All Categories

History

This section provides an overview for chamfering cutters as well as their applications and principles. Also, please take a look at the list of 14 chamfering cutter manufacturers and their company rankings. Here are the top-ranked chamfering cutter companies as of February, 2026: 1.Rock River Tool, Inc., 2.Bagon Engineering Works Tools Division, 3.WAT Tool Co.,Ltd.

Table of Contents

Categories Related to Chamfering Cutters

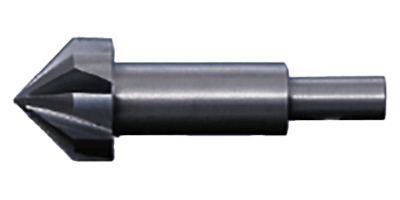

A chamfering cutter is a tool that is attached to the tip of an electric screwdriver or impact driver and rotated to deburr or reshape a screw hole.

Normally, when drilling holes in materials, corners (called faces) and burrs are formed. The role of a chamfering cutter is to remove these surfaces and burrs and smooth the surface.

They can also be used for processing the tip of the hole into a conical shape to prevent the screw head from sticking out when a screw is inserted into the drilled hole.

Chamfering cutters are usually attached to power tools. The tip of the chamfering cutter is in the form of a bit, so select a shape that matches the tool to which it is attached.

Chamfering and deburring are almost the same. Both are used for cleaning up the edges of holes drilled with a drill or other tool. Usually, after drilling holes in metal or wood, the edges of the holes have burrs. In deburring, these burrs are removed using a chamfering cutter.

Chamfering is a process to remove the edge (surface) between the hole and the material surface, which is almost perpendicular to the hole after drilling. Chamfering is achieved by pushing the chamfering cutter further into the hole than deburring. These processes improve the appearance and feel of the threaded hole and prevent injuries due to spikes sticking into the hand.

The countersunk process, also known as countersunk fir, is a process to create a conical space for the countersunk portion of a screw to sink into after the screw is fastened to the wood or metal. When screws are fastened to wood or metal that has not been countersunk, the plate portion protrudes from the surface of the object.

Not only does this look bad, but hands or clothes may get caught on the plate and cause injury. For this reason, the plate is removed to create a space where the plate part is hidden, so that the plate part does not show after screwing.

Another reason for countersunk processing is to prevent cracks in the material. If screws or screws are tightened with a high-tightening force tool, such as an impact driver without countersunk processing, cracks may appear in the material. This problem can be prevented by performing the countersunk process. The amount of chamfering is adjusted based on the size of the pan of the screw or screw to be used.

The tip of the chamfering cutter is conical, but it is not a perfect cone; instead, the cone is notched, and the notch is the cutting edge. This cutting edge makes it possible to shave wood in a conical shape.

Insert the chamfering cutter into the tip of the power tool, place it in the hole after drilling, and rotate it. The cutting edge on the tip of the chamfering cutter rotates at high-speed to remove the surfaces and burrs (shavings) generated during the drilling process and to form a conical hole.

The following three points should be considered when selecting a chamfering cutter.

Although chamfering cutters can process a wide variety of materials, the material of the chamfering cutter blade must be changed according to the material. The most common blade materials are steel, HSS, and carbide tips. Usually, steel blades are used when the material is soft wood, etc. However, when the material is hard wood, resin, light metal, etc., it is better to use HSS or carbide-tipped blades.

Chamfering cutters are available in two types of shaft shapes: straight shaft and hexagonal shaft. Generally, chamfering cutters are often attached to electric screwdrivers, and in such cases, either shaft shape can be used. However, when used with an impact driver, only the hexagonal shaft can be attached.

When using chamfering cutters, the required diameter varies depending on the type of processing. For chamfering and deburring, a slightly larger diameter (+5 to 10 mm) than the diameter of the hole to be processed is optimal.

On the other hand, if the purpose is to remove a countersunk hole, it is recommended to select a size that is the same as or slightly larger than the diameter of the screw head.

*Including some distributors, etc.

Sort by Features

Sort by Area

Conical Cutting Tools was established in 1944 and Michigan, United states as a manufacturer of mills for the metalwork company. The company product portfolio includes diverse line of conical end mills tailored for aerospace, automotive, and mold-making industries. The company serves both small and large organizations, and its distinctive advantage resides in its custom solutions, which enable clients to cut machine time by 20% and boost productivity by 15%. The company position has been strengthened by notable alliances with company's titans, which have resulted in a spectacular 40% increase in sales.

Super Tool, Inc., founded in 1927 and headquartered in Bradenton, Florida, USA, is a manufacturer of carbide tipped, solid carbide, and high speed steel cutting tools. The company offers products that include angle cutters, core drills, countersinks, milling cutters, reamers, and SA Swiss automatic tools. Its products are utilized in automotive firms such as Chrysler and Ford corporations. The company also provides coatings available for tools such as TiCN, TiN, AlTiN, and TiAlN.

Rock River Tool, Inc., established in 1986, is an American manufacturer and distributor based in Bradenton, Florida, specializing in carbide tipped and solid carbide cutting tools. The company’s product offerings include a range of tools, including various drills such as aircraft extension and stub length drills. It also provides a selection of reamers, catering to general purposes and steel cutting needs, as well as various types of centers. Additionally, the company offers an array of counterbores and countersinks, along with single point tools for steel and non-ferrous metals. Notably, for milling operations, the company offers arbor and shank style milling cutters.

Established in 1960, and located in Meridian, ID, Micro 100 is a supplier of carbide milling and turning cutting tools for the machine manufacturing industry and they specialize in CNC grinding technology. The company provides tools and tool holders for construction processes including boring, grooving, and, threading. They also offer Quick Change Tool Holders &Parts, Rotational Holders &Parts, and Collets with various industrial applications. Servicing both the turning and milling industries, the company offers Hardened Steel, Taper Integrated Holders, Aluminum Alloys, Plastics & Composites.

Daishowa Seiki Co. Ltd., established in 1967 and headquartered in Osaka, Japan, is a designer, manufacturer, and supplier of precision tool holders, FA systems, and measuring accessories. The company offers cutting tools, multitasking turning tools, and work position measurement masters. It also offers a range of accessories, including tool clamping stands, machine spindle cleaners, and machine T-slot chip protection equipment. These tools and accessories are used with metal-machining machines and CNC routers. Its services include logistics management and the stocking of 1.5 million items ready to ship around the world.

STAR-M CORPORATION, established in 1923 and based in Hyogo Prefecture, Japan, is a manufacturer of woodworking drill bits. The company specializes in auger bits and adjustable circle cutters, catering to various sectors, from electric facility construction to horticulture. It crafts various machine drills, including the highly precise T.C.T. carbon and custom-made drills. The company product line offers tools for various materials, including wood, bamboo, and gypsum board. It ensures that each drill bit and tool is not just a piece of metal but a promise of durability and excellence to customers worldwide.

Speed Tiger Precision Technology Co., Ltd., established in 1998 and based in Taiwan, is a manufacturer of cutting tools. The company is the first in Taiwan to integrate milling cutter coating technology. It has a good position in the performance CNC tool market. The firm specialises in producing drills, inserts, end mills, and other cutting tools made of tungsten carbide steel with accuracy. The company has more than 100 sets of grinding machines from Germany, Switzerland, Japan, and Taiwan. It is the first producer to combine coating processes with cutting equipment.

YIH TROUN ENTERPRISE CO., LTD. (YT) is a manufacturer of indexable cutting tools established in 1977 and based in New Taipei City, Taiwan. The company's product lineup includes various saw blades, thread milling and T-slot cutters, and a range of drills including center and spot models. They offer over 4,500 different products and 30 patented designs. YT's indexable tools have applications in various markets including mold and die creation, metalwork, and the medical device industry.

Bagon Engineering Work Tools Division, established in 1975 and headquartered in Rajkot, Gujarat, India, is a manufacturer, exporter, and importer of work tools for industrial applications. The company offers pneumatic cutting blades, milling cutters, circular shearing blades, tool bits, and HSS & chamfer cutters. The company's infrastructure unit is segmented into various sections including manufacturing, quality testing, warehousing, and administrative sections. It also executes Alloy Steel Heat Treatment Job Works as per the specifications of its patrons and has recruited various C & F agents to enable them to deliver the consignments at clients' destinations within the stipulated time period.

Zhuzhou Cemented Carbide Cutting Tools Co., Ltd., founded in 2002, stands as an eminent manufacturer and supplier of advanced carbide cutting tools from China. The company excels in crafting an extensive array of cutting implements, including inserts, end mills, and drills, which find applications across diverse industrial sectors. With an unwavering devotion to precision and innovation, Zhuzhou Cemented Carbide Cutting Tools is resolute in equipping industries like manufacturing, aerospace, and automotive with tools that amplify productivity and elevate quality standards. Their all-encompassing product spectrum caters adeptly to professionals seeking efficient cutting solutions for intricate machining operations.

WAT Tool Co., Ltd. was established in 2011 based in China as a manufacturer of custom-made carbide cutting tools and CNC machine tool accessories. The company offers various products such as carbide end mills, drills, reamers, taps, and saw blades, as well as tool holders, collets, and coolant nozzles. It trades with other companies, including Mitsubishi, Kyocera, TaeguTec, Korloy, and more, serving multiple industries like CNC machining, motor vehicle manufacture, IT industries, and glass production.

Eskenazi SA (EZI), founded in 1916 and headquartered in Carouge, Geneve, Switzerland, is a designer and manufacturer of cutting tools for precision machining. The company offers an extensive range of performance cutting tools tailored to the needs of micro-machining and machining of metals, plastics, and alloys. Its product families include carbide blanks, end mills, and chamfering. These products are widely used for precision CNC machining in specialized market sectors such as machine tools, measuring instruments, and aeronautics. The company offers services that include on-demand custom tooling and part production.

De Boer Tool Ltd, established in 1996 in Canada, is a manufacturer and distributor of solid carbide cutting tools. The company has an 18,000-square-foot manufacturing facility equipped with modern tools and cutter grinders in Mississauga, Ontario. De Boer Tools is the authorized distributor of Mitutoyo Corporations, Sumitomo, Korloy, Big Kaiser, Morse, and VSM. The company's product portfolio includes thread mills, spacematic drills, drivematic drills, and custom cutting tools made with solid carbide. The company uses tools to serve the aerospace, automotive, and medical industries.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Rock River Tool, Inc. |

21.4%

|

| 2 | Bagon Engineering Works Tools Division |

14.3%

|

| 3 | WAT Tool Co.,Ltd |

14.3%

|

| 4 | Super Tool, Inc. |

14.3%

|

| 5 | YIH TROUN ENTERPRISE CO., LTD. |

14.3%

|

| 6 | Eskenazi SA |

7.1%

|

| 7 | BIG DAISHOWA SEIKI CO., LTD. |

7.1%

|

| 8 | Derek lndustry Group Sweden Co.,Ltd |

7.1%

|

Derivation Method

The ranking is calculated based on the click share within the chamfering cutter page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

4 | 30.8% |

China

China

|

3 | 23.1% |

Japan

Japan

|

2 | 15.4% |

Taiwan

Taiwan

|

2 | 15.4% |

India

India

|

1 | 7.7% |

Canada

Canada

|

1 | 7.7% |

263 products found

263 products

Xebec Technology Co., Ltd.

160+ people viewing

Last viewed: 18 hours ago

■Summary Realizes burr-free chamfering with the world's first V-shaped cutting edge ■Compatible models It can be used in the following environment...

4 models listed

Nichia Alloy Co., Ltd.

130+ people viewing

Last viewed: 20 hours ago

■Summary - 45° double-sided chamfering is possible on the front and back sides. ・Can be installed on shank with M screw specifications *Please use...

9 models listed

Asahi Tool Manufacturing Co., Ltd.

270+ people viewing

■ Features ・ Row mounting shape bilateral horn tolerance ± 15 ° ・ Maintain shape accuracy by direct blade ■ Selected table by coating material ...

10 models listed

Kyowa Seiko Co., Ltd.

280+ people viewing

Last viewed: 30 minutes ago

Small diameter sizes are available for chamfering precision machined parts and deep engraving. In addition to general drills, end mills, and reame...

Kuroda Co., Ltd.

200+ people viewing

■Summary TAG has released a new cutter specifically for chamfering machines. We promise stable and long life for general steel, die steel, and allo...

5 models listed

Kyowa Seiko Co., Ltd.

430+ people viewing

Last viewed: 7 hours ago

4 straight blades. 90° (double angle type). In addition to general drills, end mills, and reamers, we also have a lineup of standard products such...

Seiko Drill Co., Ltd.

290+ people viewing

■Product overview Special tools such as φ3.0 shank carbide end mills, flat cones, half moons, step drills, boring bars, reamers, chamfering drills,...

Omi Industries Co., Ltd.

400+ people viewing

For customers who want high-speed machining of a wide range of work materials and particular attention to surface roughness. ■Work material stainl...

Kyowa Seiko Co., Ltd.

340+ people viewing

4 straight blades. 45° (single angle type). In addition to general drills, end mills, and reamers, we also have a lineup of standard products such...

Is tail

520+ people viewing

Last viewed: 2 hours ago

GERIMA Hand Bverler SMA Series German GERIMA (Gerima) High quality hand beerer (manual surface). Contributes to improving processing quality and e...

4 models listed

Omi Industries Co., Ltd.

340+ people viewing

Last viewed: 1 day ago

Compatible with hard and non-sticky materials by using cobalt high speed steel ■Work material stainless steel/cast iron ■Compatible models Electr...

NT Tools Co., Ltd.

290+ people viewing

■For chamfering, countersunking, and corner shaving. Ideal for chamfering slender and deep holes. Throw-away tip type (dedicated tip) enables small...

Omi Industries Co., Ltd.

440+ people viewing

For customers who want high-speed machining of non-ferrous metals/customers who are particular about surface roughness. ■Work material Aluminum/br...

Omi Industries Co., Ltd.

430+ people viewing

Last viewed: 1 day ago

For deburring and chamfering soft and sticky materials ■Work material Aluminum/brass/steel ■Compatible models Electric drill/drilling machine

Kyowa Seiko Co., Ltd.

400+ people viewing

Last viewed: 30 minutes ago

In addition to general drills, end mills, and reamers, we also have a lineup of standard products such as stepped drills, V-shaped end mills, and c...

Kyowa Seiko Co., Ltd.

360+ people viewing

In addition to general drills, end mills, and reamers, we also have a lineup of standard products such as stepped drills, V-shaped end mills, and c...

Kyowa Seiko Co., Ltd.

320+ people viewing

Last viewed: 1 day ago

In addition to general drills, end mills, and reamers, we also have a lineup of standard products such as stepped drills, V-shaped end mills, and c...

Kanefusa Co., Ltd.

310+ people viewing

Last viewed: 1 day ago

The surface shape of each blade is precisely molded, and the weight balance is adjusted with high precision, so high-speed rotation produces beauti...

Kyowa Seiko Co., Ltd.

350+ people viewing

Last viewed: 9 hours ago

In addition to general drills, end mills, and reamers, we also have a lineup of standard products such as stepped drills, V-shaped end mills, and c...

Kyowa Seiko Co., Ltd.

340+ people viewing

Cubic boron nitride is a diamond crystal structure material composed of boron and nitrogen. It is used for machining ferrous metals and specializes...

Kyowa Seiko Co., Ltd.

340+ people viewing

Cubic boron nitride is a diamond crystal structure material composed of boron and nitrogen. It is used for machining ferrous metals and specializes...

Tool System Co., Ltd.

300+ people viewing

Last viewed: 10 hours ago

■Features The countersink (3 blades, 90° and 60° tips) from Germany's Irix is a product of the company's accumulated technology, and has outstand...

2 models listed

Daigen Shokai Co., Ltd.

160+ people viewing

Last viewed: 1 day ago

■Summary ・Various types of joint removal processing can be performed using an electric trimmer. *Electric trimmer is not included. ■Applications ...

Miniter Co., Ltd.

180+ people viewing

■Features -A tool that can chamfer the front and back sides of a hole in one step. - It is also possible to deburr holes in curved surfaces such as...

Miniter Co., Ltd.

180+ people viewing

Last viewed: 16 hours ago

■Features -A tool that can chamfer the front and back sides of a hole in one step. ・Always perform constant chamfering. ■Compatible materials ・T...

Shinano Manufacturing Co., Ltd.

310+ people viewing

■Standard accessories Handle/bead cutter jig (693-98) ・Allen wrench (3mm) ・T-type wrench

Shinano Manufacturing Co., Ltd.

260+ people viewing

■Standard accessories Service oil, air plug (20PM type), Allen wrench (3mm), T-type wrench, adjustment jig

Shinano Manufacturing Co., Ltd.

280+ people viewing

■Standard accessories Service oil, air plug (20PM type), Allen wrench (3mm), T-type wrench, adjustment jig