All Categories

History

This section provides an overview for blasting equipment as well as their applications and principles. Also, please take a look at the list of 54 blasting equipment manufacturers and their company rankings. Here are the top-ranked blasting equipment companies as of February, 2026: 1.Gibson Abrasive Equipment Co., 2.Clemco Industries Corporation, 3.Airblast.

Table of Contents

Categories Related to Blasting Equipment

Blasting Equipment is a general term for devices that perform a surface treatment called blasting on a product or material.

Blasting refers to the process of shaving or creating fine irregularities on a product or material, such as metal, by projecting hard, fine abrasive particles of iron or sand at high speed and beating them against the surface of the workpiece.

There are several different types of blasting processes, and accordingly, several types of blasting equipment exists. Typical blast processes include sand blasting, shot blasting, and grit blasting.

Blasting Equipment is used for surface finishing.

Specific applications include the following:

Grinding the workpiece for surface finishing and deburring. By changing the abrasive projected onto the workpiece, it is possible to achieve a mirror finish or a pear-like finish.

Rust on metal surfaces can be removed instantly. Since blasting is a physical process, it can remove rust not only from steel, but also from aluminum and copper.

By impacting abrasive material onto the surface of the metal to be processed, compressive residual stresses act to harden the surface of the metal more. This leads to improved wear resistance and fatigue strength.

Paint can be stripped off by projecting abrasive material and grinding the surface of the workpiece. Blasting can be done by hand, but if the workpiece is large or bulky, it is generally blasted by blasting equipment.

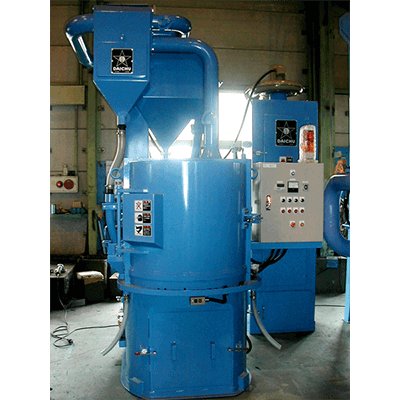

In addition to the blasting method, there are many types of blasting equipment, such as table, hanger, drum, and rail types, depending on the object to be blasted and the number of pieces to be blasted. Therefore, it is important to select the most suitable blasting equipment according to the object to be blasted.

Sandblasting equipment uses high-pressure compressed air to inject abrasive (silica sand, glass grains, etc.) for sandblasting. After impacting the object to be blasted, the abrasive is usually collected by a dust collector and used again as abrasive.

During the recovery process, the abrasive is generally separated from the dust and other powders that have been removed from the object to be blasted.

Shot blast equipment projects abrasive by centrifugal force generated by a projector with an impeller rotating at high speed. The abrasive used in shot blasting equipment must be hard and of high specific gravity, such as iron, stainless steel, or zinc, and must be projected at high speed.

Therefore, shot blasting equipment must have such a mechanism. Also, since the abrasive being projected is hard and heavy, many of the objects to be treated are metals such as iron.

Blasting treatment, in which abrasive particles are projected directly onto the surface of the workpiece, has the following features:

All blast processing methods do not use chemicals because the abrasive is projected onto the surface of the workpiece and physically polishes it.

In the blast process, no other external forces are applied once the abrasive is injected. Therefore, by adjusting the mass, shape, and speed of the abrasive at the time of projection, the surface finish of the workpiece will be uniform.

Also, since a large amount of abrasive is used to polish the entire surface of the workpiece, it is possible to achieve a surface finish with no directionality compared to other types of polishing.

All methods of blasting are physical processes, so they can be applied to any material. It is possible to process a wide variety of materials, including metal, glass, stone, plastic, and wood.

*Including some distributors, etc.

Sort by Features

Sort by Area

Little Swede Industries established in 1977 serves as a manufacturer of custom surface treatment machinery and metal finishing/cleaning products and its manufacturing facility is based in Wichita, Kansas. The company's product line includes Washers, Shakers, and Blasters used in the aerospace, metal fabrication, and oil and gas industries and it offers a 12-month warranty for its products. It provides support from the product selection stage through the life-cycle of the machines and manufactures automated cleaning systems.

Viking Corporation, founded in the year based in Kansas, United States, is a manufacturer and supplier of industrial cleaning equipment. The product portfolio includes short blast machines, industrial washers, vibrating equipment, industrial dust-collecting equipment, stock machines, and other cleaning solutions. The products are used in foundry, forge, structural and plate, propane, and welding industries. The company also offers repair and rebuild services with tailor-fit customized solutions under the guidance of professional engineers.

Halo Metal Prep, Inc., founded in 2015, is a supplier and a source for premium quality Cleveland metal finishing, based in the United States. The company's core services include metal finishing, shot peening, sandblasting, deburring , glass beading, ceramic peening, aluminum oxide blasting, and shot blasting. It offers unparalleled expertise in metal finishing and its highly skilled staff ensures to solve customers' most challenging metal improvement issues. Its ISO-compliant system assures products with zero defects, fast turnaround, competitive pricing, and superior metal finishing of components.

SAFE Systems, Inc., founded in 1993, is a designer and manufacturer of surface preparation products and accessories in Street NE, Auburn, Washington, USA. The company’s products include blast vessels, dust collectors, blast lights, deadman switches, and enduro guard cables used in government agencies, transportation, utilities, manufacturers, and painting contractors. It also produces portable vacuums and spare parts such as pinch valves, halogen bulbs, charge valves, blast light LEDs, and metering valves.

ACE Sandblasting, since 1976, has been a manufacturer of sandblasting and soda blasting equipment in North Griffin Street, Grand Haven, MI. The company's product line includes dust collector systems, turntables, tumble baskets, abrasive blast media, and tumble baskets. It also manufactures siphon and direct pressure sandblast cabinets, portable units, and portable and cabinet soda blasters used in offices, residential, industrial and automotive industries. The company produces replacement parts and accessories such as blast guns, air-line filters, parts trays, glove clamps, and work surfaces.

Hydro Engineering, Inc., founded in 1980, is a manufacturer of Hydroblaster, Hydrokleen, and Hydropad products for washing, collecting, and recycling wash water. The products are used in recycling and filtration equipment, pressure washers, and above-ground steel portable/permanent wash racks. Based in Salt Lake City, UT, the company serves car washes, construction, military, and manufacturing industries. The CE, UL, and CSA standards are applied to the products produced as the company is ISO 9001:2015 Certified. The company offers diagnostics, safety system testing, pump rebuilding, and heating system repair services for pressure washers.

Gibson Abrasive Equipment, founded in 1998 and headquartered in Indianapolis, Indiana, USA, is a manufacturer, distributor, supplier of wheel blast and shot blasting equipment. Their product range includes wheel blast equipment, shot blasting equipment, replacement parts which caters to industries such as manufacturing, aerospace, automotive, and construction. Their equipments are used for surface preparation, cleaning, and finishing applications. Gibson's adherence to customer satisfaction has earned them a reputable position in the market for their efficient solutions.

Pioneer Metal Finishing, founded in 1945, is a US-based supplier headquartered in Green Bay, Wisconsin specializing in metal finishing services. The company offers various metal finishing solutions including adhesives, coatings, plating, anodizing and proprietary finishing services such as ARP Acid Etch, ChroLube and NorKote.The company’s solutions cater to diverse industries, including aerospace, automotive, medical, military, and more. The company holds ISO 9001:2015 and Nadcap accreditation and complies with RoHS requirements. With 11 facilities across the United States and Mexico. Pioneer serves customers across the country and worldwide.

Finishing Systems, incorporated in 1972, is a manufacturer of metal finishing equipment, services, parts, and abrasives in Circle York, PA. The company’s products include abrasive blasting equipment, wet painting booths, and powder coating equipment for curing, drying, and baking applications. Its services include wheel blast deburring, vibratory polishing, and hydraulic fluid reservoir blasting. The company has received government contracts and was acquired in 2015 by Cris Keener, who took over the business's daily operations.

Jiangsu Henglihong Technology Co. Ltd. is a surface blasting media manufacturer based in Wuxi, Jiangsu. Certified with ISO 9001 and ISO 14001, the company manufactures various blasting media, including ceramic beads, ceramic shots, zirconia beads, alumina balls. The company also supplies plastic deflashing media, including nylon polyamide 6, shperical polystyrene and cryogenic polycarbonate, beside, plastic cleaning media, including urea-formaldehyde and melamine to meet various industrial needs. Henglihong blasting media are widely used in industries of aerospace, 3C electronics, hardware machinery, medical equipment and automotive. Henglihong is trusted by world-leading businesses all over the world and served over 3000 global clients including Foxconn, BYD Electronic, and etc.

PROCECO Ltd. is a Canadian manufacturer of water based or aqueous parts washers and washer systems that was established in 1975 in Montreal, Quebec. The company’s product portfolio includes spray-immersion washers, reciprocating nozzle frame washers, conveyor washers, and turntable cabinet washers. It also offers hydro deburring equipment, slurry blasting machines, and wastewater treatment systems. The company’s products are used mainly by its clients in the automotive, aerospace, rail, and renewable energy industries.

Qingdao Taide Machinery Co. Ltd. is a shot blasting machine manufacturer that was established in Qingdao, Shandong in 2007. The company’s product lineup includes shot blasting machines for cleaning or strengthening metal surfaces, as well as sand blasting machines for removing rust or paint. It also offers dust collectors for collecting or filtering particles, and blast wheels for propelling abrasive media. Aside from its own products, the company provides custom manufacturing services for shot blasting machines and equipment tailor made to customer specifications.

joke Technology GmbH is a manufacturer of industrial polishing and grinding tools and machines that was established in Cologne, Germany, in 1940 before relocating its headquarters to Bergisch Gladbach. The company’s products include robotic systems for automated surface deburring or finishing, post-processing systems for finishing 3D printed parts, and micro-machining systems. It also offers diamant fluids and pastes for lapping and polishing processes. The company markets its products under its ENESKA brand name, and mainly serves clients in the industrial manufacturing and metalworking sectors.

Tabata Industrial Machinery CO., LTD., established in 1947 and headquartered in Tokyo, Japan, is a manufacturer that specializes in processing equipment for the plastics industry. The company's processing systems include blending, preforming, extrusion, and oven systems for the production of PTFE tubing and coated wire. It also produces small injection molding machines, exhaust gas treatment devices, cleaning ovens, and pelletizers. Its product offers high-intensity interval training (HIIT) that can be performed using various exercises. It serves the plastics industry, specifically for the production of PTFE tubing and coated wire.

Nicchu CO., Ltd, established in 1959 and based in Tokyo, Japan, is a manufacturer and supplier of surface processing equipment. The company's product range includes portable abrasive blasting machines, blast cabinets, shot peening machines, and dust collectors. These products play a pivotal role in surface treatment, cleaning, and enhancing material properties. They serve sectors like automotive, construction, electronics, and shipbuilding. Beyond equipment manufacturing, the company offers machinery maintenance, equipment rental, and technical support to its customers.

Reitel Feinwerktechnik GmbH is a manufacturer of stainless steel devices and equipment for use in dental laboratories that was established in 1988 in Lower Saxony, Germany. The company offers sandblasters for polishing or roughening dental surfaces, steam cleaners for disinfection or cleaning of dental instruments and materials, and waxing units for melting and applying dental wax. It also offers casting machines for creating molds from dental alloys, and polishing units that utilize filtration and suction functionalities. The company’s products are mainly used in the dental industry, with additional applications in mechanical engineering and the jewelry industry.

International Surface Technologies in Alle du Golf, Saint-Eustache Quebec, is a manufacturer and designer of industrial equipment for industrial applications and industries, founded in 1978. The equipment categories are sandblasting equipment, solvent distillation systems, spray equipment, industrial washers, and dust collection systems used in aluminum smelters, general manufacturing, mass transit, civil engineering, and energy industries. The company offers services such as turnkey installation, technical troubleshooting, preventive maintenance, custom manufacturing, and process testing.

Progressive Surface, started in 1967 and headquartered in Grand Rapids, Michigan, is a manufacturer of automated machinery and closed-loop process controls for grit blasting, waterjet cleaning, and short peening applications. It also makes systems used in thermal spray coating and has installed over 2,000 machines in over 33 countries. The company also designs and builds custom automation and material handling systems for customers’ unique application needs and provides lifetime after-sale service and support. It is ISO 9001 certified, and it built its first automated abrasive grit blasting system in 1967, then introduced its first automated thermal spray in 1983.

Cym Materials S.A., founded in 1960, is an Argentina-based manufacturer headquartered in Soldini, Santa Fe, engaging in the metallurgical industry. The company, certified with ISO 9001, ISO 14001, and ISO 45001, provides standard and custom shot blasting machines. It also produces a line of sandblasting, wheel blasting, and shot blasting cleaning equipment. Spare parts and accessories are also available for compressed air projection and blasting centrifugal equipment. Other products include dust collectors and abrasives, such as spherical and angular carbon steel shots, glass microspheres, and aluminum oxides.

Zhejiang TongBao Surface Processing Equipment Technology Co. Ltd is a manufacturer of surface treatment equipment and machinery that was established in 2000 in Tongxiang, Zhejiang, China. The company produces shot blasting machines such as hook-type and crawler models, sand blasting machines such as conveyor and automatic models, and centrifugal disc and round bowl-type vibratory polishing machines. The company mainly serves clients in the industrial processing sector, such as clients in metal processing, stone cutting, and industrial coating formulation.

CMV®, established in 1973 and based in Cachoeirinha, Brazil, is a manufacturer and supplier specializing in the production of blasting machines. The company's range of blasting machines includes airblast machines, wheelblast machines, shot peening machines, blast wheels, and dust and welding fume extractors. These blasting machines have found successful global applications, including in the manufacturing industry, automotive industry, aerospace industry, construction industry, and other industries. The company also operates under the Blastibrás® brand, which it acquired in 1997. The company is ISO 9001:2015 certified and has locations in Brazil, Hong Kong, the United States, and Russia.

KIGO OE was founded in 2001 and headquartered in Thessaloniki, Greece is a manufacturer of powder coating plant equipment. The company offers a diverse product portfolio, including aerial transportation systems, filters for spray booths, and paint protection clothing. It extends services like installation of the products and rapid repairs backed by the manufacturer’s warranty. These products find applications in wastewater treatment, automotive, and automatic conveyor lines for aerial. In 2012, Kigo participated in the PaintExpo international exhibition in Karlsruhe.

Fevi S.r.l, founded in 1997, is an Italian manufacturer based in Pilastrello, Parma, producing sandblasting, shot blasting, and surface treatment solutions. The company produces sandblasting machines with recycling systems, such as automatic atmospheres explosibles (ATEX) and portable sandblasting machines. It also offers single—and three-phase industrial vacuum cleaners, dust removers, and manual and automatic filter cleaning. The company also provides a range of accessories and spare parts, including abrasives, compressors, and sandblasting safety helmets.

CryoSnow GmbH, incorporated in 2005 and established in Berlin, Germany, is an ISO 9001-certified manufacturer of CO2 snow blasting and dry ice cleaning equipment. The company offers automated blasting systems designed for cyclical or continuous operation, CO2 snow blasting machines for residue-free or dry surface cleaning operations, and manual blasting machines in a range of specifications. It also offers related accessories, including CO2 nozzle arrays for pre-treating plastic components. The company’s products are used by clients in the automotive, consumer electronics, and aerospace industries.

Guangdong Jingzhongjing Industrial Painting Equipment Co. Ltd is based in Guangzhou, Guangdong, China, and is a manufacturer of painting and environmental production equipment established in 1999 before its acquisition by Jingzhongjing Group Co. Ltd. The company offers shot and sandblasting rooms for surface preparation and cleaning, powder coating lines for electrostatic spraying, and spray booths for vehicles, including cars and buses. It also offers foldable field camping cabins and exhaust gas treatment equipment. The company’s products are used in the rail, automotive, and aerospace industries.

Steelex International, established in 2000 and headquartered in Bang Kapi, Bangkok, is a manufacturer of equipment for surface preparation and coating of steel. The company products include automatic shot blasting machines, manual and mobile blast rooms, dust extractors, and various coating application systems such as manual and automatic painting rooms, airless spray pumps, and fume extraction systems. The company’s series 2 direct drive blast wheels are known for high efficiency, ease of maintenance, and retrofit capabilities. It also offers consultancy services for coating process improvements, facility layout, and design of special-purpose machinery.

Gostol TST d.d., established in 1992 and based in Tolmin, Slovenia, is a manufacturer of shot blasting machines with three subsidiaries in China, Russia, and India. The company’s product range also includes vibratory finishing machines, custom-made automated sandblasting chambers, and air-blasting equipment. It has manufactured over 2,500 shot-blasting machines, of which 1,500 are still operational. The company is ISO 9001 and ISO 14001 certified, and its machines comply with CE and other standards according to the country’s needs. It has representatives in more than 20 countries and has been in the industry for over 70 years.

FerroČrtalič d.o.o., established in 1964 and headquartered in Dolenjske Toplice, Slovenia, is a manufacturer and supplier of specialist surface treatment technologies. The company's products include robotic dry blasting machines, shot blasting machines for internal blasting of boilers, and automatic dental implant blasting machines. Its technologies and equipment provide solutions that include dental, industrial coatings, and dry snow cleaning. It provides ongoing service and support for its surface treatment equipment throughout its life cycle and serves industries that include automotive, foundry, and aerospace.

Guyson International Limited, founded in 1938 and headquartered in Skipton, North Yorkshire, is a custom manufacturer offering machinery for surface treatment and finishing of components. Its product range includes blast finishing equipment for surface treatment processes, spray washes for parts cleaning, ultrasonic cleaning equipment for precision cleaning, manual blast cabinets for abrasive blasting, and automated blast systems for high-volume repeatable tasks. The company is registered to ISO 9001:2015 and ISO 45001:2018, while its Hose & Couplings division, based in Guiseley near Leeds, is also accredited to BS EN ISO 9001:2015.

Airblast, established in 1974, based in Heerhugowaard, Netherlands, is a manufacturer of surface treatment equipment intended to engage in providing blasting and painting solutions. The company provides a complete range of blasting equipment, metalization, painting, blast equipment, and sandblasting, among others, They also specialize in developing customized solutions for specific applications. The company caters to shipyard, oil and gas, pipeline, metal, construction, and other sectors. They address inquiries through phone calls and emails.

Kelco Sales & Engineering Co., founded in 1961, is a manufacturer of abrasive blast cleaning equipment and safety equipment based in Norwalk, CA. The equipment includes portable blast pots, syphon blast cabinets, blast rooms & cabinets, pressure blast cabinets, and automated blast systems, as well as airless blast machines. The safety equipment includes leather chaps, gloves, and jackets. The company facility has a wedding shop, fabrication shop, CAD department, and machine shop. The abrasive cleaning equipment manufactured meets the OSHA requirements.

Hodge Clemco Ltd., a subsidiary of Samuel Hodge Ltd., was founded in 1959 and based in South Yorkshire, UK, as a manufacturer and supplier of abrasive blasting and surface treatment equipment. The company offers a series of abrasives for air blast cleaning applications. It also produces recyclable abrasives, abrasive recovery systems, and dust collectors. The company offers services such as abrasive disposal, blasting training, and equipment servicing, and its products find applications in the aerospace and automotive sectors.

LM Industry S.R.L, founded in 1971 and headquartered in Veneto, Italy, is a manufacturer and supplier specializing in centrifuges and industrial systems. The company's product portfolio includes centrifugal force tumbling barrels, surface treatment systems, and military ovens. These products find applications in various industries, including metal parts manufacturing, precious metal processing, and the galvanizing and surface treatment industry. The company offers services including technical support, training on the use of its products, and product customization based on the needs of the clients.

VIXEN Surface Treatments is a manufacturer and supplier of wet blast cleaning and surface treatment products that was established in Stockton-On-Tees, United Kingdom, in 1990. The company’s product lineup includes aqueous degreasing machines for removing contaminants from metal surfaces, wet blasting machines for slurring applications, and phosphating machines for conversion coating of metal or iron parts. The company’s products are commonly used by its clients in the aerospace, additive manufacturing, and automotive industries.

Airbrasive Jet Technologies LLC., started in 2014 and headquartered in South Plainfield, New Jersey, is a manufacturer of micro-abrasive blasting solutions. The company stocks different micro-abrasive blasting units, including model HME, which has a 20lb powder capacity and can work for several hours, and model H, which allows high-volume micro-blasting in any environment. The units have several applications, such as marking helicopter blades, cutting circuit board conductors, and deburring syringes. The company also sells parts and accessories, including dust collectors, blasting nozzles, and work chambers designed for use with all the micro-abrasive blasting units.

Mayflay Machinery (Huizhou) Co. Ltd., established in 2016 and headquartered in Huizhou City, Guangdong Province, China, is a surface treatment equipment developer, manufacturer, and B2B supplier. The company's primary products include spinner hanger shot blasting machines, sandblasting rooms, and sandblasting cabinets. Its secondary product line of coil handling equipment includes compact coil feed lines, high-speed cam drive feeders, and combined decoiler straighteners. The company offers a number of assembled solutions, such as wire mesh belt shot blasting machines for automobile motor electric spray systems and roller conveyor shot peening machines for coil spring manufacturers.

Hangzhou Kafan Machinery & Equipment Co. Ltd., established in 2009 and headquartered in Hangzhou, China, is a surface finishing equipment designer, manufacturer, and B2B supplier. The company specializes in the production of industrial sandblasting equipment, mass finishing machines, and complete powder coating equipment products. Its primary products include automatic conveyor belt blasting machines and centrifugal disc finishing machines. It also offers multifunctional systems, such as sandblasting and powder coating machines for metal surfaces, and custom-engineered finishing solutions. The company has extensive experience with custom automatic alloy vehicle rim shot blasting machines and galvanized part sandblasting machines.

Quantum Blast Australia Pty Ltd, founded in 2018 and headquartered in Para Hills, South Australia, is a developer, distributor, and manufacturer of sandblasting equipment and supplies. The company distributes products from brands such as Elcometer, Bullard, and RPB. These products include the Nova helmet with constant flow control, handheld dry film thickness meters, and Graco contractor airless spray guns. Quantum Blast also develops and manufactures VAPR-Blast Wet Blast Cabinets and RapidBlast dustless blasting machines, which are capable of cleaning surfaces and walls and removing paint from vehicle panels.

Wuxi Canon Intelligent Equipment Technology Co. Ltd., established in 2008, is a Chinese manufacturer and supplier based in Wuxi, Jiangsu, producing hydraulic machine tools. The company specializes in production solutions, specifically for steel cylinder manufacturers. Its product range includes machinery for air tanks, such as hydraulic presses, rolling machines, and trimming machines. It also produces machinery for liquid petroleum gas (LPG) cylinders, such as halve embossing and flange punching presses, foot ring welding machines, and shroud welding machines. The company serves international clientele in Africa, Southeast Asia, and the Middle East.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Gibson Abrasive Equipment Co. |

6.8%

|

| 2 | Clemco Industries Corporation |

5.8%

|

| 3 | Airblast |

5.0%

|

| 4 | SAFE Systems, Inc. |

4.3%

|

| 5 | Finishing Systems |

3.2%

|

| 6 | Kelco Sales and Engineering |

3.2%

|

| 7 | Crystal Mark, Inc. |

2.9%

|

| 8 | Viking Corporation |

2.9%

|

| 9 | Little Swede Industries |

2.9%

|

| 10 | FEVI |

2.5%

|

Derivation Method

The ranking is calculated based on the click share within the blasting equipment page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

11 | 45.8% |

China

China

|

3 | 12.5% |

Japan

Japan

|

3 | 12.5% |

Canada

Canada

|

2 | 8.3% |

Germany

Germany

|

2 | 8.3% |

United Kingdom

United Kingdom

|

2 | 8.3% |

Italy

Italy

|

1 | 4.2% |

214 products found

214 products

Mako Co., Ltd.

1020+ people viewing

Last viewed: 10 hours ago

This is the smallest manual device that is ideal for cleaning work. Our unique wet blast system has been compactly packaged into a unique shape. ■...

Sanoyas engineering Co., Ltd.

530+ people viewing

Last viewed: 12 hours ago

■ Ideal for mass production of small and medium -sized products with large surface area Put the product in the apron or the barrel, and automatical...

10 models listed

Mako Co., Ltd.

850+ people viewing

Last viewed: 10 hours ago

This is a higher-end device of COCOTTE with expanded applications and cabinet size. The biggest difference is the wide range of uses. It is possibl...

Sanoyas engineering Co., Ltd.

400+ people viewing

Last viewed: 9 hours ago

■ General -purpose machine options that can be bradped for products that can be placed on the turntable ・ This is a device that puts a product on ...

6 models listed

Mako Co., Ltd.

810+ people viewing

Last viewed: 12 hours ago

The load capacity is 5 times that of COCOTTE. Easy and tough top model. This flagship model has high wear resistance, a large cabinet, and a load c...

G-TOOL Co., Ltd.

450+ people viewing

Last viewed: 12 hours ago

■Set contents ・Power tool E1-3200 J 1 unit ・Blastriker® Life Max Metal 1 piece ・Blastriker® Life Max adapter 1 set ・Grip 1 piece ・Tool box 1 box

Sanoyas engineering Co., Ltd.

300+ people viewing

Last viewed: 6 hours ago

■ By moving the table, you can attach and detach the product while blasting. It is a compact machine that can provide high -efficiency clinical cli...

5 models listed

G-TOOL Co., Ltd.

430+ people viewing

Last viewed: 2 hours ago

■Set contents ・Air tool P1-3500 J 1 unit ・Coupler 1 piece ・Grip 1 piece ・Blastriker® Life Max Metal 1 piece ・Blastriker® Life Max adapter 1 se...

Sanoyas engineering Co., Ltd.

470+ people viewing

Last viewed: 12 hours ago

■ You can blast while hanging a large weight It is a device that hangs a product on a crane hook and blasts while automatically rotating in the cab...

4 models listed

Sanoyas engineering Co., Ltd.

410+ people viewing

Last viewed: 12 hours ago

■ The hanger movement type can be attached and detached while blasting. Hang the product on a rotating hook, and blast while rotating it to the aut...

4 models listed

Sanoyas engineering Co., Ltd.

420+ people viewing

Last viewed: 11 hours ago

■ Suitable for long -shaped and complex works with small items Put the product on the belt conveyor and blast while transporting it automatically. ...

5 models listed

Sanoyas engineering Co., Ltd.

460+ people viewing

Last viewed: 12 hours ago

■ Roller type ideal for long items ・ It is a device that performs surface treatment processing while automatically transporting it with a roll con...

4 models listed

Sanoyas engineering Co., Ltd.

840+ people viewing

Last viewed: 4 hours ago

■ Ideal for mass production of small and medium -sized products with large surface area The product is placed on the belt conveyor, it is transport...

G-TOOL Co., Ltd.

460+ people viewing

Last viewed: 3 hours ago

■Set contents ・Power tool E1-3200 J 1 unit ・23mm width adapter (for brush/SL disc) 1 set ・Grip 1 piece ・1 marine blaster brush ・Blaster brush ...

Illy Co., Ltd.

450+ people viewing

Last viewed: 9 hours ago

■Features Handy type allows for easy soda blasting work.

Illy Co., Ltd.

500+ people viewing

Last viewed: 12 hours ago

■Features ・Continuous soda blasting work is possible with a large capacity tank. - Excellent workability as the amount of soda discharged can be a...

Illy Co., Ltd.

410+ people viewing

Last viewed: 12 hours ago

■Features ・Continuous soda blasting work is possible with a large capacity tank. - Excellent workability as the amount of soda discharged can be a...

Illy Co., Ltd.

510+ people viewing

Last viewed: 12 hours ago

■Features - Handy type allows for easy blasting work. ・Since blast sand is collected, clean work is possible. ・Sand can be collected efficiently ...

Illy Co., Ltd.

400+ people viewing

Last viewed: 5 hours ago

■Features - Cabinet capacity of 90 liters, sufficient for parts polishing and shot work - Desktop type that can be installed in a space-saving mann...

Illy Co., Ltd.

490+ people viewing

Last viewed: 12 hours ago

■Features ・Side door type makes it easy to put in and take out parts - The cabinet is a large type, and the door has a side door that makes it eas...

Illy Co., Ltd.

390+ people viewing

Last viewed: 7 hours ago

■Features ・For polishing work and shot work ・Cabinet capacity 56 liters ・Desktop type, lightweight and space saving - Comes with durable protect...

Illy Co., Ltd.

470+ people viewing

Last viewed: 5 hours ago

■Features - The foot switch allows you to use both hands freely, allowing you to sand small items. - There is a middle tier of mesh inside the cabi...

G-TOOL Co., Ltd.

380+ people viewing

Last viewed: 12 hours ago

■Set contents ・Power tool E1-3200 J 1 unit ・23mm adapter (for brush/SL disc) 1 set ・Grip 1 piece ・SL disc Y type 3 pieces ・Tool box 1 piece

TABATA INDUSTRIAL MACHINERY CO., LTD.

580+ people viewing

Last viewed: 12 hours ago

Clean Shot has a proven track record of cleaning hundreds of plastic processing machine parts such as screws, breaker plates, nozzles, and dies. A ...

G-TOOL Co., Ltd.

360+ people viewing

Last viewed: 12 hours ago

■Set contents ・Power tool E1-3200 J 1 unit ・23mm width adapter (for brush/SL disc) 1 set ・Grip 1 piece ・1 marine blaster brush ・Blaster brush ...

G-TOOL Co., Ltd.

370+ people viewing

Last viewed: 12 hours ago

■Set contents ・Air tool body (with coupler) P1-3500J 1 unit ・23mm adapter (brush/SL disc) 1 set ・Grip 1 piece ・1 marine blaster brush ・Blaster...

G-TOOL Co., Ltd.

250+ people viewing

Last viewed: 12 hours ago

■Set contents ・Air tool body (with coupler) P1-3500J 1 unit ・23mm adapter (for brush/SL disc) 1 set ・Grip 1 piece ・SL disc Y type 3 pieces ・To...