All Categories

History

This section provides an overview for shearing services as well as their applications and principles. Also, please take a look at the list of 10 shearing service companies and their company rankings. Here are the top-ranked shearing service companies as of February, 2026: 1.Advantage Metal Services, Inc., 2.Sawing & Shearing Services, inc., 3.Accurate Products.

Table of Contents

Categories Related to Shearing Services

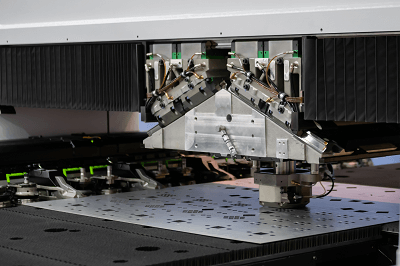

Shearing is a metal cutting process utilizing shear force. As a subset of stamping, it shapes or divides metal into parts through operations such as blanking and piercing. Unique among metalworking methods, shearing exclusively focuses on cutting without removing material.

Shearing employs a die to exert shear force on metal, precisely cutting it into the required shape. This process capitalizes on the force between the press and the metal, essential for achieving the desired configuration.

Shearing plays a foundational role in metalworking, shaping components like automobile frames through press-applied shear force. It initiates the sheet metal forming process through blanking, setting the stage for further shaping in the production of furniture, building materials, and machinery parts.

Moreover, shearing facilitates the creation of metal enclosures by punching out curved lines in sheet metal, using either pre-existing dies or employing nibbling for more complex shapes.

The principle behind shearing involves clamping metal between an upper punch and a lower die to generate shear force, effectively splitting the metal. This process may result in burrs or distortions, underscoring the challenge of producing precise parts without subsequent finishing steps.

Shearing outcomes can include parts with directional burrs, highlighting the importance of deburring for accuracy.

Shearing encompasses several techniques, with blanking, drilling, and compound processing as prominent examples.

Blanking shapes metal sheets into pre-press forms, involving shearing, dividing, and punching based on the blank's characteristics.

Drilling involves creating holes in metal sheets, producing scrap from the punched areas. It can range from the multiplicity of holes for complex shapes to closely spaced holes achieved through nibbling.

Also known as total punching, compound processing allows for simultaneous cutting and punching, enabling efficient mass production of precise parts, albeit with higher maintenance costs.

*Including some distributors, etc.

Sort by Features

Sort by Area

Cutting Edge Fabrication (CEF) has been a custom manufacturer, specializing in welding medium to large structures and metal parts since 1990. As a Milwaukee-based metal cutting company, CEF employs state-of-the-art CNC plate cutting methods including laser, oxy-fuel flame, and high-definition plasma cutting, along with production sawing and shearing. The company does precise metal forming, bending, and rolling, complemented by metal assemblies and surface finishing for comprehensive product creation. Holding ISO 9001:2015 certification, its metal fabrication services span the regions of Wisconsin and Northern areas.

Advantage Metal Services, Inc. was founded in 1985 and is based in South El Monte, California is a custom fabrication manufacturer and distributor of metallic products for industries including food processing, paper, agriculture, and construction. The company offers shipping to many locations and free local delivery. The company’s services include custom metal fabrication, custom screw conveyor production, flame & hi-definition plasma cutting, saw cutting, and shearing. The company’s end products include carbon steel, stainless steel, aluminum, and expanded metal.

Accurate Products was founded in 1958 and is headquartered in Chicago, Illinois. The company manufactures and distributes rubber products for the agricultural, manufacturing, and automotive industries. Its die-cutting operation in Chicago provides custom die and rubber molding services for Neoprene, EPDM, silicone rubber, as well as plastic injection molding. The company’s standard products are divided into molded rubber parts and injection molding. Molded rubber parts include SBR, Bun-N, natural rubber, and other parts and products. Injection molding parts include button bumpers, grommets, extrusions, and leg tips.

TW Metals was founded in 1998 in Pennsylvania as a supplier of specialty metals. The company supplies bars, pipes, rods, plates, and sheets of specialty metals like stainless steel, aluminum, nickel, titanium, and carbon alloy material. There are also aerospace extrusions and specialty products being distributed by them. They also provide premier metals services to process extrusions, tubing, etc. to any specification using sheet shearing, waterjet cutting, abrasive sawing, lathe cutting, and more to achieve the results. These metals are supplied to various industries like Aerospace, Medical, Fabricators, Oil & Gas, and Nuclear to name a few.

M&K Metal Co. was founded in 1982 in Los Angeles, USA as a supplier of metal products, such as copper and copper alloys. The company provides a range of metal processing services, including precision cutting of aluminum plates, as well as waterjet and laser cutting services. Aluminum rods, round plates, channels, sheets, and beams are part of its aluminum fabrication. Besides metal processing, it offers direct-to-metal (DTM) paints, alkaline primer coatings with low VOC, that are TTE-489 compliant. These paints are suitable for indoor and outdoor use on industrial machinery, heavy equipment, steel doors, etc.

Lapham-Hickey Steel Corp., Chicago, USA, in 1926 is a steel services provider. The company's services include laser cutting, press brake forming, punch/plasma cutting, plasma & oxy-fuel cutting, and shot blasting. The company also offers supply solutions such as distribution, fabrication, logistics, and inventory management. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. They have national distribution network and a customer support center.

Schebler Specialty Mfg, which was founded in 1895 in Bettendorf, Iowa, US, is a manufacturer of metal fabrication. The company products include fabrications and tailored metal fabrications used in robotic welding, laser, waterjet, and plasma cutting. The products are also vital in TIG welding and fabrication to provide clean weld. The products also offer consistent accuracy in stamping applications used in laser cutting, painting, and assembly. As an ISO 9001:2008 certified company, it also provides multiple services such as customization, production fabrication, equipment capabilities, and field services.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Advantage Metal Services, Inc. |

20.6%

|

| 2 | Sawing & Shearing Services, inc. |

17.6%

|

| 3 | Accurate Products |

17.6%

|

| 4 | Cutting Edge Fabrication |

11.8%

|

| 5 | Mr Metal |

5.9%

|

| 6 | Astron Metal Works Corp. |

5.9%

|

| 7 | Schebler Specialty Fab |

5.9%

|

| 8 | M & K Metal Co. |

5.9%

|

| 9 | TW Metals, LLC. |

5.9%

|

| 10 | Lapham-Hickey Steel Corporation |

2.9%

|

Derivation Method

The ranking is calculated based on the click share within the shearing service page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

7 | 77.8% |

Canada

Canada

|

1 | 11.1% |

| Philipines | 1 | 11.1% |