All Categories

History

This section provides an overview for coating process equipment as well as their applications and principles. Also, please take a look at the list of 17 coating process equipment manufacturers and their company rankings. Here are the top-ranked coating process equipment companies as of March, 2026: 1.Musashi Engineering, Inc., 2.Wagner SprayTech Corp.,, 3.Valco Melton.

Table of Contents

Categories Related to Coating Process Equipment

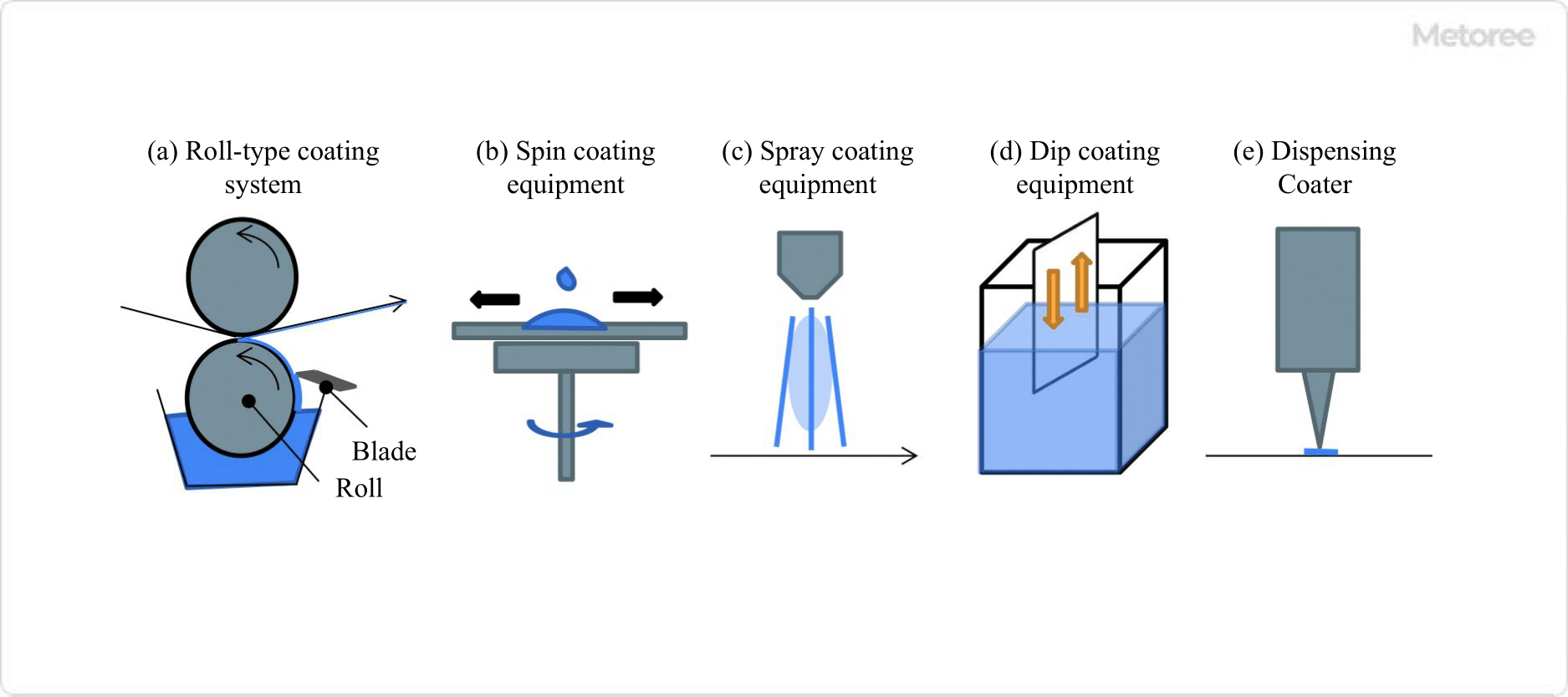

Figure 1. Types of Coating Equipment

Coating process equipment is used to apply chemicals to products or materials.

Coating process equipment generally uses various coating methods such as roll coaters, spin coaters, dip coaters, spray coaters, and dispense coaters, depending on the shape of the object to be coated, the chemical to be coated, and the purpose of the coating.

In recent years, coating process equipment has evolved dramatically along with improvements in coating technology, as precision coating accuracy is required in industrial fields such as semiconductor manufacturing, flat panel display (FPD) manufacturing, solar cell and rechargeable battery manufacturing.

Coating equipment is used to apply coating liquids to objects in a variety of manufacturing processes, such as in the semiconductor field and secondary battery manufacturing. Spin coating process equipment is often used to apply photoresist in the photolithography process in the semiconductor and flat panel display (FPD) manufacturing fields, which require particularly thin, high-performance, high-density devices such as PCs, LCD TVs, smart phones, and tablets.

For functional films and sheet products used in rechargeable batteries, solar cells, automotive parts, housing construction materials, textiles, medical care, etc., roll, spray, and dispense coating process equipment are used to apply chemicals such as sealants, adhesives, and electrode materials.

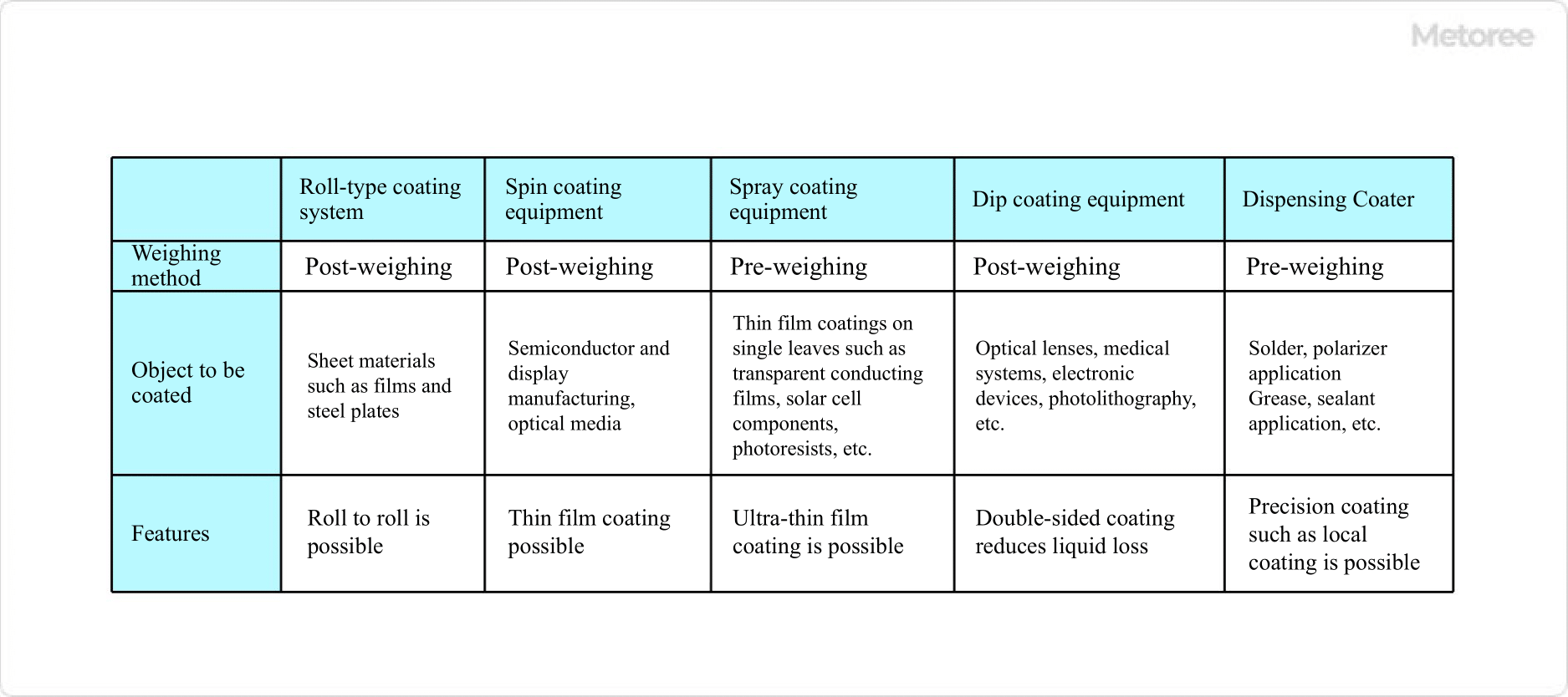

Figure 2. Features of Coating Equipment

Coating process equipment is used to apply materials such as correspondence and chemicals to various production materials. They can be broadly classified into roll, spin, spray, and dispense dispensing systems.

Roll coating process equipment is generally used for coating relatively thin and flat materials such as films and sheets.

Various coating methods are used depending on the nature and viscosity of the chemical to be applied and the film thickness to be applied, such as gravure coaters and reverse coaters that use the rotation of a roller in contact with a liquid reservoir of the chemical to be applied and the winding rotation of the film or sheet material.

Roll-to-roll coating is possible, and this method is most suited for high-speed coating. The characteristic feature of these methods is that a bead is formed between the coating liquid and the object to be coated, and the object to be coated or both the object to be coated and the roll are moved or rotated to apply shear force to the coating liquid and thinly apply it.

Stabilizing this bead is essential for high-quality coating.

Spin coating process equipment is used in the photolithography process in the semiconductor and flat panel display (FPD) manufacturing fields. This is the thinnest coating method.

This is the thinnest coating method, but it is not suitable for mass production because it cannot apply multiple coats and continuous production is not possible.

Spray coating process equipment converts chemicals into fine particles and applies them to automobiles, exterior walls, building materials, and other large objects.

Three types of methods exist for generating granular spray: air, electric, and ultrasonic.

Dip coating process equipment is a method in which the object, regardless of its shape, is dipped into the dip coating solution and pulled up. It can form a uniform thin film and is used for optical lenses, medical systems, electronic devices, and other applications.

Dip coating process equipment is characterized by its ability to form a uniform thin film with minimal loss of coating solution, regardless of the shape of the object.

Dispensing coating process equipment is used in situations where relatively precise linear coating is required. This coating process equipment is equipped with a dispensing mechanism that can control the amount of coating, and when even more precise coating is required, a robot is used to provide both accuracy and precision in the amount of coating. Although the dispensing speed is of course inferior, spot dispensing to small areas and coating films of complex shapes can be formed.

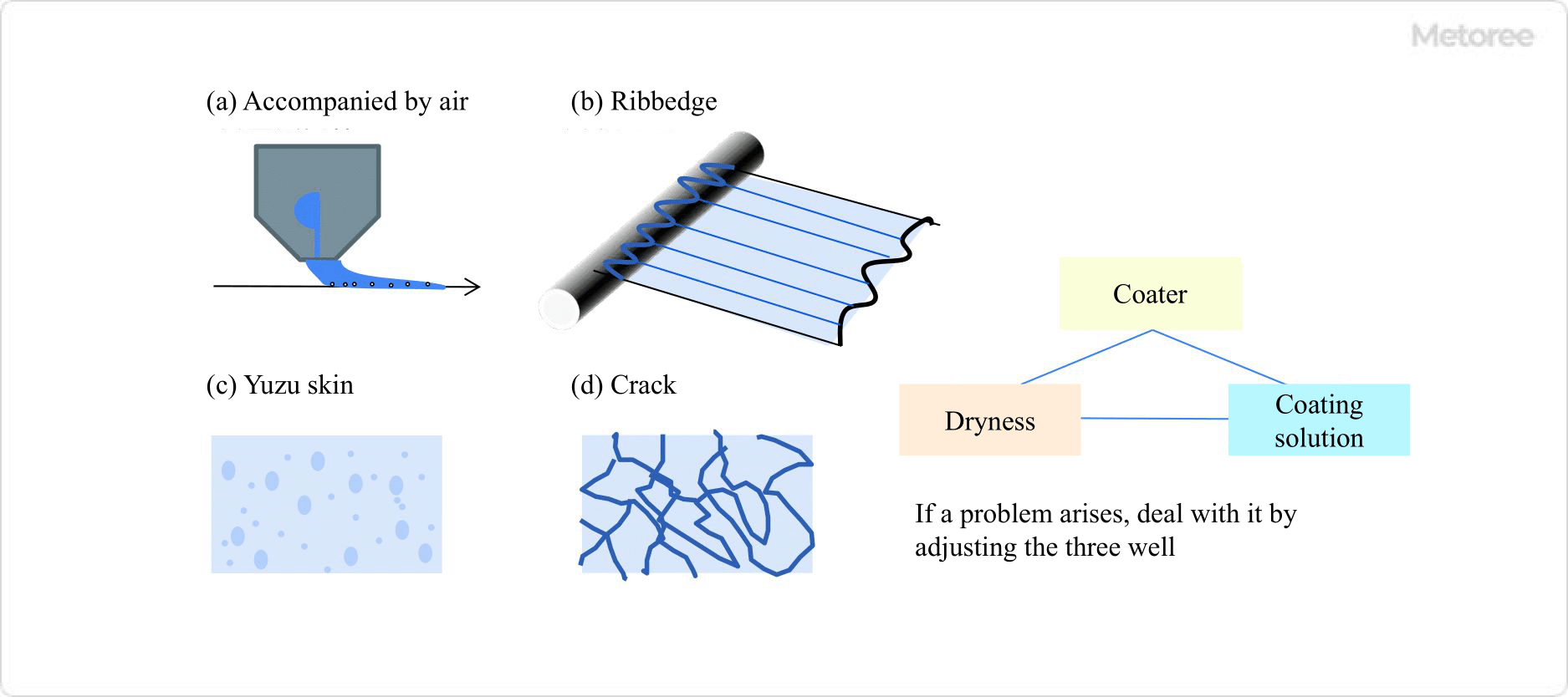

Figure 3. Lack of Coating and Coating Equipment

No matter how sophisticated the Coating Process Equipment is, a clean coated surface may not be obtained depending on the coating conditions, such as a coating fluid with an incompatible viscosity or coating speed. The types of coating defects and their remedies are as follows.

| Defect | Cause | Remedy |

| Air entrainment | Occurs when air cannot escape during the application of the coating liquid to the coated object. | Solved by reducing the coating speed. |

| Livestock | This occurs when there is a reverse pressure gradient in the coating section in the direction of the coating. | Solution is to reduce the viscosity of the coating liquid and the coating speed. |

| Strips and holes caused by air bubbles | This is caused by the presence of bubbles in the coating liquid. | Take measures to eliminate bubbles. |

| Uneven horizontal damping | Occurs mainly in reverse gravure coating systems. | Solution is to suppress vibration of the coated object or change the rotational speed of the gravure. |

| Unevenness | Unevenness is caused by the flow of coating liquid in the coating film. | This is solved by improving the coating liquid. |

| Foreign matter | Coating liquid agglomerates or becomes gelatinous. | This can be solved by introducing a filter, etc. |

| Flickering is caused by the high surface tension of the coating solution. | This is caused by the high surface tension of the coating liquid. | Add a surfactant or other agent. |

| Defect | Cause | Remedy |

| Yuzuhada (uneven coating surface like yuzu peel) | This defect occurs when the drying speed is too fast. | This defect is caused by drying too fast, and can be corrected by reducing the drying speed or adding a surfactant. |

| Wind ripples | Occurs during hot-air drying. | This is caused by hot-air drying, and can be handled by reducing the speed of the hot-air blow. |

| Cracking | Occurs due to shrinkage of the coating film. | It can be solved by reducing the thickness of the coating. |

Coating is a technology that can be achieved by appropriately selecting Coating Process Equipment, Drying, and Coating Liquid. It is important to select the appropriate Coating Process Equipment, taking into consideration the conditions of the coating liquid to be used and the specifications of the drying oven.

*Including some distributors, etc.

Sort by Features

Sort by Area

Musashi Engineering, Inc. is a Japanese manufacturer specializing in fully-automated dispensing systems and equipment established in 1978 and based in Tokyo. The company produces various valve types, pneumatic and manual dispensers, and pumps that facilitate fluid transport, as well as robots and controllers that can be customized to work with different interfaces. These are primarily used in the cosmetics, automotive, electronics, and medical markets. Musashi Engineering also offers additional services like consultation, training, installation, and product maintenance to customers with demanding requirements.

Valco Melton, established in 1952 and based in Cincinnati, Ohio, USA, is a manufacturer and supplier of adhesive dispensing and quality inspection equipment. The company's product range includes cold glue systems, hot melt dispensing systems, pattern controls and electronics, vision and quality assurance systems, and central adhesive supply | pot filling systems. These products are utilized in different applications, from simple hand-operated gluers to advanced camera inspection systems. They serve industries such as automotive, bag and sack manufacturing, and corrugated boxes. The company offers services including machinery manufacturing, design, and integration of precision metering, and mixing.

Linden Industries, LLC, established in 1989 and headquartered in Cuyahoga Falls, Ohio, USA, is a manufacturer of polyurethane processing equipment. The company offers a diverse product range, including high-pressure metering systems, mix heads, and foam molding equipment. These products empower industries to achieve precision and efficiency in polyurethane foam production, resulting in reduced waste, enhanced product quality, and lowered production costs. Industries such as automotive manufacturing, furniture production, insulation, and footwear benefit from these solutions. Moreover, the products boast user-friendly interfaces, ensuring ease of operation and maintenance.

SDC Technologies, Inc, established in 1986, in Irvine, California, USA, is a manufacturer of advanced surface coating technologies and unique products. Specializing in optical coatings, the company manufactures coatings that enhance the performance and durability of various products such as Formable coatings, index matched coatings, multi-purpose coatings, and 3D print resins. These coatings find applications in diverse industries such as electronics, automotive, aerospace, eyewear, and medical devices. The products offer multiple benefits, including scratch resistance, anti-reflective properties, and improved visual clarity. The coatings not only extend the lifespan of products but also elevate the user experience.

Wagner SprayTech Corp. (Wagner), a manufacturer headquartered in Plymouth, Minnesota, United States, specializing in paint applicators, was founded in 1970 as Spray Tech Corporation and is currently a subsidiary of Wagner Holding, Inc. The company’s portfolio comprises paint and stain sprayers designed to provide smooth and consistent finishes. The company also offers heat guns for home improvement and do-it-yourself (DIY) projects, paint rollers for ceiling and wall painting, as well as spray tents for enclosed spraying areas. It also provides surface preparation tools, as well as steamers for cleaning carpets and furniture. These products find applications in outdoor and indoor projects.

Nordson Corporation, established in 1954 and headquartered in Westlake, Ohio, USA, is a global manufacturer and marketer of differentiated products for precision dispensing and processing. They cater to diverse end markets, including packaging, electronics, medical, energy, and transportation. With over 6,800 employees across more than 35 countries, Nordson offers solutions for bonding, adhesive dispensing, fluid management, test and inspection, and UV curing. Their product line includes dispense tips, syringe barrels, dispensers, srapy valves, fluids, and syringe systems among others. Comprised of eight divisions, they are ISO 9001:2015 certified and provide systems, precision technology, and after market parts.

C. H. Reed, Inc. is a distributor and service provider of compressed air, paint finishing, and fluid handling products and services that was established in 1946 and is headquartered in Hanover, Pennsylvania, USA. The company’s products include compressors, dryers, filters, regulators, paint sprayers, and cleaning equipment. Its products are used in various industries, including manufacturing, construction, and food processing. The company also offers a wide range of services, including consulting and system services, sales, installation, repair, and maintenance for compressed air and finishing and fluid.

Sono-Tek Corporation was established in 1975 and is headquartered in Milton, New York. The company specializes in precision ultrasonic coating solutions, serving diverse industries, including electronics, medical, and industrial. Its product range encompasses ultrasonic spray nozzles, coating systems, and fluxers. Sono-Tek's pioneering technology is evident through multiple patents and global market recognition such as the acquisition of ISO 9001: 2015. The company is also found in many other countries, with seven application labs and over 50 factory-trained distributors to add to its design and manufacturing headquarters in the US.

Yasui Seiki Inc., established in 1979 and headquartered in Kanagawa, Japan, is a manufacturer that builds custom coaters and offers R&D coating services. The company manufactures roll-to-roll, precision custom coating machines, including MICROGRAVURE and slot die coaters. It also offers R&D coating services including roll-to-roll coating feasibility tests, new flexible material development, coating consultation, and new product contracts. Its products and services are adaptable and can participate in many industries that require sub-micron coatings with its MICROGRAVURE and Slot Die. It serves a wide range of industries, such as Medical devices, Energy, Optics, Packaging, and Textiles.

ASAP Co., Ltd., founded in 1999 with headquarters in Saitama, Japan, is a manufacturer of semiconductor production equipment. The company's product line includes a range of coating and developing modules and pressure-jet metal lift-off equipment with ASAP’s unique nozzles for research and development to mass production, as well as ASAP-designed mask alignment equipment. It also offers fully custom-built equipment, with clients that include UC Berkeley's Nano Lab. The company was recognized as a leading Saitama business in 2016.

Sprimag Spritzmaschinenbau GmbH & Co. KG, founded in 1925, is a German manufacturer headquartered in Kirchheim unter Teck, Baden-Wurttemberg, specializing in automated coating systems. The company’s offerings include machinery for surface coatings of mass-produced parts, as well as internal coatings for metal packaging like cans and collapsible tubes. The company also offers various testing and inspection machinery, along with application technology and spraying equipment for coating machines such as diaphragm pumps and spray guns. Additionally, the company handles customized painting processes like anti-friction coating, coating with corrosion protection, internal coating, metallization or physical vapor deposition (PVD) coating, rubber-metal bonding, and surface finishing.

Gema Switzerland GmbH, a company founded in 1897 and based in St. Gallen, Switzerland, is a manufacturer and supplier of liquid conveyance systems and electrostatic powder coating. The company’s products include automatic booth systems, reciprocators, automatic equipment and powder guns. Their products are used in various industries such as automotive, aerospace, furniture, and architecture, enabling efficient surface finishing. Additionally, the company also provides technical support, training programs, and personalized assistance to ensure working implementation and operation of their products.

Dubois Equipment Company, LLC., a company founded in 1876, based in Jasper, Indiana United States is a manufacturer of scuff sanders, conveyors, and finished equipment. The company's products include flat-line, UV, spray, wood, metal and specialty finished systems, as well as vacuum coat, roll coat, cured ovens, scuff sand, profile sander, spray machines and other finished equipment for applications. The products are used to handle equipment flawless finishes, run after run to complement systems.

Toray Engineering Co., Ltd., a company founded in the year 1960, based in Tokyo, Japan is a manufacturer and supplier of engineering equipment. The product portfolio includes plant engineering, factory automation, semiconductor-production equipment, FFD- production equipment, film-production equipment, battery production equipment, software, and measuring equipment. The company also provides effective solutions with the latest innovations which include green innovation, life innovation, AI technology, and laser transfer technology. The products are used in multiple industries which include pharmaceutical, fine chemical, film, plant maintenance, and core technologies.

Miyako Roller Industry Co. Ltd., founded in 1973, is a Japanese manufacturer and supplier headquartered in Soka City, Saitama, specializing in coating solutions. The company offers various roll coatings, including satin mirror, hybrid carbon, and water-absorbing sponge rolls. It also offers eco-friendly coating liquids, such as fluorine resin and diamond-like carbon (DLC) coatings, alongside coating machines, like precision coating machines. These products serve diverse industries, including construction, printing, and semiconductors. In 2008, Miyako Roller Industry Co. Ltd. was selected as one of Japan's 300 Most Vibrant Monozukuri (Manufacturing) Small and Medium Enterprises (SMEs) by the Ministry of Economy, Trade, and Industry.

Optimal Technologies, established in 1997 and based in Hertfordshire, United Kingdom, is a manufacturer and supplier of cleaning and coating systems. The company's product portfolio includes lens cleaning machines, implant processing systems, and dip coating machines. These products are used in various sectors, including the ophthalmic industry, precision optics, and semiconductor industries. The company offers services including installation of products at customers' sites, training, and tailoring electrical and mechanical design to meet specific performance and safety criteria.

Nagase Techno Engineering Co. Ltd., established in 1989 and headquartered in Yokohama, Japan, is a pumps, valves, and manufacturing recycling equipment wholesale distributor. The company's products include cryopumps, cryocoolers, and valves. It also offers wafers and substrates, fabrication handling tools and equipment, electrostatic coating systems, and chemical management systems for chemical recycling systems for semiconductors and liquid crystal manufacturing. Its services include onsite repairs, the supply of spare parts, and operator training.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Musashi Engineering, Inc. |

21.4%

|

| 2 | Wagner SprayTech Corp., |

9.5%

|

| 3 | Valco Melton |

8.1%

|

| 4 | Sprimag |

7.4%

|

| 5 | SDC Technologies, Inc |

5.9%

|

| 6 | Nordson Corporation |

5.7%

|

| 7 | Linden Industries, LLC. |

5.5%

|

| 8 | Sono-Tek Corporation |

4.7%

|

| 9 | Gema Switzerland Gmbh |

4.7%

|

| 10 | Yasui Seiki Inc. |

4.5%

|

Derivation Method

The ranking is calculated based on the click share within the coating process equipment page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

7 | 50.0% |

Japan

Japan

|

4 | 28.6% |

Germany

Germany

|

1 | 7.1% |

Switzerland

Switzerland

|

1 | 7.1% |

United Kingdom

United Kingdom

|

1 | 7.1% |

305 products found

305 products

Graco Inc.

330+ people viewing

Last viewed: 14 hours ago

■Accurate and highest efficiency The Z Pump is compatible with Graco's metering and mixing dispense systems for sealants and adhesives, including e...

10 models listed

SCREEN Febax Co., Ltd.

610+ people viewing

A multi-functional, high-performance slit-type coating device that can handle various coating materials from nano-level thin films to thick films, ...

Kyowa Finetech Co., Ltd.

600+ people viewing

Last viewed: 7 hours ago

Excellent pressure resistance and stable discharge! Achieves high viscosity, high pressure, high accuracy, and highly durable fixed quantity dispen...

Morinaga Giken Co., Ltd.

320+ people viewing

■Summary Amid market needs for speedy delivery and high-mix, small-lot production, there is now a need for automation of post-assembly work that co...

5 models listed

MINO INTERNATIONAL LTD.

210+ people viewing

Last viewed: 1 day ago

■Ideal coating changes your work I will help you professionally. Economical and easy-to-use photosensitive emulsion coating machine MCM-L series. ...

Nippon Sossee Kogyo Co., Ltd.

410+ people viewing

Achieves mixing of materials with different mixing ratios and viscosity differences, and maintains high stirring capacity at small size and low spe...

Nippon Baldwin Co., Ltd.

420+ people viewing

This is a non-contact spray applicator for the textile industry that sprays chemical liquid from a nozzle in the form of a mist and applies it even...

San-A Co., Ltd.

480+ people viewing

Herbicides kill weeds down to their roots. Easy to work with easy push-button operation The foamy chemical solution settles on the stems and leave...

Tenryu Seiki Co., Ltd.

570+ people viewing

Last viewed: 1 day ago

■Features This is the successor to the popular TSP-700V. ■Compact footprint ・Compared to other companies' equipment in Japan (exclusive ground ar...

DINOV Co., Ltd.

230+ people viewing

■Product introduction Advances in manufacturing technology have made precision liquid dispensing extremely important. There is an increasing need f...

10 models listed

SCREEN Febax Co., Ltd.

400+ people viewing

Last viewed: 48 minutes ago

A compact slit-type coating device that flexibly accommodates all coating conditions and materials and achieves highly accurate coating uniformity....

2 models listed

Feather Glass Co., Ltd.

400+ people viewing

■BM spray system By combining a special nozzle and a particle sorting tank, it has become possible for the first time to spray large amounts of nan...

Engineering Lab Co., Ltd.

420+ people viewing

Last viewed: 1 day ago

■Product overview The in-line precision coating device EI-3325 is a mass-production model for production lines equipped with a dual stage + two dis...

UK Tech Co., Ltd.

440+ people viewing

■Details ・Are there any problems where the coating thickness cannot be maintained due to undulations of the material being coated? ・Since our bar...

Minato Concept Co., Ltd.

320+ people viewing

We have a track record of manufacturing in various fields such as semi-automatic machines for production equipment and PC control management system...

Phi Corporation Co., Ltd.

730+ people viewing

Last viewed: 18 hours ago

■Features ・High film thickness uniformity ・Simultaneous application on both sides ・Improved coating efficiency ・Can be applied to thin substrates

Ishii Notation Co., Ltd.

230+ people viewing

■High-definition patterning/partial coating A model that can perform everything from high-definition patterning to partial coating to drying. Parti...

ANEST IWATA Corporation

750+ people viewing

Last viewed: 3 hours ago

■ Characteristics ・ Efficient paint supply system that minimizes the amount of paint and thinner used ・ Improvement of maintenance by adopting ma...

Techno Roll Co., Ltd.

480+ people viewing

Last viewed: 9 hours ago

It is an "attachment system" that allows customers to select ancillary equipment that suits their intended use and budget. Specifically, it is conf...

Minato Concept Co., Ltd.

410+ people viewing

Last viewed: 1 hour ago

We have a track record of manufacturing in various fields such as semi-automatic machines for production equipment and PC control management system...

EARS Co., Ltd.

350+ people viewing

This device is an "ultra-compact to compact test coater specifically designed for new material development" that has the functionality, performance...

3 models listed

Toshin Kogyo Co., Ltd.

450+ people viewing

Last viewed: 13 hours ago

Liquid resist coating, etc.

Y Drive Co., Ltd.

130+ people viewing

■YDrive inkjet printing machine ・DPN drive control board (Y Drive install) ・Konica Minolta or Dimatix head ・Air adsorption, heating function, UV...

4 models listed

Asianeotech

290+ people viewing

■Summary Inner layer liquid photoresist coating

Prematec Co., Ltd.

240+ people viewing

Last viewed: 20 hours ago

A device that draws organic materials such as peripheral sealing material, silver paste, OCR, and dam material onto the substrate.

Tokki Co., Ltd.

320+ people viewing

Last viewed: 9 hours ago

■Reduces labor and costs and extends the life of crane wheels and rails. By using a specially developed solid lubricant, crane inspection work is r...

Osaka Asahi Chemical Co., Ltd.

550+ people viewing

Last viewed: 1 day ago

■Features ・Supports L size board ・Flux application 50 points ・Model memory 20 models (optional PC specifications/100 dispensing points x 500 mod...

Phi Corporation Co., Ltd.

770+ people viewing

■Features ・Device overview This device clamps a workpiece vertically on a movable hanger arm with X, Y, Z, and θ axes, and has spray nozzle units ...

Osaka Asahi Chemical Co., Ltd.

570+ people viewing

Last viewed: 17 hours ago

■Features ・Supports M size board ・Flux application 50 points ・Model memory 20 models (optional PC specifications/100 dispensing points x 500 mod...

Feather Glass Co., Ltd.

390+ people viewing

Last viewed: 1 day ago

■BM spray system By combining a special nozzle and a particle sorting tank, it has become possible for the first time to spray large amounts of nan...