All Categories

History

This section provides an overview for resistance welding services as well as their applications and principles. Also, please take a look at the list of 39 resistance welding service companies and their company rankings. Here are the top-ranked resistance welding service companies as of March, 2026: 1.WES Ltd. Engineering, 2.Vista Industrial Products, Inc., 3.Argo Products Company.

Table of Contents

Categories Related to Resistance Welding Services

Resistance welding is a technique that utilizes the heat generated by electrical resistance when current is passed through metal. This process involves applying an electric current to the metals to be joined under moderate pressure. The heat generated melts the metal, which then cools and solidifies, forming a strong joint.

Resistance welding is a technique that utilizes the heat generated by electrical resistance when current is passed through metal. This process involves applying an electric current to the metals to be joined under moderate pressure. The heat generated melts the metal, which then cools and solidifies, forming a strong joint.

Distinct from arc and laser welding, resistance welding relies on internally generated heat rather than an external heat source. This method directly melts the base metals, creating a strong bond without the need for solder or other welding aids, thus reducing costs. Moreover, weld marks are typically less noticeable, providing a more aesthetically pleasing finish.

Resistance welding is known for its efficiency, often completing processes faster than other welding methods due to the rapid melting of metal under current. This ease of automation, often implemented with robotics, makes it a popular choice in mass-production settings such as home appliances and automotive manufacturing. Its ability to achieve a visually appealing finish also makes it suitable for exterior parts of automobiles and railcars.

However, resistance welding is not suitable for all materials. It requires materials that conduct electricity, are not overly thick, and have suitable properties for resistance welding. Materials like nickel and stainless steel are commonly used in resistance welding services.

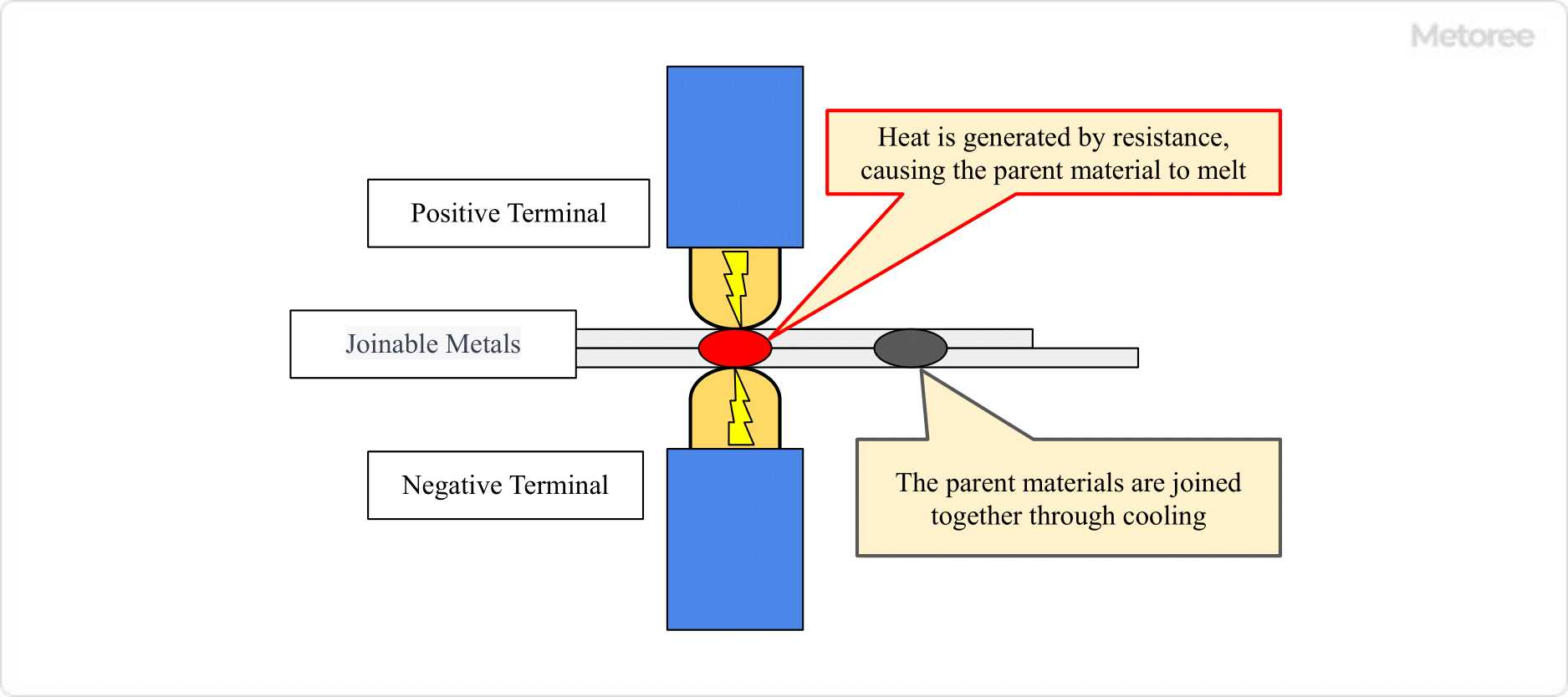

Figure 1. Principle of resistance welding

Resistance welding operates on the principle of using heat generated by electrical resistance when current is applied to metal. This process is a reversal of conventional electricity use, where resistance and the resulting heat are typically minimized. In resistance welding, however, this conductive loss is harnessed to melt and join metals.

The process is governed by four key factors, often referred to as the "four major conditions of resistance welding": applied pressure, welding current, energizing time, and electrode shape. These factors are crucial in determining the quality of the welding.

Applied pressure refers to the force exerted by the electrode on the metal, facilitating the flow of electric current and affecting the stability of the weld.

The welding current influences the rate at which heat is generated and the speed of metal melting, impacting the overall strength of the weld.

Energizing time, the duration for which the current is applied, directly affects welding efficiency.

The shape of the electrode impacts the distribution of the current and the area of metal melted, affecting the strength and quality of the weld.

Resistance welding can be primarily categorized into two types: spot welding and seam welding.

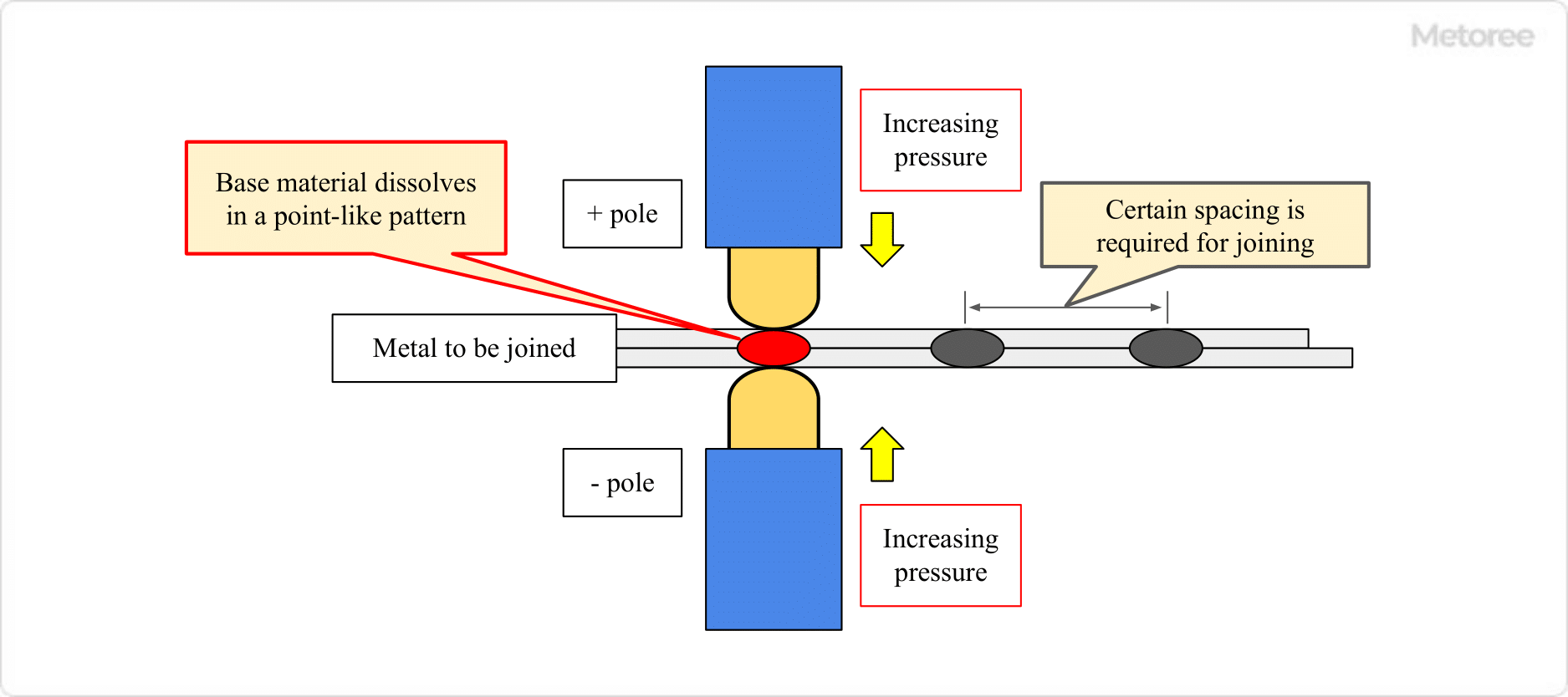

Figure 2. Spot welding

Spot welding involves welding at specific points using two electrodes. This method is effective for joining two metal rods with minimal heat distortion. However, care must be taken to avoid shunting in areas near existing welds.

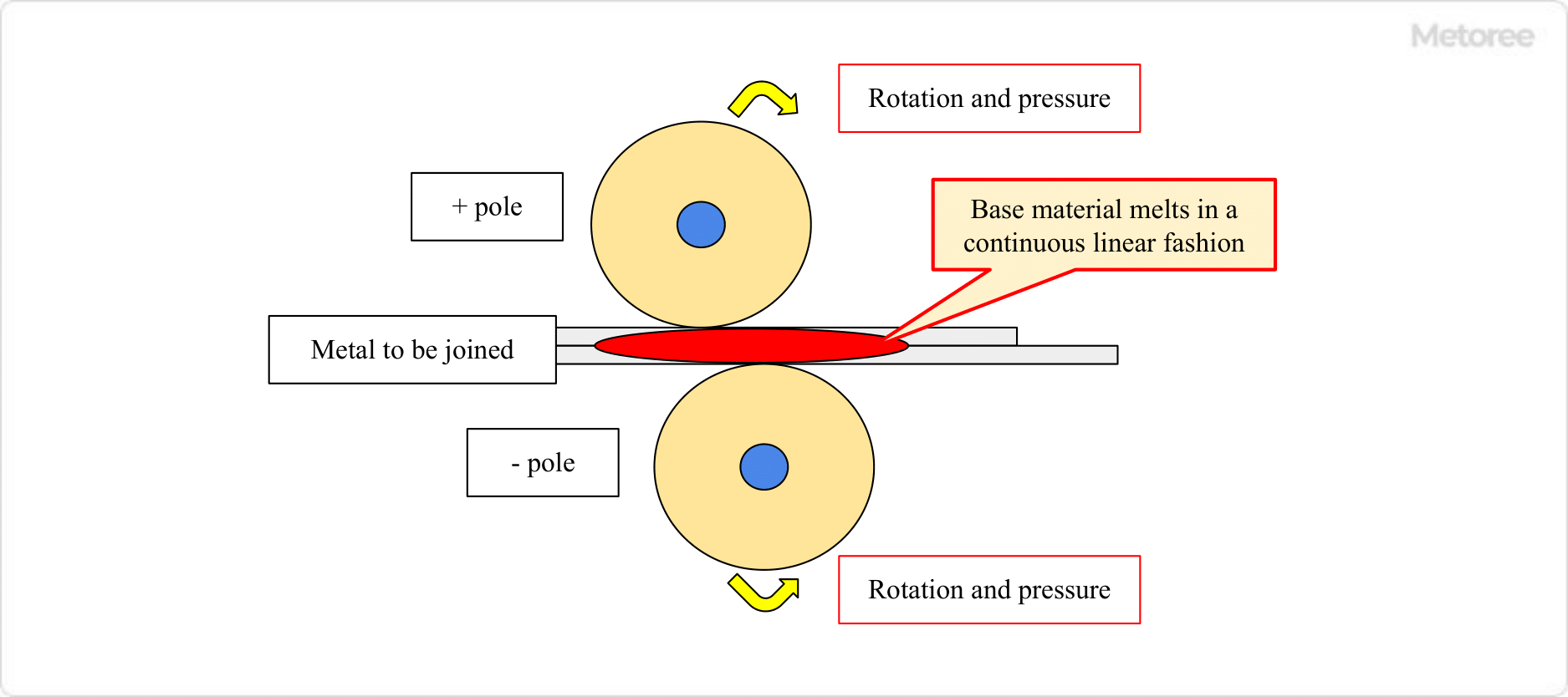

Figure 3. Seam Welding

Seam welding uses roller-shaped electrodes to create continuous, linear welds. While this method is efficient and strong, it can lead to heat distortion in the processed product.

*Including some distributors, etc.

Sort by Features

Sort by Area

RoMan Manufacturing, Inc., founded in 1980 and headquartered in Grand Rapids, Michigan, USA, is a manufacturer of power conversion systems. The company specializes in producing various products, including transformers, water-cooled power leads, and DC power supplies, that have optimal efficiency, durability, and stability for desired performance. These advanced power conversion systems serve industries like automotive, metalworking, and industrial automation while playing an essential role in powering various applications for industrial operations and necessary output. It is ISO 9001 certified and a member of the American Welding Society and IHEA.

Electro-Space Fabricators, Inc. was founded in 1962 and is headquartered in Topton, Pennsylvania, US, as a manufacturer of sheet metalwork products. The comprehensive product portfolio encompasses cosmetic front panels, sheet metal fabrication, VME products, injection molding products, and frames, among others. The company also offers welding, bending, and finishing services. These products find applications across various industries, including electronics, manufacturing, automotive, and industrial sectors. They serve purposes such as creating precise components, panels and frames, and facilitating efficient fabrication processes.

Taylor Winfield Technologies, Inc., is a manufacturer of material joining equipment and systems, founded in 1882 and headquartered in Youngstown, Ohio. The company specializes in designing and manufacturing a range of equipment for various industries, offering solutions in resistance welding, automation-based material joining, coil joining and processing, induction heating, as well as capacitor discharge, multi-gun resistance welders, arc welding, and linear friction welding. Its range of services includes field service, machine health assessment, preventative maintenance assistance, upgrade supervision, startup & commissioning, and more.

Loyal Manufacturing Corporation, operating since 1975 from Indianapolis, Indiana, is a manufacturer producing precision metal stampings and sheet metal fabrications. Its services include shearing, punching, welding, tube bending, and various metal fabrication processes, allowing the creation of precise stampings from a range of materials like steel, aluminum, copper, brass, and stainless steel. The company offers engineering and design services and can work with electronic drawings in .dxf, .pdf, and .dwg formats provided by customers, using CAD software to facilitate the process.

ABC Sheet Metal traces its roots to 1870 and is headquartered in Anaheim, California. The company provides cutting and shaping services to several industries including aerospace, defense, medical, packaging, and construction. The company is AS9100 and ISO 9001 certified, assuring aerospace, defense, and other industry customers of build quality. The company’s cutting and shaping services include laser and water jet cutting, forming & rolling, welding, and CNC machining and punching. The company takes full advantage of 2D and 3D CAD for sheet metal engineering to reduce manufacturing labor and material expenses.

AMADA WELD TECH is a subsidiary of AMADA WELD TECH Co., LTD, which was founded in 1972. AMADA is based in Southern California and is a manufacturer of equipment and systems for resistance welding, hot bar bonding, laser marking, and other laser cutting services for industries such as aerospace, automotive, electronics, medical, and photonics. AMADA is ISO 9001:2015 certified. Examples of AMADA products include machines and systems for resistance welding, laser cutting, hermetic steam sealing, laser micromachining, and more.

H&H METALS, which was launched in 1980 and is located in Thornton, Colorado, is a manufacturer of sheet metals. The company produces sheet metal, aluminum sunshades, spandrel panels, and perforated metal panels. It also makes architectural decorative metal panels, aluminum composite panels, flat seam metal panels, and prefabricated metal canopies. Its sheet metal is used by various companies, which are glass & glazing contractors, overhead door contractors, metal roofers, and insulation contractors & suppliers.

Premier Products of Racine, Inc., established in 1999 and located in Racine, Wisconsin, is a custom manufacturer specializing in roll formed products. They provide custom roll formed products for various industries, including office furniture manufacturing, barbecue grill production, appliance manufacturing, solar technology development, and telecommunications equipment manufacturing. Their roll forming capabilities encompass cleaning, cut-off, in-line edge conditioning, embossing, and pre-notching. They also offer press brake, welding, riveting, assembly, and custom packaging. Premier Products of Racine ensures compliance with ANSI, ASTM, and DOT standards.

Advanced Integrated Technologies, Inc., established in 1975 in Mountain View, Arkansas, USA, is a manufacturer of spot welding, hot bar soldering, and ACF bonding. The spot welding capabilities allow for strong, flexible connections for various applications, and the hot bar soldering enables precise and efficient soldering of electronic components. ACF bonding technology allows for the creation of intricate, optimal-performance electronic assemblies. These processes are instrumental in the aerospace, defense, medical, and telecommunications industries, where precision and accuracy are paramount. The company offers advanced technology and patented manufacturing process, ensuring optimal quality and accuracy in the products with ISO, CE certifications.

Weld System Integrators, Inc., founded in 2000 in Warrensville Heights, Ohio, USA, is a manufacturer of advanced welding equipment and automated welding tools. The company makes various welding-related products, including resistance welding equipment, welding controls, and automation systems. The products are designed to enhance welding processes, improve precision, and increase productivity, making these tools ideal for industries where precise and stable welding is critical. Weld System Integrators, Inc. serves a wide array of industries, including automotive manufacturing, aerospace, electronics, and medical device manufacturing, where the advanced welding solutions play a pivotal role in ensuring the production of optimal-quality components.

Electron Beam Engineering, Inc., founded in 1991 and headquartered in Anaheim, California, serves as a manufacturer and provider of electron beam and laser welding services. The company offers electron beam welding for robust, deep welds on metals like titanium, stainless steel, and aluminum. Its laser welding capabilities produce precise welds on materials such as copper, brass, and gold. Additionally, the company provides CNC machining to shape metals intricately, and vacuum furnace brazing for joining metals and ceramics. Its services extends to welding consultation, guiding clients in selecting optimal welding methods for varied applications.

Precise Metal Products, established in 1957, is a manufacturer and supplier based in Phoenix, Arizona, specializing in metal, machining, formed and finished assemblies. The company offers metal fabrication and machined components for the aerospace, power generation and military industries. Their portfolio of services includes hydroforming and punch press services, metal spinning. roll forming services, CNC machining services, and others. The company holds ISO 9001:2015 certification and offers solutions and value-added products to customers across diverse industries and locations.

Lynn Welding Co., Inc., founded in 1979, is an American manufacturer based in Newington, Connecticut, specializing in industrial welding services. The company offers various welding services, including resistance welding, fusion welding, and brazing. It also provides precision computer numerical control (CNC) machining, featuring wire electrical discharge machining (EDM), waterjet cutting, as well as fixture and tooling machining. Catering to the aerospace and military sectors, the company offers tailored fabrication services, with products like aerospace tooling, crew door components, ground support equipment (GSE), as well as armored vehicle and defense system components, accredited by Nadcap (National Aerospace and Defense Contractors Accreditation Program).

Clairon Metals Corp. was established in 1989 in Covington, Georgia, USA, as a manufacturer of metal stamping products. The company provides engineering design consultation, metal stamping, in-house tool and fixture design, robotic and manual MIG welding, resistance welding, machining, assembly, and custom packaging. Its expertise covers metal stamping, resistance welding, tooling and fixtures, and robotic MIG welding services. The products find applications throughout the manufacturing process, including engineering design consultation and prototype development, among others. The company supports diverse industries, including power sports, home improvement, lawn and garden, and automotive, among others.

Superior Joining Technologies, Inc. was founded in 1992 and is a manufacturer of precision welding products and services based in Machesney Park, Illinois, United States. The company offers various precision welding services such as manual welding, microscopic welding, laser welding, seam welding, and resistance spot welding. Various industries have been served by the company including aviation, medical, defense, nuclear, and maritime. The company has been certified with ITAR, Nadcap Accreditation, and Military Critical Technical Data Agreement.

HI TecMetal Group, established in 1943 and based in Eastlake, Ohio, USA, is an ISO 9001:2008 certified manufacturer and supplier of metal substrates. The company's product range includes heat exchangers, metallic substrates, hydraulic assemblies, pneumatic dispensing machines, and syringes. These products are used in constructing and maintaining various equipment. The company primarily serves industries such as Aerospace, Automotive, Foodservice, and Medical. Its services include brazing, heat treating, welding, and engineering solutions.

Algonquin Industries, Inc., established in 1974 and based in Bellingham, MA, USA, is an ISO 9001:2015 certified manufacturer and supplier of precision metal products. The company's product range includes laser cutting, CNC punching, CNC 4-axis horizontal milling, forming, and spot welding. These products are used in the fabrication and assembly of metal components. It serves the technology, manufacturing, wind power, and solar power industries. In addition to its products, the company offers services such as engineering support for manufacturability, CAD development support, prototype development, and production.

Resistance Welding Machine & Accessory (ResWeld), established in 1987 and based in Saint Joseph, Michigan, is a manufacturer and distributor of resistance welding supplies and equipment. The company serves multiple industries, including aircraft, automotive, railroad, food machinery, and construction with various products such as spot welding machines, air-cooled cables, welder arms, electrode holders, and swivel tips. It allows for custom manufacturing & designs, and manufactures products based on the customer’s specification and requirements. The company also stocks refractory metals and copper alloys in custom and standard cut sizes to meet specific needs.

NSRW, Inc., is a resistance welding manufacturing company, providing both new, custom resistance welding machines as well as used resistance and spot welders, was established in 1983, based in the United States. The company's portfolio includes from raw materials to finished products, is also a metal service center specializing in copper, copper alloys and specialty metals used in welding process. It stock and supply all components for customers' welding needs. With a team of experts proficient in every aspect of welding process, it operates as a full-service copper and resistance welding specialist. It has been ISO 9001 certified since 1997.

Production Products Inc. is based in Maryland and is known as a supplier of products and machinery for the HVAC industry. The company's list of machines includes Flangers, Clinchers, Cheek and Cleat Benders, Rotary Machines, and more and many are available in manual as well as powered types. There are also Plasma Pro CNC Machines, Water Jet/Router Liner Cutting Machines, Plasma Cutting Machine Controls, Retrofits, And Repairs along with various supplies and consumables such as HVAC Machine parts and etc. Overall PPI provides machinery and equipment to HVAC duct and sheet metal fabricators exclusively.

Vista Industrial Products, Inc., established in 1956 and located in Vista, United States of America, is a supplier of fabrication solutions. The company offers sheet metal punching, sheet metal forming, CNC machining, and welding services. It also provides metal finishing, engineering, mechanical assembly, and laser cutting services. Its sheet metal punching machines are all equipped with fully rotational punching heads, which permits various tooling to be rotated to any punching angle. It serves defense, medical, retail, commercial, as well as aerospace industries.

Spotwelding Consultants, Inc. was established in 1983 and based in Rowlett, Texas. The company is a welding consultant and distributor of new and used resistance welders to customers across the United States and many countries overseas. The company also provides rebuilding, tooling, and customization services for customers’ welding equipment and machinery. The company’s primary lines are spot welding equipment which includes maintenance and quality control devices, and resistance soldiering products including soldering irons and resistance soldering systems.

Mechanical Designs of Virginia, Inc., founded in Stuart, VA in 1983 is a supplier of custom CNC precision machining services. The company's product portfolio includes CNC machining services, Materials Expertise, CNC Laser Cutting, MIG, TIG, and Resistance Welding and Powder Coating / Finishing. Their products are used in industries such as Electronics and Telecommunications, Automotive, Transportation and aerospace and Defense. The company provides services including, quality assurance, product selection, customized services, technical support and customer service.

Andritz AG was initially founded as a much smaller company back in 1852 as an iron foundry, but today the company is a manufacturer and supplier of a wide range of industrial machinery, chemicals, fuels, and textiles, among many more. The company's product portfolio includes over 20 core areas: pulp and paper, metals, cyber security, feeds, and biofuels. Examples include decanter centrifuges, mechanical separation extractors, contact and paddle dryers, and batch helix dryers used in the environment, chemicals, food and beverage, and mining industries. Secondary services include the supply of spare parts, rentals, process consulting, and on-site repairs and upgrades.

AMADA WELD TECH, headquartered in Monrovia, California, USA, and established in 1948, is a manufacturer and supplier of equipment and systems for metal and plastic material joining, marking, cutting, and processing. Its offerings include resistance welding machines, laser welding systems, hot bar bonding tools, hermetic sealing systems, and micro TIG welding solutions. These products find application in diverse sectors, including automotive, medical, aerospace, electronics, and battery manufacturing. The company holds ISO 9001:2015 certification for quality management and was honored with the Laser Focus World Innovators Award in 2019 for its MM-L300A laser weld monitor.

Lansco Manufacturing Services, Inc. was founded in 1986 and is headquartered in Chagrin Falls, Ohio. The company is a manufacturer of equipment ranging from Swiss machined components to complete factory automation. The company’s service offerings include prototyping and R&D services, concurrent engineering, and Kansan stocking programs. Machining capabilities include custom metal fabrication, precision stamping, assemblies, adjustable ergonomic workstations, and more. The company works with many types of plastics and metals including aluminum, high-temperature alloys, carbon steel, and more.

Fractory Ltd., headquartered in Manchester, England, has been a manufacturer specializing in sheet metal fabrication services since 2017. The company operates as an online platform that connects customers needing custom sheet metal parts with a network of manufacturing partners. Its digital platform streamlines the entire sheet metal fabrication process, from design to delivery. The company offers various sheet metal materials, including steel, aluminum, stainless steel, and different alloys. The company's services can be applied to multiple industries, including manufacturing, construction, electronics, and more.

Aero Manufacturing Corporation is a manufacturer of precision metal fabricated and machined components for Ground Turbine, Aircraft, Industrial, and Commercial applications. The company was established in 1971, and is based in Beverly, Massachusetts. Aero Manufacturing Corporation offers prototype and production welding services, laser fabrication services, and CNC machining services for aircraft and aerospace, as well as power generation industries. The company works with various materials including alloy steels, cobalt, aluminum, and superalloy metals

Centerline (Windsor) Limited is a reputable manufacturer that specializes in the automotive industry. The company was established in 1957 and is based in North America. With a strong market proximity, Centerline offers a wide range of outstanding automotive solutions, which include automated welding systems, assembly lines, and tools. The company experienced team provides comprehensive engineered services, from design and prototype to full-scale production. Centerline (Windsor) Limited's allegiance to excellence and customer satisfaction has solidified its position as an authentic and dependable partner for automotive manufacturers worldwide.

Bosch Rexroth South Africa Group of Companies, established in 1966 and headquartered in Johannesburg, Gauteng, South Africa, is a distinguished manufacturer and supplier of fluid power and automation solutions. The company's product range includes hydraulic components and systems, pneumatic components and systems, drives and controls, and automation solutions. These products find utility in a wide spectrum of industries, including automotive, manufacturing, mining, power generation, and water and wastewater treatment. Its aim to deliver holistic fluid power and automation solutions is affirmed by their ISO 9001:2015 accreditation.

Nelson Industrial Inc., established in 1973 and based in Toronto, Canada, is a manufacturer and supplier of precision fabricated metal products. The company's product range includes Contract Manufacturing, Architectural Metals, ACUDOR Construction Products, and NEOS Storage Systems. These products are used in various architectural, construction, and storage solutions. They primarily serve industries such as Building Materials, Metal Fabrication, and Architectural Design. Its services include Design and engineering, provision of Acudor Access Doors and roof Hatches, NEOS Technician Bench Systems, and custom-designed metal products.

WES Ltd has been based in Cornwall, England since 1984 as a manufacturer and supplier of precision engineering and CNC machining products and services. The company provides advanced engineering solutions for the machining, assembly, and testing of components and systems, along with resistance welding for the manufacturing of spot-welding consumables and equipment, and the hard metal engineering division specializes in the machining of complex components from very hard metals such as tungsten carbide. The components and services benefit the nuclear, scientific instrumentation, automotive, marine, and aerospace sectors.

D&H Industries, Inc. was founded in 1937 and is headquartered in Wisconsin, United States, as a metal stamping and welding service supplier for agricultural, automotive, military, furniture, and railroad industries. The company provides precision deep draw and progressive metal stamping services, catering to the individual requirements of its customers. The stampings are fabricated using a diverse range of materials, such as aluminum, brass, copper, cold-rolled steel, stainless steel, and high strength materials. Furthermore, these metalworking services, the company also offers MIG welding, TIG welding, and resistance welding techniques.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | AMADA WELD TECH |

7.8%

|

| 2 | WES Ltd. Engineering |

3.6%

|

| 3 | Vista Industrial Products, Inc. |

3.3%

|

| 4 | Argo Products Company |

3.3%

|

| 5 | Premier Products of Racine, Inc. |

3.3%

|

| 6 | Loyal Manufacturing Corporation |

3.3%

|

| 7 | Stone City Products |

2.9%

|

| 8 | H&H METALS |

2.9%

|

| 9 | Algonquin Industries, Inc. |

2.9%

|

| 10 | Advanced Integrated Technologies, Inc. |

2.9%

|

Derivation Method

The ranking is calculated based on the click share within the resistance welding service page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

29 | 85.3% |

Austria

Austria

|

1 | 2.9% |

Germany

Germany

|

1 | 2.9% |

South Africa

South Africa

|

1 | 2.9% |

Canada

Canada

|

1 | 2.9% |

United Kingdom

United Kingdom

|

1 | 2.9% |