All Categories

History

This section provides an overview for metal bendings as well as their applications and principles. Also, please take a look at the list of 11 metal bending companies and their company rankings. Here are the top-ranked metal bending companies as of March, 2026: 1.Tempco Manufacturing Co., Inc, 2.OSH Cut, 3.ABT Metals Manufacturing, LLC.

Table of Contents

Categories Related to Metal Bendings

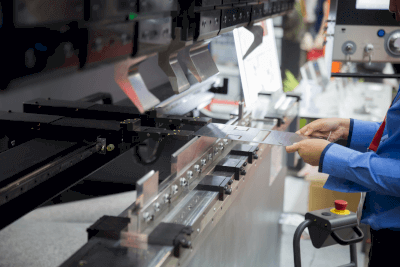

Metal bending is the process of bending sheet metal using a die.

Metal bending is the process of bending sheet metal using a die.

Sheet metal is placed in a die that matches the desired shape, and another die is pressed against it to form a bend in the sheet metal. Metal Bendings is a type of bending process.

Most products that use sheet metal, such as desktop computers and other office automation equipment and home appliances such as refrigerators, are formed by sheet metal bending or metal bending. In addition, automobile frames are a typical example of products formed by metal bending.

Metal bending uses a press brake and press work. In press brakes and press processing, sheet metal is inserted between the punch of the upper die and the die of the lower die, and the sheet metal is plastically deformed by applying an external force in the unit of several tons while the punch is lowered.

Metal bending is used to form products that are indispensable to our daily lives. For example, office automation equipment such as desktop computers, home appliances such as refrigerators and washing machines, and automobile frames are products made using metal bending.

Most parts that are not seamless and flat, such as welds, bolts, and rivets, are manufactured by metal bending. Elevators are a special case in which colored steel sheets that have been painted from the start are used.

A simple rectangular shape can be fabricated using a bender's mold, but a specialized shape, such as an automobile, requires a specialized mold. When ordering a prototype, there are cases in which the cost of fabricating the die will depend on the shape of the prototype, and the cost will be higher than that of metal bending for mass-produced products.

The basic principle of sheet metal bending is simply to plastically deform sheet metal. By taking advantage of the metal's irreversible properties (plasticity), an external force is applied to the plastically deformed material to form it.

In metal bending, there is a part where the sheet metal is pushed (inside the sheet metal) and a part where the sheet metal is pulled (outside the sheet metal). Compressive stress occurs on the inside of the sheet metal and tensile stress occurs on the outside of the sheet metal, which can cause cracking if the sheet metal is thin.

To prevent cracks from occurring in metal bending, it is necessary to use a more ductile material.

There are eight main types of metal bending. Although the principles of metal bending are the same, the applications differ depending on the product to be manufactured.

Each processing method is as follows:

This is a bending processing method in which the upper die is pressed into the V-shaped lower die. It is also called bottom butt bending. When we generally speak of bending, we are referring to bottoming.

Compared to bottoming, coining is a method in which the top of the upper die is pressed with higher pressure to bite into the material. Accuracy is better than that of bottoming, but wear and tear on the die is more severe.

Therefore, metal bending with long bending widths is difficult to be processed by coining.

This method uses a die with rounded corners and the required diameter. This method is used in areas where design is a concern, and is a processing method to create a curved radius shape.

This method uses a V-shaped die to perform R-bending. The corners are rounded. Generally, a press is used as the processing machine.

This method uses a roll bender to create a cylindrical shape by inserting a plate between three rotating rolls. The position of the rolls determines the size of the arc.

Also called Z-bending, this method bends sheet metal into a staircase shape. The metal fittings used in the process are specially called stepped bending metal fittings.

This is a processing method in which the edge of sheet metal is folded back. It has the advantage of increasing strength as well as preventing burrs on the edge from touching the operator's hand at the same sheet thickness.

This is a processing method in which the bending angle can be adjusted to any desired one. The sheet metal does not contact the V-shaped lower die on the surface, and the bending angle can be freely determined.

Since the accuracy of bending is lower, high technical skills are required depending on the desired accuracy.

*Including some distributors, etc.

Sort by Features

Sort by Area

TPC Group, established in 1940 and formerly known as Texas Petrochemicals Inc., is a Houston-based petrochemicals manufacturer that also offers critical infrastructure and logistics services along the Gulf Coast. They deliver a diverse range of products to chemical and petroleum-based companies worldwide. They are a large producer of butadiene for synthetic rubber production, MTBE for gasoline blending, and polyisobutylene for lubricant and fuel additive applications. TPC Group is ISO 9001:2015 certified and has operations in Port Neches, Texas, and Lake Charles, Louisiana.

OSH Cut, established in 2018, is a sheet metal fabrication manufacturer based in Utah, USA. The company offers precision laser cutting and metal fabrication services to various industries and customers, including individuals, small businesses, and larger corporations. The company's primary service is laser cutting, a precise method of cutting different metals, including steel, aluminum, and stainless steel. Its metal fabrication processes include bending, welding, and assembly to transform laser-cut metal pieces into finished products or components. The company serves various industries, including manufacturing, electronics, signage, art and sculpture, and many others.

Max Weiss Company LLC founded in 1946 and based in Milwaukee, Wisconsin, is a manufacturer and supplier of curved structural steel and formed metal products. The company offers fabricated, forged, bent, formed, and rolled structural steel parts and metal products made from various materials including sheet metal, copper, aluminum, carbon alloys, and stainless steel. It has completed the ISO 9001:2015 certification and is a member of AISC Associate allowing them to serve the shipbuilding, foundries, heavy machinery, construction, and heating & plumbing industries.

Fractory Ltd., headquartered in Manchester, England, has been a manufacturer specializing in sheet metal fabrication services since 2017. The company operates as an online platform that connects customers needing custom sheet metal parts with a network of manufacturing partners. Its digital platform streamlines the entire sheet metal fabrication process, from design to delivery. The company offers various sheet metal materials, including steel, aluminum, stainless steel, and different alloys. The company's services can be applied to multiple industries, including manufacturing, construction, electronics, and more.

SendCutSend is an online manufacturing and fabrication platform for laser and waterjet cutting services that is headquartered in Reno, Nevada, and was established in 2014. The company offers a wide range of materials that can be laser cut or waterjet cut, including acrylic, metal, wood, and plastic. SendCutSend also offers multiple finishing services, such as drilling, Laser Cutting, CNC Routing, Waterjet Cutting, Anodizing, and bending. Its customers include makers, engineers, and businesses of all sizes. SendCutSend is a certified member of the Fabricators & Manufacturers Association International (FMA).

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Tempco Manufacturing Co., Inc |

20.4%

|

| 2 | OSH Cut |

16.3%

|

| 3 | ABT Metals Manufacturing, LLC |

14.3%

|

| 4 | Max Weiss Company LLC |

10.2%

|

| 5 | LaserNett |

8.2%

|

| 6 | SendCutSend |

8.2%

|

| 7 | Fractory Ltd |

8.2%

|

| 8 | Dongguan Kemo Hardware Co., Ltd. |

4.1%

|

| 9 | JSI Metal Fabrication |

4.1%

|

| 10 | The Laser Cutting Co. Ltd, |

4.1%

|

Derivation Method

The ranking is calculated based on the click share within the metal bending page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

4 | 44.4% |

United Kingdom

United Kingdom

|

2 | 22.2% |

Japan

Japan

|

1 | 11.1% |

Canada

Canada

|

1 | 11.1% |

China

China

|

1 | 11.1% |