All Categories

History

This section provides an overview for air blasters as well as their applications and principles. Also, please take a look at the list of 12 air blaster manufacturers and their company rankings. Here are the top-ranked air blaster companies as of February, 2026: 1.Airmatic Inc., 2.Composition Materials Co., Inc., 3.CRW Finishing, Inc..

Table of Contents

Categories Related to Air Blasters

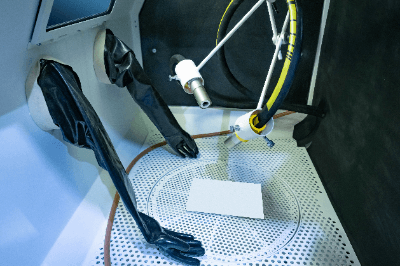

Air blasting refers to a technique and equipment for blasting abrasive materials by blowing them with a compressed air-produced compressor.

There are three types of air blasting systems: direct pressure type, blower type, and suction type (gravity type), and they are used according to the material and shape of the workpiece.

Similarly, there are variations in abrasive materials, and the most suitable one is selected according to the object and the intended use. Generally, the suction type is the most commonly used equipment.

Air blasting can be used to process a variety of materials, including metal, resin, glass, stone, and wood. Depending on the material and processing application, abrasive materials with different hardness and shapes are used. Various materials are used for abrasives, including metal, glass, and nylon.

The main processes of air blasting are as follows:

Air blasting is also used for peening to increase the strength and stress of metal surfaces by tapping them.

Air blasting uses compressed air from a compressor to inject abrasive material onto an object for various types of processing.

Air blasting can be divided into three main types: direct pressure type, suction type, and blower type.

The direct pressure method is the fastest of the three.

The suction method is also called the gravity method. The abrasive is stored inside the machine gun, where compressed air sucks the abrasive and injects it through the nozzle.

The compressed air and the flow of abrasive from the hopper utilize gravity, which is why it is also called the "gravity type.

Using the same principle as an air gun, this is the most commonly used method of air blasting, but the force of the jet is less powerful than the direct pressure type.

The blower type blows the abrasive material with air from a blower fan. Since a compressor is not required, the cost of purchasing a system can be reduced.

However, it is not suitable for processing hard materials due to its low power.

The word "blast" means "a strong blow," but several blast processes depend on the spraying method and type of abrasive. Among these, air blasting and shot blasting are the most common.

The difference is that air blasting blows abrasives with compressed air, while shot blasting uses the powerful centrifugal force generated by an impeller rotating at high speed with a motor.

Shot blasting is more powerful in terms of spraying power and is suitable for rough surface grinding, such as for thermal spraying surface preparation or for removing stubborn rust. On the other hand, air blasting can produce a softer output by adjusting the type and particle size of the abrasive, making air blasting the method of choice for finishing work that requires precision.

Air blasting is also known as "sandblasting" because it uses the force of air to blow a granular abrasive onto the mating material.

The type of material as fine as that "sand" is mainly low specific gravity materials, such as resin and glass (silica sand). Even if abrasive metal materials are used, they are limited to light metals such as alumina.

This is because lightweight materials mix better and can be sprayed more effectively due to the characteristics of air blasting, in which air is mixed with air and sprayed.

On the other hand, shot blasting is used to use high-specific gravity materials, such as stainless steel and zinc, as abrasive materials.

Deburring is one of the processes in which air blasting, which uses low specific gravity, and fine-grained abrasives, excels. Since the treatment is limited to the tip of the nozzle, it is possible to target only the burrs that occur in the details of even complex-shaped mating materials, contributing to quality improvement and labor savings.

In addition to deburring metal gears, this system can also be used for delicate deburring that improves machinability while providing an appropriate radius, like the edge of a tool. By reducing the amount of heat generated by air blasting, deburring can be performed without damaging thermoplastic and thermosetting resins.

*Including some distributors, etc.

Sort by Features

Sort by Area

Composition Materials Co., Inc., founded in 1923 and located in Milford, Connecticut, is a supplier and manufacturer of abrasives, fillers, extenders, blast media, and all-natural exfoliation ingredients. The company’s broad range of products includes plastic media, biofilters, recycled fillers, cosmetics, and abrasive blasting. These products find specific applications in industries such as surface finishing, cleaning, surface preparation, cosmetics, and environmental solutions. Composition Materials Co., Inc.'s offerings play essential roles in enhancing surfaces, improving material properties, facilitating cleaning processes, and being used in an array of industrial and commercial applications.

CRW Finishing, Inc. was founded in 1977 and is located in Addison, Illinois is a manufacturer and trader of metal finishing equipment. The company offers an array of products including wastewater treatment system supplies, centrifugal disk finishing equipment, and abrasive belt and buffing equipment. It extends services like surface refinement, decorative finishing, and tube polishing. These products find applications in sewage and water treatment plants, welding and woodwork facilities, and manufacturing of automobiles.

Omni Finishing, founded in 1986, is a distributor in the surface finishing and coating industry, headquartered in Ivyland, Pennsylvania, USA. The company is WBNEC certified and provides a comprehensive range of finishing equipment, parts, supplies, abrasive media, and compounds. Their team consists of experts who can assist in developing or fine-tuning surface finishing systems and processes. They also offer customized training for their all equipment, complimentary consulting services, sample processing, and equipment service and repair. Their diverse range of products include Air Blast Cabinets, Wheel Blast, Vibratory Finishing, Wet Blast, Portables, and Blast Rooms among others.

AIRMATIC was founded in Philadelphia in 1944. AIRMATIC serves a many industries including cement and concrete, oil, gas, energy, biomass, chemical products, feed & grain, food manufacturing, glass & ceramics, and clay. For these industries, AIRMATIC provides installation, maintenance, fabrication, silo cleaning, inspection, and repair, as well as repair and rebuilding of power tools. AIRMATIC also has an extensive lineup of products for sale including air cannons, automatic lubrication systems, belt conveyor components, flow detectors, finishing equipment, safety equipment, industrial vibrators, railcar openers and unloading equipment, rebar tools, valves and actuators, and mechanical force exciters.

Nicchu CO., Ltd, established in 1959 and based in Tokyo, Japan, is a manufacturer and supplier of surface processing equipment. The company's product range includes portable abrasive blasting machines, blast cabinets, shot peening machines, and dust collectors. These products play a pivotal role in surface treatment, cleaning, and enhancing material properties. They serve sectors like automotive, construction, electronics, and shipbuilding. Beyond equipment manufacturing, the company offers machinery maintenance, equipment rental, and technical support to its customers.

Tega Industries Limited., established in 1976, and headquartered in Kolkata, India, is a manufacturer of mill liners, conveyor components, and hydro cyclones for mining, mineral processing, and material handling industries. Its flagship mill liners products include DynaSteel (composite mill liners), DynaPrime (combination liner), DynaWear (rubber mill liner), and DynaPulp (pulp discharger). Presently, the company has manufacturing hubs in India, Australia, Chile, and South Africa and offers 55 products in 70 countries and partners with over 700 customers.

DR Air Boost (P) Ltd., established in 1989 and headquartered in Faridabad, Haryana, India, is a manufacturer of air boosting products for various needs. The product offerings are engineered to enhance ventilation systems, fostering improved indoor air quality, energy efficiency, and regulated airflow. The products find applications across sectors including commercial, healthcare, industrial, and residential. The range comprises specialized systems designed to optimize air circulation, such as air blasters, air receivers, valves, H T nozzles, and control panel boxes. The products are important in sustaining conducive environments in various industries by facilitating optimum air exchange, temperature regulation, and resource conservation.

Kaveri Ultra Polymers P Ltd., established in 1984, and headquartered in India, is a manufacturer of bulk material handling equipment, including polyurethane linings, pneumatic air blasters, and conveyor care products. It also promotes Soil-Tech technology, Dust-Tech, and Poly Seal. Its conveyor care products such as belt scrapers, skirt board sealing systems, and belt tracking systems, etc. These technologies use polymer materials for road stabilization, dust control for haul roads, and waterproof liner for reservoir and holding tanks. Industries the company serves are cement, coal or power, mining, etc. The company also provides installation or commissioning, periodic and annual maintenance services.

Air Boost Private Limited, established in 1992, and headquartered in India, is a manufacturer of air blasters, air receivers, and related spares. The company's products include reciprocating compressors (ranging from 0,15 HP to 15 HP and pressure up to 12 kg/cm2), modified pistons, nozzles, pneumatic panel boxes, etc.It introduces pistons with savers, which save the customer from buying new pistons in the future. It serves over 300 heavy industries in over 40 countries, including cement, thermal power, chemical, Agro, etc.

Thejo Engineering Limited, founded in 1974 and headquartered in Chennai, Tamil Nadu, India, is a manufacturer and service supplier in the fields of bulk material handling, mineral processing, and corrosion protection. The company offers various services, including conveyor belt services, transfer point services, and abrasion and wear services, aimed at optimizing the life cycle of wear parts. Its product range includes the TEZ mechanical splice system for conveyor belts, synthetic adhesives, as well as earthmoving equipment designed for construction and excavation purposes.

Jamieson Equipment Company (JEC) was founded in 1982 and located in the state of Georgia. JEC serves infrastructure-related industries including pavement with concrete, aggregate, and asphalt, chemicals, sewage and waste management, and agriculture and food. JEC sells, installs, retrofits, repairs, and offers training and troubleshooting for a range of components and tools from simple fittings to motion sensors to electronics to valves to actuators, cranes, mixers, silos, hoppers, and plants.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Airmatic Inc. |

14.7%

|

| 2 | Composition Materials Co., Inc. |

13.2%

|

| 3 | CRW Finishing, Inc. |

12.5%

|

| 4 | Tega Industries Limited. |

11.8%

|

| 5 | DR Air Boost (P) Ltd. |

10.3%

|

| 6 | Kaveri Ultra Polymers P Ltd. |

8.8%

|

| 7 | Omni Finishing |

8.8%

|

| 8 | Air Boost Private Limited |

7.4%

|

| 9 | Jamieson Equipment Co., Inc. |

7.4%

|

| 10 | Thejo Engineering Limited |

2.2%

|

Derivation Method

The ranking is calculated based on the click share within the air blaster page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

4 | 57.1% |

India

India

|

2 | 28.6% |

Japan

Japan

|

1 | 14.3% |

98 products found

98 products

Yutou Co., Ltd.

470+ people viewing

Last viewed: 14 hours ago

Sand (SAND) means "sand", and blast (blast) means "spray". In other words, sandblasting refers to spraying sand and processing. In addition, a devi...

Illy Co., Ltd.

510+ people viewing

Last viewed: 14 hours ago

■Features - Handy type allows for easy blasting work. ・Since blast sand is collected, clean work is possible. ・Sand can be collected efficiently ...

Illy Co., Ltd.

490+ people viewing

Last viewed: 14 hours ago

■Features ・Side door type makes it easy to put in and take out parts - The cabinet is a large type, and the door has a side door that makes it eas...

Illy Co., Ltd.

470+ people viewing

Last viewed: 7 hours ago

■Features - The foot switch allows you to use both hands freely, allowing you to sand small items. - There is a middle tier of mesh inside the cabi...

Illy Co., Ltd.

450+ people viewing

Last viewed: 11 hours ago

■Features Handy type allows for easy soda blasting work.

Illy Co., Ltd.

500+ people viewing

Last viewed: 14 hours ago

■Features ・Continuous soda blasting work is possible with a large capacity tank. - Excellent workability as the amount of soda discharged can be a...

Illy Co., Ltd.

410+ people viewing

Last viewed: 14 hours ago

■Features ・Continuous soda blasting work is possible with a large capacity tank. - Excellent workability as the amount of soda discharged can be a...

TABATA INDUSTRIAL MACHINERY CO., LTD.

470+ people viewing

Last viewed: 8 hours ago

Clean Shot" is a product originally developed by Tabata Machine Industry, which consists of a carbonization furnace and an air blast device. Clean ...

3 models listed

Sanoyas engineering Co., Ltd.

270+ people viewing

Last viewed: 14 hours ago

■ Energy saving The spraying pressure is 30-60 kpa from 1/8 to 1/10 compared to the compressor type (suction method), so the electricity fee is gre...

6 models listed

MEIJI AIR COMPRESSOR MFG.CO.,LTD.

430+ people viewing

Last viewed: 7 hours ago

A complete lineup that allows you to work easily with simple operations anytime, anywhere. ■Product overview ・Water is blocked by an expansion an...

Izumiya Machinery Co., Ltd.

600+ people viewing

Last viewed: 14 hours ago

STC low -pressure blasting technology with 25 years of experience Included transmitted devices and transportation devices, polishing devices, clean...

Kansai Special Machinery Co., Ltd.

790+ people viewing

Last viewed: 14 hours ago

This is a blasting machine that can be used for various purposes. ■Summary ・Applications: Carving processing of glass, plastic, stone, wood, etc....

NICCHU Co., Ltd.

400+ people viewing

Last viewed: 14 hours ago

■Summary The abrasive material is injected using compressed air produced by a compressor. There are three types of air blast: ``direct pressure ty...

Osawa Co., Ltd.

200+ people viewing

Last viewed: 14 hours ago

Wonder Gun Air Blast Type W301-ES-22 (without hose joint) is a modification of W301-ES-22 into a mounting type. It can suck up and spray abrasive m...

NICCHU Co., Ltd.

460+ people viewing

Last viewed: 20 hours ago

■Summary The abrasive material is injected using compressed air produced by a compressor. There are three types of air blast: ``direct pressure ty...

Osawa Co., Ltd.

290+ people viewing

Last viewed: 14 hours ago

Wonder Gun Air Blast Type W301-ES-26 can suck up and spray abrasive materials and liquids. It can perform rust removal, deburring, and surface trea...

NICCHU Co., Ltd.

340+ people viewing

Last viewed: 14 hours ago

■Summary The abrasive material is injected using compressed air produced by a compressor. There are three types of air blast: ``direct pressure ty...

Osawa Co., Ltd.

230+ people viewing

Last viewed: 14 hours ago

Wonder Gun Air Blast Type W301-ES-26-LC is a modified version of W301-ES-26 into a mounting type. It can suck up and spray abrasive materials and l...

NICCHU Co., Ltd.

430+ people viewing

Last viewed: 14 hours ago

■Summary The abrasive material is injected using compressed air produced by a compressor. There are three types of air blast: ``direct pressure ty...

Osawa Co., Ltd.

200+ people viewing

Last viewed: 5 hours ago

Wonder Gun Air Blast Type W301-ES-26-TC is a modified version of W301-ES-26 into a mounting type. It can suck up and spray abrasive materials and l...

NICCHU Co., Ltd.

320+ people viewing

Last viewed: 14 hours ago

■Summary The abrasive material is injected using compressed air produced by a compressor. There are three types of air blast: ``direct pressure ty...

Osawa Co., Ltd.

210+ people viewing

Last viewed: 11 hours ago

Wonder Gun Air Blast Type W301-ES-26-LH is a modified version of W301-ES-26 into a mounting type. It can suck up and spray abrasive materials and l...

NICCHU Co., Ltd.

380+ people viewing

Last viewed: 14 hours ago

■Summary The abrasive material is injected using compressed air produced by a compressor. There are three types of air blast: ``direct pressure ty...

Osawa Co., Ltd.

190+ people viewing

Last viewed: 14 hours ago

Wonder Gun Air Blast Type W301-ES-26-TH is a modified version of W301-ES-26 into a mounting type. It can suck up and spray abrasive materials and l...

NICCHU Co., Ltd.

420+ people viewing

Last viewed: 14 hours ago

■Summary The abrasive material is injected using compressed air produced by a compressor. There are three types of air blast: ``direct pressure ty...

Osawa Co., Ltd.

220+ people viewing

Last viewed: 14 hours ago

Wonder Gun Air Blast Type W301-ES-26 (without hose joint) is a modified version of W301-ES-26 into a mounting type. It can suck up and spray abrasi...

NICCHU Co., Ltd.

390+ people viewing

Last viewed: 14 hours ago

■Summary The abrasive material is injected using compressed air produced by a compressor. There are three types of air blast: ``direct pressure ty...

Osawa Co., Ltd.

180+ people viewing

Last viewed: 14 hours ago

Wonder Gun Air Blast Type W301-ES-28 can suck up and spray abrasive materials and liquids. It can perform rust removal, deburring, and surface trea...

NICCHU Co., Ltd.

300+ people viewing

Last viewed: 6 hours ago

■Summary The abrasive material is injected using compressed air produced by a compressor. There are three types of air blast: ``direct pressure ty...

NICCHU Co., Ltd.

300+ people viewing

Last viewed: 14 hours ago

■Summary The abrasive material is injected using compressed air produced by a compressor. There are three types of air blast: ``direct pressure ty...