All Categories

History

This section provides an overview for lathe turrets as well as their applications and principles. Also, please take a look at the list of 8 lathe turret manufacturers and their company rankings. Here are the top-ranked lathe turret companies as of February, 2026: 1.Louis Levin & Son, Inc.,, 2.Chiah Chyun Machinery Co., Ltd., 3.ARTCO - American Rotary Tools Co.

Table of Contents

Categories Related to Lathe Turrets

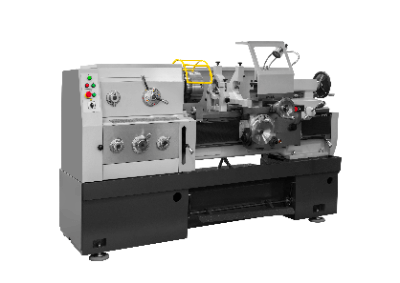

A Turret Lathe is a type of lathe that has a rotatable turret with multiple tools.

A Turret Lathe is a type of lathe that has a rotatable turret with multiple tools.

A turret is a device that can hold and rotate multiple tools. It is fitted with multiple tools and can switch between cutting tools as needed. Lathe Turrets are suitable for small-lot production because they can perform complex work with multiple tools on a single workbench with high precision.

Turret Lathes are characterized by their ability to eliminate the need to change tools, thereby reducing work time and increasing work efficiency.

Recently, automation has been progressing, which improves the accuracy and efficiency of machining and at the same time reduces the workload of the operator.

The main applications of Turret Lathes are as follows:

Turret Lathes can cut a wide variety of metal materials such as steel, aluminum, brass, copper, and alloy steel, and can cut, turn, drill, thread, and groove parts.

In the automotive industry, parts such as shafts, pistons, crankshafts, and gears are manufactured on Turret Lathes.

Turret Lathes can automatically change a large number of tools and perform continuous machining with high precision. They are especially used in the energy industry to manufacture turbine blades, coils, valves, cooling water pipes, etc.

Turret Lathes can cut parts with very complex geometries. They are used to manufacture parts for the aircraft industry, such as turbine blades, bolts, nuts, and fuel injectors for jet engines.

Turret Lathes are suitable for the production of small batches of products and prototypes. They are used to produce bolts and nuts for construction parts, door handles, columns, and metal window and door frames.

Lathe Turrets are a processing machine that attaches multiple cutting tools to the material to be processed, and by controlling the position, direction of travel, and speed of the tools, the material is cut out.

Currently, CNC lathes equipped with computerized NC (numerical control) devices are the mainstream, automating some or all of the following processes.

NC stands for Numerical Control. CNC stands for Computer Numerical Control. CNC is an advanced version of NC technology that enables more advanced and precise machining.

Turret Lathes are used in the following procedures:

Fix the material to be processed to the worktable of the Turret Lathe.

The Turret Lathe can be equipped with several cutting tools. Since the material to be cut and its shape vary depending on the type of tool, select the appropriate tool before operation.

Adjust the tool position by moving the tool closer to or away from the material to be machined, or by moving it up, down, left, or right.

Cutting is started by bringing the tool into contact with the material to be machined while adjusting the direction and speed of the tool.

The tool is replaced with the one required for the next cutting operation.

The basic structure of a Turret Lathes is as follows:

It is the part that supports the spindle, and the motor and gear box to rotate the spindle are mounted. The spindle is the central axis of the lathe and rotates the workpiece. The spindle has a shank (tool mount) to which tools such as tool holders and chucks (devices to hold the workpiece) are attached.

A turret can hold multiple tools and rotate perpendicular to the centerline of the Turret Lathe. It is characterized by its ability to use multiple tools without having to change cutting tools, thereby increasing productivity. Since a single worktable can process with a variety of tools, it is suitable for high-mix, small-lot production.

The reciprocating table can move horizontally across the lathe and carry tools for shaving workpieces. It can also be moved vertically, allowing adjustment of the depth to which the workpiece is machined.

The feeder is a device used to accurately move the workpiece along the reciprocating table. Feed devices include mechanical feed devices and computer-controlled feed devices (CNC lathes).

The bed is one of the basic components of a lathe, supporting the spindle and reciprocating table. Since it is made of highly rigid cast iron or steel, the lathe as a whole is highly stable and can perform high-precision machining. The bed is equipped with rails for the spindle and reciprocating table to move.

Tools used on Turret Lathes include external cutting tools, internal cutting tools, threading tools, grooving tools, and chamfering tools. Various shapes can be machined by combining these tools.

Turret Lathes are capable of not only cutting but also drilling and grooving. By attaching a drill chuck to the lathe part, precision drilling can be performed using tools such as drills and reamers.

A reamer is a type of tool used for high-precision drilling of metal or plastic workpieces. A reamer is a cylindrical bar-shaped component with a conical tip. The tip of the reamer consists of multiple blades that gradually increase in size, which are inserted into the workpiece while rotating to accurately enlarge the inside diameter of the workpiece.

*Including some distributors, etc.

Sort by Features

Sort by Area

O'Connell Machinery Co., Inc., founded in 1975 and headquartered in Buffalo, New York, USA, is a manufacturer of industrial precision machinery and equipment. The product line includes precision machining tools, automated systems, and industrial automation equipment. These product offerings optimize efficiency, accuracy, and productivity in automotive, aerospace, electronics, and medical device manufacturing. The company holds ISO certifications for quality assurance, and meets industry standards for CNC lathes and bullard parts. Its products cater to various industries, addressing needs from large-scale production facilities to smaller workshops, thus enhancing manufacturing processes globally.

Louis Levin & Son, Inc., founded in 1917 and headquartered in California, USA, is a manufacturer of CNC machinery and CNC lathe parts. The product line encompasses precision-machined components, precision collets, tool holders, CNC lathes for aerospace, and cutting tools. These products offer increased accuracy, efficiency, and stability for various machining processes. Industries such as aerospace, automotive, medical device manufacturing, and industrial equipment integration utilize these parts for distinct applications. The CNC machine parts come at reduced costs and improvise advanced technology for precision in operations.

ARTCO - American Rotary Tools Co, founded in Monrovia, California, in 1931 is a supplier of tools for Screw Machining, Tool and Die Making, Precision Deburring, Plastic and Rubber Molding. The company's product portfolio includes Finishing Stones, Abrasives, Flexible Shaft Units, Carbide Burs, and Mounted Wheels. Their products are used in markets such as Die Casting, Forge Die, Investment Mold, Jewelry, and Engraving. The company also provides services including national distribution, product selection, customized services, technical support and customer service.

Chiah Chyun Machinery Co., Ltd., established in 1988 and headquartered in Taichung City, Taiwan, is a manufacturer of CNC precision machine tools, and auto lathes. The company specializes in manufacturing customized precision CNC machinery equipment that enhances productivity, and reduces the cost of operation. The products offered are CNC lathe, CNC auto lathe, CNC turning center, and associated lathe machinery for various purposes. The product benefits comprise enhanced performance, precision machining, longer durability, and automatic quality control efficacy for industries such as automotive, aerospace, electronics, industrial automation and other associated purposes.

Hellmerich Precision Components, established in 1979 and headquartered in Seeboden, Austria, is a manufacturer of advanced precision components for milling, turning, and grinding. The products offered find applications in various industries, including aerospace, medical, automotive, and more. The product category includes precision-machined parts, complex assemblies, and custom-engineered solutions. These components offer benefits such as tight tolerances, stability, and enhanced performance in critical applications. The ISO 9001 and ISO 14001 certified company specializes in manufacturing tailor-made parts for improved performance, and proficient machining purposes.

CITIZEN MACHINERY CO., LTD. is based in Kitasaku-gun, Nagano-ken, and is a Japanese manufacturer of industrial machinery originally established in 1982 as CITIZEN PRECISION MACHINERY CO. LTD. before its consolidation and rebrand in 2005. The company produces three automated CNC lathes for different use cases: the CINCOM for working with long, thin pieces; the MIYANO for machining short, thick pieces, and the MC20 machining cell that can work with a wide range of workpiece configurations. The company is a subsidiary of CITIZEN WATCH CO. LTD., and chiefly serves the automotive, aerospace, and consumer electronics industries.

Takisawa Machine Tool Co., Ltd, a company founded in 1922 and headquartered in Okayama, Japan, is a manufacturer and supplier of machine tools and related equipment. The company's product portfolio includes CNC lathes, multi-tasking machines, piston machines, vertical machining centers, and software. These products have applications in various industries, including medical device manufacturing, the energy industry, consumer electronics, metalworking and fabrication, and heavy equipment manufacturing. The company is ISO 9001 and ISO 14001 certified, with offices in Europe, the USA, Southeast Asia, and East Asia, establishing a global network.

TSUGAMI CORPORATION was founded in 1937 and is a manufacturer and supplier of precision machine tools based in Chuo, Tokyo, Japan. The company offers various precision equipments such as opposed gang tool post, turning center, CNC lathe, vertical machining center, and CNC precision cylindrical grinding machine. The products are used in manufacturing various products such as medical equipments, digital camera, cellular phone, and optical communication devices. The company holds ISO 9001 certification for the Quality Control Management System and ISO 14001 for Environment Management System.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Louis Levin & Son, Inc., |

22.9%

|

| 2 | Chiah Chyun Machinery Co., Ltd. |

17.3%

|

| 3 | ARTCO - American Rotary Tools Co |

15.6%

|

| 4 | O'Connell Machinery Co, Inc. |

12.8%

|

| 5 | Hellmerich Precision Components |

11.7%

|

| 6 | Takisawa Machine Tool Co., Ltd |

8.9%

|

| 7 | CITIZEN MACHINERY CO.,LTD. |

6.1%

|

| 8 | TSUGAMI CORPORATION |

4.5%

|

Derivation Method

The ranking is calculated based on the click share within the lathe turret page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

3 | 42.9% |

Japan

Japan

|

2 | 28.6% |

Taiwan

Taiwan

|

1 | 14.3% |

Austria

Austria

|

1 | 14.3% |

77 products found

77 products

Utsunomiya Manufacturing Co., Ltd.

820+ people viewing

Last viewed: 19 hours ago

■TGR-016 series The TGR-016 series is a CNC tool grinder developed specifically for "tool edge polishing". It comes standard with the interactive p...

Tokai Trading Co., Ltd.

610+ people viewing

Last viewed: 1 hour ago

■We have a variety of product lineups, including high-speed series and heavy-duty cutting series. Our company handles vertical CNC lathes (turning ...

Tomita Co., Ltd.

610+ people viewing

Last viewed: 19 hours ago

■Simple automation structure Low-cost automation by mounting the supply/recovery device on the turret, which is possible only with comb blades. ■E...

Tomita Co., Ltd.

590+ people viewing

Last viewed: 3 hours ago

■Micro compound machining with 3-axis control gang tool turret ・Small 3-axis control turret ・Vertical type comb blade turret specification with X...

Japan INSDAC Co., Ltd.

670+ people viewing

Last viewed: 1 hour ago

■Features ・2in1 and manual functions ・Pre-installed handwheel ・PC-based CNC system, high reliability, simple operation ・Connect to PC with netw...

ND Seiko Co., Ltd.

340+ people viewing

Last viewed: 19 hours ago

■Product overview The frame of this processing machine is made of high-performance Jinan granite. This material has changed over time due to the in...

ND Seiko Co., Ltd.

470+ people viewing

Last viewed: 19 hours ago

■Product overview The frame of this processing machine is made of high-performance Jinan granite. This material has changed over time due to the in...

ND Seiko Co., Ltd.

480+ people viewing

Last viewed: 11 hours ago

■Product overview The frame of this processing machine is made of high-performance Jinan granite. This material has changed over time due to the in...

ND Seiko Co., Ltd.

540+ people viewing

Last viewed: 19 hours ago

■Product overview The frame of this processing machine is made of high-performance Jinan granite. This material has changed over time due to the in...

ND Seiko Co., Ltd.

480+ people viewing

Last viewed: 6 hours ago

■Product overview The frame of this processing machine is made of high-performance Jinan granite. This material has changed over time due to the in...

ND Seiko Co., Ltd.

460+ people viewing

Last viewed: 19 hours ago

■Product overview The frame of this processing machine is made of high-performance Jinan granite. This material has changed over time due to the in...

ND Seiko Co., Ltd.

390+ people viewing

Last viewed: 19 hours ago

■Product overview The frame of this processing machine is made of high-performance Jinan granite. This material has changed over time due to the in...

ND Seiko Co., Ltd.

420+ people viewing

Last viewed: 19 hours ago

■Product overview The frame of this processing machine is made of high-performance Jinan granite. This material has changed over time due to the in...

ND Seiko Co., Ltd.

390+ people viewing

Last viewed: 19 hours ago

■Product overview The frame of this processing machine is made of high-performance Jinan granite. This material has changed over time due to the in...

ND Seiko Co., Ltd.

380+ people viewing

Last viewed: 14 hours ago

■Product overview The frame of this processing machine is made of high-performance Jinan granite. This material has changed over time due to the in...

ND Seiko Co., Ltd.

380+ people viewing

Last viewed: 14 hours ago

■Product overview The frame of this processing machine is made of high-performance Jinan granite. This material has changed over time due to the in...

ND Seiko Co., Ltd.

410+ people viewing

Last viewed: 14 hours ago

■Product overview The frame of this processing machine is made of high-performance Jinan granite. This material has changed over time due to the in...

ND Seiko Co., Ltd.

460+ people viewing

Last viewed: 14 hours ago

■Product overview The frame of this processing machine is made of high-performance Jinan granite. This material has changed over time due to the in...

ND Seiko Co., Ltd.

410+ people viewing

Last viewed: 7 hours ago

■Product overview The frame of this processing machine is made of high-performance Jinan granite. This material has changed over time due to the in...

ND Seiko Co., Ltd.

360+ people viewing

Last viewed: 19 hours ago

■Product overview The frame of this processing machine is made of high-performance Jinan granite. This material has changed over time due to the in...

Seiwa Precision Machinery Co., Ltd.

180+ people viewing

Last viewed: 3 hours ago

■Set contents (A~D drill) ・1 standard head ・1 shank ・2 center drills ・2 sets of spare blades ・1 oil plug ・1 set of wrench

5 models listed

Seiwa Precision Machinery Co., Ltd.

190+ people viewing

Last viewed: 14 hours ago

■Set contents (A~D drill) ・1 standard head ・1 shank ・2 center drills ・2 sets of spare blades ・1 oil plug ・1 set of wrench

5 models listed

Seiwa Precision Machinery Co., Ltd.

160+ people viewing

Last viewed: 14 hours ago

4 models listed

Gloria Co., Ltd.

720+ people viewing

Last viewed: 19 hours ago

A machine that can perform processing such as drilling, scraping, threading, boring, and milling on metal. A new CNC lathe with multiple functions...

Iwashita Co., Ltd.

510+ people viewing

Last viewed: 28 minutes ago

A long NC processing machine is a machining center-like machine that specializes in long materials (3m to 6m) and performs cutting operations (mill...

Todai Seiki Japan Co., Ltd.

280+ people viewing

Last viewed: 19 hours ago

■Features ・Ensuring high dynamic stiffness and stability through simulation using the finite element method ・Highly efficient turning ability ・R...

Todai Seiki Japan Co., Ltd.

240+ people viewing

Last viewed: 14 hours ago

■Features ・Excellent heavy cutting performance due to sliding guide and high torque spindle design ・High stability and easy chip evacuation due t...

Hasegawa Machinery Co., Ltd.

230+ people viewing

Last viewed: 19 hours ago

■NC lathe Turret type: TZ25MY. A 12-sided turret turning center that can accommodate 24 tools. By moving the main axis to the X axis and the dodeca...

Todai Seiki Japan Co., Ltd.

210+ people viewing

Last viewed: 14 hours ago

■Features ・Ensuring high dynamic stiffness and stability through simulation using the finite element method ・Highly efficient turning ability ・R...

Todai Seiki Japan Co., Ltd.

210+ people viewing

Last viewed: 14 hours ago

■Features ・Excellent heavy cutting performance due to sliding guide and high torque spindle design ・High stability and easy chip evacuation due t...