All Categories

History

This section provides an overview for contour machines as well as their applications and principles. Also, please take a look at the list of 19 contour machine manufacturers and their company rankings. Here are the top-ranked contour machine companies as of July, 2025: 1.DoAll Saws, 2.Foamcraft, Inc., 3.Kewell Converters Ltd.

Table of Contents

A contour machine is a machine tool for cutting sheet metal and steel.

A contour machine is a machine tool for cutting sheet metal and steel.

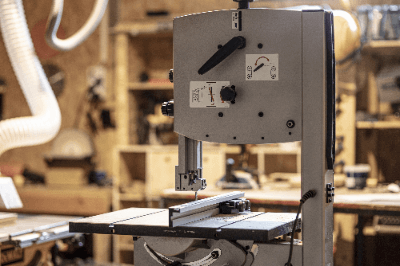

Also called a band saw, as the name implies, it can cut sheet metal and steel by rotating a band saw (a metal wheel with a saw blade).

The sheet metal or steel material is prescribed, and the workpiece is moved along the line and pressed against it as it is processed. A relatively small contour machine can process not only straight lines but also any desired shape, such as a rounded edge. Larger machines are designed to cut thicker steel materials, so they do not allow as much freedom in the cutting process.

Contour machines are used for cutting and processing metal materials. Here are some examples of use.

It is installed in many places where metal materials are handled daily, such as sheet metal, molds, and ironworking shops.

Roughing with contour machines reduces the amount of time and effort required for finishing work. Some large contour machines can be set up and operated by simply pushing a button, and the machine does not need to be operated until cutting is completed.

So, by using good contour machines, workability can be improved. In addition to large, installed machines, there are also small, portable types that can be brought to construction sites, and they are used in a variety of locations.

This section describes the types and features of contour machines (band saws).

The tabletop horizontal type is relatively small and can be carried around.

The horizontal tabletop type is relatively small and portable. They are used for cutting metal pipes, plates, L-shaped angles, H steel, etc. at construction sites. However, it is not possible to cut any shape at will. It is possible to cut in straight lines and at set angles.

The tabletop vertical type is used for cutting relatively soft materials such as wood and aluminum. Since the workpiece is pressed against the blade for cutting, it can be cut into any desired shape.

The installation type is mainly used in manufacturing and other places where metal materials are handled. There are two types of installed types, horizontal and vertical, and it is necessary to select the type to use depending on whether you want to cut large steel materials or sheet metal, or relatively thin steel materials automatically, into desired shapes.

The portable type is useful for materials that need to be cut on the spot or in high places. They are generally rechargeable, cordless, and stress-free. However, the blade must be applied at a certain angle or the band saw may break. While the flexibility is high, the frequency of band saw breakage tends to be higher than with other types.

*Including some distributors, etc.

Sort by Features

Sort by Area

Matteuzzi Srl, founded in 1956 and headquartered near Bologna, Italy, is a manufacturer of machinery and equipment for the tire and retreading industries. Its product portfolio comprises machines for tire production, complete tire retreading plants, precured tread finishing machines, inspection and testing machines, and trimming machines. These offerings cater to manufacturers of new tires and tire retreaders across various sectors, including cars, light trucks, trucks, earthmovers, and aircraft. In 1989, the company introduced the first computerized buffing machine, the RAS 90 DC buffing machine, which uses computerized controls to precisely and uniformly remove the old tread, ensuring a smooth and even surface.

Baumer of America Inc., established in 1979 and headquartered in New Jersey, USA, is a supplier that specializes in machines and plants for the foam industry, including foam cutting machines. The company provides cutting machinery and tools including blades, saws, scissor lift tables, block printing devices, and more. It also offers advice and consultation, from single foam cutting machines to complete plants. Its products offer same-day shipping with no additional charges, miniature sensors and flat designs for narrow machine designs, and sensors that meet high hygienic requirements. It serves various industries, including construction, furniture, automotive, and packaging.

ZEISS Microscopy, established in Jena, Germany, in 1846 is a manufacturer of optics and optoelectronics used in Precision Mechanics, Binoculars, Microscopy, and Eyeglass Lenses. Their product portfolio includes precision optics, such as lenses, mirrors, and prisms, laser mirrors used in laser cutting, and medical devices, optoelectronic devices and Coatings and Thin Films. The company also provides solutions including industrial quality, microscopy research, project simulation, sample testing and product development. The company also offers customer services that include support, custom research projects and customized services.

AMADA MACHINERY CO., LTD., established in 1937 and headquartered in Kanagawa, Japan, is a leading manufacturer and provider of cutting-edge metalworking machinery. The company specializes in developing, manufacturing, and selling metal cutting machines, grinding machines, shearing machines, deburring machines, general-purpose machines, band saw blades, and cutting tools. With strong innovation, AMADA MACHINERY serves diverse industries globally. Led by Representative Director and President Yasuhiro Kawashita, the company's dedicated team of 581 employees ensures customer satisfaction and continuous improvement.

Dongguan Hengsheng Import & Export Co., Ltd, founded in 2000 in Dongguan, China, is a manufacturer of foam production machinery. The company offers numerous foam machines, including foam cutting machines, laminators, foam shredders, and foam compressors. It holds ISO 9001:2000 and CE certifications, and the products offer numerous benefits, such as increased efficiency in foam manufacturing processes, precise cutting and shaping capabilities, and reduced material waste. Its foam manufacturing machines find applications in various industries, including packaging, furniture production, and automotive manufacturing.

Kewell Converters Ltd, established in 1971 and based in Edenbridge, England, United Kingdom, is a manufacturer of foam converter and fabricator equipment. The company specializes in manufacturing a broad line of foam-based products, including foam packaging, foam gaskets and seals, protective foam inserts, and acoustic insulation solutions. It holds ISO 9001 and ISO 14001 certifications, and the products offer benefits such as cushioning, impact resistance, thermal insulation, and sound absorption. These qualities make them important in various industries, including automotive, electronics, healthcare, and construction.

Sunkist Chemical Machinery Ltd, established in 1979 and based in Taoyuan City, Taiwan, is a manufacturer of polyurethane foam making machines. The company’s product portfolio includes a broad range of machinery and equipment, such as cutting, foaming, post-conversion, and laminating machines for producing polyurethane foam, serving the needs of various industries. It holds ISO 9001 certification, and its advanced machines enable efficient and precise polyurethane foam production, finding applications in industries such as furniture manufacturing, automotive, insulation, and construction.

Shanghai Gaohe Imp. and Exp. Co., Ltd, established in 2006 and based in Shanghai, China, is a manufacturer of textile machinery and components. The company’s product range includes braiding machines, tipping machines, winding machines, braiding machine spindles, and motors. It holds ISO 9001, CE, and R&TTE certifications for the stability and performance of the equipment, and its precision machines find applications in various industries, such as textile manufacturing, apparel, and cordage production, enabling efficient and advanced-quality production processes in the textile industry.

QS METROLOGY PVT. LTD, established in 1996 in Gurugram, India, is a manufacturer of a broad range of precision measuring and testing equipment. The company offers a comprehensive product lineup, including welding inspection systems, surface roughness testers, microhardness testers, video measuring systems, and metallurgical image analyzers. It holds ISO 9001:2015 certification, and the advanced measurement and testing instruments play an essential role in industries such as manufacturing, automotive, aerospace, and research, facilitating quality control, process optimization, and product development.

Unimetro Precision Machinery Co., Ltd. is a manufacturer of metrology products that was established in 2007 and headquartered in Dongguan, China. The company produces several categories of metrology products such as Vision Measurement Machines, 3D Coordinate Measuring Machines, Tool Inspection Systems and Image Dimension Measurement. Unimetro’s products include circuit boards, electronic components, plastic/rubber products, stamping parts, clocks and watches as well as connectors, touch screen testing, and bottle blank testing. The company also offers multiple services, including OEM or ODM support, remote online support, on-site installation, technical training, and metrology consulting services for manufacturers or dealers of metrology worldwide.

Tecnodinamica, founded in 1981 and headquartered in Veneto, Italy, is a manufacturer of industrial automation products. The company specializes in unique machines and automation solutions for the Expanded Polystyrene (EPS) industry, and its product portfolio includes EPS cutting lines, shape molding machines, block molding machines, and recycling systems. With ISO 9001 certification, it offers stable and durable equipment that offers benefits such as increased productivity, energy efficiency, and reduced material waste. Its machines find applications in various industries, including construction, packaging, and automotive for EPS production and processing.

Guiyang Xintian OETECH Co., Ltd, founded in 1966 and situated in Guiyang, China, is a manufacturer of precision optical measurement instruments. The company specializes in crafting a broad line of advanced products, including optical measuring machines, gauge block comparators, microscopes, vision measuring systems, and laser scanning systems. It has obtained ISO 9001:2015 certification, and the products offer numerous advantages, including robust accuracy, repeatability, and efficiency, making them important equipment for industries such as aerospace, automotive, electronics, and medical devices for measurement and inspection needs.

Chotest Technology Inc., founded in 2005, is a manufacturer of precision measuring instruments headquartered in Shenzhen, China. The company offers a range of high-precision measuring equipment, including White Light Interferometer SuperView W1, Laser Tracker GT series, universal length measuring machines, laser interferometer SJ6000, and profilometers SJ5700 series. Its products are manufactured in accordance with ISO9001 and 6S standards, ensuring quality products for its customers. The company's precision measuring equipment is used in various industries, including government metrology and quality inspection agencies, automotive, aerospace, and machinery. Its instruments are employed for accurate measurements in quality control and industrial applications.

Dongguan Sirui Machinery Manufacturing Co., Ltd, established in 2004 and located in Guangdong, China, is a manufacturer of foam and sponge manufacturing machines. The company specializes in the production of sponge machines, foam machines, and related accessories. It holds ISO 9001 and CE certifications, and the products offer several advantages, including enhanced production efficiency, precise manufacturing capabilities, and reduced material waste. Its machines find applications across various industries, such as upholstery, automotive, packaging, and construction, helping businesses maintain the production processes and improve the quality of foam and sponge products.

International Equipments, established in 1998 and headquartered in Mumbai, Maharashtra, India, is a pioneering manufacturer, supplier, and exporter of Material Testing Equipment. The company's product range includes Vicat Softening Point Apparatus, Tensile Testing Machine, and COF Testers, catering to industries like packaging, automotive, and electronics. Serving companies worldwide, they offer comprehensive testing solutions. With a strong devotion to quality and creativity, it aims to the forefront in material and component testing. Besides, the company’s ISO 9001:2015 certification reflects its passion for brilliance.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Shanghai Gaohe Imp. and Exp. Co.,Ltd |

20.0%

|

| 2 | Tecnodinamica |

20.0%

|

| 3 | DoAll Saws |

20.0%

|

| 4 | Foamcraft, Inc. |

10.0%

|

| 5 | Kewell Converters Ltd |

10.0%

|

| 6 | Matteuzzi |

10.0%

|

| 7 | ZEISS Microscopy |

10.0%

|

Derivation Method

The ranking is calculated based on the click share within the contour machine page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

China

China

|

4 | 26.7% |

United States of America

United States of America

|

2 | 13.3% |

Italy

Italy

|

2 | 13.3% |

India

India

|

2 | 13.3% |

Germany

Germany

|

1 | 6.7% |

| Deutschland | 1 | 6.7% |

Japan

Japan

|

1 | 6.7% |

United Kingdom

United Kingdom

|

1 | 6.7% |

Taiwan

Taiwan

|

1 | 6.7% |

59 products found

59 products

Tynatec Co., Ltd.

260+ people viewing

Last viewed: 1 day ago

■Simple wire mechanism Approximately 200m of molybdenum wire is wound around a wire winding drum and the same wire can be used repeatedly for a lon...

Kato Saw Co., Ltd.

220+ people viewing

Last viewed: 1 day ago

■Summary All widths from 2 inches to 8 inches can be made new and sharpened. We can meet all your specifications, such as cutting hard wood, cuttin...

Luxo Co., Ltd.

460+ people viewing

Last viewed: 18 hours ago

■Various shapes can be cut freely. This is a standard contour machine that is said to be necessary for every factory. We have a wide selection of r...

Tynatec Co., Ltd.

250+ people viewing

Last viewed: 17 hours ago

■Simple wire mechanism Approximately 200m of molybdenum wire is wound around a wire winding drum and the same wire can be used repeatedly for a lon...

Luxo Co., Ltd.

290+ people viewing

Last viewed: 6 hours ago

■Various shapes can be cut freely. This is a standard contour machine that is said to be necessary for every factory. We have a wide selection of r...

Tynatec Co., Ltd.

220+ people viewing

Last viewed: 1 day ago

■Simple wire mechanism Approximately 200m of molybdenum wire is wound around a wire winding drum and the same wire can be used repeatedly for a lon...

Luxo Co., Ltd.

390+ people viewing

Last viewed: 4 hours ago

■Various shapes can be cut freely. This is a standard contour machine that is said to be necessary for every factory. We have a wide selection of r...

Tynatec Co., Ltd.

190+ people viewing

Last viewed: 1 day ago

■Simple wire mechanism Approximately 200m of molybdenum wire is wound around a wire winding drum and the same wire can be used repeatedly for a lon...

Luxo Co., Ltd.

370+ people viewing

Last viewed: 1 day ago

■More precise, more efficient, direct automatic cutting series. This is the current mainstream contour machine that retains the features of the L s...

Luxo Co., Ltd.

370+ people viewing

Last viewed: 4 hours ago

■More precise, more efficient, direct automatic cutting series. This is the current mainstream contour machine that retains the features of the L s...

Daido Kogyo Co., Ltd.

190+ people viewing

Last viewed: 8 hours ago

A band saw cutting machine that can cut at both angles. With one machine, you can perform both bundle cutting and angle cutting. ■Features - Compa...

Luxo Co., Ltd.

370+ people viewing

Last viewed: 12 hours ago

■More precise, more efficient, direct automatic cutting series. This is the current mainstream contour machine that retains the features of the L s...

Taiyo Mold Supplies Co., Ltd.

450+ people viewing

Last viewed: 7 hours ago

For all cutting work. Smallest and lightest. It's cordless so it's easy to use X-BAND was created by Scott, the president of Stout, who used to be...

Luxo Co., Ltd.

290+ people viewing

Last viewed: 16 hours ago

■Cutting-edge electronics equipped with all functions The fully automatic band saw machine AZ series brings together Luxo's advanced technology. El...

Marunaka Iron Works Co., Ltd.

270+ people viewing

Last viewed: 12 hours ago

Equipped with variable speed and automatic lifting device that allows you to freely select the feeding speed according to the thickness and conditi...

Marunaka Iron Works Co., Ltd.

260+ people viewing

Last viewed: 12 hours ago

■Features - Equipped with a saw tension detection device, and has a safety design that prevents operation when the saw is loose. - You can visually...

Yagyu Shokai Co., Ltd.

250+ people viewing

Last viewed: 5 hours ago

■Features - Adopts a new high-rigidity aluminum frame to prevent blades from coming off and slipping. ・Speed can be adjusted according to the ma...

Yagyu Shokai Co., Ltd.

280+ people viewing

Last viewed: 8 hours ago

■Features - Suitable for cutting iron, aluminum, brass, copper, plastic, etc. ・The table can be tilted up to 45°. -Blade feed speed is steplessly ...

Luxo Co., Ltd.

310+ people viewing

Last viewed: 1 day ago

■Cutting-edge electronics equipped with all functions The fully automatic band saw machine AZ series brings together Luxo's advanced technology. El...

Illy Co., Ltd.

310+ people viewing

Last viewed: 10 hours ago

■Features ・Saw blade Speed adjustment from 0.3m/s to 0.8m/s (50Hz) allows safe and accurate cutting of carbon steel and non-ferrous metals. - Ha...

Illy Co., Ltd.

270+ people viewing

Last viewed: 1 day ago

■Features - The work table can be tilted up to 45 degrees, making diagonal cutting of materials easy. - A miter gauge and fence (parallel ruler) ar...

Illy Co., Ltd.

240+ people viewing

Last viewed: 1 day ago

■Features - Dial-type stepless saw blade speed adjustment allows cutting according to the hardness of materials such as carbon steel and non-ferrou...

Illy Co., Ltd.

290+ people viewing

Last viewed: 1 day ago

■Features - The work table can be tilted up to 45 degrees, making diagonal cutting of materials easy. - A miter gauge and fence (parallel ruler) ar...

Tool System Co., Ltd.

390+ people viewing

Last viewed: 20 hours ago

■Features ・Development type manufacturer specializing in band saws and hole saws. - We can solve all your cutting and drilling problems. ■Main ty...

4 models listed

Marto Co., Ltd.

190+ people viewing

Last viewed: 1 day ago

■Features You can cut the thread like this. ■Applications Aluminum, soft metal, wood, plastic, etc.

Marto Co., Ltd.

190+ people viewing

Last viewed: 2 hours ago

■Features This is a band saw type cutting machine. <Set example> ■Main body 1) Bander (MC-140) main unit: 1 unit 2) Diamond saw for bander: 1 piece

Winning Boar Co., Ltd.

190+ people viewing

Last viewed: 20 hours ago

■Features - Adopts a combination pitch, which is the mainstream in the world, where the saw blades are unevenly lined up. ・Uses the highest qualit...

Winning Boar Co., Ltd.

210+ people viewing

Last viewed: 15 hours ago

■Features - Adopts a combination pitch, which is the mainstream in the world, where the saw blades are unevenly lined up. ・Uses the highest qualit...