All Categories

History

This section provides an overview for buffing services as well as their applications and principles. Also, please take a look at the list of 10 buffing service companies and their company rankings.

Table of Contents

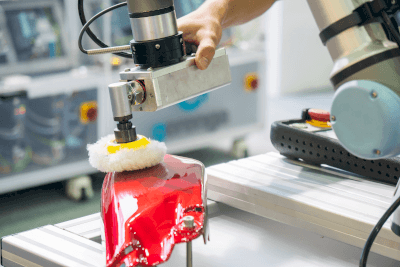

A buffing service is a method used to smooth surfaces by eliminating irregularities. This process involves applying abrasives to a buffing wheel, typically made of cloth or similar materials, which then rotates to polish the object.

A buffing service is a method used to smooth surfaces by eliminating irregularities. This process involves applying abrasives to a buffing wheel, typically made of cloth or similar materials, which then rotates to polish the object.

Suitable for both metal and plastic resin materials, buffing services enhance surface properties, providing chamfering, improved surface roughness, mirror finishes, and slipperiness. The buffing process, often performed before and after plating, allows for adjustable levels of finishing by varying the buffing materials and abrasives.

Buffing services are essential for smoothing material surfaces, adding luster, removing burrs and chamfers, and enhancing surface finish post-plating. These services are particularly vital when specific surface roughness is required.

Typically, buffing employs materials like cloth, linen, wool, or sponge—softer than grinding wheels. Buffing grains are graded by numbers, such as "#00"; higher numbers indicate finer grains and a higher luster on the polished surface.

Buffing works on the principle of micro-cutting action from abrasive grains. This action, combined with high-speed rotation-induced temperature rise (friction), produces a lustrous finish through both mechanical surface flow and the chemical impact of the abrasives.

The buffing process typically includes three stages: Rough Polishing, Intermediate Polishing, and Finishing Polishing.

The chosen process depends on the required finish quality; consultation with the processing manufacturer is recommended.

As outlined, buffing services significantly enhance product quality, contributing to improved durability and lifespan.

*Including some distributors, etc.

Sort by Features

Sort by Area

Arthur Harris & Co., established in 1884, is a job shop manufacturer that specializes in the production of stainless steel, float balls, and tanks, and its headquarters are located in Illinois, United States. Stainless steel floats are very suitable for applications involving elevated pressure and concomitant high temperatures, particularly in aqueous environments or when exposed to corrosive liquids. The products include bespoke stainless steel floats, and a range of options in terms of shapes, metals, connections, gauges, and sizes.

Delstar Metal Finishing, Inc., established in 2002 and headquartered in Texas, USA, is a manufacturer of metal finishing services. The company provides electropolishing, metal pickling, and chemical cleaning services. These products serve in semiconductor manufacturing, pharmaceutical processing, and defense industries. Its operations span polishing small 1/16-inch diameter tubing to handling colossal process vessels akin to railroad tank cars. The company has SEM, AES, and ESCA certifications facilitated by reputable U.S. independent laboratories. It employs computerized procedures and strict bath chemistry controls in its processes and services.

GlobalSpec, based in NY, United States, is an online destination for engineers, delivering the single source for critical engineering content, information, insight, and community for engineers and technical professionals across multiple industries and disciplines. The company's website offers information comprised of news and analysis, products and suppliers, standards directory, and reference library – a gateway to more than 95 million engineering documents, including technical articles, reports, patents, and e-books, and more. They connect industrial marketers with their target audience of engineering and technical, professionals – generating awareness, demand and engagement opportunities at all stages of the buy cycle.

TDC CO., LTD., established in 1989 and headquartered in Miyagi, Japan, is a manufacturer that specializes in precision technologies. It employs polishing and lapping technology capable of achieving ultra-fine specifications, even for materials with surface roughness as low as Ra1 nanometer. It specializes in achieving sub-micron level super fine flatness, parallelism, and size tolerance, all while accommodating multiple requirements. The company processes various materials, including metals, ceramics, glasses, and semiconductor materials. The company has created precision-finished surface plates, precision machining of XY stage spindles, precision feed rails, positioning jigs, and glass scales for encoders, leveraging precision dimensional control technology.

Mirror Finish Polishing Company, based in Springfield, Missouri, US, has been a metal polishing and buffing services supplier since 2009. The company offers various polished products such as metal polishing by metal type, coating, and metal polishing by part type. The company's polishing services are compatible with multiple materials, including stainless steel, magnesium, brass, titanium, and metal. It also offers custom painting, welding, sandblasting, fabrication, grinding and metal shaping services.

Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

3 | 75.0% |

Japan

Japan

|

1 | 25.0% |