All Categories

History

This section provides an overview for ultrasonic cutting services as well as their applications and principles. Also, please take a look at the list of 13 ultrasonic cutting service companies and their company rankings. Here are the top-ranked ultrasonic cutting service companies as of March, 2026: 1.CR Technology, Inc., 2.Gorreri Srl, 3.Marchant Schmidt, Inc..

Table of Contents

Categories Related to Ultrasonic Cutting Services

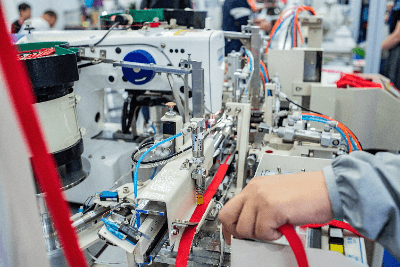

An ultrasonic cutting service is a method of cutting workpieces by applying ultrasonic vibrations to cutting tools such as knives.

An ultrasonic cutting service is a method of cutting workpieces by applying ultrasonic vibrations to cutting tools such as knives.

The occurrence of burrs, chips, cracks, etc. is greatly reduced, as well as the formation of altered layers and machining distortion, resulting in improved machining accuracy. In addition, machining time can be shortened and tool life can be extended due to reduced machining resistance.

Ultrasonic cutting service facilitates the cutting of resin products, rubber products, non-woven fabrics, layered composite materials, and food products such as cakes, which are difficult to cut with ordinary cutters.

Ultrasonic cutting service can cut hard metals and ceramics as well as cakes that easily lose their shape. It cuts hard-to-cut carbon fibers, polishes molds smoothly, and even cuts ultra-fine patterns on printed circuit boards.

Using the high-frequency vibration of ultrasonic cutting service, it can cut carefully and with high precision. Thus, it is ideal for cutting hard, brittle materials such as ceramics, glass, and jewelry. Since no heat is generated and a clean cross-section is obtained, it can be used for cutting resin.

Ultrasonic cutting services can also be used to cut fine electrical contacts, such as in circuit boards, batteries, and power devices. Furthermore, ultrasonic cutting services are expected to be utilized for lithium-ion batteries.

In the food industry, it can be used as an ultrasonic food cutter to cut cakes and other confectionery items that may lose their shape. The ultrasonic cutting service produces a clean cutting surface due to the fine blade movement caused by ultrasonic vibration.

Ultrasonic cutting services are mainly used for cutting packaging materials, non-woven fabrics, and sheet materials. Ultrasonic cutters, which vibrate at high speeds, prevent food, rubber, and sheet materials from sticking to the cutter, thereby contributing to faster processing, less product material, and lower energy consumption.

The device that performs ultrasonic cutting service is called an ultrasonic cutting machine and consists of an oscillator and a transducer. The oscillator emits ultrasonic signals at 15,000 to 40,000 Hz, and the transducer applies ultrasonic vibration to the workpiece. The oscillator is generally equipped with a function to maintain a constant amplitude to ensure constant sharpness at all times.

When an ultrasonic signal from the oscillator is given to the piezoelectric element made of ceramics, the piezoelectric element stretches and contracts to generate ultrasonic vibrations. A blade tool is fixed to the oscillator, and the ultrasonic vibration of the blade cuts the workpiece. The blade, called a horn at the tip, functions to amplify the vibration efficiently. Continuous vibration of about 100μ at both amplitudes is possible.

Objects have natural frequencies, and when an external force synchronized with that frequency is applied, even a small external force will cause a large vibration. This is resonance. Ultrasonic cutters use resonance to cause the cutting edge to vibrate significantly.

Because of the wide variety of ultrasonic cutting machines available, the choice should be based on the application. For example, food cutters can cut soft breads and cakes without losing their shape, and the circular blade allows continuous cutting. Other useful functions to ensure the same sharpness at all times are oscillators of a constant amplitude type.

There are two ways to cut food: one is to use oscillating force to cut by dragging the blade, and the other is to use impact force by swinging it down and striking it. The oscillating method is used when the blade is knife-shaped, and the impact method is used when the blade is guillotine-shaped.

The selection of a small handy type ultrasonic cutter is based on the following four points: first, whether it is an inexpensive and handy type for hobby use or an expensive and high-performance type for industrial use; second, whether the switch is located on the oscillator, transducer, or foot pedal; third, whether it is equipped with a TAF circuit (automatic adjustment function); and fourth, whether it has a replacement blade. The fourth is whether the machine comes with a blade or whether replacement blades are readily available.

Improved Processing Accuracy

Even flexible workpieces such as sheet materials can be processed with high accuracy due to low deformation distortion.

Reduction of Chips, Burrs, and Cracks

Since cutting is performed using minute vibrations, there are fewer chips and burrs.

Reduced Processing Resistance

Since machining resistance is reduced, transformation and machining strain due to machining are reduced, and tool life is extended.

Reduced Machining Time

Ultrasonic waves have a higher frequency, resulting in faster machining speeds.

Extremely Clean Cut Surfaces

Cutting is performed with minute amplitude, resulting in smooth cut surfaces.

Reduction of Defect Rate

Stable cutting process is possible with repetition of a small amount of processing.

Ideal for Cutting Food Products

No food residue or shavings, which can be a problem with rotary blades, etc., are produced, making the cutting process hygienic.

*Including some distributors, etc.

Sort by Features

Sort by Area

Marchant Schmidt, Inc., established in 1963 in Wisconsin, USA, is a manufacturer of food-cutting solutions used in the confectionery and bakery industries. The company's product catalog includes cheese-converting machinery, inspection systems, specialty food-cutting equipment, and hygienic automation. It also offers services such as equipment design and manufacturing, equipment installation, spare parts for food processing. The company has worked on projects like shredding and grating non-dairy cheese, high-speed loaf cutting, hygienic robot food loading, and many more.

Swift Glass Company, Inc. (SGC) is an American ISO 9001:2015 certified contract manufacturer specializing in glass parts fabrication that was established in Elmira, New York in 1927. The company offers various precision glass fabrication capabilities, including glass CNC machining, waterjet cutting, surface lapping, drilling, and edge grinding and polishing. They commonly manufacture products such as glass wafers, lenses, panels, and panes for a broad range of applications in industry and aerospace manufacturing. SGC primarily produces biomedical device components and industrial equipment for their clients, which include Auer Lighting GmbH, Corning Inc., and General Electric.

SONOBOND ULTRASONICS, INC., founded in the United States in 1960, is a supplier of ultrasonic metal welding and textile bonding equipment. The company offers a range of textile bonding machines for applications like nonwoven fabric bonding and embossing, ultrasonic metal welding machines are capable of welding various metals with speed and precision, and ustomized equipment and solutions to meet the specific needs. It serves industries such as electronic, environmental, filtration, HVAC, photovoltaic, and medical.

Rinco Ultrasonics is based in Romanshorn, Switzerland, and is a manufacturer of ultrasonic cutting and welding machines that was established in 1976 following the merger of Rinco AG and Ultrasonics AG. The company produces ultrasonic cutting machines for precision cutting of synthetic textiles or food products, ultrasonic welding machines for joining thermoplastic materials, and ultrasonic atomizers for creating fine water droplets in humidification or coating operations. It also offers related components for integrated ultrasonic technology into automated systems or machine lines. The company’s products are mainly used in the automotive, textiles, and food processing industries.

Gorreri Srl, established in 1987 and headquartered in Brescello, Italy, is a manufacturer of turn-key solutions for the confectionery sector. The company offers mixing systems, turbo emulsifiers, and ultrasonic cutting devices. Its product range covers various cakes such as sponge cakes, birthday cakes, and cheesecakes. The company provides advanced technologies for every stage of cake production, from mixing to decoration. It also offers comprehensive after-sales services, including installation, technical training, and maintenance, and minimizes waste in industrial cake production processes.

FoodsFact is a manufacturer of bakery and confectionery production machinery that was established in 2018 in Varna, Bulgaria. The company’s product lineup includes filling conveyor machines for filling doughnuts or mini pies, packaging machine feeders, and cooling conveyors for rapid cooling of baked or deep fried products in a production line. It also offers cooking steam boilers, electric melters, and rotary conveyors. The company’s products are used by clients in snack foods, confectionery, and bakery operations.

Empowering Technologies, a Europe Technologies company, is a manufacturer headquartered in Trussville, Alabama, specializing in metal, composite, and thermoplastics solutions to the North American market. The company was founded in 2010 and caters to various industries, primarily the industrial sector. With eight international subsidiaries, it continues to provide engineered products for metal enhancement. Empowering Technologies utilizes three peening processes for metal using STRESSONIC technology: Ultrasonic Shot Peening, Ultrasonic Peen Forming, and Ultrasonic Impact Treatment.

B.S. SRL, a company founded in 1980 and headquartered in Parma, Italy, is a manufacturer and supplier specializing in food production machines. The company's product portfolio includes automatic bread dispensers, ice cream tray filling lines, and dosages for pizzas. These products are utilized in various sectors, including the ready meals industry, ice cream, and confectionery industries. The company offers services, including 24/7 technical support, identifying problems, making modifications, and correcting software issues without the need for an on-site visit, as well as maintenance.

Sunstone Engineering LLC, established in 2006 and headquartered in Payson, Utah, United States, is a micro welding equipment designer, manufacturer, and B2B supplier. The company primarily produces precision welding components and assemblies, such as laser, pulse arc, and hot bar reflow welding systems. It also offers portable power generators, laser engraving machines, and related accessories. These products are used in the manufacture of precision products such as eyeglass frames, consumer electronics, and aerospace parts. The company offers approved clients online purchasing and support through its global network of dealers.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | CR Technology, Inc. |

22.9%

|

| 2 | Gorreri Srl |

14.3%

|

| 3 | Marchant Schmidt, Inc. |

10.0%

|

| 4 | Rinco Ultrasonics |

8.6%

|

| 5 | Sunstone Engineering LLC |

7.1%

|

| 6 | Empowering Technologies |

7.1%

|

| 7 | Swift Glass Company, Inc. |

7.1%

|

| 8 | B.S. SRL |

5.7%

|

| 9 | Adwells Co., Ltd. |

5.7%

|

| 10 | FoodsFact |

4.3%

|

Derivation Method

The ranking is calculated based on the click share within the ultrasonic cutting service page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

4 | 40.0% |

Italy

Italy

|

2 | 20.0% |

Switzerland

Switzerland

|

1 | 10.0% |

| Romania | 1 | 10.0% |

Japan

Japan

|

1 | 10.0% |

China

China

|

1 | 10.0% |