All Categories

History

This section provides an overview for bucket conveyors as well as their applications and principles. Also, please take a look at the list of 9 bucket conveyor manufacturers and their company rankings. Here are the top-ranked bucket conveyor companies as of March, 2026: 1.Gough Econ, Inc., 2.Martin Sprocket & Gear, Inc., 3.VC999 Packaging Systems, Inc..

Table of Contents

Categories Related to Bucket Conveyors

Engaged in research on nitride semiconductor growth using the MBE method at Waseda University Graduate School. After graduating from graduate school in 2016, he joined a non-ferrous metal manufacturer.

Engaged in equipment maintenance and engineering work at metal smelting plants. Moved to a chemical manufacturer in 2022. Engaging in similar tasks.

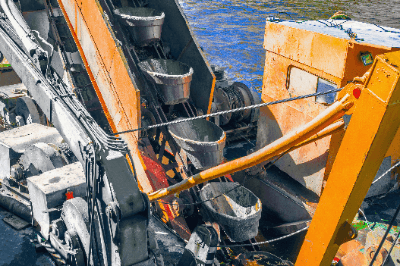

A bucket conveyor is a conveyor with a series of box-like containers (buckets, etc.) with open tops mounted on a belt.

Bucket Conveyor is a type of conveyor used to transport materials by placing the materials to be transported inside the bucket. It is characterized by its ability to convey amorphous materials such as granules and powders without leakage. Another advantage of this type of conveyor is that it can convey materials vertically.

The bucket conveyor has a proven track record in a variety of fields, including the conveyance of various raw materials, foodstuffs, crushed stones, and fertilizers.

Bucket Conveyors are often used in industrial production lines because their structure allows them to convey large quantities of goods at high speed and efficiency. They are particularly suited for conveying amorphous materials such as powders.

Therefore, they are suitable for conveying raw material powders and pellets (granular resins) in chemical plants. They are often used for vertical conveying of rice and flour in food factories. They are also used to transport dried fruits and canned foods.

They are also widely used in the mining industry to transport ore and coal. Bucket Conveyors are needed to transport ore in underground mines and open pit mines. Bucket Conveyors are sometimes used to transport ore before it is transferred to trucks, railcars, or other means of transportation.

In recent years, they are also used in the recycling industry. For example, Bucket Conveyors are used in recycling plants to convey and sort waste materials. The Buckets prevent spillage of conveyed materials and ensure smooth transportation.

Bucket Conveyor consists of a belt, bucket, and drive source.

The belt of a bucket conveyor is often designed to be rotated by a rotating shaft. Power transmission for the belt is typically provided by a three-phase induction motor. As the belt begins to rotate, the buckets are also carried by the belt.

The buckets are attached to the belt at regular intervals, lifting and carrying items as the bucket moves. As the bucket moves, the goods in the bucket are carried with the bucket. Designed for continuous goods transport, the bucket is capable of efficiently conveying large quantities of goods.

When the bucket arrives at its destination, the goods are unloaded from the bucket. At the end of the line, the bucket is unloaded by inverting as the belt is turned over. The bucket is discharged to the next process by means of a chute or other device installed below the belt turnover.

The Bucket Conveyor has a hopper attached to the material feeding section, and the materials fed from the previous process are concentrated directly above the bucket by the hopper. Adjacent buckets on the conveyor are connected to each other in the direction of conveyance to avoid gaps between them and prevent the material from falling out of the bucket conveyor.

If the amount of material to be conveyed exceeds the capacity of the Bucket Conveyor, a fixed-feed mechanism such as a rotary feeder is used at the bottom of the hopper.

Bucket Conveyors are selected based on the material to be conveyed, the amount of material to be conveyed, and the environment in which it will be used.

If powder or small particles are to be conveyed, an enclosed Bucket Conveyor should be selected to prevent dust generation. If the destination height or distance is long, a longer Bucket Conveyor should be selected.

Determine the size of the Bucket Conveyor and the capacity of the motor to be installed by ascertaining the volume and speed to be conveyed. It is important to ascertain the volume and speed to be conveyed and select the necessary equipment.

Materials should be selected to match the environment in which they will be used. If the goods to be conveyed are corrosive, select stainless steel or resin. If the material is explosive, a Bucket Conveyor manufactured from a durable material should be selected.

*Including some distributors, etc.

Sort by Features

Sort by Area

Martin Sprocket & Gear, Inc. (MSG) is an Arlington, Texas-based manufacturer and supplier of power transmission products, material handlers, and industrial hand tools. Founded in 1951, the company primarily serves clients in the pulp and paper, petrochemical, automotive, and agriculture industries. The company produces various products including conveyors, sprockets, sheaves, bushings, and custom products for client companies like John Deere and General Electric. MSG has over thirty operating plants across the United States, with retail locations and storage facilities on three continents.

YT Conveyor, founded in 1989 with headquarters in China, is a manufacturer of elevator and conveyor components for handling bulk materials. The company's products include bucket elevator components, drag scraper conveyor chain components, belt conveyor components, sieve pan cleaners, and proximity sensors. YT Conveyor's equipment and components are used in various industries, including agriculture, mining, food processing, and consumer manufacturing. The company provides custom manufacturing and has completed projects that include rubber conveyor belts, nylon chain rollers, and nylon feed screw design and production.

NERAK GmbH Fördertechnik, founded in 1987 and headquartered in Brigitta, Hamburhren, Germany, is a manufacturer of vertical conveying unit loads and bulk solids. The products include bucket and pendulum conveyors for bulk solid materials and packaging items such as vertical conveyors, portable lifters, and reciprocating lifts. It also manufactures rubber block chains, and all its products are used in the construction, chemical, automotive, and food industries. The business has a Quality Management certificate and a service network in Norway, Australia, the United States, and Japan.

Gough & Co. (Engineering) Ltd., established in 1940 is a designer and manufacturer of material handling and process equipment based in Staffordshire, UK. Their production line is segmented into product handling equipment, sieves, screens, & separators, and their parts & services. The product handling equipment is segmented into bucket elevators, linear vibratory feeders, product conveying schemes, belt conveyor systems, and floveyor aero mechanical. The company supplies their material handling and process equipment solutions to companies in the food & beverage, pharmaceuticals, additives manufacturing, chemicals & aggregates and ceramics industries.

WIESE Förderelemente GmbH, founded in 1999 and located in Burgwedel, Germany, is a manufacturer of process-compliant conveying systems for bulk material food and non-food applications. The products are rubber chains, continuous and pendulum bucket conveyors with casings such as self-contained sheets, removable side parts, open tubular frameworks, and gas-tight casings. The conveyors are used in product areas such as ceramics, chemicals, plastics, powders, and building materials. The company provides project planning, consulting, development, assembly, and management services.

VC999 is a global manufacturer of vacuum packaging machines with a parent company in Herisau, Switzerland, and offices in Kansas City, Missouri, Germany, Canada, Austria, Colombia, and over 70 other countries. The brand name VC999 is an acronym for vacuum capacity 99.9%. It refers to the highest vacuum performance achievable, which echoes VC999 quality and performance. From small tabletop vacuum machines to dryers and thermoformers, VC999 stocks different types of vacuum machines to cater to various client needs.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | NERAK GmbH Fördertechnik |

26.9%

|

| 2 | Gough Econ, Inc. |

19.4%

|

| 3 | Martin Sprocket & Gear, Inc. |

14.0%

|

| 4 | WIESE Förderelemente GmbH |

9.7%

|

| 5 | VC999 Packaging Systems, Inc. |

9.7%

|

| 6 | Gough & Co. Engineering Ltd. |

7.5%

|

| 7 | YT Conveyor |

5.4%

|

| 8 | Showa Co., Ltd. |

5.4%

|

| 9 | Tsubakimoto Chain Co., Ltd. |

2.2%

|

Derivation Method

The ranking is calculated based on the click share within the bucket conveyor page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

2 | 22.2% |

Japan

Japan

|

2 | 22.2% |

Germany

Germany

|

2 | 22.2% |

China

China

|

1 | 11.1% |

United Kingdom

United Kingdom

|

1 | 11.1% |

Switzerland

Switzerland

|

1 | 11.1% |

68 products found

68 products

Naniwa Machine Manufacturing Co., Ltd.

530+ people viewing

Responding to a wide range of customer needs and proposing products that meet usage conditions in increasingly diverse transport equipment We hand...

Fuji Koki Co., Ltd.

660+ people viewing

Last viewed: 8 hours ago

Bucket elevators are transportation devices with a reputation for vertically transporting powder and granular materials. We have a lineup of three ...

Nishimura Iron Works Co., Ltd.

360+ people viewing

Last viewed: 6 hours ago

■Features and specifications of NZ Conveyor, a horizontally and vertically adjustable conveyor The horizontal/vertical flexible NZ conveyor manufac...

Shoraku Sangyo

790+ people viewing

Last viewed: 2 hours ago

・ Easy -to -clean feeder type ・ A small bucket supplies raw materials little by little.

Advan Co., Ltd.

430+ people viewing

Last viewed: 8 hours ago

■What is Advanlift? This is an overlapping continuous bucket conveyor. During horizontal transport, the bucket flanges overlap and the buckets run ...

Showa Co., Ltd.

390+ people viewing

Last viewed: 6 hours ago

■NCON (flight conveyor) This is a flight conveyor developed through a technical partnership with Nissin Seisakusho, which has many years of experie...

Daido Kogyo Co., Ltd.

540+ people viewing

Last viewed: 13 hours ago

We handle many conveyor systems not only in Japan, but also overseas, including China, other Asian countries, the United States, Brazil, and Saudi ...

Dainichi Hanso co.,ltd.

320+ people viewing

Last viewed: 9 hours ago

■Summary Conveyance device from above. An elevator that unloads powder and granular materials in continuous operation. ■Applications This is a dev...

2 models listed

Daido Kogyo Co., Ltd.

340+ people viewing

Last viewed: 23 hours ago

■We create optimal conveyors using the know-how of conveyor chains that have supported key industries. We handle many conveyor systems not only in ...

2 models listed

Wintec Co., Ltd.

410+ people viewing

Last viewed: 1 day ago

Pivoted bucket conveyors can transport all kinds of powder and granules, as well as small lumps and sticky materials, both horizontally and vertica...

Nishimura Iron Works Co., Ltd.

410+ people viewing

Last viewed: 1 day ago

■Features and specifications of vertical conveyor I-B conveyor Introducing the vertical conveyor I-B conveyor manufactured by Nishimura Iron Works....

Shoraku Sangyo

930+ people viewing

Last viewed: 1 day ago

・ One stainless steel bucket puts raw materials. ・ Cleaning is easy. ・ You can make up to 40 to 100 liters.

Showa Co., Ltd.

320+ people viewing

■NCON (flight conveyor) This is a flight conveyor developed through a technical partnership with Nissin Seisakusho, which has many years of experie...

Makino Sangyo Co., Ltd.

570+ people viewing

Last viewed: 4 hours ago

■The pivot conveyor is a conveyor that does not break the conveyed items. ・A general term for bucket conveyors in which buckets rotate around pins...

Showa Co., Ltd.

350+ people viewing

■Bucket conveyor Bucket conveyors, which integrate three stages of transportation (horizontal, vertical, and horizontal), have been used for more t...

Showa Co., Ltd.

320+ people viewing

■Bucket conveyor Bucket conveyors, which integrate three stages of transportation (horizontal, vertical, and horizontal), have been used for more t...

Wintec Co., Ltd.

330+ people viewing

Last viewed: 1 day ago

Bulk material conveyor exclusively for vertical conveyance Ideal for transporting grain, resin, and powder fluids with low wear.

Showa Co., Ltd.

390+ people viewing

Last viewed: 1 day ago

■Bucket conveyor Bucket conveyors, which integrate three stages of transportation (horizontal, vertical, and horizontal), have been used for more t...

Wintec Co., Ltd.

440+ people viewing

Last viewed: 15 hours ago

Bulk material conveyor. The layout allows for steep slope conveyance from horizontal to 90°. Cereals, confectionery, ingredients, plastics, metal ...

Dainichi Hanso co.,ltd.

640+ people viewing

Last viewed: 1 day ago

■Summary Conveyance device from above. An elevator that unloads powder and granular materials in continuous operation. ■Disadvantages of conventio...

Showa Co., Ltd.

400+ people viewing

■Bucket conveyor Bucket conveyors, which integrate three stages of transportation (horizontal, vertical, and horizontal), have been used for more t...

Showa Co., Ltd.

370+ people viewing

■Bucket conveyor Bucket conveyors, which integrate three stages of transportation (horizontal, vertical, and horizontal), have been used for more t...

Showa Co., Ltd.

210+ people viewing

■ Gently transported goods, horizontal, vertical, horizontal transport The bucket conveyor, which integrates three -stage transportation means of h...

4 models listed

Showa Co., Ltd.

290+ people viewing

■ Gently transported goods, horizontal, vertical, horizontal transport The bucket conveyor, which integrates three -stage transportation means of h...

4 models listed

Showa Co., Ltd.

240+ people viewing

Last viewed: 18 hours ago

■ Gently transported goods, horizontal, vertical, horizontal transport The bucket conveyor, which integrates three -stage transportation means of h...

4 models listed

Dainichi Hanso co.,ltd.

380+ people viewing

■Summary Manufacture of transport equipment for small diameter steel ball assembly line. A catch-and-release mechanism suppresses the impact of the...

Maruyasu Machine Co., Ltd.

190+ people viewing

Last viewed: 1 day ago

Features ■Standard for conveyor selection The compact belt conveyor "Mini Series" uses a frame made of high-precision aluminum extrusion, allowing ...

4 models listed

Makitec Co., Ltd.

490+ people viewing

Last viewed: 1 day ago

Cup conveyors can transport your precious products (small items and bulk items) without spilling the load. This is an easy-to-use, high-performance...

4 models listed

Advan Co., Ltd.

400+ people viewing

■What is Advanlift? This is an overlapping continuous bucket conveyor. During horizontal transport, the bucket flanges overlap and the buckets run ...