All Categories

History

This section provides an overview for spot welding as well as their applications and principles. Also, please take a look at the list of 24 spot welding manufacturers and their company rankings. Here are the top-ranked spot welding companies as of February, 2026: 1.Seedorff ACME, 2.Spot Weld, Inc., 3.Classic Sheet Metal, Inc..

Table of Contents

Categories Related to Spot Welding

Spot Welding is a type of welding method along with Arc Welding and Gas Welding.

Spot Welding is a type of welding method along with Arc Welding and Gas Welding.

Two pieces of welded material are sandwiched between electrodes under pressure, and a large current is applied. Then, the metals are joined together by melting and solidifying in a spot manner due to electric resistance heat.

There are three basic types of welding methods: pressure welding, brazing, and fusion welding.

Spot Welding is categorized as pressure welding. Unlike arc welding, which forms a wide bead (welding surface), spot welding joins only one small point, resulting in a clean finish.

Spot Welding is also called Resistance Spot Welding because the base metal is heated by electrical resistance.

Spot Welding is used to join parts of automobiles, railroad cars, and household appliances because of its ability to maintain a clean appearance.

One of the advantages of Spot Welding is that, unlike other welding methods, it welds directly across the base metal and does not require any fusing materials such as shielding gas or flux.

Another advantage of Spot Welding is that even novice welders can easily perform spot welding, whereas arc welding and gas welding are dependent on the skill of the welder. Spot Welding can be combined with a robot arm to automate the welding process.

There are three types of Spot Welding: Resistance Spot Welding, Laser Spot Welding, and Seam Welding.

Resistance Spot Welding is a method of joining two pieces of metal to be welded by applying electrode rods to them from above and below, applying pressure, and passing a large current through them to cause the base metal to melt and solidify with the heat generated.

When the term Spot Welding is used, it simply means resistance spot welding.

Electrode rods are often water-cooled. It is used to join relatively thin materials and is frequently used in the production of automobile bodies. Welding quality is determined by welding current, as well as energization time, pressing pressure, and material. These conditions must be controlled to improve the quality of the nugget, which is the joint in Spot Welding.

In Resistance Spot Welding, the temperature near the weld zone is lower than that of arc welding, so the effect of heat is limited to a narrow area. Therefore, it is characterized by less deformation and residual stress after welding. On the other hand, because it heats with the heat of high-current electric resistance, the capacity of the welding machine is larger than that of arc welding, which has the disadvantage of higher equipment costs.

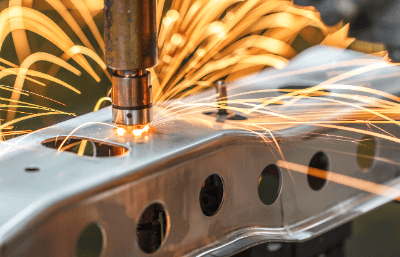

Laser Spot Welding is a method of heating base metal by irradiating it with a laser. Heating is done on one side only, and it is mainly used for welding small, thin objects or objects that require high precision.

Compared to Resistance Spot Welding, the heating time is very short for high power. This has the advantage of minimizing weld distortion.

This is a method of continuously overlapping resistance Spot Welding. It is a type of Spot Welding. The electrode is made in the shape of a roller, sandwiched between two base materials, and heated by rotating the electrode while applying pressure and intermittently passing an electric current. It is used when watertight or airtight is required.

There are approximately 6,000 welding spots on a single automobile. The welds are made on the body, frame, suspension members, lower arms, etc.

There are many types of welding methods used in automobiles, including resistance welding, arc welding, and laser welding. Nowadays, laser welding is becoming the mainstream in terms of productivity and manufacturing cost.

Among these, Spot Welding is used to weld plate materials such as bodies and pressed doors. Spot Welding used here includes resistance spot welding and laser spot welding.

Spot Welding uses the electrical resistance properties of metal to perform welding. And there are several causes of defects in resistance welding such as Spot Welding.

*Including some distributors, etc.

Sort by Features

Sort by Area

Seedorff ACME, established in 1913 and located in Des Moines, Iowa, USA, is a manufacturer and supplier of quality construction equipment. Their primary product line comprises concrete paving and road maintenance equipment, essential for the construction industries. These products play a crucial role in building and maintaining infrastructure such as roads, highways, and airports. The company provides ideal solutions that enhance construction processes and efficiency. Their equipment is designed to withstand the demands of heavy-duty applications, ensuring durability and reliability on job sites. Seedorff ACME also continues to enhance the development of robust infrastructure, supporting economic growth and connectivity.

Spot Weld Inc. has been based in Minnesota since 1973 and is a manufacturer and supplier of resistant welding equipment. The company provides various Welding equipment like Inverters, Rocker Arm, Bench Top, Seam and other types of welds that aid in welding fasteners, studs, HVAC, tubes, and pipes. For standard to light weld force requirements, reaching into tight spaces, using offset tooling to fixture a part, and rare tooling changes. There are welding accessories available as well which consist of Transformers, Current Meters, Force Gauges, Electrodes, and Holders, and together they help with welding applications in the automotive industry among others.

Wirefab, Inc. is an American contract manufacturer specializing in metal fabrication services that was established in Worcester, Massachusetts in 1955. The company offers various custom metal fabrication capabilities including welding, wire forming and bending, laser cutting, and sheet metal or tube fabrication into customer-specified dimensions, shapes, and finishes. It also offers CNC machining services, such as chamfering, tapping, milling, and boring. Wirefab serves clients in the food service and medical equipment manufacturing sectors, as well as OEMs in the automotive, aerospace, and defense industries.

TRIAC Corporation, established in Greensboro, NC, in 1995, is a manufacturer of electrical contact assemblies and switches. The company's product range includes General Purpose Electrical Contact Assemblies and Connectors, Tube Connectors Switches and Relays. The company serves markets including Transportation, Military, Residential Appliance, Transportation, Aircraft and Energy. The company has operations in the US, Puerto Rio, Dominican Republic, Canada and Mexico. They also provide services including product selection, installation, preventative maintenance, troubleshooting, and repair.

Classic Sheet Metal, established in 1962, is an ISO 9001:2015 certified manufacturer of sheet metal fabrication based in Addison, IL. The company offers various services including design & engineering consulting, inventory management, as well as fabrication capabilities such as punching, stamping, and laser cutting, serving the telecommunications, electronics, energy, transportation, and medical industries. Classic Sheet Metal also provides welding services and contract assembly for other companies adopting the assembly areas to handle multiple electro-static discharge stations.

South Alliance, established in 1989 and based in South El Monte, CA, U.S.A, is a manufacturer of precision machine components and assemblies serving the aerospace, defense, space, medical, and automotive industries. The company manufactures hydraulic equipment, motor components, hardware, mills, and pins that have applications in the technology, electronics, energy, and transportation industries. They offer CNC machining & turning, custom metal fabrication, welding, part assembly, and tooling manufacturing services that are needed in the medical sector, power transmission industry, and hydraulic equipment manufacturing industries. The company is certified with ISO9001 and AS9100D standards and is also registered in ITAR.

ABC Sheet Metal traces its roots to 1870 and is headquartered in Anaheim, California. The company provides cutting and shaping services to several industries including aerospace, defense, medical, packaging, and construction. The company is AS9100 and ISO 9001 certified, assuring aerospace, defense, and other industry customers of build quality. The company’s cutting and shaping services include laser and water jet cutting, forming & rolling, welding, and CNC machining and punching. The company takes full advantage of 2D and 3D CAD for sheet metal engineering to reduce manufacturing labor and material expenses.

For over 45 years, UWC has supplied quality wire mesh products to numerous industries with distinct applications. Our products range from industrial grade wire cloth & wire mesh for sizing & filtration to security solutions and architectural applications. We carry an extensive inventory of woven & welded wire cloth in various specifications available for immediate shipping. Also, our weaving capabilities allow us to manufacture standard as well as custom crimped mesh. Our fabrication services include cut to size pieces, discs, infill paneling and screen sections with a variety of edging options. Additionally, we routinely produce baskets, trays, cylinders and test sieves.

ETMA Metal Parts (Emp. Técnica de Metalurgia S.A.), founded in 1940 and headquartered in Braga, Portugal, is a metallurgy manufacturer specializing in customized prototypes. The company designs and develops prototypes for a wide range of products, such as progressive tools for high-speed stamping presses, cold forming tools, and robotic assembly machines. It also produces precision-turned parts for auxiliary processes, as well as screws and rivets. Additionally, the company offers wire and tube forming services with various finishing options, including beveling, threading, and welding. These products are utilized in various sectors, such as automotive, electric appliance manufacturing, and plastic injection.

HLC Metal Parts Co. Ltd. is an IATF 16949-certified manufacturer of precision metal parts and components founded in 2003 and based in Dongguan City, Guangdong, China. The company primarily produces custom precision metal parts using a range of in-house capabilities, such as metal stamping, CNC machining, and in-mold welding. It also offers assembly and fitting services for metal and plastic accessories. The company operates internationally, with additional locations in Mexico, Taiwan, and Bulgaria.

Superwave Laser Technology Co., Ltd is a manufacturer of laser equipment and solutions founded in 2005 and located in Shenzhen, China. The company produces and distributes laser marking, welding, engraving, and cutting systems. The laser wavelengths vary from Ultraviolet and Infrared to Far Infrared. The laser systems are running in North America, Europe, and Asia. It maintained business partnerships with companies from various industries, namely Honda, Yamaha, Chow Tai Fook, TTF Jewelry, and Foxconn. The company's machines are certified with CE and FDA, and its quality system has passed the ISO 9001 certification.

The Be-Ge Group, founded in 1934 and headquartered in Oskarshamn, Sweden, is a family-owned manufacturer of chairs, seats, and seating solutions. The company operates through divisions such as Be-Ge Seating, Be-Ge Components, and Be-Ge Vehicle. Its main products include adjustable driver seats for commercial vehicles, machinery, and forklifts. It also produces M1-approved passenger seats for the OEM truck market and ergonomic office chairs. These products are used in passenger transportation, semitrailer cargo transporters, and office environments. Be-Ge also provides custom seating solutions and received the Best Managed Companies 2024 award by Deloitte and NASDAQ.

DAIHEN Corporation, established in 1919 and headquartered in Osaka, Japan, is a manufacturer of Power Products, Industrial Robots, and RF/MW Generators & Automatic Matching Units for plasma applications. The company provides an extensive array of products, including Oil-immersed Transformer, Cast Resin Transformer suitable for high buildings, public facilities, and hospitals, Power Distribution Equipment such as closed type power distribution boards and remote monitoring systems, as well as Sensors for Robot Welding and Positioners & Sliders. The company also offers various welding & cutting machines, including TIG Welding Machines, Plasma Cutting Machines, as well as Peripheral Devices for Welding.

KJ Laser Micromachining, founded in 2001 and located in Toronto, Canada, is a manufacturer of advertising and promotional products. They offer precision laser micromachining services, including laser cutting and engraving for various materials like metals, plastics, and composites. This enables the precise and efficient creation of complex shapes, patterns, and permanent markings such as logos and serial numbers. Their product portfolio includes laser cut custom Gauge, ornaments cut from steel, laser engraved acrylic, and stainless steel medical implants.

KIMURA Group, founded in 1988 and based in Kure City, Hiroshima Prefecture, is a manufacturer of environmental and industrial machinery. The company produces crushers, presses, and cutting machines for waste management and recycling. Its offerings include a patented REC aluminum casting method for part production at the Higashi Hiroshima Plant. Its machinery caters to industries like automobile recycling and shipbuilding. The company's portfolio also encompasses packing machines for PET bottles and industrial equipment. It also offers OEM and ODM services based on customer specifications, from design to development.

Cubotonic is a Portuguese contract manufacturer specializing in metalworking products and services that was established in Venda do Pinheiro, Mafra in 2014. The company offers a range of metal sheet, tube, surface, and component fabrication capabilities. These include bending, welding, laser cutting, assembly, and powder coating services, as well as custom design and development for unique projects or product use cases. The company chiefly serves clients in the automotive, construction, electrical, and aerospace industries.

Biagosch and Brandau Germany GmbH (BIBRA), established in 1889 with headquarters in Hamburg, Germany, is a manufacturer and supplier of machines and homemade toolings for the metal packaging industry worldwide. The company specialized in the production of equipment that produces bottoms and lids for all types of round and non-round cans. Its products include sheet feed presses, can-making machines, and end-making machines. It offers complete production lines that are equipped with PLCs for remote control and management. The company's services include upgrading old machinery, repairs, and ongoing maintenance.

ZS Industries Co., LTD, founded in 2003 and headquartered in Shanghai, China, is a manufacturer and distributor of mechanical and engineering metal parts. The company provides a range of products, including plastic parts, sheet metal welding, and precision machining. Additionally, it offers services such as computer-aided design, material analysis of the chemical and mechanical properties, and defining and selecting prototyping processes. These products and services are applied across various industries, including environmental protection, new energy fields, and hydraulic cylinders.

koyo giken Inc., established in 1976 and based in Sagamihara, Japan, is a manufacturer and supplier specializing in tabletop spot welders. The company’s product portfolio includes static pressure spot welders, NK-03 series tabletop spot welders, and simplified tensile testers. These products find applications in various industries, including electronics manufacturing, metal fabrication, and the aerospace industry. The company provides services including technical support, customization based on clients’ needs and requirements, and assistance with diagnosing and resolving issues that may arise during machine operation.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Seedorff ACME |

13.2%

|

| 2 | Spot Weld, Inc. |

12.3%

|

| 3 | Classic Sheet Metal, Inc. |

7.6%

|

| 4 | TRIAC Corporation |

7.5%

|

| 5 | Wirefab, Inc. |

6.9%

|

| 6 | T. J. Snow, Co. |

5.2%

|

| 7 | Kooks Industries |

5.0%

|

| 8 | ZS Industries Co., LTD |

4.7%

|

| 9 | South Alliance |

4.7%

|

| 10 | ABC Sheet Metal |

4.7%

|

Derivation Method

The ranking is calculated based on the click share within the spot welding page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

10 | 55.6% |

China

China

|

2 | 11.1% |

Japan

Japan

|

2 | 11.1% |

Portugal

Portugal

|

1 | 5.6% |

Sweden

Sweden

|

1 | 5.6% |

Canada

Canada

|

1 | 5.6% |

Germany

Germany

|

1 | 5.6% |

35 products found

35 products

Daido Kogyo Co., Ltd.

600+ people viewing

Last viewed: 1 day ago

It can handle high welding conditions and high pressure conditions, and has excellent operability. ■Features ・Rated capacity 19KVA Maximum weldin...

Daido Kogyo Co., Ltd.

550+ people viewing

Last viewed: 1 day ago

■Possible to spot weld on one or both sides ・Welding time can be adjusted by using a special circuit using transistors. - Compact and lightweight,...

Daido Kogyo Co., Ltd.

240+ people viewing

Last viewed: 1 day ago

ART-3664P equipped with advanced functions clears increasingly strict welding conditions. ■Features ・Suitable for high welding conditions. (Maxim...

3 models listed

250+ people viewing

■PSP-15 Passpo Since sparks, fumes, and working noise are less likely to be produced during welding, work can be done indoors. Perfect for sheet me...

Daido Kogyo Co., Ltd.

450+ people viewing

Last viewed: 19 hours ago

Reinforcement of various shapes and sizes can be manufactured by spot welding. For houses and buildings, it contributes to shortening the process a...

Daido Kogyo Co., Ltd.

490+ people viewing

Last viewed: 22 hours ago

■Features ・2.5KVA Maximum 2.5mm+2.5mm welding possible ・Since pressurization is done manually, there is no need to prepare incidental equipment. ...

Daido Kogyo Co., Ltd.

400+ people viewing

Last viewed: 1 day ago

■Features ・2.5KVA, 2.5mm+2.5mm welding possible ・Labor saving possible by pressurizing air

Daido Kogyo Co., Ltd.

400+ people viewing

Last viewed: 1 day ago

■Features ・16KVA, 3.0mm+3.0mm weldable ・Standard model of portable spot

THANK METAL

340+ people viewing

Last viewed: 1 day ago

■Spot welding machine The spot welder is used for can bottom welding and top cap and tab welding of cylindrical batteries. The control method is PW...

ART-HIKARI Co., Ltd.

410+ people viewing

Last viewed: 1 day ago

■DC spot welding machine ・Power supply capacity ranges from 50KVA to 300KVA class ・Plate thickness is about 0.1t to 1.6t ・Materials are general ...

ART-HIKARI Co., Ltd.

460+ people viewing

Last viewed: 21 hours ago

Improved operability with airless and servo motor pressurization ■Servo motor The electrode position can be set to any position within the stroke....

ART-HIKARI Co., Ltd.

480+ people viewing

Last viewed: 1 day ago

■Portable welding machine with built-in transformer ・Servo pressure method ・Power saving and excellent operability ・Lightweight and compact ■Fe...

ART-HIKARI Co., Ltd.

420+ people viewing

Last viewed: 1 day ago

■Single-sided spot welding machine ・Low pressure control one side spot ・Ideal for box-related items ・Power saving type ■High versatility ・Spat...

Daido Kogyo Co., Ltd.

240+ people viewing

Last viewed: 17 hours ago

■Features ・2.5KVA, 2.5mm+2.5mm welding possible ・Continuous welding possible by water cooling

Daido Kogyo Co., Ltd.

280+ people viewing

Last viewed: 17 hours ago

■Features ・23KVA, 4.0mm+4.0mm weldable ・Good operability with C gun

FURUKAWA ELECTRIC POWER SYSTEMS CO., LTD

320+ people viewing

Last viewed: 1 day ago

■Summary This is copper thermite welding equipment that firmly joins bond wires to railway rails. Copper thermite welding is a welding method that ...

FURUKAWA ELECTRIC POWER SYSTEMS CO., LTD

330+ people viewing

Last viewed: 13 hours ago

A portable welding gun with excellent operability. ■Applications ・Welding of automobile bodies ・Welding of steel furniture

FURUKAWA ELECTRIC POWER SYSTEMS CO., LTD

290+ people viewing

Last viewed: 1 day ago

A portable welding gun with excellent operability. ■Applications ・Welding of automobile bodies ・Welding of steel furniture

FURUKAWA ELECTRIC POWER SYSTEMS CO., LTD

490+ people viewing

Last viewed: 5 hours ago

A robot gun driven by a servo motor that contributes to improving welding quality, improving the working environment, and simplifying equipment. ■...

FURUKAWA ELECTRIC POWER SYSTEMS CO., LTD

390+ people viewing

Last viewed: 5 hours ago

A robot gun driven by a servo motor that contributes to improving welding quality, improving the working environment, and simplifying equipment. ■...

Maruka Corporation

340+ people viewing

Last viewed: 5 hours ago

■Features This is a next-generation spot welding robot with a hollow arm structure. The cables used for the welding gun are built-in, increasing th...

Maruka Corporation

300+ people viewing

Last viewed: 5 hours ago

■Features The definitive spot welding robot. In pursuit of acceleration and vibration damping, we have achieved a 30% reduction in cycle time (comp...