All Categories

History

This section provides an overview for bending machinery as well as their applications and principles. Also, please take a look at the list of 16 bending machinery manufacturers and their company rankings. Here are the top-ranked bending machinery companies as of January, 2026: 1.CML USA, Inc., 2.KAKA Industrial, 3.Oakley Industrial Machinery Inc..

Table of Contents

Categories Related to Bending Machinery

Bending machinery is a processing machine used to bend thin sheet metal materials.

Bending machinery goes by a variety of names, including brake presses, benders, and bending machines. The mechanism of this machine itself is simple. Similar to a press machine, the punch die (upper die) and die block (lower die) are moved up and down to apply pressure and bend the metal sheet.

By applying vertical pressure and preparing dies that match the hardness, thickness, and bending angle of the material, it is possible to bend the material to the desired angle.

Bending machinery is used to produce shapes that are difficult to cut or to cut costs. A wide variety of products are produced using bending machinery, ranging from home appliances to automobile parts, industrial products, and parts for building materials such as aluminum sashes.

Products using these machines are made from thin metal materials, which are lightweight and can be produced in large quantities. In most cases, bending machinery is used to bend thin metal materials.

As mentioned above, the bending machinery itself is simple. Similar to a press, the punch die (upper die) and die block (lower die) are moved up and down to apply pressure and bend the metal sheet. Currently, the hydraulic press brake is the most major processing machine.

In this machine, the hydraulic cylinder will serve as the power structure for the vertical movement. The load and processing speed can be controlled because the crank part does not protrude too much.

The disadvantage of bending is that bending accuracy may vary due to springback caused by plastic deformation, which is a characteristic of bending metal under pressure. Spring back refers to the phenomenon of metal returning to its original shape.

When using bending machinery, it is necessary to understand the types of bending that are possible. There are various types of upper and lower dies, and complex bending processes can be realized by combining parts.

The bending methods mainly used are as follows:

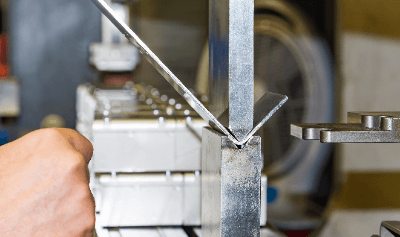

1. V-Bending

V-bending is a processing method that literally uses a V-shaped punch to push and bend a metal sheet. The die is simple and used for various bending processes. V-bending is classified into the following three types according to the degree of punching pressure.

Generally, in V-bending, the more pressure is applied, the smaller the bending R and springback becomes. Therefore, the coining bend can perform the most precise processing, but it requires 5 times more pressure than the bottoming bend to apply pressure, and the die is subject to severe wear.

2. L-Shape Bending

L-shape bending is a processing method to bend a metal sheet at right angles by clamping the top and bottom of the sheet and pressing the protruding part with a punch. It is also called "hold down bending." Since the sheet is bent while being held down, the forming process is more stable than V bending. It is also possible to bend long metal sheets that cannot be bent with V-bending.

3. U-Bending

U-bending is a processing method in which pressure is applied to a metal sheet while holding it with a punch from above and a movable pad from below, and the sheet is bent into a U-shape in line with the fixed platforms on either side during processing. Since there is little variation in bending accuracy and forming is possible with a single bending, man-hours required for bending can be reduced.

However, a dedicated die is required for each shape when forming, and the startup cost is high.

4. Z-Bending

Z-bending is a processing method to bend a metal sheet into a Z-shape. z-bending is a method to bend a metal sheet into a Z-shape by either performing L-bending twice as described above (once bent, the reverse side of the sheet is reversed and bent again) or by bottom-bending with a special punch during L-bending and pushing the sheet once.

Forming once is more accurate than L-bending twice, but the cost is naturally higher.

*Including some distributors, etc.

Sort by Features

Sort by Area

Oakley Industrial Machinery Inc., established in 1946 and based in Elk Grove Village, Illinois, United States, is a manufacturer of heating element production machinery and terminal pins. The company produces heating elements used for domestic, commercial, and industrial applications. Various companies to which the heating elements and terminal machines are supplied include medical, oil & gas, transportation, military, and power generation. The terminal pins manufactured by the company are used for filling, sealing, trimming, straightening, and bending.

KAKA Industrial LLC is a manufacturer and provider of metalworking, woodworking, and fabrication equipment metal machines. The company is headquartered in the United States and is founded in 2015. The company extensive product range includes bands saws, drilling machines, grinding machines, shearing machines, slip roll machines, and many more. The company meet the diverse needs of our customers across various industries, including manufacturing, construction, metal fabrication, and woodworking. The company offers unprecedented customer service, comprehensive support and guidance.

Winton Machine Company, established in 1997 in Suwanee, Georgia, USA, is a manufacturer and supplier of tube and pipe fabrication machinery. The company provides a diverse range of machinery solutions for bending, forming, and end-finishing of tubes and pipes. These machines find applications in various industries, including automotive, HVAC, furniture, and more. Winton Machine aims to deliver essential, quality machines that cater to the specific needs of its clients. Courtesy of its technical expertise, Winton Machine ensures the efficiency and productivity of tube and pipe fabrication processes worldwide.

DMI International, LLC. was established in 1992 and is headquartered in Tulsa, Oklahoma, and is a manufacturer of pipeline bending equipment for various industrial applications. The company provides hydraulic & pneumatic pipeline clamps, pneumatic & hydraulic wedge mandrels, ditch pumps, fencing systems, and, launchers along with cradles, vacuum lifters, and, air compressors and also offers pipe welding and technical assistance services for oil & gas, mining, electronics & electrical, automotive & agriculture, and, water treatment sectors.

CML USA Inc,established in 1988, and based in Iowa, USA, is a manufacturer and supplier of pipe and tube benders. Their product portfolio includes a diverse range of benders such as tube bend machines, pipe benders, rotary draw benders, mandrel, and non-mandrel benders. They also provide angle rolls, pipe notchers, and other metalworking machinery with pipe bending equipment. The products are used in various industries ranging from light automotive to heavy fabrication machinery.

Carell Corporation, founded in Stapleton, AL in 1992 is a manufacturer of industrial metal working machines. The company's product portfolio includes Grinding Machines, Milling Machines, Turning Lathes, bending and shearing machines that offer precise metal forming and cutting capabilities for sheet metal and structural components and punching and press machines that deliver high-speed and efficient operations for metal punching. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation.

Unison Ltd was established in 1973 and is based in Germany is a manufacturer of computerized control systems for various industries. The company provides CNC tube bender, Nukon Fiber laser cutting machines, integrated & user-friendly control systems, Web App, and, 3D tube bending simulation software along with system optimization solutions, automation accessories, pipe bending & electric tube bending machinery, and, CNC-bending machines that have applications in automotive, aerospace, construction, power production, and, material handling sectors.

BLM GROUP was founded in 1960 and is based in Cantù, CO, Brianza, and is a manufacturer of digitizing systems & machines for various industrial applications. The company provides laser tubes, 3D cutting cells, sheet laser cutting machines, tube bending machines, and sawing machines as well as tube end-forming machines and wire bending machines, along with related software namely ArTube, VGPNext, ArtCut, ProTube, and PartViewer that have applications in Automotive, Aerospace, Motorcycles, Furniture, and, HVAC and also in Industrial vehicles, Structural equipment, Fitness, and, Household appliances sectors.

Eagle Bending Machines, Inc. is a manufacturer of tube and pipe bending machines. Established in 1993, the company is based in Stapleton, Alabama, USA. The company specializes in designing and producing tube and pipe-bending machines for various industries. Its product range includes manual and CNC bending machines such as CP20 SERIES, CP30 SERIES, CP40 SERIES, CP60 SERIES, Z402 SERIES and CPS SERIES as well as BA SERIES. The company serves sectors such as manufacturing, automotive, and furniture. Eagle Bending Machines offers services like financing, leasing, machine training and technical support.

Freedman Seating Company. founded in Chicago, Illinois, USA, in 1894, is a manufacturer and distributor of transportation seats and seating-related products. The company’s product catalog includes bus seats, rail seating products, delivery truck driver seats, commercial vehicle seats, and marine seating solutions. The company is ISO 9001-2015 certified and also offers customized seating solutions to customers. It has 1,000 employees and a network of verified distributors across Canada and the USA.

Trumpf Inc. Was founded in Farmington, Connecticut in 1923 were it remains to this day. The company is a developer of connect production technology, making customer’s upstream and downstream operations more efficient, precise, and future-proof. The company serves the automotive, photovoltaic, aerospace, dental, and construction industries. The company’s product segments include hardware, software, and services; machines & systems, power electronics, and power tools. Services include process optimization, technical assistance, training, aftermarket product enhancement, and financing.

CRC-Evans Pipeline International was founded in and is based in Houston, Texas, U.S.A., and is a supplier of pipeline equipment, welding services, and coating solutions for various industries. The company has achieved ISO 9001:2008 certification and provides pipe-facing machines, hydraulic power units, internal pneumatic line-up clamps, hydraulic wedge mandrels, and, angle measurement systems that have applications in infrastructure, nuclear, renewables, and, oil & gas sectors. The company also specializes in field joint coating services and offers induction generators and coils, inverters, on-pipe powder coating equipment, and, pumping equipment as per the specific requirements of customers.

Ranking as of January 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | CML USA, Inc. |

11.1%

|

| 2 | KAKA Industrial |

9.6%

|

| 3 | Oakley Industrial Machinery Inc. |

9.1%

|

| 4 | Carell Corporation |

8.7%

|

| 5 | TRUMPF |

8.2%

|

| 6 | Eagle Bending Machines, Inc. |

7.7%

|

| 7 | DMI International, LLC. |

6.7%

|

| 8 | CRC-Evans Pipeline International |

5.8%

|

| 9 | Unison Ltd. |

5.3%

|

| 10 | Winton Machine Company |

5.3%

|

Derivation Method

The ranking is calculated based on the click share within the bending machinery page as of January 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

5 | 62.5% |

China

China

|

1 | 12.5% |

Republic of Korea

Republic of Korea

|

1 | 12.5% |

Germany

Germany

|

1 | 12.5% |

225 products found - Page 2

225 products - Page 2

Ecold Japan Co., Ltd.

270+ people viewing

■Hand former HF 100 PA allows you to use both hands freely With this machine, you can use both hands freely to control the workpiece, and the press...

Yoshino Machinery Co., Ltd.

400+ people viewing

Last viewed: 1 day ago

AC servo motor-driven panel bending machine that is easy to use and enables high-speed processing, high precision, and stable production. Features...

Yoshino Machinery Co., Ltd.

350+ people viewing

AC servo motor-driven panel bending machine that is easy to use and enables high-speed processing, high precision, and stable production. Features...

Toho Seiko Co., Ltd.

350+ people viewing

Last viewed: 9 hours ago

Adopting a cassette system, external setup is possible, reducing setting time, and at the same time, easy reproducibility, making it ideal for high...

Ecold Japan Co., Ltd.

320+ people viewing

■Small type with easy turning The Mobile Former MZ 20 is the smallest model in the series. This machine is capable of flanging forming in the plate...

Ecold Japan Co., Ltd.

310+ people viewing

■For relatively thick flanging Mobile pliers suitable for flanging in container and tank manufacturing. Flange forming is possible for sheet thickn...

Ikura Seiki Co., Ltd.

360+ people viewing

Last viewed: 6 hours ago

■Easy to carry on-site, split type Power unit and frame can be separated ■High power with maximum pressurization of 28t Maximum processing capacit...

2 models listed

Ecold Japan Co., Ltd.

290+ people viewing

Last viewed: 2 minutes ago

■For highly difficult flanging A mobile craft former suitable for flanging in container and tank manufacturing. Available for plate thickness range...

Ecold Japan Co., Ltd.

260+ people viewing

Last viewed: 22 hours ago

■For flanging with very high demands The Mobile Former MKF 140 is the largest model in the series. This machine can be used for plate thickness ran...

Ecold Japan Co., Ltd.

320+ people viewing

Last viewed: 11 hours ago

■Features You can choose from 5 models depending on the angle and profile size. Both machines can bend workpieces of various materials and dimensio...

Yoshino Machinery Co., Ltd.

320+ people viewing

Last viewed: 5 hours ago

AC servo motor-driven panel bending machine that is easy to use and enables high-speed processing, high precision, and stable production. Features...

Kotobuki Trading Co., Ltd./Mechanics Co., Ltd.

220+ people viewing

Last viewed: 3 hours ago

◼︎Overview - Can be widely used for various types of work such as prototyping, research, and models. -Uses hydraulic pressure, so bending can be do...

Kotobuki Trading Co., Ltd./Mechanics Co., Ltd.

170+ people viewing

Last viewed: 3 hours ago

◼︎Overview - Can be widely used for various types of work such as prototyping, research, and models. -Uses hydraulic pressure, so bending can be do...

Fuji Kiko Co., Ltd.

280+ people viewing

Last viewed: 1 day ago

■Product features ・You can easily bend the roll just by passing it through. ・The roll is coated with urethane. ・Non-slip and does not damage mat...

Original Mind Co., Ltd.

460+ people viewing

Last viewed: 1 day ago

An assembly kit for a tabletop metal bending machine born from a unique design concept. Although the structure is simple, just push down the lever ...

Maruka Corporation

230+ people viewing

■Features ・Systemization of pipe cutting, bending, terminal processing, measurement, and communication ・Integrated management of pipe processing ...

Ueda Co., Ltd.

230+ people viewing

Last viewed: 1 day ago

■For bending aluminum and steel plates By combining the groove spacing, it is possible to bend most of the four sides in 5mm or 10mm increments fro...