All Categories

History

This section provides an overview for glass cutting machinery as well as their applications and principles. Also, please take a look at the list of 7 glass cutting machinery manufacturers and their company rankings. Here are the top-ranked glass cutting machinery companies as of March, 2026: 1.Billco, 2.Intermac, 3.CMS Glass Machinery.

Table of Contents

Categories Related to Glass Cutting Machinery

Glass Cutting Machinery is a generic term for machines used for cutting glass.

Glass Cutting Machinery is a generic term for machines used for cutting glass.

Glass processing begins with the cutting of glass sheets, which are made in constant dimension, mainly in inches, to the required size, the original size.

Regular dimensions range from sub-loc boards (3ftx6ft = 36inches x 72 inches = 914mm x 1829mm), such as gypsum board or plywood, which are sold at home improvement stores and can be easily moved by hand, to ceiling clays, such as 96inches x 144inches = 2438mm x 3658mm), to sizes that can only be transported with an overhead crane.

The principle of glass cutting machinery is to first make a scratch on the surface and then cut that area. When making the scratch, the force applied to the cutter must be in one direction or the material glass will crack and cannot be cut cleanly.

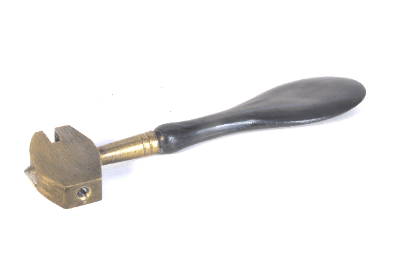

The cutting machinery or manual glass cutting machinery is designed to release oil from the cutting edge of the wheel cutter. This is to allow oil to enter the scratched surface so that the glass can be split along the scratches smoothly. If the scratches were broken without oil, the glass would break (a failure of cutting described as "running") instead of following the scratches made on the glass.

Glass cutting may be done manually with a tool called a glass cutter. In such cases, the quality of the process depends on the skill of the craftsman for the reasons mentioned above and the condition of the cut.

Glass cutting machinery is the first thing used in glass processing. After that, the glass is heated and shipped as a finished product.

The most important characteristic of glass material, which is its tendency to break easily, is used to deform it and apply it to a variety of products.

In this section, we mainly use architectural and industrial glass (thicknesses from 2 mm to 19 mm) as an example.

The general procedure for cutting glass is as follows:

1. Preparation for cutting

Place the glass cutting machinery on the cutting table and prepare for cutting by checking the horizontal right angle.

If cutting is performed under automatic control, control the machine on the computer to prevent unnecessary processing before cutting. If there is no difference between vertical and horizontal glass, such as transparent glass, it can be used efficiently. However, for patterned mold glass and other types of glass, vertical and horizontal use may or may not be possible, so careful consideration should be made before cutting. Once the cutting simulation and the calculation of the usability and loss ratio have been completed, the cutting process can proceed.

2. Scratching the glass surface

Cutting glass is more like breaking than cutting. The main component of glass is crystalline silicon oxide, but its molecular structure is amorphous crystal, not crystalline structure as typified by metals.

It has a property of irregular structural breakage, which is used to cut glass in reverse. The glass dimensions are aligned by scratching the surface and applying force to break the glass along the scratches. A rotating blade called a wheel cutter is used to make scratches on the glass surface.

3. Cutting

The scratched area is manually folded to cut the glass. When cutting by machine, the machine uses the same principle as an NC lathe. The wheel cutter head runs at the target coordinates in the X and Y directions, and the wheel cutter head runs at the exact dimensions to make scratches on the bare glass surface.

After the wheel cutter head runs, the operator breaks the glass. Since the table of the glass cutting machinery is equipped with a breaking platform that lifts the glass along the scratches that the wheel cutter head has run along, the operator can break the bare glass accurately by lifting only the scratched area.

The above cutting process method is used to take advantage of the breakable characteristics of glass.

*Including some distributors, etc.

Sort by Features

Sort by Area

Billco Manufacturing, established in 1948 and headquartered in Zelienople, Pennsylvania, is a manufacturer specializing in producing equipment tailored for the flat glass industry. Its machinery serves diverse sectors, including architectural, automotive, photovoltaic, and specialty applications. The company assists enterprises in discovering glass processing solutions, offering customized options such as washers, cutters, and various equipment for glass handling, insulating, laminating, loading, and storage. Typical products processed with its machinery encompass windows, doors, and touchscreens.

Intermac, founded in 1969, is an Italian manufacturer of machinery for converting materials to shining for all production processes. For different materials, the company provides categories such as BiesseWood, BiesseGlass, BiesseStone, and BiesseMateria. BiesseWodds has integrated wood machining lines and machines in the window and furniture sectors. BiesseGlass has glass processing machinery for the building, furniture, and automobile industries. BiesseStone stone processing equipment is used in the tombstone, building, and furniture sectors. The BiesseMateria category includes integrated machines and lines for milling plastic and composite materials.

Shandong Farin International Trade Co., Ltd., in Jinan City, Shandong Province, is a manufacturer of professional aluminium profile, UPVC, and metal processing machines and a seller of used equipment established in 2016. The metal processing machines include CNC angles steel towers, flanges, structure processing machines, and metal cutting machines. The glass machines are used for insulating, washing, cutting, polishing, and drilling. It also provides window machines for plastic extrusion, solar panel making, profiling, and hardware tools.

S. K. GLASS MACHINES INDIA PVT. LTD, founded in 1986, is a manufacturer, supplier, and exporter of glass processing machinery in Uttar Pradesh, India. The products include glass washing machines, bending kilns, automatic sheet loaders, straight-line glass beveling machines, and fabrication machines used for corner grinding, profile edging, sandblasting, and drilling. The company is ISO 9001:2008 certified, offers installation services, and exports the products to 13 countries such as South Africa, Pakistan, Kenya, Mauritius, and Cameron Malaysia.

Anhui Ruilong Glass Machinery Co., Ltd. has been a manufacturer of glass machinery since 2008 in Bengbu City, Anhui Province. The machines are used for glass cutting, microscope slide making, glass edging, brick or glass cutting, and automatic glass processing. The machinery also performs other glass transformations such as loading, drilling, washing, and drying glass. The company also provides accessories such as saw blades, drilling bits, CNC machine cutters, wheel holders, and carbide glass cutters used in electronics, electrical appliances, glass furniture, edging of buildings, and glassware.

CMS Glass Machinery is a manufacturer of glass machinery solutions since 1995 in Turkey. The company provides Glass Cutting Machines, Insulated Glass Production Machines, Glass Tempering Furnaces, and Laminated Glass Production Lines which have four various machine options. The Float Glass Production Line helps manufacturers of float glass by providing them with raw materials and Manual glass sealing extruders along with Automatic glass sealing robots too largely serve the glass industry.

Jinan Penn CNC Machine Co.,Ltd. is a manufacturer and distributor of CNC machines and related products that was established in Jinan, China in 2006. The company’s product portfolio includes laser machines, waterjet machines, and plasma machines. It also offers various CNC routers including multi-head, ATC, and mini models, along with technical support services such as installation and personnel training. The company’s products are commonly used within the woodworking, metalworking, and industrial manufacturing sectors.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Billco |

29.4%

|

| 2 | Intermac |

24.5%

|

| 3 | CMS Glass Machinery |

11.8%

|

| 4 | Shandong Farin International Trade Co.,ltd |

9.8%

|

| 5 | Jinan Penn CNC Machine Co.,Ltd. |

8.8%

|

| 6 | S. K. GLASS MACHINES INDIA PVT. LTD |

8.8%

|

| 7 | Anhui Ruilong Glass Machinery Co., Ltd |

6.9%

|

Derivation Method

The ranking is calculated based on the click share within the glass cutting machinery page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

China

China

|

3 | 42.9% |

United States of America

United States of America

|

1 | 14.3% |

Italy

Italy

|

1 | 14.3% |

India

India

|

1 | 14.3% |

Turkey

Turkey

|

1 | 14.3% |

73 products found

73 products

Arms System Co., Ltd.

570+ people viewing

Last viewed: 20 hours ago

■Summary This device is a device that manually cuts large glass substrates. Since the cutter is installed in two directions, vertical and horizonta...

Astellatech Co., Ltd.

320+ people viewing

Last viewed: 14 hours ago

■ Overview ・ Light plate glass can be easily cut accurately. ・ Ideal for creating a sample of cross section SEM. ・ Laser blade (for 0.05-2mm) is...

10 models listed

Sun Technical Co., Ltd.

430+ people viewing

When cutting laminated glass, etc., it has been difficult to cut materials with different hardness due to clogging of the interlayer film in the cu...

Astellatech Co., Ltd.

280+ people viewing

■ Overview It is an option for the baseboard for the experimental glass cut.

2 models listed

Miki Giken Co., Ltd.

260+ people viewing

■Dal splitting table Please use it as a set with a hammer. ■What is cemented carbide? It is a special sintered alloy that has a hardness second on...

Meyer Hearing Healthcare Co., Ltd.

300+ people viewing

Last viewed: 18 hours ago

Made of stainless steel, 10 pieces

Luxo Co., Ltd.

440+ people viewing

■Small body and compact, perfect for handcrafts and teaching materials The high performance of a diamond saw machine is packed into a compact body....

Marto Co., Ltd.

460+ people viewing

Last viewed: 12 hours ago

■Features This is a power cutter (MC-420) equipped with a handle and is a lower blade type cutting machine that allows you to easily feed and cut. ...

Arms System Co., Ltd.

340+ people viewing

■Features - Compatible with various glass substrate sizes ・The photo shows the specifications for glass width within 300mm. ・Device dimensions: W...

Arms System Co., Ltd.

340+ people viewing

■Summary This is a device that manually cuts large glass substrates. Since the cutter is installed in two directions, vertical and horizontal, it i...

Astellatech Co., Ltd.

250+ people viewing

Last viewed: 19 hours ago

■ Overview It is an option of a loupe for the position of the experimental glass cut.

4 models listed

Astellatech Co., Ltd.

280+ people viewing

■ Overview It is an option for a magnet substrate for experimental glass.

7 models listed

Iwashita Co., Ltd.

330+ people viewing

Last viewed: 1 day ago

■Series features Special machine tools and dedicated machines have the following two advantages. Improved products and cost reduction by reducing ...

Luxo Co., Ltd.

500+ people viewing

Last viewed: 1 day ago

■Small body and compact, perfect for handcrafts and teaching materials The high performance of a diamond saw machine is packed into a compact body....

Miki Giken Co., Ltd.

330+ people viewing

RS-1 will be shipped in units of 6 pieces. ■What is cemented carbide? It is a special sintered alloy that has a hardness second only to diamond an...

Astellatech Co., Ltd.

190+ people viewing

Last viewed: 1 hour ago

■ Overview It is an optional head for experimental glass.

8 models listed

Luxo Co., Ltd.

470+ people viewing

Last viewed: 1 day ago

■Small body and compact, perfect for handcrafts and teaching materials The high performance of a diamond saw machine is packed into a compact body....

Marto Co., Ltd.

390+ people viewing

Last viewed: 1 day ago

■Summary This is a large machine from the "Lab Cutter Series" that facilitates the cutting of large research samples in research and testing labora...

Marto Co., Ltd.

440+ people viewing

■Summary This is a compact three-axis movable general-purpose upper-blade cutting machine that can fit into the limited space of a laboratory, base...

Astellatech Co., Ltd.

250+ people viewing

■ Overview ・ It is a replacement blade for experimental glass. ・ The corresponding glass plate thickness is the value for blue plate glass. ・ Us...

8 models listed

Marto Co., Ltd.

680+ people viewing

Last viewed: 1 day ago

■Summary Cutting, which is the basis for making research samples in laboratories and laboratories, can be done easily without compromising the shar...

Luxo Co., Ltd.

390+ people viewing

Last viewed: 1 day ago

■Small body and compact, perfect for handcrafts and teaching materials The high performance of a diamond saw machine is packed into a compact body....

Luxo Co., Ltd.

510+ people viewing

Last viewed: 13 hours ago

■Automatic, high-speed cutting of all hard materials in straight lines We can handle all new materials such as ceramics, plate glass, scientific gl...

Marto Co., Ltd.

440+ people viewing

Last viewed: 13 hours ago

■Summary This is an upper blade type cutting machine suitable for free-hand cutting of irregularly shaped samples of other types. This is the main ...

Luxo Co., Ltd.

530+ people viewing

■Automatic, high-speed cutting of all hard materials in straight lines We can handle all new materials such as ceramics, plate glass, scientific gl...

Kosaka Laboratory Ltd.

280+ people viewing

■Features This is a fully automatic device that scribes the glass substrate supplied from the loader's cassette in the X and Y directions, turns it...

Luxo Co., Ltd.

560+ people viewing

Last viewed: 2 hours ago

■Automatic, high-speed cutting of all hard materials in straight lines We can handle all new materials such as ceramics, plate glass, scientific gl...

Marto Co., Ltd.

460+ people viewing

Last viewed: 40 minutes ago

■Features This is a lower blade type cutting machine with a wide work table that performs rough cutting of medium-sized samples such as rocks, glas...

Kosaka Laboratory Ltd.

240+ people viewing

■Features This is a device that accurately cuts scribed glass substrates into small substrates.

Kosaka Laboratory Ltd.

280+ people viewing

■Features This is a device that accurately cuts scribed glass substrates into small substrates.