All Categories

History

This section provides an overview for shearing machinery as well as their applications and principles. Also, please take a look at the list of 10 shearing machinery manufacturers and their company rankings. Here are the top-ranked shearing machinery companies as of March, 2026: 1.DENER USA, 2.Jorgenson Machine Tools, Inc., 3.Yunsing Industrial Co., Ltd..

Table of Contents

Categories Related to Shearing Machinery

Shearing machinery is a machine used to cut metal sheets into straight lines by shearing.

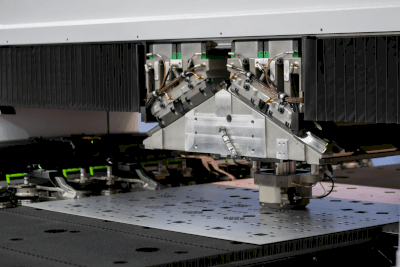

Shearing machinery is equipped with an upper blade and a lower blade.

Shearing is performed by mechanically applying pressure from above and below to the metal plate to be cut. Shearing machinery can be powered by either a mechanical or hydraulic source, which should be selected based on cost and maintenance requirements.

In recent years, turret punch press processing and laser processing have become more common, and the demand for shearing machinery is decreasing.

Shearing machinery is used in sheet metal processing plants for cutting sheet metal. Depending on the model, some Shearing Machinery can cut even metal sheets as long as several meters. However, due to the limitation of the blade length, the cutting length is limited to about 6 meters.

Shearing machinery can be used to cut plates of materials such as stainless steel and steel sheets with metal sheets that fit within this size. For cutting longer metal sheets that cannot be handled by Shearing Machinery, laser cutting machines are generally used.

Shearing machinery is similar to the principle of cutting paper with scissors that we use in our daily lives. The metal sheet to be cut is positioned where the blade of the Shearing Machinery will strike it, and then the upper blade descends to cut the sheet.

Shearing machinery can be classified into mechanical and hydraulic types, depending on the blade drive system.

In the case of the mechanical type, the blade is driven by a motor and clutch, and is characterized by its high cutting speed. Compared to the hydraulic type described below, the mechanical type is inexpensive, and since it does not use oil, maintenance is relatively simple.

The hydraulic type uses hydraulic pressure generated in the cylinder to drive the blade powerfully, resulting in high cutting performance. It can cut even relatively thick metal plates, which is difficult with the mechanical type. On the other hand, care must be taken to avoid problems such as oil leakage.

There are several points to keep in mind when using Shearing Machinery to produce high-quality products and to work safely.

1. Adjusting the Clearance

Clearance in shearing machinery is the distance between the upper and lower blades. Even with scissors that we use in our daily life, paper cannot be cut well with scissors that have a large gap between the two blades.

For the same reason, in shearing machinery, the clearance between the upper and lower blades is important, and the size of the clearance makes a difference in the quality of the cut surface. If the clearance is too narrow, the load on the blade is too great and the blade wears easily, shortening the life of the blade.

Conversely, if the clearance is too large, the cut surface will have sagging and burrs. The appropriate clearance is determined by the material to be cut and the plate thickness, but in general, the appropriate clearance is approximately 6~10% of the plate thickness.

2. Adjustment of Shear Angle

The shear angle is the opening angle between the upper and lower blades, just like the angle between two blades when scissors are opened. When the shear angle is large, or in scissors, when the scissors are wide open at the beginning of a cut, a small amount of force can be used to cut.

However, if the shear angle is too large, the cut material is prone to deflection (bow), twist (twist), and warp (camber).

3. Do Not Cut Materials Over the Maximum Thickness

Shearing machinery has a maximum thickness limit. Cutting material that exceeds the maximum thickness will put a heavy load on the shearing machine, and in the worst case, may result in a breakdown.

When handling a shearing machine, you should check the maximum plate thickness and be careful not to cut any material that is thicker than the machine is capable of cutting.

*Including some distributors, etc.

Sort by Features

Sort by Area

H.P. Singh Machinery Pvt. Ltd. is a manufacturer and supplier of industrial machines and equipment. Established in 1976, the company is headquartered in Ludhiana, Punjab, India. The company's main activities include designing, manufacturing, and supplying a diverse range of machinery for metalworking, such as Workshop Machines, Auto Mobile Reconditioning Machinery, Sheet Metal Machines, Special Purpose Machines and Wire Nail Making Machines. Its products such as hydraulic press brakes, shearing machines, and power presses cater to industries including automotive, aerospace, and construction. Its main services encompass technical support, machine customization, and training.

Yunsing Industrial Co. Ltd., established in 1972 and based in Taiwan, China, is a manufacturer and supplier of cold roll machines. The product portfolio includes a diverse range of roof and corrugated roll machiners, tile, and edge cap roll machinery, roller door and shutter machine, uncoiler, and other automation types of equipment. All the products are ISO-certified. The company also offers customized solutions with technical support. The products are used in multiple industries which include carports, garages, and agricultural barns for residential and commercial purposes.

LVD Group, founded in 1952, is a manufacturer with its global headquarters in Gullegem, Belgium, and offices in New York, United States, Banbury, United Kingdom, and other cities around the world, specializing in sheet metal working machinery and software. The company’s product line includes laser cutting machines, press brakes, punch presses, and shearing machines, accompanied by the CADMAN and Touch-i4 software. These offerings serve an array of industries such as agriculture, construction, defense, electronics, and more. Other industries utilizing the products are food and catering equipment, industrial and commercial machinery, medical and scientific equipment, steel service centers, and subcontract fabricated metal products.

Grangier S.A.S. (Grangier Constructeur), originally founded in 1920 and headquartered in Lyon, France, is a manufacturer of machines and tools for the electrical industry. The company's core products include metal shearing machines, punching machines, and tooling for panel building by electrical and sheet metal construction workshops. These products are specifically designed for complex electrical panel construction and industrial-scale switchboard installation. The company provides various examples of industrial electrical cabinets created by professional electricians using its products.

AMADA, founded in 1948 and based in Kanagawa, Japan, is a manufacturer of metalworking machines and equipment. The company offers a comprehensive range of solutions, including sheet metal machinery, cutting machines, grinding machines, stamping presses, and micro welding equipment. Additionally, it provides software, peripheral equipment, tooling, and maintenance. Its offerings are instrumental in improving productivity, precision, and efficiency in metalworking processes, benefiting the manufacturing and production sectors. It operates with a network of 90 subsidiaries and affiliated companies, all led by AMADA Co., Ltd.

Komatsu Ltd., a company founded in 1917, based in Tokyo, Japan, is a manufacturer and distributor specializing in construction, mining, utility and industrial machinery. The company offers a diverse range of products, including hydraulic excavators, bulldozers, wheel loaders, motor graders, and mini excavators, among others. These products support industries such as construction, mining, forestry, agriculture, industrial machinery, and more. The company provides onsite support and training for their products and boasts a worldwide sales network to serve clients across the globe.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | DENER USA |

22.9%

|

| 2 | Jorgenson Machine Tools, Inc. |

19.6%

|

| 3 | Yunsing Industrial Co., Ltd. |

11.2%

|

| 4 | Komatsu Ltd. |

7.8%

|

| 5 | LVD Company |

6.7%

|

| 6 | H.P. Singh Machinery Pvt.Ltd. |

6.7%

|

| 7 | AMADA CO., LTD. |

6.7%

|

| 8 | Berlin Machine Corporation |

6.1%

|

| 9 | MAQFORT |

5.6%

|

| 10 | Grangier Constructeur |

4.5%

|

Derivation Method

The ranking is calculated based on the click share within the shearing machinery page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

2 | 25.0% |

India

India

|

2 | 25.0% |

United States of America

United States of America

|

1 | 12.5% |

Taiwan

Taiwan

|

1 | 12.5% |

Belgium

Belgium

|

1 | 12.5% |

Portugal

Portugal

|

1 | 12.5% |

67 products found

67 products

Shibaura Machine

430+ people viewing

Last viewed: 1 day ago

The high-shear screw in this device, which consists of three different extruders, can control the viscosity of the resin by rotating at a maximum r...

DK Machinery Co., Ltd.

620+ people viewing

Last viewed: 55 minutes ago

For research laboratories, prototyping rooms, etc. A small shearing machine that is ideal for making sample chips, making simple petri dishes, and ...

Sanritsu Machine Industry Co., Ltd.

460+ people viewing

■The strongest and largest latest model “THE Saurussha” The cutting force is 60 tons, the strongest in its class. The blade is 600 mm, twice the le...

Ashizawa Fine Tech Co., Ltd.

440+ people viewing

Last viewed: 18 hours ago

Planetary mixer is a mixer that conducts two blades and a planetary movement that revolves while rotating. A large shearing force is obtained betwe...

10 models listed

Highland Co., Ltd.

340+ people viewing

■Summary This product allows for prototyping with one device by replacing the bending, cutting, and punching units. The foot-operated hydraulic typ...

Holai

700+ people viewing

Last viewed: 7 hours ago

Feature ● A lineup of both types of sheaes that are cut off with a sharp blade, and the steep shell that can be sandwiched with a durable double -e...

28 models listed

DK Machinery Co., Ltd.

660+ people viewing

Last viewed: 1 day ago

For research laboratories, prototyping rooms, etc. A small shearing machine that is ideal for making sample chips, making simple petri dishes, and ...

Ashizawa Fine Tech Co., Ltd.

340+ people viewing

Last viewed: 16 hours ago

Low shear type vacuum foam It is now possible to process with low rotation and moderate share to objects that were difficult with the conventional...

3 models listed

Sanritsu Machine Industry Co., Ltd.

440+ people viewing

Last viewed: 1 day ago

■Standard model with attractive high power Cutting force of 60 tons, one of the largest in Japan! It is possible to cut a wide variety of things th...

Sanritsu Machine Industry Co., Ltd.

430+ people viewing

Last viewed: 22 hours ago

■Mechanical standard model Compact design with cutting force of 15 tons. It can cut thin electric wires, aluminum sashes, etc. in continuous operat...

Ashizawa Fine Tech Co., Ltd.

440+ people viewing

Last viewed: 10 hours ago

■ Characteristics The combination of the rotor and the status will result in a large shearing force, and the mixing time is reduced. ■ Use Printin...

Fuji Kiko Co., Ltd.

450+ people viewing

Last viewed: 1 day ago

■Product features - Cutting edge shearing machine with high precision cutting. Cuts even ultra-thin plates smoothly and beautifully ・One point NC ...

Sanritsu Machine Industry Co., Ltd.

370+ people viewing

■Hydraulic basic model Although it is the most compact in the series, it has a powerful cutting force of 30 tons and can handle even thick electric...

Marui Co., Ltd.

410+ people viewing

Last viewed: 7 hours ago

Soil testing equipment Soil: Mechanical testing ■This is a testing device for investigating the strength and deformation characteristics of soil in...

Aizawa Iron Works Co., Ltd.

360+ people viewing

■Features ・Introducing a reasonably priced coil cut line ・Can cut feed lengths of 20 mm ・Achieved cutting accuracy of ±0.15mm ・30,000 cuts per ...

Aizawa Iron Works Co., Ltd.

380+ people viewing

Last viewed: 1 day ago

■Features ・Delivered over 500 systems ・Integrate everything from material supply to shearing and accumulation ・Materials are supported by a conv...

Marui Co., Ltd.

380+ people viewing

Last viewed: 13 hours ago

Soil testing equipment Soil: Mechanical testing ■This is a testing device for investigating the strength and deformation characteristics of soil in...

Aizawa Iron Works Co., Ltd.

450+ people viewing

Last viewed: 1 day ago

■Features ・Small rake angle suppresses bow, twist, and camber ・One-touch handle for clearance adjustment ・High-speed NC back gauge with one-poin...

Aizawa Iron Works Co., Ltd.

470+ people viewing

Last viewed: 1 hour ago

■Features ・World's first servo shear ・Variable speed during stroke ・Significant reduction in noise and vibration ・Suitable for cutting non-ferr...

Aizawa Iron Works Co., Ltd.

580+ people viewing

Last viewed: 8 hours ago

■Features ・A new era shearing system that saves labor and manpower. ・The cut parts remain in the front, reducing the need for work at the rear of...