3 hours ago

■ Characteristics ・ Make Stag has a long life because a TIN coat is applied to the unique rafing ball blade. ・ Used for rough shaving such as mol...

10 models listed

Kyowa Seiko Co., Ltd.

250+ people viewing

Cubic boron nitride is a diamond crystal structure material composed of boron and nitrogen. It is used for machining ferrous metals and specializes...

Asahi Tool Manufacturing Co., Ltd.

320+ people viewing

Last viewed: 1 day ago

■ Features ・ ~ R4.5 (Muku) specifications, the R part can improve the efficiency of imitating processing by the screw shape. ・ Ideal for R proces...

10 models listed

EISEN Co.Ltd.

370+ people viewing

Last viewed: 2 hours ago

■Special tools for machining cemented carbide and die steel (die sack mill) Die Sac Mill is Eisen's original diamond/CBN electroplated tool that ca...